Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hüseyin Emre Ilgın | -- | 1399 | 2023-12-28 07:01:57 | | | |

| 2 | Catherine Yang | Meta information modification | 1399 | 2023-12-28 07:17:14 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ilgın, H.E.; Karjalainen, M. Cross-Laminated Timber in Finland. Encyclopedia. Available online: https://encyclopedia.pub/entry/53203 (accessed on 07 February 2026).

Ilgın HE, Karjalainen M. Cross-Laminated Timber in Finland. Encyclopedia. Available at: https://encyclopedia.pub/entry/53203. Accessed February 07, 2026.

Ilgın, Hüseyin Emre, Markku Karjalainen. "Cross-Laminated Timber in Finland" Encyclopedia, https://encyclopedia.pub/entry/53203 (accessed February 07, 2026).

Ilgın, H.E., & Karjalainen, M. (2023, December 28). Cross-Laminated Timber in Finland. In Encyclopedia. https://encyclopedia.pub/entry/53203

Ilgın, Hüseyin Emre and Markku Karjalainen. "Cross-Laminated Timber in Finland." Encyclopedia. Web. 28 December, 2023.

Copy Citation

Although cross-laminated timber (CLT) construction, driven by only a few domestic manufacturers, is relatively new in Finland, sustainability concerns may increase interest in renewable materials, and therefore, CLT may be more accepted in the Finnish construction market. Additionally, active communication about successful projects and new applications can open new avenues for CLT to gain popularity in the Finnish construction market.

wood/timber

CLT

construction practice

Finland

1. Introduction

The global construction market contributes substantially to greenhouse gas emissions and is among the biggest consumers of natural sources [1][2]. At present, approximately 40% of carbon dioxide (CO2) emissions and 35% of overall energy consumption emanate from the construction industry [3][4]. In addition, according to the Paris Agreement, CO2 emissions worldwide must be lowered by 50% by 2050 (compared to the 1990s) to maintain the average temperature increase below 2 degrees Celsius worldwide [5]. Considering the current annual carbon dioxide emissions worldwide [6][7], a critical step towards realizing such a vision is to reduce the climate impacts caused by the construction sector as much as possible.

Likewise, the significance of the Finnish construction sector extends to its crucial role in addressing climate goals, considering that approximately 30% of CO2 emissions and around 40% of energy consumption in Finland are attributed to the construction industry [8]. Aligned with the ambitious 2050 targets set by the European Union, the Finnish government’s policy aims to achieve carbon neutrality by the year 2035 [9][10]. To actively contribute to these environmental objectives, the contemporary construction sector employs two pivotal strategies: (a) the adoption of ‘green’ construction materials and (b) the optimization of energy consumption throughout the service life of structures [11][12]. These approaches underscore a proactive commitment within the Finnish construction industry to foster sustainable practices and minimize its environmental footprint in the pursuit of national and international climate targets.

Advances in building technologies are vital to achieving sustainability targets in this industry. At the level of construction materials, this objective can be achieved by adopting solutions that promote either reduced usage of the same material or the incorporation of alternative ecological materials [13][14][15]. Concrete and steel, which are the most employed building materials today, are carbon-intensive materials [16][17][18]. As per the International Energy Agency, the production of one ton of steel results in the direct release of approximately 1.4 tons of carbon dioxide into the atmosphere [19]. On a global scale, the annual production of cement surpasses the substantial quantity of 4 billion tons. Remarkably, the environmental impact of this production is significant, as each ton of cement contributes to carbon dioxide emissions. The emissions vary depending on the type of cement, with high-mix cement producing around 250 kg of carbon dioxide per ton, while regular Portland cement emits a notably higher amount, reaching up to 930 kg per ton [20]. On the other hand, it is known that bio-based building materials such as timber (engineered wood products (EWPs)) have many more advantages in terms of environmental benefits compared to their traditional non-renewable alternatives (for example, steel or concrete) [21][22][23].

