Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Laura Ricciotti | -- | 5561 | 2023-12-22 10:05:16 | | | |

| 2 | Lindsay Dong | -4 word(s) | 5557 | 2023-12-25 01:26:01 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Extrusion-Based 3D-Printing. Encyclopedia. Available online: https://encyclopedia.pub/entry/53060 (accessed on 16 January 2026).

Ricciotti L, Apicella A, Perrotta V, Aversa R. Geopolymer Materials for Extrusion-Based 3D-Printing. Encyclopedia. Available at: https://encyclopedia.pub/entry/53060. Accessed January 16, 2026.

Ricciotti, Laura, Antonio Apicella, Valeria Perrotta, Raffaella Aversa. "Geopolymer Materials for Extrusion-Based 3D-Printing" Encyclopedia, https://encyclopedia.pub/entry/53060 (accessed January 16, 2026).

Ricciotti, L., Apicella, A., Perrotta, V., & Aversa, R. (2023, December 22). Geopolymer Materials for Extrusion-Based 3D-Printing. In Encyclopedia. https://encyclopedia.pub/entry/53060

Ricciotti, Laura, et al. "Geopolymer Materials for Extrusion-Based 3D-Printing." Encyclopedia. Web. 22 December, 2023.

Copy Citation

3D-printing is a sustainable approach to geopolymer material manufacturing, promoting waste reduction, energy consumption reduction, and CO2 emission reduction. In addition, 3D-printing technology based on geopolymers confronts hurdles that must be overcome to produce high-performance goods. One of the most important aspects of the quality and accuracy of 3D-printed geopolymers is the design of the mixture. Utilising industrial waste from mining and building as well as alternate aluminosilicate sources are two ways to advance the development of printing geopolymer combination compounds.

geopolymer

3D-printing

additive manufacturing

printability

flowability

rheology

1. Introduction

An emerging and rapidly growing field of additive manufacturing (AM) technology (according to ISO Standards [1], AM is a process in which focused thermal energy is used to fuse materials by melting as they are being deposited) is 3D-printing (fabrication of objects through the deposition of a material using a print head, nozzle, or another printer technology, according to ISO Standards [1]) with geopolymers (GPs). Increasing the construction industry’s productivity is the main driver behind the development of 3D-printing technology [2]. Moreover, this technology has great potential to decrease construction waste and improve the freedom of shape in built items [2][3]. According to data from the literature, using 3D-printing in construction can help reduce fabrication waste, labour costs, and production time by 30–60%, 50–80%, and 50–70%, respectively [4]. As a result, although 3D concrete printing is still in its early stages of development compared to other industries, it has garnered significant interest worldwide in recent years.

The first additive manufacturing technique used in building, contour crafting, was created in the middle of the 1990s [5] and is based on fused deposition modelling [2][6]. Later, particle bed printing, which selectively deposits the binder liquid into the powder bed to bond the powder particles [2], which was inspired by the technology of stereolithography [2][7], came into view. The most widely used additive manufacturing technique in the construction sector is extrusion-based 3D-printing, in which the object is built by depositing material extruded from the nozzle layer by layer [1][2][8].

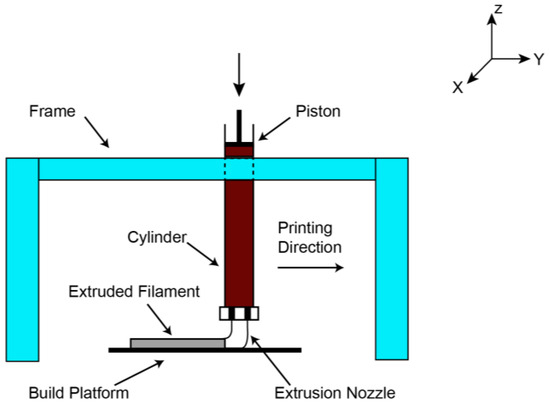

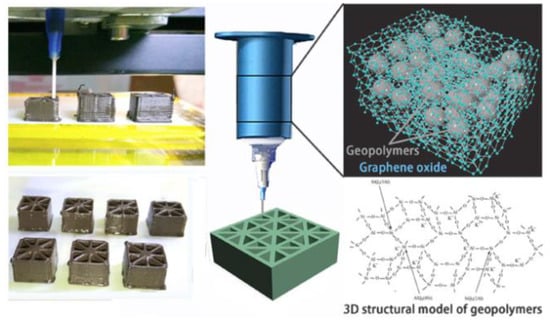

The extrusion-based 3D-printing process is schematically represented in Figure 1.

Figure 1. Schematic representation of the extrusion-based 3D-printing process.

This method involves extruding geopolymer paste via a nozzle, which is then applied layer by layer to make the result. The mechanical components of such printers are propelled by a kinematic system represented by a gantry or a robotic arm.

The main binder material is Portland cement, which is between 15% and 45% of the total mix proportion in most 3D-printed concrete [9]. In addition, 3D-printed cementitious materials often include more binder than traditional cementitious materials cast in moulds [10]. Since the production of Portland cement accounts for around 8% of the world’s CO2 emissions, the growing use of Portland cement could lead to higher material costs and decreased sustainability [11][12].

Geopolymers, called ‘inorganic polymers’, are amorphous ceramic systems with an aluminosilicate matrix produced by alkalinising natural or waste substances, such as metallurgical, industrial, urban, and agricultural wastes [13]. The term “geopolymer” describes various alkali-activated materials (AAMs) in the current literature. Still, it is most frequently used to describe systems whose binding phase primarily consists of aluminosilicate and is highly coordinated [14]. The aluminosilicate precursor powder reacts with an activating alkaline solution of sodium and/or potassium hydroxides and silicates to form a ceramic amorphous matrix at temperatures below 100 °C [13].

Their potential application is currently being investigated in a variety of scientific and industrial fields, including civil engineering, the automotive and aerospace industries, nonferrous foundries, metallurgy–ceramics, building retrofitting, waste management, art, and decoration. When employed as cement and concrete components, they can decrease production-related energy use, greenhouse gas emissions, and environmental impacts [13][14].

Because of their complexity and extreme variability, it is difficult to create geopolymer mixtures that meet all the strict requirements of additive manufacturing. The development of extrusion-based 3D-printing technology using geopolymers largely depends on acceptable settings and curing durations for extruded layers and their high adhesion. In addition, the mixture needs to be thixotropic. Thixotropy is a time-dependent property that reflects the state changes of pastes under shear and nonshear forces. For the extrusion 3D-printing process, pumping and screw mixing actions are required before the paste enters the extrusion nozzle. At this time, the paste must exhibit good fluidity (low dynamic yield stress) before extrusion, while excellent stacking characteristics (high static yield stress) must be exhibited in the constructed structure after extrusion. This time-dependent phenomenon is affected by the change in the paste state; hence, thixotropy can be used to describe the buildability and 3D structural performance [10][15][16]. It needs to be a viscoelastic liquid-like paste with specific rheological properties [16] for extrusion as well as display solid-like properties to remain stable after deposition, allowing the development of a self-sustaining structure. The quality (depositability, wettability) and uniformity of the aluminosilicate powder used in the 3D-printing process are crucial, and deviations from these requirements result in an anisotropic phenomenon in terms of linear dimensions and mechanical properties, as well as low strength of printable GPs [17]. Instrumentation problems are just as significant as the recipe components. This holds for the dimensional specifications and printing speeds of commercially available 3D-printers. Although 3D-printing with inorganic binders has been a practice for a while [18][19][20], only in the last three years have scientific publications explaining the use of GPs been actively published.

2. Geopolymer Materials: Synthesis and Applications

Geopolymers have recently received great attention and research interest due to their potential as green and low-carbon cementitious material [21]. French academic Davidovits was the first to highlight the potential of geopolymers in the 1970s [22]. In the 1980s, he created the first inorganic geopolymer material by reacting natural minerals containing silicon (Si) and aluminum (Al), such as slag, clay, fly ash, pozzolan, and an alkaline activator under mild conditions (below 160 C) [23]. They are a class of aluminosilicate materials produced by an inorganic polycondensation reaction. The geopolymerisation occurs when solid aluminosilicate precursors are combined with alkaline solutions such as potassium hydroxide (KOH), sodium hydroxide (NaOH), sodium silicate (Na2SiO3), potassium silicate (K2SiO3), or highly concentrated aqueous alkali hydroxide. Metakaolin and byproducts of various industrial processes, such as biomass ash, steel slag fly ash, bottom ash, red mud, volcanic ash, waste glass, coal gangue, diatomite, bauxite, high-magnesium nickel slag, and so on, can form the solid precursor.

The “two grinding and one burning” procedure typical of Portland cement production, which involves grinding raw materials, calcining clinker, and grinding cement, is avoided by this method, which also considerably benefits energy saving and emission reduction. For instance, just 0.18 kg CO2 was released during the production of 1 kg of geopolymer slurry, or around 1/5 of the amount of ordinary Portland cement, and when compared to traditional concrete, the amount of CO2 emitted during the production of geopolymer material was decreased by 26% to 45%.

