| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sabyasachi Parida | -- | 4309 | 2023-12-20 05:00:03 | | | |

| 2 | Lindsay Dong | Meta information modification | 4309 | 2023-12-20 08:49:14 | | |

Video Upload Options

Piezoelectric polymers are a class of material that belong to carbon–hydrogen-based organic materials with a long polymer chain. They fill the void where single crystals and ceramics fail to perform. This characteristic of piezoelectric polymers made them unique. Their piezoelectric stress constant is higher than ceramics and the piezoelectric strain is lower compared to ceramics.

1. Introduction

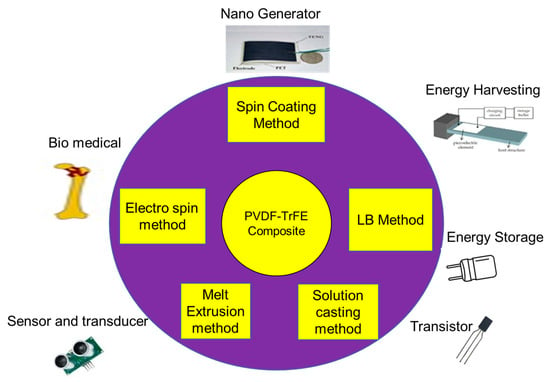

2. Synthesis Methods of P(VDF-TrFE) Composite and Their Applications

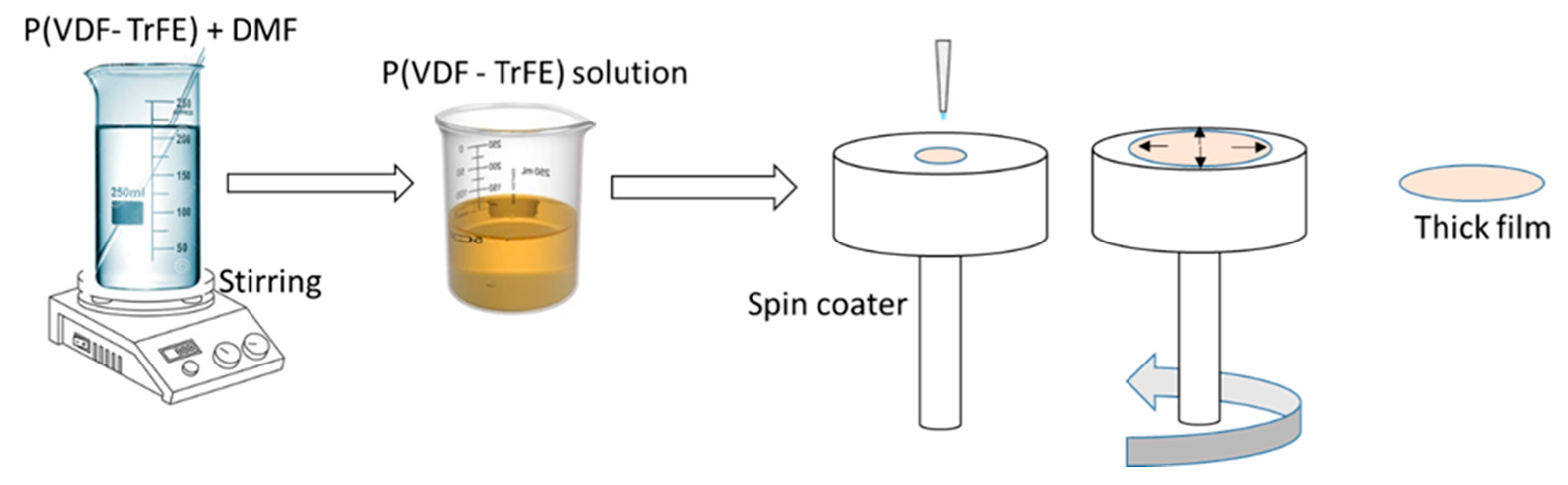

2.1. Composite Prepared from Spin-Coating Method

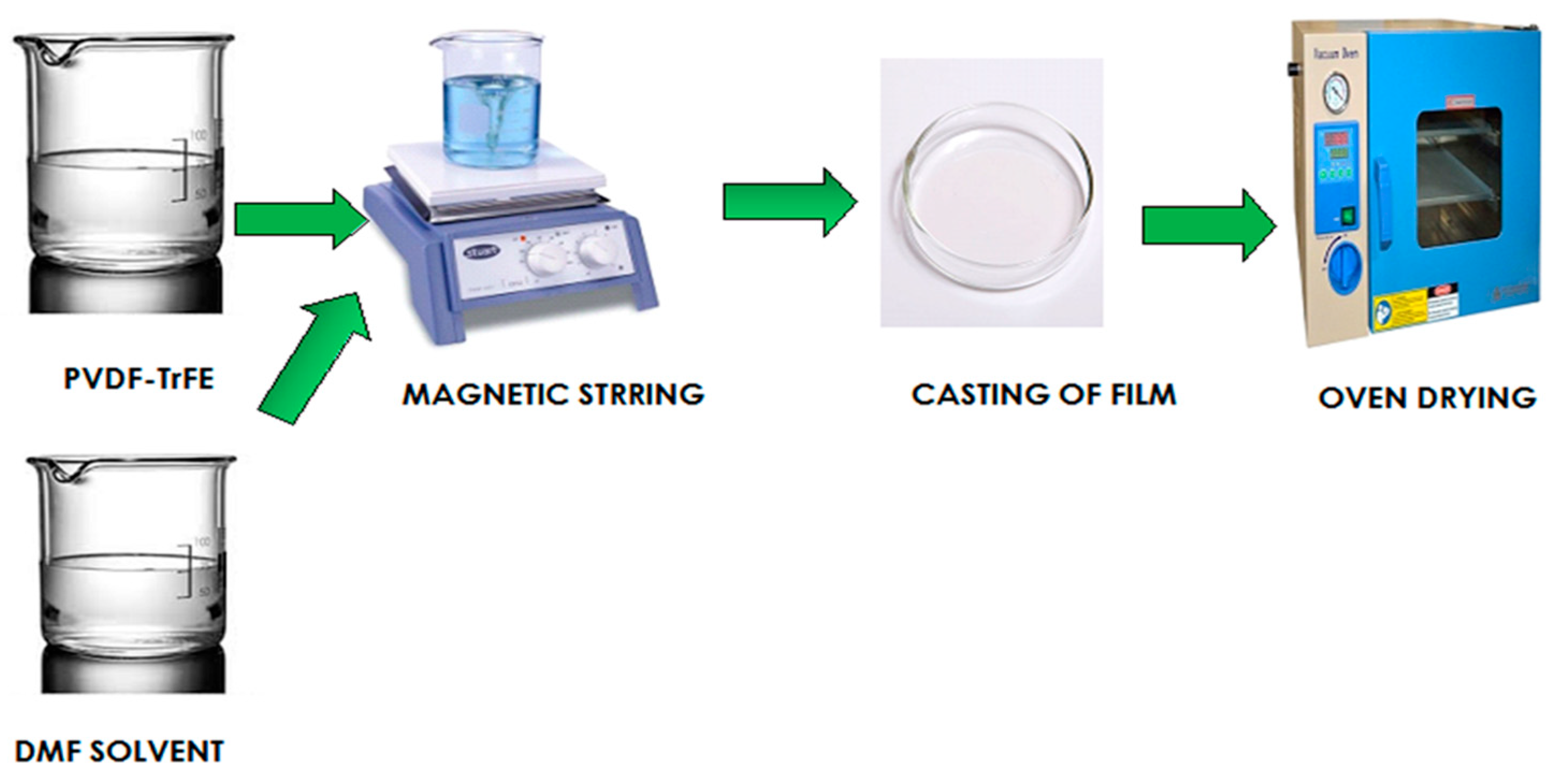

2.2. Composite Prepared from Solution Casting Method

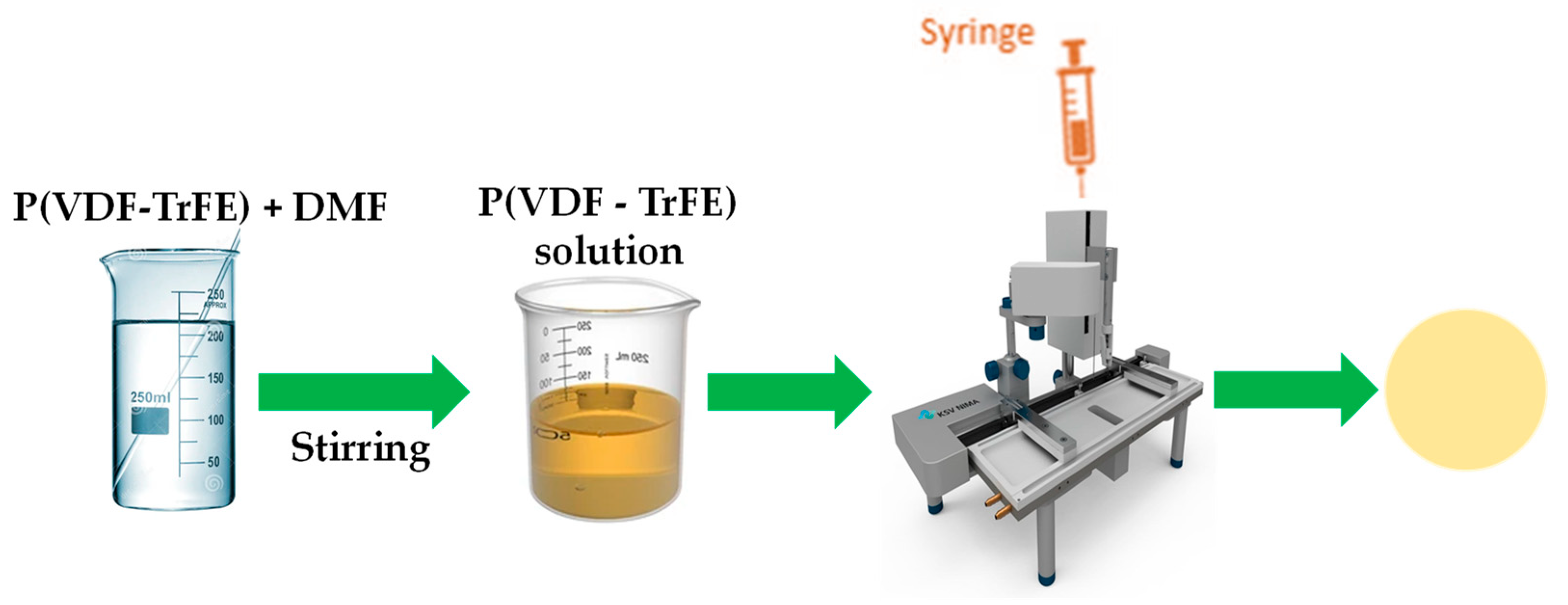

2.3. Composite Prepared from Langmuir–Blodgett Method

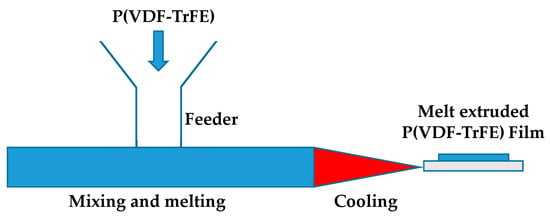

2.4. Composite Prepared from Melt Extrusion Method

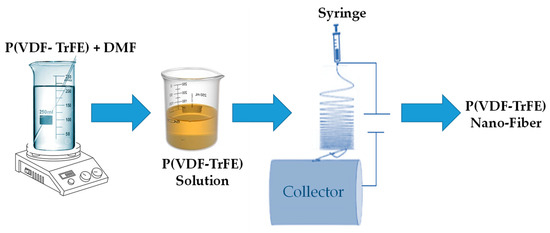

2.5. Composite Prepared from Electrospinning Method