EWPs are increasingly used as structural materials owing to their various mechanical advantages, e.g., uniform strength and rigidity, as well as their environmental properties [24]. Moreover, EWPs are becoming progressively more viable, specifically in tall building construction [25][26]. These products are frequently assembled by laminating smaller boards or lamella into larger structural elements, possessing exceptional structural characteristics that enable the construction of intricate timber frameworks [27]. During the fiscal year 2022, the EWP market exhibited robust performance, attaining a valuation in proximity to USD 18.5 million. This promising trajectory is underpinned by a projected compound annual growth rate (CAGR) of approximately 9.4%, which is anticipated to persist consistently over the entire forecast duration. As the market continues to evolve, this steady growth pattern is foreseen to lead to a substantial expansion, culminating in an estimated market size of around USD 32 million by the conclusion of the year 2028. [28].

Within the realm of EWPs, cross-laminated timber (CLT) occupies a pivotal position [29]. CLT stands out as a prefabricated and multilayered EWP, crafted by bonding the surfaces of at least three layers of panels together in a 90-degree configuration using adhesive under pressure [30]. Originating in the early 1990s, CLT has evolved into a globally recognized construction material, with its production footprint expanding significantly across the world, particularly within the European Union [31]. Notably, as of 2017, approximately 70% of the global CLT output was concentrated in Europe [32], underlining the region’s prominence in this industry. This prevalence of CLT production in Europe has attracted attention from academics and experts in the construction field worldwide, highlighting its significance as a subject of interest and study in both research and practical applications.