The organic phase can be added to geopolymer paste in liquid or solid form, such as powder, fibres, or particles [24][25][26][27][28]. Adding a second liquid to a nonmiscible water geopolymer is particularly difficult because of the chemical incompatibility of extremely polar aqueous and apolar organic phases. The organic component, in particular, can be added in various ways and at various stages of the composite’s production: (i) Direct mode. The solid precursors first dissolve in the alkaline aqueous solution to slurry the paste. The organic phase is instantly incorporated into the slurry while being forcefully mechanically agitated before the system hardens. (ii) Pre-emulsification method. Initially, while the activating solution still lacks solid precursors, the organic component emulsifies. To begin the paste-hardening process, the solid precursor is introduced to the stable emulsion of the organic phase in the aqueous activating solution. (iii) Solid impregnation process. The organic phase is impregnated on a solid powder (either the aluminosilicate precursor or a particular adsorbing powder) and added to the alkaline activating solution before being added to the geopolymer slurry.

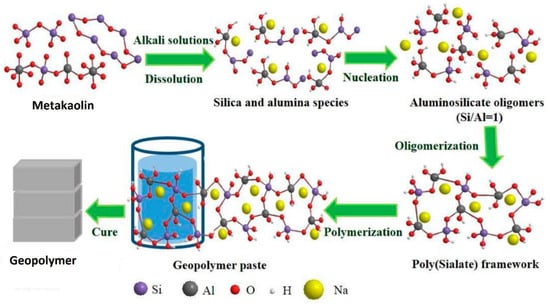

The geopolymer reaction mechanism model (see Figure 2) consists of the processes of dissolution–depolymerisation and reconstruction–polycondensation when made from low-calcium aluminosilicate raw materials [29][30].

Figure 2. Reaction mechanism of the metakaolin-based geopolymer system [31].

During alkali dissolution, the chemical bonds of aluminosilicate minerals are broken, causing the minerals to break down into aluminum–oxygen [AlO4]5− and silicon–oxygen [SiO4]4− monomers. As the dissolution progresses, monomers connect to form dimers, and dimers with other monomers form trimmers, multimers, and so on. Then, a reorganisation and polycondensation occur to form a three-dimensional network structure amorphous sodium aluminosilicate hydrate (N-A-S-H) gel.

Since Al3+ dissolves more quickly than Si in the aluminosilicate matrix in the alkaline environment, the concentration of Al3+ is higher during the early stages of the reaction (when the reaction achieves saturation). As a result, a metastable N-A-S-H gel with a high aluminium content (Si/Al ratio: 1.0 to 1.3, Al-rich gel I) would precipitate as a byproduct [32]. More Si-O groups dissolve during the reactionmore Si4+ concentration increases in the solution and its percentage in the N-A-S-H gel (Si/Al ratio about 2, Si-rich gel II). The silica–alumina skeleton and a metal cation with a balanced charge determine the polymer’s three-dimensional network structure, and this structural rearrangement defines the material’s pore shape and distribution. High temperatures increase the system’s kinetic energy, which improves intermolecular attraction and the efficiency of solute molecular bond breaking by solvent molecules [33].

There are two types of geopolymer application fields: those with standard physical and mechanical properties, as well as those with functional and advanced properties.

In the first category, geopolymers are used in building, construction, repair, restoration, maritime construction, pavement foundation materials, 3D-printing, high-temperature and fire-resistant materials, and thermal and acoustic insulation. Some specific applications include heavy-metal pollution immobilisation, pH regulator materials, catalysts, conductive materials for moisture sensor applications, and thermal storage [34][35][36][37][38][39][40].

Buildings in specific industries, such as firefighting structures, insulation walls, and nuclear power plants, might benefit from functional applications. These include fire control, isolation, heat preservation, and hazardous ion adsorption [41][42][43][44][45][46][47][48].

All these exciting features encourage geopolymer use in additive manufacturing, for environmental, technological, and commercial reasons (see Figure 3).

Figure 3. Benefits of geopolymer materials used in 3D-printing technology.

3. Characteristics for Geopolymer Printability

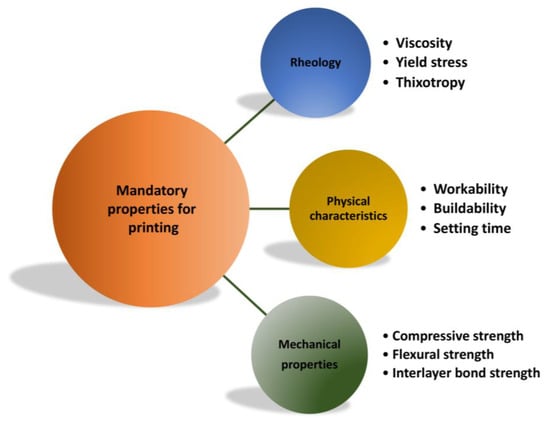

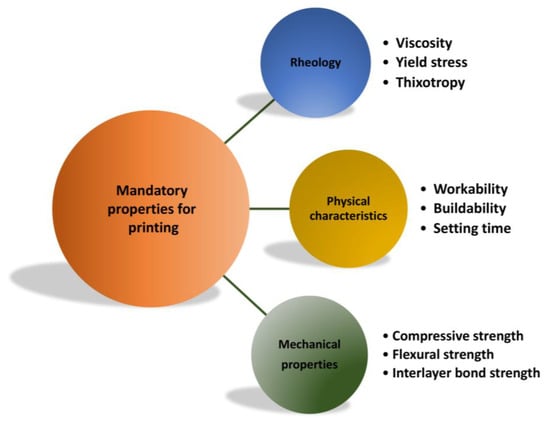

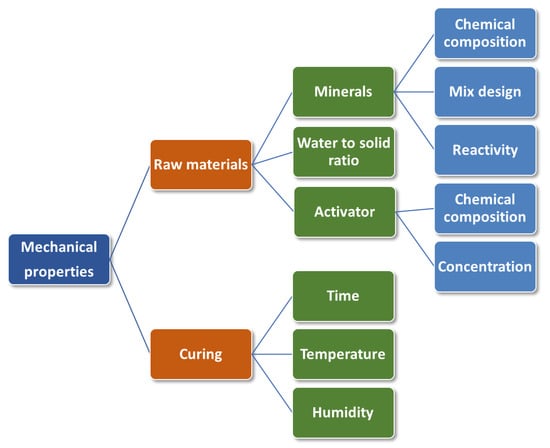

Geopolymer materials should possess many characteristics to meet the critical parameters for 3D-printing technology, such as rheological, physical, and mechanical properties (see Figure 4). The key parameters include aluminosilicate raw material and activator compositions, reinforcement fillers, printing variables, curing conditions (temperature and time), and post-processing of the 3D-printed specimens.

Figure 4. Key properties for 3D-printed geopolymer products.

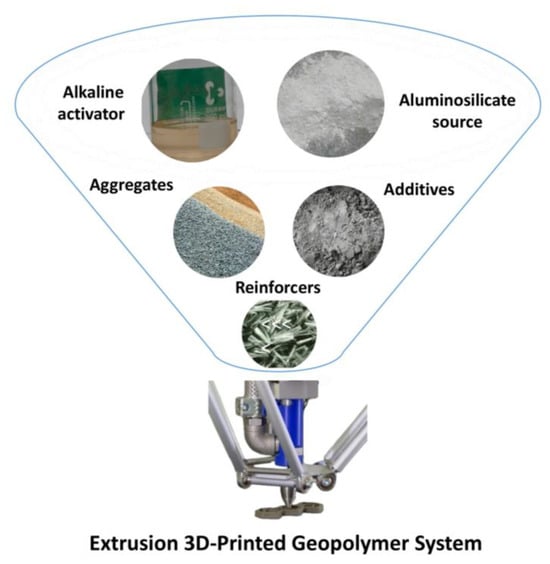

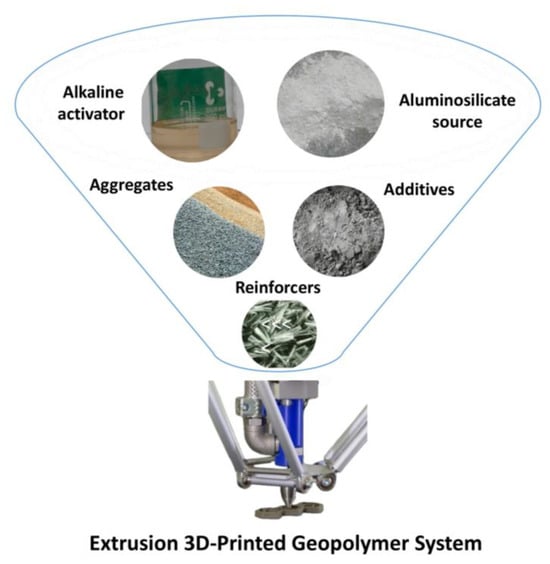

One of the most critical parameters is the composition of the raw materials. To meet the printability characteristics in addition to the aluminosilicate source material and alkali silicate/hydroxide activating agent, it is possible to include plasticisers, accelerators or retarders of hardening, thixotropic thickener, and other components, as shown in Figure 5.

Figure 5. The main additives used in 3D-printing geopolymer technology.

Aggregates such as quartz, accelerators or setting retarders, plasticisers, and so on can be added as additives. Their characteristics will be discussed in detail in the following sections.