3. Application of Piezoelectric P(VDF-TRFE) Composite

3.1. Energy Harvesting and Nanogenerators

3.2. Sensor Application

3.3. Biomedical Application

3.4. Transducer and Resonator

4. Conclusions

P(VDF-TrFE)-based polymer composites are widely used in sensors, generators, transducers, and biomedical applications. Studies have widely investigated the energy harvesting applications of the polymer composite with increases in piezoelectricity, output current, and voltage achieved with the addition of fillers. High flexibility and power density are the two main highlights of piezoelectric vibrational harvesters. A change in relatively low pressure can be detected by piezoelectric sensors, as their sensitivity is determined mostly by their piezoelectricity and permittivity. They are most frequently used in tissue engineering applications.

References

- Habib, M.; Lantgios, I. A review of ceramic, polymer and composite piezoelectric Materials. J. Phys. D Appl. Phys. 2022, 55, 423002.

- Santucci, S.; Esposito, V. Electrostrictive Ceramic and their application. In Encyclopedia of Materials: Technical Ceramics and Glasses; Pomeroy, M., Ed.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 3, pp. 369–374.

- Lipsa, L.; Rajput, S.; Parida, S.; Ghosh, S.P.; Verma, S.K.; Gupta, S. Influence of Hot-press Temperature on β-phase Formation and Electrical Properties of Solvent Casted PVDF-HFP Co-Polymer Films Prepared from Two Different Solvents: A Comparison Study. Macromol. Chem. Phys. 2023, 224, 2300204.

- Abbasipour, M.; Khajavi, R. A comprehensive review on piezoelectric polymeric and ceramic nano generators. Adv. Eng. Mater. 2022, 24, 2101312.

- Muduli, S.P.; Parida, S.; Behura, S.K.; Rajput, S.; Rout, S.K.; Sareen, S. Synergistic effect of graphene on dielectric and piezoelectric characteristic of PVDF-(BZT-BCT) composite for energy harvesting applications. Polym. Adv. Tech. 2022, 33, 3628–3642.

- Eltouby, P.; Shyha, I.; Li, C.; Khaliq, J. Factors affecting the piezoelectric performance of ceramic-polymer composites: A comprehensive Review. Ceram. Int. 2021, 47, 17813–17825.

- Rajput, S.; Parida, S.; Sharma, A.; Sonika. Dielectric Materials for Energy Storage and Energy Harvesting Devices; River Publishers: Aalborg, Denmark, 2023; Available online: https://ieeexplore.ieee.org/book/10177830 (accessed on 1 October 2023).