2. History of CLT Construction in Finland

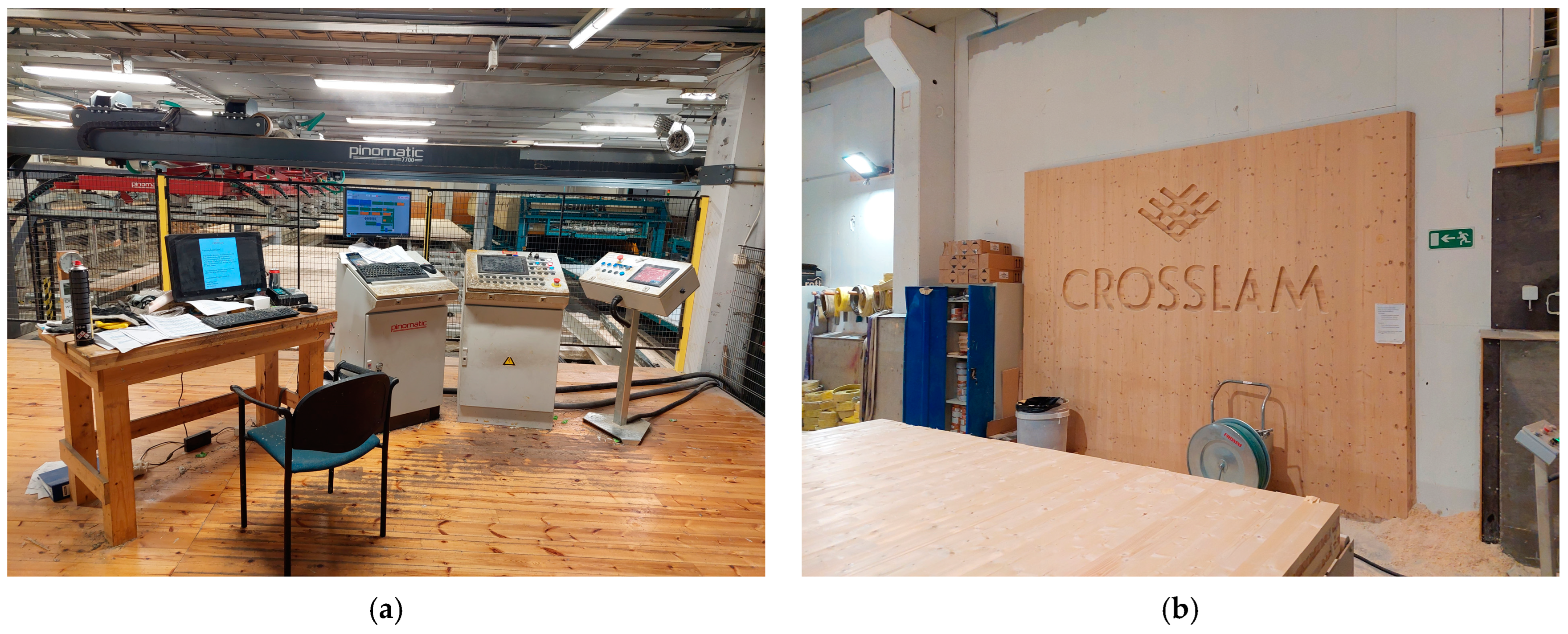

Despite Finland’s extensive history of large-scale wood construction, such as the traditional log technique, CLT represents a relatively recent but emerging construction method within the Finnish context. The inaugural Finnish CLT manufacturing facility commenced operations in Kuhmo in 2014, as illustrated in Figure 1. Since its inception, numerous small houses have been erected utilizing CLT. Noteworthy among these constructions is the Tuupala elementary school and daycare center, showcased in Figure 2, boasting a substantial total area of 6165 m2. This establishment, completed in 2018, holds the distinction of being the first CLT school building in Finland. A distinctive feature of the project is its structural CLT crafted from spruce, a characteristic that extends to the external facade where the CLT panel structure corresponds with a solid spruce veneer [33]. Furthermore, CLT elements were employed in the lower ceiling panels of Helsinki-Vantaa Airport, serving as one of the pioneering and prominent instances of CLT application in Finland [34]. These early examples showcase the nascent yet promising trajectory of CLT as a noteworthy construction methodology in the Finnish architectural landscape.

Figure 1. Crosslam Kuhmo: (a) production control area; (b) an interior view (photo by authors).

Figure 2. Tuupala elementary school: (a) atrium view; (b) inner staircase view (photo by authors).

In contemporary construction practices within Finland, CLT has ascended to the status of the preferred material for multi-story and tall buildings. This trend mirrors the utilization of CLT observed in the 8-story high TOAS-Kauppi (Figure 3) and the 14-story high Lighthouse Joensuu (Figure 4), highlighting a broader shift in the construction industry towards embracing CLT as a key component in the construction of high-rise structures. The preference for CLT in these buildings can be attributed to its inherent qualities, including structural strength, environmental sustainability, and efficiency in construction processes. This signifies a noteworthy transformation in architectural and construction paradigms, underlining CLT’s role as a leading material in the built environment, particularly evident in the architectural landscape of Finland.

Figure 3. TOAS—Kauppi: (a) exterior view (photo by authors); (b,c) interior views (Photos courtesy of Suomen metsäkeskus).

Figure 4. Lighthouse Joensuu (photo by authors).

Overall, in Finland, the integration of CLT into discussions within the construction industry gained considerable prominence with the decision to embark on the construction of the Haltia Nature Centre in Espoo. Notably, the facility was meticulously designed, with CLT serving as its primary structural material. The project, initiated in 2012, reached completion in May 2013, marking a significant milestone. However, a noteworthy development unfolded in the media and governmental sectors, revealing a somewhat incongruous situation. Despite Finland actively endorsing large-scale timber construction, CLT elements for a substantial public project were imported from Austria, raising sustainability concerns. This situation prompted a strategic response, leading to the establishment of Finland’s inaugural CLT manufacturing facility in Kuhmo in December 2014 under the name CrossLam Kuhmo Oy (Kuhmo, Finland). Subsequent expansions included the establishment of additional facilities in Alajärvi (CLT Finland Oy, Hoisko, Finland) in 2016 and Kauhajoki (CLT Plant Oy, Kauhajoki, Finland) in 2018, as depicted in Figure 5 and Table 1. These facilities, equipped with advanced capabilities, currently have the capacity to meet the country’s demand by producing CE-marked standardized CLT. The collaborative efforts of these competitive factories culminated in a significant development in 2023 with the formation of a unified CLT association in Finland. This association serves as a collective platform for advocating and standardizing CLT practices within the nation, aligning with the shared objective of advancing the sustainable and widespread use of CLT in Finnish construction projects.

Figure 5. CLT plant: (a) view from the production line; (b) prefabricated building facade module produced (photo by authors).