Reinforcing components (fibrous or dispersed) are also employed in the mixture to minimise shrinkage deformations and increase the hardened material’s fracture toughness and mechanical properties (see Figure 5).

The raw materials for the printed geopolymer are chosen depending on the product operating conditions, target functional features, and the features of the 3D-printing method.

3.1. Aluminosilicate Raw Materials

This is due to Class F fly ash’s widespread availability and high SiO2 and Al2O3 oxide content [49][50][51]. Ashes with a high CaO concentration (Class C) are less appropriate for these applications due to their excessively quick setting, which interferes with the production of geopolymer gel (sodium aluminosilicate hydrate, N-A-S-H) [52]. With the application of high concentrations of NaOH, the setting time and degree of geopolymerisation can be increased [53]. Fly ash can be used alone as a precursor to 3D-printing GPs [54][55][56][57] or in combination with other industrial wastes and byproducts [17][23][34][39][58][59][60][61][62][63][64].

The poor reactivity of Class F fly ash can be overcome by adding blast-furnace slag (BFS) with amorphous character and high solubility in an alkaline medium [53]. Partly substituting fly ash with blast-furnace slag (up to 15–40 wt%) in 3D-printed GP mixes increases yield stress, thixotropy, and compressive strength [65]. The BFS contribution does not considerably alter the change in the rheological characteristics of geopolymer pastes at low replacement levels (up to 10 wt%). However, the early age compressive strength modifications more dramatically affect the homogeneity of the GP microstructure [15]. In the printable geopolymer mix, silica fume (SF), also known as micro silica, is used as an additional source of amorphous SiO2 [34][39][61][62][63][64]. SF, along with BFS, is primarily used to replace FA in partial replacement and helps to manage the rheological parameters of GPs. The presence of reactive silanol groups on the surface of the SF particles, as well as their fine particle size (95% of particles smaller than 1 μm [66], increase the yield stress and viscosity of printed geopolymers in the fresh state [15]. SF is also used to improve mixture cohesion [15].

3.2. Alkali Activators

The fundamental component of geopolymers in the alkaline activating reaction is alkaline activators [67]. These considerably affect the rheological properties of geopolymers. In addition, the presence of alkaline activators is critical in the kinetics of the geopolymerisation.

An alkaline activator typically comprises alkali metal hydroxide and alkali metal silicates to activate geopolymers. NaOH and Na2SiO3 are two of the most commonly utilised because of their inexpensive cost and outstanding rheological performance [68]. Potassium-based geopolymers have a higher yield stress than sodium-based geopolymer systems [68]. The Na2SiO3 activating systems, on the other hand, are consistent with the deflocculating action in particle suspensions [69]. As a result, the amount of hydroxide and silicate in the geopolymer mixture is carefully controlled to get the best Si/Na or SiO2/Na2O ratio. Because sodium ions firmly connect and retain the hydration layer of water molecules, an increase in Na ions in the solution promotes the dissolution of aluminosilicate minerals in the mixture. They are less likely to interfere with condensation and reduce free water [70]. As demonstrated in the literature [65], increasing the alkali activator increases the geopolymers’ yield stress and apparent viscosity. A higher alkali activator amount results in increased pH, higher yield stress, and ionic strength of surface charge [71].

3.3. Aggregates and Fillers

3D-printed geopolymer mixtures, like cementitious materials, can incorporate aggregates, the most common of which are silica (quartz) sand. Additive manufacturing technologies limit the size of fine aggregates. They primarily employ fine sand with a median particle size (d50) of 170–250 µm [17][55][72][73][74]. This is critical for obtaining improved powder bed homogeneity in powder-based 3D-printing and maintaining a narrow extruder nozzle diameter in extrusion-based 3D-printing. Sand incorporation in printed geopolymer mixes decreases the slump rate [73]. The constant gradation of various types of sand might increase mixture extrudability [75].

The rheology of fresh geopolymer mixes is also influenced by reinforcement fibres or particles. Variation in fibre content in the combination has a significant impact on the SYS and PV. Various reinforcement types (RTs) such as polypropylene (PP), polyvinyl alcohol (PVA) [76], polyethylene (PE) [77], and nano-graphite particulates (NGPs) [78], attapulgite [79], benzobisoxazole (PBO), and microcrystalline cellulose (MCC) have been commonly used to improve the fresh and hardened characteristics of geopolymers for 3D-printing. The overlapping and mechanical interlocking of the needle-like fibres with the matrix material improves the SYS when a sufficient number of wollastonite fibres are used.

3.4. Additives for Printability

The use of active organic and mineral additives in the formulation allows the rheological characteristics of printed geopolymer mixes to be controlled. Plasticising additives have a unique position in them. Surface active functional groups and finely distributed fillers with a high specific surface area considerably influence the geopolymer mortar’s viscosity. Sun et al. used ball milling to produce a surface modification of hexagonal boron nitride, producing many hydroxyl groups on its surface. When reacting with alumino–silicate oxides, such fillers can both decrease (at low levels) and enhance (at high contents) viscosity and viscoelasticity in geopolymer mortar [78]. Urea, naphthalene, and polycarboxylate exhibit the qualities of a superplasticiser for 3D-printing geopolymers [80]. Because of its flocculation properties, attapulgite clay can be employed as a thixotropic thickener to increase the yield stress of geopolymer blends [55][58]. Magnesium alumino-silicate also improves the thixotropy of new geopolymer pastes [81]. CMS (sodium carboxymethyl starch) is a viscosity modifier and retardant [82]. Increasing CMS content increases water retention and the setting time of geopolymer paste.

Additive manufacturing technologies provide prospects for various advanced energy and environmental applications of 3D-printed geopolymers as catalysts, water purification filters, conductive materials, and smart sensors in addition to their use in the construction industry. Beyond the examples given, scholars anticipate that research will shortly broaden the spectrum of practical applications of AM technologies, incorporating GPs into new fields. 3D-printed geopolymer nanocomposites are interesting. By adding nanoparticles to geopolymer matrices, composites of this kind gain multifunctionality in addition to improved mechanical and durability qualities. This creates new opportunities for the production of sophisticated geopolymer nanocomposites with special electrical, thermal, electromagnetic, photocatalytic, sensing, and self-healing properties when coupled with the advantages of AM technology. A few of these materials have already been successfully constructed with graphene oxide and graphite nanoplates. The effects of adding various types of nanoparticles to 3D-printable graphene oxides, including carbon nanotubes, nanocellulose, TiO2, and ZnO nanoparticles will soon be examined. 3D-printing can be used to create structures with a hierarchical micro, meso, and macro pore size distribution because geopolymer materials may contain nanocrystalline zeolites in addition to the amorphous gel phase, depending on the original component composition and synthesis circumstances [131][132]. This technique combines the functional properties of both the amorphous geopolymeric materials used to immobilise zeolites and the zeolites themselves due to their high surface area and adsorption capacitance with the design freedom of additive manufacturing of geometrically complex structures. These hybrid geopolymer–zeolite materials printed on them have potential applications in filtering, adsorption, and catalysis. These processes, as well as thermal insulation, could benefit from the 3D-printing of foamed geopolymers. Regarding structural design, biomimicry concepts can be used to construct new bio-inspired geopolymer structures with novel functionality.4. Fresh-State Properties

4.1. Rheology

Flowability is a crucial characteristic of a fresh geopolymeric paste in extrusion-based 3D-printing, defining its ability to flow under pressure in the printing system. Flowability relates to rheological viscoelastic parameters, particularly yield stress (associated with the elastic and storage response of the paste) and its dynamic viscosity (related to the dissipative viscous character of the fresh geopolymer). High values of these viscous and elastic components decrease flowability while avoiding the collapse of the 3D-printed part [55][70][76]. Organic and inorganic modifiers can be utilised to modify viscosity. However, often, a negative impact on buildability has been observed [16]. As a result, determining rheological characteristics necessitates striking a compromise between flowability and buildability to provide a high-quality geopolymer 3D-printing material. Internal parameters such as source materials, type, and activator content all have a substantial impact on the viscosity of geopolymer mixtures [75].

4.2. Buildability

Another critical parameter of the extrusion 3D-printing process of a new geopolymer mixture is buildability, as this determines the shape and buildability stability of 3D-printed systems [83][84]. As fibre content increases, so does the ability to maintain form [56]. However, the adhesive strength between the layers deteriorates as well [56][85]. The aluminosilicate supply, reinforcement elements, and fillers all affect the slump rate, which is used to assess the form stability of the printed layers. Archez et al. [73] showed that nonreactive fillers, particularly argillite, reduce the liquid-to-solid ratio contribution. The addition of reinforcement materials (such as glass fibres and wollastonite) and metakaolin to the geopolymer mixture can also reduce the slump rate value, resulting in a change in the viscosity of the geopolymer paste and an acceleration of the geopolymerisation reactions [73]. The slump rate is affected by printing settings as well as mixture composition. A decrease in printing speed contributes to a decrease in droop because it implies a longer time between layers [73]. The time interval, however, should be adjustable because the start of polycondensation processes can limit interaction with the following layer.