- Mammeri, F. Chapter 3—Nanostructured flexible PVDF and fluropolymer—Based hybrid films. In Frontiers of Nanoscience; Benelmekki, M., Erbe, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2021; Volume 14, pp. 67–101.

- Spin Coating Overview. Available online: www.costeffectiveequipment.com/servicesupport/technical-resourses/spincoating-theory (accessed on 4 January 2023).

- Xia, K.; Li, Y.C.; Li, J.; Xie, B.; Zhao, C. Research on the effect of spin coating process on ferroelectric phase of P(VDF-TrFE)/ZnO film. In Proceedings of the IEEE Symposium on Piezoelectricity, Acoustic Waves and Applications, Xi’an, China, 27–30 October 2017; IEEE: Piscataway, NJ, USA, 2017.

- Dahan, R.; Arshad, A.N.; Razif, M.H.M.; Zohdi, N.S.N. Structural and electrical properties of PVDF-TrFE/ZnO bilayer and filled PVDF-TrFE/ZnO single layer nanocomposite films. Adv. Mater. Process. Technol. 2017, 3, 300–307.

- Lau, K.; Liu, Y.; Chen, H.; Withers, R.L. Effect of annealing temperature on the morphology and piezoresponse characterization of poly(vinylidene fluoride-trifluoroethylene) films via scanning probe Microscopy. Adv. Condens. Matter. Phys. 2013, 2013, 435938.