Table 1. Finnish CLT manufacturers.

| Producer | Factories and Operation Started |

P = Production C = Capacity |

Wood Species |

Strength Class |

Adhesive | Thickness Max. Width Max. Length |

Application |

|---|---|---|---|---|---|---|---|

| CLT Plant | Kauhajoki 2018 |

C = 50,000 m3 | spruce pine |

C24 | Polyurethane Reactive (PUR) |

60–360 mm 3.5 m 16 m |

(non)load-bearing framework |

| Crosslam Kuhmo | Kuhmo 2014 |

P = 13,000 m3 | spruce pine |

C24 | PUR | 60–300 mm 3.2 m 12 m |

(non)load-bearing framework |

| Hoisko | Hoisko 2016 |

C = 12,000 m3 | spruce pine |

C24 | PUR | 60–400 mm 3.2 m 12 m |

wall floor bridges |

References

- Brussels Energy, European Commission. New Rules for Greener and Smarter Buildings Will Increase Quality of Life for All Europeans. NEWS. 15 April 2019. Available online: https://ec.europa.eu/info/news/new-rules-greener-and-smarter-buildings-will-increase-quality-life-alleuropeans-2019-apr-15_en (accessed on 12 December 2023).

- Li, Y.L.; Han, M.Y.; Liu, S.Y.; Chen, G.Q. Energy consumption and greenhouse gas emissions by buildings: A multi-scale perspective. Build. Environ. 2019, 151, 240–250.

- Zhao, C.; Zhou, J.; Liu, Y. Financial inclusion and low-carbon architectural design strategies: Solutions for architectural climate conditions and architectural temperature on new buildings. Environ. Sci. Pollut. Res. 2023, 30, 79497–79511.

- Ahmed Ali, K.; Ahmad, M.I.; Yusup, Y. Issues, impacts, and mitigations of carbon dioxide emissions in the building sector. Sustainability 2020, 12, 7427.

- Horowitz, C.A. Paris agreement. Int. Leg. Mater. 2016, 55, 740–755.

- de Oliveira, R.S.; de Oliveira, M.J.L.; Nascimento, E.G.S.; Sampaio, R.; Nascimento Filho, A.S.; Saba, H. Renewable energy generation technologies for decarbonizing urban vertical buildings: A path towards net zero. Sustainability 2023, 15, 13030.

- Mostafaeipour, A.; Bidokhti, A.; Fakhrzad, M.B.; Sadegheih, A.; Mehrjerdi, Y.Z. A new model for the use of renewable electricity to reduce carbon dioxide emissions. Energy 2022, 238, 121602.

- Kuittinen, M.; le Roux, S. Procurement Criteria for Low-Carbon Building, Environment Guide 2017; Finnish Ministry of the Environment; Department of the Built Environment; Lönnberg Print Promo: Helsinki, Finland, 2017; Available online: https://julkaisut.valtioneuvosto.fi/bitstream/handle/10024/80654/YO_2017_Vahahiilisen_rakentamisen_hankintakriteerit.pdf?sequence=1&isAllowed=y (accessed on 12 December 2023). (In Finnish)

- Finnish Ministry of the Environment. Government’s Climate Policy: Climate-Neutral Finland by 2035. Available online: https://ym.fi/en/climate-neutral-finland-2035 (accessed on 12 December 2023).

- European Commission. 2050 Long-Term Strategy. Available online: https://ec.europa.eu/clima/eu-action/climate-strategiestargets/2050-long-term-strategy_en (accessed on 12 December 2023).

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Suburban Residents’ Preferences for Livable Residential Area in Finland. Sustainability 2021, 13, 11841.

- Mahmoudkelaye, S.; Azari, K.T.; Pourvaziri, M.; Asadian, E. Sustainable material selection for building enclosure through ANP method. Case Stud. Constr. Mater. 2018, 9, e00200.

- Zabalza Bribián, I.; Valero Capilla, A.; Aranda Usón, A. Life cycle assessment of building materials: Comparative analysis of energy and environmental impacts and evaluation of the eco-efficiency improvement potential. Build. Environ. 2011, 46, 1133–1140.

- Bribián, I.Z.; Uson, A.A.; Scarpellini, S. Life cycle assessment in buildings: State-of-the-art and simplified LCA methodology as a complement for building certification. Build. Environ. 2009, 44, 2510–2520.

- Carreras, J.; Boer, D.; Cabeza, L.F.; Medrano, M.; Jiménez, L.; Guillén-Gosálbez, G. Reducing the Life Cycle Environmental Impact of Buildings Following a Simulation—Optimization Approach. In Advances in Energy Systems Engineering; Springer International Publishing: Cham, Switzerland, 2016; pp. 823–839.