4.3. Open Time

Open time describes the period during which a fresh geopolymer mixture has a suitable consistency for printing. On the one hand, the optimal available time must be short for the geopolymer material to quickly gain sufficient strength to withstand successive extruded layers without significant deformation. On the other hand, it must be long enough to ensure that the neighbouring printed layers are linked together and do not develop cold joints [86]. The open time of printed geopolymers is less than the first setting time of traditionally mould-cast GPs [60][62][75]. The type and dosage of the aluminosilicate precursor and alkaline activator used could have a large impact on the open time and setting time [87][88][89][90][91][92][93]. When the concentration of reactive calcium sources, such as BFS, is increased, the open time decreases, resulting in the formation of calcium silicate hydrate (C-S-H) and calcium aluminosilicate hydrate (C-A-S-H) gels [60][62][86]. Heating increases the open time of printed geopolymers [84].

Utilising the high electrical conductivity of geopolymers supplied by the alkaline solution in their pores and GPs’ capacity to form robust chemical bonds with the rich calcium-based surfaces of OPC concrete, the authors developed a printed GP temperature sensor with a resolution of 0.1 °C and long-term repeatability of 0.3 °C. This example shows how 3D-printing processes in civil engineering can be used for self-sensing and self-healing repairs of critical engineering structures in the field, even though the adhesive bond strength of the printed patch to the concrete substrate was less than that of a typical GP repair material due to the high drying shrinkage [130]. 3D geopolymer printing attempts have been documented. The authors achieved a printed GP temperature sensor with a resolution of 0.1 °C and long-term repeatability of 0.3 °C by utilising the GPs’ capacity to form strong chemical bonds with the rich calcium-based surfaces of ordinary Portland cement (OPC) concrete, in addition to the high electrical conductivity of geopolymers supplied by the alkaline solution in their pores. Although the printed patch’s adhesive bond strength to the concrete substrate was not as strong as that of a standard GP repair material due to the high drying shrinkage, this example highlights the potential of 3D-printing in civil engineering for self-sensing and self-healing repairs of crucial engineering structures in the field. However, surface colonisation by biological micro- and macro-organisms is a feature of 3D-printing GPs and cement-based formulations.

Utilising the high electrical conductivity of geopolymers supplied by the alkaline solution in their pores and GPs’ capacity to form robust chemical bonds with the rich calcium-based surfaces of OPC concrete, the authors developed a printed GP temperature sensor with a resolution of 0.1 °C and long-term repeatability of 0.3 °C. This example shows how 3D-printing processes in civil engineering can be used for self-sensing and self-healing repairs of critical engineering structures in the field, even though the adhesive bond strength of the printed patch to the concrete substrate was less than that of a typical GP repair material due to the high drying shrinkage [130]. 3D geopolymer printing attempts have been documented. The authors achieved a printed GP temperature sensor with a resolution of 0.1 °C and long-term repeatability of 0.3 °C by utilising the GPs’ capacity to form strong chemical bonds with the rich calcium-based surfaces of ordinary Portland cement (OPC) concrete, in addition to the high electrical conductivity of geopolymers supplied by the alkaline solution in their pores. Although the printed patch’s adhesive bond strength to the concrete substrate was not as strong as that of a standard GP repair material due to the high drying shrinkage, this example highlights the potential of 3D-printing in civil engineering for self-sensing and self-healing repairs of crucial engineering structures in the field. However, surface colonisation by biological micro- and macro-organisms is a feature of 3D-printing GPs and cement-based formulations.

5. Hardened-State Properties

5.1. Density

When the mixture design or printing process settings are ineffective, 3D-printing with extrusion contributes to lower geopolymer density than casting due to under-filling samples [60][62][86]. Defects or heterogeneities in the extrusion-based printing process create voids in the cured GPs. The existence of gaps in 3D-printed geopolymers can reduce their mechanical strength [86]. Extrusion at high-pressure aids in improving the density of printed geopolymers [60][62].

5.2. Mechanical Properties

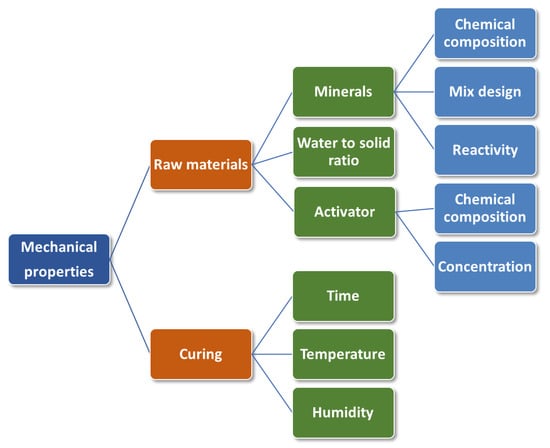

Mineral types, reinforcement, alkaline activators, printing parameters, and post-processing of printed specimens all have a direct impact on the mechanical properties of geopolymers. The effects of these parameters on compressive strength (CS), flexural strength (FS), interlayer bond strength (IBS), tensile strength (TS), and Young’s modulus (YM) have been investigated individually and the actual phenomena behind these effects have been investigated. Controlling the mechanical properties of printed geopolymers is more difficult than controlling OPC due to the numerous internal and external parameters involved, as shown in Figure 6.

Figure 6. Parameters affecting the mechanical properties of 3D-printed geopolymers.

Because of printing process peculiarities, the mechanical strength of 3D-printed geopolymers exhibits anisotropic behaviour depending on testing direction [18][34][59][61][65][94]. The laminated method of manufacturing in an extrusion-based process yields the following results: The longitudinal direction (specifically, the direction of printing) always has greater strength than the lateral or perpendicular directions [59][94]. The mechanical anisotropy of the geopolymers created by powder-based 3D-printing is caused by the preferential orientation of the powder particles and the weak interlayer adhesion [18][95].

When compared to casted geopolymers, the mechanical properties of 3D-printed GPs are degraded by the presence of voids and weak interlayer bonding [60][72]. However, several studies demonstrate that comparable strength values can be achieved by controlling printing parameters, along with a thorough material design and dying mode optimisation [60][86][96]. Heat treatment increases the mechanical strength of printed geopolymers compared to room temperature-cured samples [54][57][96], as seen in casted geopolymers [97].

5.3. Shrinkage

Drying shrinkage is intimately related to the long-term dimensional stability and crack formation of 3D-printed geopolymers. Although several studies have been conducted on shrinkage in traditionally mould-cast geopolymers [98][99][100][101], comparatively few studies have been conducted on shrinkage in printable GPs. Because of the lack of formwork, the printed geopolymers’ drying shrinkage has a vast surface area. This promotes significant water evaporation rates, which is apparent in the shrinkage of 3D-printed GPs throughout the drying process. It is widely understood that modifying agents, such as sodium carboxymethyl starch (CMS) [82], deter shrinkage value.

Short fibres are also helpful in reducing shrinking [73][102]. J. Archez et al. [73] studied the influence of high temperatures on the shrinking of 3D-printed geopolymer lattices. The volumetric shrinkage of the metakaolin-based GPs rose by 20% after thermal treatment at 300 °C compared to the reference sample cured at 80 °C for 1 day, which was ascribed to the total loss of bound water. Short fibres are also helpful in reducing shrinking [73][102]

5.4. Layer Adhesion

In extrusion-based 3D geopolymer printing, providing adhesive strength between neighbouring layers is a critical criterion for final product stability. Interfacial bond strength is directly affected by printing speed and the time gap between applying additional layers [39][73]. Short time intervals allow for better material mixing, resulting in a strong links between the layers. On the other hand, long intervals cause an interface to form and limit the interaction of adjacent layers due to the onset of the polycondensation process. The adhesion between the layers is harmed by the reinforced fresh geopolymer mixture’s increased stiffness, which includes fibres [56][85][103]. It is preferable to align the threads parallel to the direction of printing [56][73]. The ambient parameters (temperature and relative humidity) are also important.

5.5. Durability

There needs to be more research on the durability of 3D-printed geopolymers. As with OPC-based printed materials [104], the penetration of layer interfaces is a vital issue influencing the durability of 3D-manufactured GPs. High porosity in the interlayer zone of printed geopolymer structures makes them less resistant to freeze–thaw attack, aggressive sulphate and chloride ion penetration, carbonation, and other effects. As a result, these features necessitate in-depth research to better understand the transport processes and long-term durability of 3D-printed geopolymers.

6. One Part Geopolymers

Usually, geopolymer is a two-part mixture made by combining an alkaline solution with precursors rich in alumina and aluminosilicates, such as fly ash and metakaolin. Laterite, a promising mineral with a high abundance and good performance, was recently used as the precursor [105]. Alkaline activators such as alkali hydroxide, silicate, and aluminate activate the precursors [106][107][108][109]. High compressive strength, fire resistance, rapid hardening, salt and acid resistance, and other environmental benefits distinguish geopolymer from ordinary concrete [110][111][112]. Despite the advantages of a two-part geopolymer, there are several issues with viscosity and managing dangerous alkaline activator solutions for large-scale printing. As a result, using a solid activator to create a one-part geopolymer can help address some of these issues [12][113][114].

In a one-part geopolymer, a solid activator can be any material that raises the pH of the reaction mixture, offers alkali cations, and aids in dissolving [115]. Anhydrous sodium metasilicate and grade sodium silicate are the most commonly utilised solid activators [116]. Solid activators have various advantages over liquid activators, including being easier to handle on-site, being free of toxic highly alkaline liquids, and being produced at a lower cost with a lesser environmental impact. Incorporating a solid activator facilitates mixing processes similar to OPC, in which the solid ingredients are dry-mixed before adding water.

6.1. Rheology

One part-geopolymer flowability and extrudability are also dependent on the rheological viscoelastic behaviour of the paste base materials and their formulation; an ideal viscoelastic mix should have a sufficiently viscous character to allow good flowability combined with a level of elasticity that could guarantee a suitable yield stress for extrusion [117]. Muthukrishnan et al. [81] measured the static yield strength with time to explore the effect of increasing the activator content on the flowability of GGBS and FA one-part geopolymers. It was discovered that increasing the activator content resulted in a faster evolution of yield stress, requiring more pumping energy. Several papers have investigated the influence of various precursor materials and discovered that loading the mix with calcium-containing elements, such as GGBS, reduces extrudability.

Regarding the rheological characteristics, Panda et al. [65] found that because of the calcium-rich chemical composition of GGBS, increasing the GGBS concentration in an FA-based one-part geopolymer improved yield stress, plastic viscosity, and viscosity recovery. The thixotropic quality of the mix is enhanced due to the increased packing density caused by the angular morphology of the GGBS particles. The rheological behaviour of geopolymers based on lateritic clay (LAC) and iron-rich laterite clay was examined by Kaze et al. [118]. LAI as iron (Fe) has a higher reaction rate than Si and Al, the results indicated that LAI had a much higher yield stress than LAC. This is explained by the more significant deformation that LAI displayed as a result of the higher interaction rate between its constituents. Iron hydroxide gel is thus produced by the rapid precipitation of iron species in an alkaline medium, which accelerates the polycondensation process and gives the gel a stiffer structure. The impact of varying calcination temperatures on the rheology of a geopolymer based on meta-halloysite was examined by Kaze et al. [119]. They found that by raising the calcination temperature, more reactive phases were formed in the geopolymer, which improved its rheological behaviour.

6.2. Mechanical Properties

Several investigations have demonstrated that equivalent strength values can still be produced by modifying the printing conditions and mix design for hardened one-part geopolymers [86][96]. The strength of a one-part geopolymer is generally more robust when a calcium-rich precursor is used, depending on the mix design. The more the GGBS incorporation, the greater the compressive strength [86][120]. However, raising GGBS above a certain limit reduces compressive strength, possibly attributable to a lack of workability. Panda et al. [65] discovered that raising the GGBS content from 15% to 40% enhanced the compressive strength values of an FA-based one-part geopolymer due to the early synthesis of C-S-H. They also discovered that increasing the activator dosage from 10% to 20% increases strength values because more Si ions are accessible for geopolymerisation. Choosing the best precursor proportion for a given activator percentage and water volume can improve compressive strength [121].

6.3. Economic and Environmental Considerations

A primary advantage of employing 3D-printing technology is the reduction of total costs. The use of 3D-printing allows more cost-effective alternatives in terms of material savings, necessary work, and energy. Concrete 3D-printing (3DCP) eliminates the need for formwork, which accounts for 10% of the total cost. As shown in [122], eliminating formwork eliminates the requirement for formwork labour, lowering overall costs by 50 per cent or more. Batikha et al. [123] evaluated several building approaches and discovered that 3DCP is more cost-effective than other construction methods.

3D concrete printing is the most sustainable construction process, producing less CO2 than other methods of construction [123]. Mohammad et al. [124] compared reinforced concrete (traditional method) to 3D-concrete printing and discovered that 3D-printing concrete created around 22% less carbon dioxide emissions. Because 3D concrete printing technology uses more cementitious binder than conventional concrete [10], researchers have focused on finding more environmentally friendly materials instead of cement due to the consumption of approximately 4% of greenhouse gas (GHG) and the release of roughly 8% of total global CO2 emissions associated with cement production [125].

7. Applications

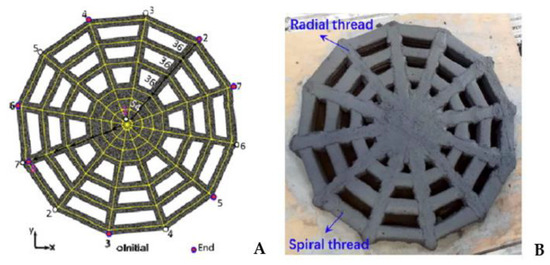

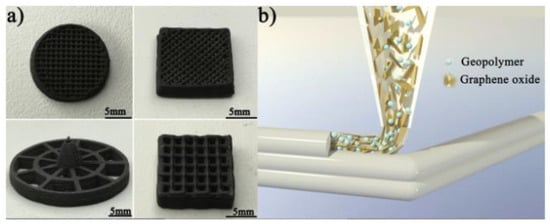

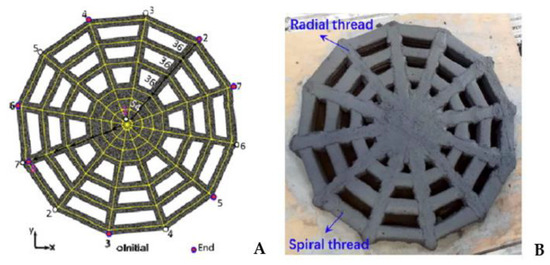

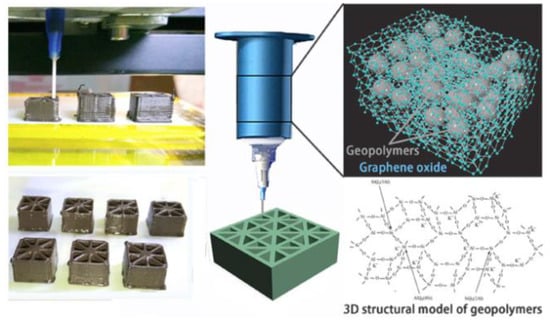

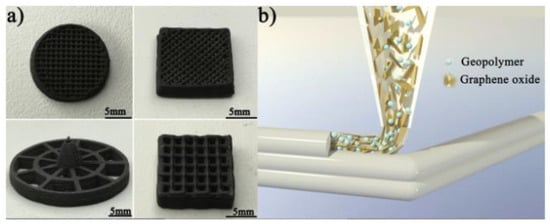

The majority of 3D-printed geopolymers are designed to be used in buildings. In a lot less time than with traditional building technologies, geopolymer technology and additive manufacturing can be used to create structures in a variety of configurations [17][34][62][65][74][75][85]. Because 3D-printed geopolymers cure more quickly and have a higher early strength than OPC-based concrete, they have a considerable advantage as building materials in addition to their substantial environmental and economic benefits. Because of these characteristics and GPs’ strong heat and chemical resistance, 3D-printing of geopolymers is a viable technology for constructing buildings in difficult climatic circumstances, such as lunar construction [80][126]. Attempts to reinforce 3D-printed geopolymer concrete, specifically with micro-cables (Figure 7A) [64][127], improves structural applications. Such composites have reasonably good strength, ductility, and toughness; nevertheless, more research is needed to overcome the limits caused by the presence of weak geopolymer planes between filaments and to improve cable–geopolymer adhesion qualities. Extrusion-based 3D-printing can create highly electrically conductive nanocomposites by adding graphene oxide (GO) nanosheets combined to form a geopolymer.

Figure 7. (A) Spiderweb-like structure; (B) 3D-printed real production of spiderweb-like structure.

The electrical conductivity of the 3D-printed GO/GPs structure shown (Figure 7B) was around 102 S/m due to the decrease of graphene oxide caused by heat treatment of samples at 1000 C. A ceramic matrix composite’s achieved value is relatively high, making it potentially useful as a joule heating thermal source. The addition of GO nanosheets significantly improved the composition’s rheological characteristics, allowing for extrusion-based 3D-printing. The mechanical properties of the nanocomposites improved to a certain critical GO level due to the reinforcing action, beyond which a drop in compressive strength was seen due to nanoparticle aggregation.

Mechanical testing on samples before and after thermal annealing, on the other hand, yielded inconsistent results, which the authors described was a result of pore development from gas evolution when the GO is converted to graphene, as well as of weakening of the graphene layer (see Figure 8) [128]. Later, Zhou et al. [129] discovered that these issues can be mitigated in part by optimising the physical size of GO (50–325 meshes). 3D-printing techniques can be used to create a variety of geopolymeric foams for thermal insulation purposes (see Figure 9).

Figure 8. Illustration of the 3D-printing process and some 3D-printed structures. The colours of the printed samples turned from brownish to blackish when the GO loading increased [128].

Figure 9. Illustration of 3D-printed structures (a), schematic diagram of 3D-printed GOGP (b) [129].

References

- BS EN ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Fundamentals and Vocabulary. ISO: West Conshohocken, PA, USA, 2021.

- Mohan, M.K.; Rahul, A.V.; De Schutter, G.; Van Tittelboom, K. Extrusion-based concrete 3D printing from a material perspective: A state-of-the-art review. Cem. Concr. Compos. 2021, 115, 103855.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. B Eng. 2018, 143, 172–196.

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Appl. Sci. Manuf. 2019, 125, 105533.