- Karjalainen, M.; Ilgın, H.E.; Metsäranta, L.; Norvasuo, M. Wooden Facade Renovation and Additional Floor Construction for Suburban Development in Finland; IntechOpen: London, UK, 2022.

- Ilgın, H.E.; Karjalainen, M. Perceptions, Attitudes, and Interests of Architects in the Use of Engineered Wood Products for Construction: A Review; IntechOpen: London, UK, 2022.

- Fisch-Romito, V. Embodied carbon dioxide emissions to provide high access levels to basic infrastructure around the world. Glob. Environ. Change 2021, 70, 102362.

- Younis, A.; Dodoo, A. Cross-laminated timber for building construction: A life-cycle-assessment overview. J. Build. Eng. 2022, 52, 104482.

- Preston, F.; Lehne, J. Making Concrete Change Innovation in Low-Carbon Cement and Concrete. 2018. Available online: www.chathamhouse.org (accessed on 12 December 2023).

- Ding, Y.; Pang, Z.; Lan, K.; Yao, Y.; Panzarasa, G.; Xu, L.; Lo Ricco, M.; Rammer, D.R.; Zhu, J.Y.; Hu, M.; et al. Emerging engineered wood for building applications. Chem. Rev. 2022, 123, 1843–1888.

- Zuo, S.; Liang, Y.; Wu, Y.; Ge, S.; Shi, J.; Ma, X.; Cai, L.; Li, J.; Lam, S.S.; Xia, C. Using environmentally friendly technology for fabricating special plywood with ultra-high strength. J. Clean. Prod. 2023, 396, 136462.

- Abed, J.; Rayburg, S.; Rodwell, J.; Neave, M. A Review of the Performance and Benefits of Mass Timber as an Alternative to Concrete and Steel for Improving the Sustainability of Structures. Sustainability 2022, 14, 5570.

- Ayanleye, S.; Udele, K.; Nasir, V.; Zhang, X.; Militz, H. Durability and protection of mass timber structures: A review. J. Build. Eng. 2022, 46, 103731.

- Ussher, E.; Aloisio, A.; Rathy, S. Effect of lateral resisting systems on the wind-induced serviceability response of tall timber buildings. Case Stud. Constr. Mater. 2023, 19, e02540.

- Kim, K. A Review of CLT-based Empirical Research on Climate Change Communication from 2010 to 2021. Environ. Commun. 2023, 17, 844–860.

- Ilgın, H.E.; Karjalainen, M. Tallest Timber Buildings: Main Architectural and Structural Design Considerations, Wood Industry—Past, Present and Future Outlook; IntechOpen: London, UK, 2022.

- Engineered Wood Products Market Future Analysis Report form 2023–2030. Available online: https://www.marketreportsworld.com/enquiry/request-sample/21342506 (accessed on 12 December 2023).

- Bhandari, S.; Riggio, M.; Jahedi, S.; Fischer, E.C.; Muszynski, L.; Luo, Z. A review of modular cross laminated timber construction: Implications for temporary housing in seismic areas. J. Build. Eng. 2023, 63, 105485.

- Asiz, A. Sustainable Timber Construction: Challenges and Opportunities. Int. J. Eng. Sci. Appl. 2023, 10, 13–21.

- Dodoo, A.; Nguyen, T.; Dorn, M.; Olsson, A.; Bader, T.K. Exploring the synergy between structural engineering design solutions and life cycle carbon footprint of cross-laminated timber in multi-storey buildings. Wood Mater. Sci. Eng. 2022, 17, 30–42.

- United Nations Publications. Forest Products Annual Market Review 2017–2018. 2018. Available online: https://unece.org/forests/publications/forest-products-annual-market-review-2017-2018 (accessed on 12 December 2023).

- Tuupala Primary School and Day-Care Centre. Puuinfo. 2020. Available online: https://puuinfo.fi/arkkitehtuuri/daycare-centres-and-schools/tuupala-primary-school-and-day-care-centre/?lang=enpdf (accessed on 12 December 2023).

- The Entrance Building of Helsinki-Vantaa Airport. Puuinfo. 2022. Available online: https://puuinfo.fi/arkkitehtuuri/julkiset-rakennukset/helsinki-vantaan-lentoaseman-sisaankayntirakennus/ (accessed on 12 December 2023).

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.4K

Revisions:

2 times

(View History)

Update Date:

28 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No