- Khan, M.S.; Sanchez, F.; Zhou, H. 3-D printing of concrete: Beyond horizons. Cem. Concr. Res. 2020, 133, 106070.

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-scale fabrication by contour crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320.

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450.

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49.

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix design concepts for 3D printable concrete: A review. Cem. Concr. Compos. 2021, 122, 104155.

- Mohan, M.K.; Rahul, A.V.; Van Tittelboom, K.; De Schutter, G. Rheological and pumping behaviour of 3D printable cementitious materials with varying aggregate content. Cem. Concr. Res. 2021, 139, 106258.

- Zhang, Z.; Yang, F.; Liu, J.-C.; Wang, S. Eco-friendly high strength, high ductility engineered cementitious composites (ECC) with substitution of fly ash by rice husk ash. Cem. Concr. Res. 2020, 137, 106200.

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34.

- Provis, J.L.; Duxson, P.; van Deventer, J.S. The role of particle technology in developing sustainable construction materials. Adv. Powder Technol. 2010, 21, 2–7.

- Duxson, P.; Fernández-Jiménez, A.; Provis, J.L.; Lukey, G.C.; Palomo, A.; van Deventer, J.S.J. Geopolymer technology: The current state of the art. J. Mater. Sci. 2007, 42, 2917–2933.

- Panda, B.; Unluer, C.; Tan, M.J. Investigation of the rheology and strength of geopolymer mixtures for extrusion-based 3D printing. Cem. Concr. Compos. 2018, 94, 307–314.

- Aversa, R.; Ricciotti, L.; Perrotta, V.; Apicella, A. Chemorheology of a Si/Al > 3 Alkali Activated Metakaolin Paste through Parallel Differential Scanning Calorimetry (DSC) and Dynamic Mechanical Analysis (DMA). Polymers 2023, 15, 3922.

- Xia, M.; Sanjayan, J. Method of formulating geopolymer for 3D printing for construction applications. Mater. Des. 2016, 110, 382–390.

- Chen, Z.; Li, Z.; Li, J.; Liu, C.; Lao, C.; Fu, Y.; Liu, C.; Li, Y.; Wang, P.; He, Y. 3D printing of ceramics: A review. J. Eur. Ceram. Soc. 2019, 39, 661–687.

- Travitzky, N.; Bonet, A.; Dermeik, B.; Fey, T.; Filbert-Demut, I.; Schlier, L.; Schlordt, T.; Greil, P. Additive manufacturing of ceramic-based materials. Adv. Eng. Mater. 2014, 16, 729–754.

- Gibbons, G.J.; Williams, R.; Purnell, P.; Farahi, E. 3D printing of cement composites. Adv. Appl. Ceram. 2010, 109, 287–290.

- Habert, G.; De Lacaillerie, J.D.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238.

- Davidovits, J. Geopolymer Cement: A Review; Geopolymer Institute Technics Paper; Geopolymer Institute: Saint-Quentin, France, 2013; Volume 21, pp. 1–11.

- Khale, D.; Chaudhary, R. Mechanism of geopolymerization and factors influencing its development: A review. J. Mater. Sci. 2007, 42, 729–746.

- Zhang, D.W.; Wang, D.M.; Liu, Z.; Xie, F.Z. Rheology, agglomerate structure, and particle shape of fresh geopolymer paste with different NaOH activators content. Constr. Build. Mater. 2018, 187, 674–680.

- Zhang, D.; Wang, D.; Xie, F. Microrheology of fresh geopolymer pastes with different NaOH amounts at room temperature. Constr. Build. Mater. 2019, 207, 284–290.

- Yan, L.; Kasal, B.; Huang, L. A review of recent research on the use of cellulosic fibers, their fiber fabric reinforced cementitious, geo-polymer and polymer composites in civil engineering. Compos. Part B 2016, 92, 94–132.

- Shaikh, F. Review of mechanical properties of short fiber reinforced geopolymer composites. Constr. Build. Mater. 2013, 43, 37–49.

- Sakulich, A. Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 2011, 1, 195–210.

- Palomo, A.; Krivenko, P.; Garcia-Lodeiro, I.; Kavalerova, E.; Maltseva, O.; Fernandez-Jimenez, A. A review on alkaline activation: New analytical perspectives. Mater. Constr. 2014, 64, 315.

- Hu, Z.; Wyrzykowski, M.; Lura, P. Estimation of reaction kinetics of geopolymers at early ages. Cem. Concr. Res. 2020, 129, 105971.

- Ricciotti, L.; Apicella, A.; Perrotta, V.; Aversa, R. Geopolymer Materials for Bone Tissue Applications: Recent Advances and Future Perspectives. Polymers 2023, 15, 1087.

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48.

- Kuenzel, C.; Ranjbar, N. Dissolution mechanism of fly ash to quantify the reactive aluminosilicates in geopolymerisation. Resour. Conserv. Recycl. 2019, 150, 104421.

- Panda, B.; Paul, S.C.; Hui, L.J.; Tay, Y.W.D.; Tan, M.J. Additive manufacturing of geopolymer for sustainable built environment. J. Clean. Prod. 2017, 167, 281–288.

- Duan, P.; Yan, C.; Luo, W. A novel waterproof, fast setting and high early strength repair material derived from metakaolin geopolymer. Constr. Build. Mater. 2016, 124, 69–73.

- Salazar, R.A.R.; Jesús, C.; de Gutiérrez, R.M.; Pacheco-Torgal, F. Alkali-activated binary mortar based on natural volcanic pozzolan for repair applications. J. Build. Eng. 2019, 25, 100785.

- Ahmad Zailani, W.W.; Bouaissi, A.; Abdullah, M.M.A.B.; Abd Razak, R.; Yoriya, S.; Mohd Salleh, M.A.A.; Mohd Remy Rozainy, M.A.Z.; Fansuri, H. Bonding strength characteristics of FA-based geopolymer paste as a repair material when applied on OPC substrate. Appl. Sci. 2020, 10, 3321.

- Palomoa, A.; Grutzeck, M.W.; Blancoa, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329.

- Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tay, Y.W.D.; Tan, M.J. Measurement of tensile bond strength of 3D printed geopolymer mortar. Measurement 2018, 113, 108–116.

- Panda, B.; Ruan, S.; Unluer, C.; Tan, M.J. Investigation of the properties of alkali-activated slag mixes involving the use of nanoclay and nucleation seeds for 3D printing. Compos. Part B Eng. 2020, 186, 107826.

- Sellami, M.; Barre, M.; Toumi, M. Synthesis, thermal properties and electrical conductivity of phosphoric acid-based geopolymer with metakaolin. Appl. Clay Sci. 2019, 180, 105192.

- Nuaklong, P.; Sata, V.; Wongsa, A.; Srinavin, K.; Chindaprasirt, P. Recycled aggregate high calcium fly ash geopolymer concrete with inclusion of OPC and nano-SiO2. Constr. Build. Mater. 2018, 174, 244–252.

- Shi, W.; Ren, H.; Li, M.; Shu, K.; Xu, Y.; Yan, C.; Tang, Y. Tetracycline removal from aqueous solution by visible-light-driven photocatalytic degradation with low cost red mud wastes. Chem. Eng. J. 2020, 382, 122876.

- Zhang, Y.J.; He, P.Y.; Yang, M.Y.; Kang, L. A new graphene bottom ash geopolymeric composite for photocatalytic H-2 production and degradation of dyeing wastewater. Int. J. Hydrogen Energy 2017, 42, 20589–20598.

- Zhang, Y.; He, P.; Zhang, Y.; Chen, H. A novel electroconductive graphene/fly ash-based geopolymer composite and its photocatalytic performance. Chem. Eng. J. 2018, 334, 2459–2466.

- Zhou, B.; Wang, L.; Ma, G.; Zhao, X.; Zhao, X. Preparation and properties of bio-geopolymer composites with waste cotton stalk materials. J. Clean. Prod. 2020, 245, 118842.

- Yu, J.; Chen, Y.; Chen, G.; Wang, L. Experimental study of the feasibility of using anhydrous sodium metasilicate as a geopolymer activator for soil stabilization. Eng. Geol. 2020, 264, 105316.

- Yu, Z.; Song, W.; Li, J.; Li, Q. Improved simultaneous adsorption of Cu(II) and Cr(VI) of organic modified metakaolin-based geopolymer. Arab. J. Chem. 2020, 13, 4811–4823.

- Zhang, P.; Gao, Z.; Wang, J.; Guo, J.; Hu, S.; Ling, Y. Properties of fresh and hardened fly ash/slag based geopolymer concrete: A review. J. Clean. Prod. 2020, 270, 122389.

- Amran, M.; Debbarma, S.; Ozbakkaloglu, T. Fly ash-based eco-friendly geopolymer concrete: A critical review of the long-term durability properties. Constr. Build. Mater. 2021, 270, 121857.

- Zhuang, X.Y.; Chen, L.; Komarneni, S.; Zhou, C.H.; Tong, D.S.; Yang, H.M.; Yu, W.H.; Wang, H. Fly ash-based geopolymer: Clean production, properties and application. J. Clean. Prod. 2016, 125, 253–267.

- Hanjitsuwan, S.; Hunpratub, S.; Thongbai, P.; Maensiri, S.; Sata, V.; Chindaprasirt, P. Effects of NaOH concentrations on physical and electrical properties of high calcium fly ash geopolymer paste. Cem. Concr. Compos. 2014, 45, 9–14.

- Kumar, S.; Kumar, R.; Mehrotra, S.P. Influence of granulated blast furnace slag on the reaction, structure and properties of fly ash based geopolymer . J. Mater. Sci. 2010, 45, 607–615.

- Singh, N.B. Fly Ash-Based Geopolymer Binder: A Future Construction Material. Minerals 2018, 8, 299.

- Guo, X.; Yang, J.; Xiong, G. Influence of supplementary cementitious materials on rheological properties of 3D printed fly ash based geopolymer. Cem. Concr. Compos. 2020, 114, 103820.

- Nematollahi, B.; Vijay, P.; Sanjayan, J.; Nazari, A.; Xia, M.; Nerella, V.N.; Mechtcherine, V. Effect of polypropylene fibre addition on properties of geopolymers made by 3D printing for digital construction. Materials 2018, 11, 2352.

- Alghamdi, H.; Neithalath, N. Synthesis and characterization of 3D-printable geopolymeric foams for thermally efficient building envelope materials. Cem. Concr. Compos. 2019, 104, 103377.

- Panda, B.; Unluer, C.; Tan, M.J. Extrusion and rheology characterization of geopolymer nanocomposites used in 3D printing. Compos. Part B Eng. 2019, 176, 107290.

- Bong, S.H.; Nematollahi, B.; Nazari, A.; Xia, M.; Sanjayan, J. Method of optimisation for ambient temperature cured sustainable geopolymers for 3D printing construction applications. Materials 2019, 16, 902.

- Albar, A.; Chougan, M.; Kheetan, M.J.A.; Swash, M.R.; Ghaffar, S.H. Effective extrusion-based 3D printing system design for cementitious-based materials. Results Eng. 2020, 6, 100135.

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149.

- Panda, B.; Tan, M.J. Experimental study on mix proportion and fresh properties of fly ash based geopolymer for 3D concrete printing. Ceram. Int. 2018, 44, 10258–10265.

- Lim, J.H.; Panda, B.; Pham, Q.-C. Improving flexural characteristics of 3D printed geopolymer composites with in-process steel cable reinforcement. Constr. Build. Mater. 2018, 178, 32–41.

- Li, Z.; Wang, L.; Ma, G. Mechanical improvement of continuous steel microcable reinforced geopolymer composites for 3D printing subjected to different loading conditions. Compos. Part B Eng. 2020, 187, 107796.

- Panda, B.; Singh, G.B.; Unluer, C.; Tan, M.J. Synthesis and characterization of one-part geopolymers for extrusion based 3D concrete printing. J. Clean. Prod. 2019, 220, 610–619.

- Mehta, A.; Ashish, D.K. Silica fume and waste glass in cement concrete production: A review. J. Build. Eng. 2020, 29, 100888.

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability assessment, potentials and challenges of 3D printed concrete structures: A systematic review for built environmental applications. J. Clean. Prod. 2021, 303, 127027.

- Ma, G.; Li, Z.; Wang, L.; Bai, G. Micro-cable reinforced geopolymer composite for extrusion-based 3D printing. Mater. Lett. 2019, 235, 144–147.

- Bong, S.H.; Nematollahi, B.; Xia, M.; Nazari, A.; Sanjayan, J.; Pan, J. Properties of 3D-Printable Ductile Fibre-Reinforced Geopolymer Composite for Digital Construction Applications; RILEM Bookseries; Springer: Cham, Switzerland, 2020; Volume 23, pp. 363–372.

- Archez, J.; Maitenaz, S.; Demont, L.; Charrier, M.; Mesnil, R.; Texier-Mandoki, N.; Bourbon, X.; Rossignol, S.; Caron, J.F. Strategy to shape; on a half-meter scale, a geopolymer composite structure by additive manufacturing. Open Ceram. 2021, 5, 100071.

- Lowke, D.; Talke, D.; Dressler, I.; Weger, D.; Gehlen, C.; Ostertag, C.; Rael, R. Particle bed 3D printing by selective cement activation—Applications, material and process technology. Cem. Concr. Res. 2020, 134, 106077.

- Voney, V.; Odaglia, P.; Brumaud, C.; Dillenburger, B.; Habert, G. From casting to 3D printing geopolymers: A proof of concept. Cem. Concr. Res. 2021, 143, 106374.

- Archez, J.; Texier-Mandoki, N.; Bourbon, X.; Caron, J.F.; Rossignol, S. Shaping of geopolymer composites by 3D printing. J. Build. Eng. 2021, 34, 101894.

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of microwave heating on interlayer bonding and buildability of geopolymer 3D concrete printing. Constr. Build. Mater. 2020, 265, 120786.

- Zhong, H.; Zhang, M. 3D printing geopolymers: A review. Cem. Concr. Compos. 2022, 128, 104455.

- Weng, Y.; Li, M.; Tan, M.J.; Qian, S. Design 3D printing cementitious materials via Fuller Thompson theory and Marson-Percy model. Constr. Build. Mater. 2018, 163, 600–610.

- Ma, S.; Fu, S.; Zhao, S.; He, P.; Ma, G.; Wang, M.; Jia, D.; Zhou, Y. Direct ink writing of geopolymer with high spatial resolution and tunable mechanical properties. Addit. Manuf. 2021, 46, 102202.

- Sun, Q.; Peng, Y.; Georgolamprou, X.; Li, D.; Kiebach, R. Synthesis and characterization of a geopolymer/hexagonal-boron nitride composite for free forming 3D extrusion-based printing. Appl. Clay Sci. 2020, 199, 105870.

- Sahin, O.; Ilcan, H.; Atesli, A.T.; Kul, A.; Yıldırım, G.; Sahmaran, M. Construction and demolition waste-based geopolymers suited for use in 3-dimensional additive manufacturing. Cem. Concr. Compos. 2021, 121, 104088.

- Pilehvar, S.; Arnhof, M.; Pamies, R.; Valentini, L.; Kjøniksen, A.-L. Utilization of urea as an accessible superplasticizer on the moon for lunar geopolymer mixtures. J. Clean. Prod. 2020, 247, 119177.

- Muthukrishnan, S.; Ramakrishnan, S.; Sanjayan, J. Effect of alkali reactions on the rheology of one-part 3D printable geopolymer concrete. Cem. Concr. Compos. 2021, 116, 103899.

- Sun, C.; Xiang, J.; Xu, M.; He, Y.; Tong, Z.; Cui, X. 3D extrusion free forming of geopolymer composites: Materials modification and processing optimization. J. Clean. Prod. 2020, 258, 120986.

- Souza, M.T.; Simao, L.; de Moraes, E.G.; Senff, L.; de Castro Pessoa, J.R.; Ribeiro, M.J.; de Oliveira, A.P.N. Role of temperature in 3D printed geopolymers: Evaluating rheology and buildability. Mater. Lett. 2021, 293, 129680.

- Munir, Q.; Peltonen, R.; Karki, T. Printing parameter requirements for 3d printable geopolymer materials prepared from industrial side streams. Materials 2021, 14, 4758.

- Al-Qutaifi, S.; Nazari, A.; Bagheri, A. Mechanical properties of layered geopolymer structures applicable in concrete 3D-printing. Constr. Build. Mater. 2018, 176, 690–699.

- Chougan, M.; Ghaffar, S.H.; Jahanzat, M.; Albar, A.; Mujaddedi, N.; Swash, R. The influence of nano-additives in strengthening mechanical performance of 3D printed multi-binder geopolymer composites. Constr. Build. Mater. 2020, 250, 118928.

- Zhang, P.; Zheng, Y.; Wang, K.; Zhang, J. A review on properties of fresh and hardened geopolymer mortar. Compos. Part B Eng. 2018, 152, 79–95.

- Elyamany, H.E.; Elmoaty, A.E.M.A.; Elshaboury, A.M. Setting time and 7-day strength of geopolymer mortar with various binders. Constr. Build. Mater. 2018, 187, 974–983.

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171.

- Arnoult, M.; Perronnet, M.; Autef, A.; Rossignol, S. How to control the geopolymer setting time with the alkaline silicate solution. J. Non-Cryst. Solids 2018, 495, 59–66.

- Topark-Ngarm, P.; Chindaprasirt, P.; Sata, V. Setting time, strength, and bond of high-calcium fly ash geopolymer concrete. J. Mater. Civ. Eng. 2015, 27, 04014198.

- Perna, I.; Hanzlícek, T. The setting time of a clay-slag geopolymer matrix: The influence of blast-furnace-slag addition and the mixing method. J. Clean. Prod. 2016, 112, 1150–1155.

- Rahmiati, T.; Azizli, K.A.; Man, Z.; Ismail, L.; Nuruddin, M.F. The effect of KOH concentration on setting time and compressive strength of fly ash-based geopolymer. Appl. Mech. Mater. 2014, 625, 94–97.

- Nematollahi, B.; Xia, M.; Sanjayan, J. Post-processing methods to improve strength of particle-bed 3D printed geopolymer for digital construction applications. Front. Mater. 2019, 6, 160.

- Xia, M.; Nematollahi, B.; Sanjayan, J. Influence of binder saturation level on compressive strength and dimensional accuracy of powder-based 3D printed geopolymer. Mater. Sci. Forum 2018, 939, 177–183.

- Alghamdi, H.; Nair, S.A.O.; Neithalath, N. Insights into material design, extrusion rheology, and properties of 3D-printable alkali-activated fly ash-based binders. Mater. Des. 2019, 167, 107634.

- Mo, B.-H.; Zhu, H.; Cui, X.-M.; He, Y.; Gong, S.-Y. Effect of curing temperature on geopolymerization of metakaolin-based geopolymers. Appl. Clay Sci. 2014, 99, 144–148.

- Ling, Y.; Wang, K.; Fu, C. Shrinkage behavior of fly ash based geopolymer pastes with and without shrinkage reducing admixture. Cem. Concr. Compos. 2019, 98, 74–82.

- Khan, I.; Xu, T.; Castel, A.; Gilbert, R.I.; Babaee, M. Risk of early age cracking in geopolymer concrete due to restrained shrinkage. Constr. Build. Mater. 2019, 229, 116840.

- Mermerdaş, K.; Algın, Z.; Ekmen, Ş. Experimental assessment and optimization of mix parameters of fly ash-based lightweight geopolymer mortar with respect to shrinkage and strength. J. Build. Eng. 2020, 31, 101351.

- Yang, Y.; Chen, Z.; Feng, W.; Nong, Y.; Yao, M.; Tang, Y. Shrinkage compensation design and mechanism of geopolymer pastes. Constr. Build. Mater. 2021, 299, 123916.

- Vlachakis, C.; Perry, M.; Biondi, L.; McAlorum, J. 3D printed temperature-sensing repairs for concrete structures. Addit. Manuf. 2020, 34, 101238.

- Nematollahi, B.; Xia, M.; Sanjayan, J.; Vijay, P. Effect of type of fiber on inter-layer bond and flexural strengths of extrusion-based 3D printed geopolymer. Mater. Sci. Forum 2018, 939, 155–162.

- Li, V.C.; Bos, F.P.; Yu, K.; McGee, W.; Ng, T.Y.; Figueiredo, S.C.; Nefs, K.; Mechtcherine, V.; Nerella, V.N.; Pan, J.; et al. On the emergence of 3D printable engineered, strain hardening cementitious composites (ECC/SHCC). Cem. Concr. Res. 2020, 132, 106038.

- Kaze, R.C.; Naghizadeh, A.; Tchadjie, L.; Adesina, A.; Djobo, J.N.Y.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C.; Tayeh, B.A. Lateritic soils based geopolymer materials: A review. Constr. Build. Mater. 2022, 344, 128157.

- Gholampour, A.; Ozbakkaloglu, T.; Ng, C.T. Ambient- and oven-cured geopolymer concretes under active confinement. Constr. Build. Mater. 2019, 228, 116722.

- Phoo-Ngernkham, T.; Maegawa, A.; Mishima, N.; Hatanaka, S.; Chindaprasirt, P. Effects of sodium hydroxide and sodium silicate solutions on compressive and shear bond strengths of FA-GBFS geopolymer. Constr. Build. Mater. 2015, 91, 1–8.

- Aupoil, J.; Champenois, J.B.; de Lacaillerie, J.B.D.; Poulesquen, A. Interplay between silicate and hydroxide ions during geopolymerization. Cem. Concr. Res. 2019, 115, 426–432.

- Vinai, R.; Soutsos, M. Production of sodium silicate powder from waste glass cullet for alkali activation of alternative binders. Cem. Concr. Res. 2019, 116, 45–56.

- Hu, W.; Nie, Q.; Huang, B.; Su, A.; Du, Y.; Shu, X.; He, Q. Mechanical property and microstructure characteristics of geopolymer stabilized aggregate base. Constr. Build. Mater. 2018, 191, 1120–1127.

- Nie, Q.; Hu, W.; Ai, T.; Huang, B.; Shu, X.; He, Q. Strength properties of geopolymers derived from original and desulfurized red mud cured at ambient temperature. Constr. Build. Mater. 2016, 125, 905–911.

- van Deventer, J.S.J.; Provis, J.L.; Duxson, P.; Lukey, G.C. Reaction mechanisms in the geopolymeric conversion of inorganic waste to useful products. J. Hazard Mater. 2007, 139, 506–513.

- Adesanya, E.; Ohenoja, K.; Luukkonen, T.; Kinnunen, P.; Illikainen, M. One-part geopolymer cement from slag and pretreated paper sludge. J. Clean. Prod. 2018, 185, 168–175.

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. Comparison of alkali and silica sources in one-part alkali-activated blast furnace slag mortar. J. Clean. Prod. 2018, 187, 171–179.

- Provis, J.L.; Van Deventer, J.S. Alkali Activated Materials: State-of-the-Art Report; Springer: Dordrecht, The Netherlands, 2013.

- Lazorenko, G.; Kasprzhitskii, A. Geopolymer additive manufacturing: A review. Addit. Manuf. 2022, 55, 102782.

- Nerella, V.; Näther, M.; Iqbal, A.; Butler, M.; Mechtcherine, V. Inline quantification of extrudability of cementitious materials for digital construction. Cem. Concr. Compos 2019, 95, 260–270.

- Kaze, C.R.; Lecomte-Nana, G.L.; Adesina, A.; Nemaleu, J.G.D.; Kamseu, E.; Melo, U.C. Influence of mineralogy and activator type on the rheology behaviour and setting time of laterite based geopolymer paste. Cem. Concr. Compos. 2022, 126, 104345.

- Kaze, C.R.; Alomayri, T.; Hasan, A.; Tome, S.; Lecomte-Nana, G.L.; Nemaleu, J.G.D.; Tchakoute, H.K.; Kamseu, E.; Melo, U.C.; Rahier, H. Reaction kinetics and rheological behaviour of meta-halloysite based geopolymer cured at room temperature: Effect of thermal activation on physicochemical and microstructural properties. Appl. Clay Sci. 2020, 196, 105773.

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190.

- Dong, M.; Elchalakani, M.; Karrech, A. Development of high strength one-part geopolymer mortar using sodium metasilicate. Constr. Build. Mater. 2020, 236, 117611.

- Dey, D.; Srinivas, D.; Panda, B.; Suraneni, P.; Sitharam, T.G. Use of industrial waste materials for 3D printing of sustainable concrete: A review. J. Clean. Prod. 2022, 340, 130749.

- Batikha, M.; Jotangia, R.; Baaj, M.Y.; Mousleh, I. 3D concrete printing for sustainable and economical construction: A comparative study. Autom. Constr. 2022, 134, 104087.

- Mohammad, M.; Masad, E.; Al-Ghamdi, S.G. 3D concrete printing sustainability: A comparative life cycle assessment of four construction method scenarios. Buildings 2020, 10, 245.

- Barcelo, L.; Kline, J.; Walenta, G.; Gartner, E. Cement and carbon emissions. Mater. Struct. Constr. 2014, 47, 1055–1065.

- Pilehvar, S.; Arnhof, M.; Erichsen, A.; Valentini, L.; Anna, K. Investigation of severe lunar environmental conditions on the physical and mechanical properties of lunar regolith geopolymers. J. Mater. Res. Technol. 2021, 11, 1506–1516.

- Li, Z.; Wang, L.; Ma, G.; Sanjayan, J.; Feng, D. Strength and ductility enhancement of 3D printing structure reinforced by embedding continuous micro-cables. Constr. Build. Mater. 2020, 264, 120196.

- Zhong, J.; Zhou, G.-X.; He, P.-G.; Yang, Z.-H.; Jia, D.-C. 3D printing strong and conductive geo-polymer nanocomposite structures modified by graphene oxide. Carbon 2017, 117, 421–426.

- Zhou, G.-X.; Li, C.; Zhao, Z.; Qi, Y.-Z.; Yang, Z.-H.; Jia, D.-C.; Zhong, J.; Zhou, Y. 3D printing geopolymer nanocomposites structure: Graphene oxide size effects on a reactive matrix. Carbon 2020, 164, 215–223.

- Ly, O.; Yoris-Nobile, A.I.; Sebaibi, N.; Blanco-Fernandez, E.; Boutouil, M.; Castro-Fresno, D.; Hall, A.E.; Herbert, R.J.H.; Deboucha, W.; Reis, B.; et al. Optimisation of 3D printed concrete for artificial reefs: Biofouling and mechanical analysis. Constr. Build. Mater. 2021, 272, 121649.

- Provis, J.L.; Lukey, G.C.; Van Deventer, J.S.J. Do geopolymers actually contain nanocrystalline zeolites? A reexamination of existing results. Chem. Mater. 2005, 17, 3075–3085.

- Dedenis, M.; Sonebi, M.; Amziane, S.; Perrot, A.; Amato, G. Effect of Metakaolin, Fly Ash and Polypropylene Fibres on Fresh and Rheological Properties of 3D Printing Based Cement Materials; RILEM Bookseries; Springer: Cham, Switzerland, 2020.

More

Information

Subjects:

Materials Science, Ceramics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

700

Revisions:

2 times

(View History)

Update Date:

25 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No