- Rozana, M.D.; Wahid, M.H.; Arshad, A.N.; Sarip, M.N.; Habibah, Z.; Ismail, L.N.; Ruso, M. Effect of various annealing temperature on the morphological and dielectric properties of Polyvinylidenefluoride-Trifluoroethylene thin film. In Proceedings of the Symposium on Humanities Science and Engineering, Kuala Lumpur, Malaysia, 24–27 June 2012; IEEE: Piscataway, NJ, USA, 2012.

- Men, T.; Liu, X.; Jiang, B.; Long, X.; Guo, H. Ferroelectric β crystalline phase formation and property enhancement in Polydopamine modified BaTiO3/PVDF-TrFE nanocomposite. Thin Solid Film. 2019, 669, 579–587.

- Chen, S.; Yao, K.; Tay, F.E.H.; Chew, L.L.S. Comparative investigation of the structure and properties of ferroelectric poly (vinylidene fluoride) and poly (vinylidene fluoride–trifluoroethylene) thin films crystallized on substrates. J. Appl. Polym. Sci. 2010, 116, 3331–3337.

- Perez, J.; Vilarinho, P.M.; Kholkin, A.L. High-quality PbZr0.52Ti0.48O3 films prepared by modified sol-gel route at low temperature. Thin Solid Films 2004, 449, 20–24.

- Losego, M.D.; Ihlefeld, J.F.; Maria, J.P. Importance of solution chemistry in preparing sol-gel. Chem. Mater. 2008, 20, 303–307.

- Das, R.; Pattanayak, A.J.; Swain, S.K. Polymer-Based Nanocomposites for Energy and Environmental Application; Woodhead Publishing: Swaston, UK, 2018.

- Galiano, F. Casting Solution. In Encyclopedia of Membranes; Drioli, E., Giorno, L., Eds.; Mannheim Media: New York, NY, USA, 2020.

- Swain, S.K.; Pattanayak, A.J.; Sahoo, A.D. Functional Biopolymers; Thakur, V.K., Thakur, M.K., Eds.; Springer: Berlin/Heidelberg, Germany, 2017.

- Koner, S.; Deshmukh, P.; Khan, A.A.; Ahlawat, A.; Karnal, A.K.; Satapathy, S. Multiferroic properties of La0.7Ba0.3MnO3/P(VDF-TrFE) (0-3) nano-composite films. Mater Lett. 2020, 261, 127161.

- Zhang, L.; Shan, X.; Wu, P.; Cheng, Z.-Y. Dielectric characteristics of CaCu3Ti4O12/P(VDF-TrFE) nanocomposites. Appl. Phys. A 2012, 107, 597–602.

- Shafee, E.E.; Behery, S.M. Preparation, characterization and properties of novel 0–3 ferroelectric composites of Ba0.95Ca0.05Ti0.8Zr0.2O3–poly(vinylidene fluoride-trifluoroethylene. Mater. Chem. Phys. 2012, 132, 740–746.

- Sheng, Y.; Zhang, X.; Ye, H.; Liang, L.; Xu, L.; Wu, H. Improved energy density in core–shell poly(dopamine) coated barium titanate/poly(fluorovinylidene-co-trifluoroethylene) nanocomposite with interfacial polarization. Colloids Surf. B 2020, 585, 124091.

- Poulsen, M.; Sorokin, A.V.; Adenwalla, S.; Ducharme, S.; Fridkin, V.M. Effects of an external electric field on the ferroelectric-paraelectric phase transition in polyvinylidene fluoride-trifluoroethylene copolymer Langmuir-Blodgett films. J. Appl. Phys. 2008, 103, 034116.

- Bystrov, V.S.; Bdikin, I.K.; Kiselev, D.A.; Yudin, S.; Fridkin, V.M.; Kholkin, A.L. Nanoscale polarization patterning of ferroelectric Langmuir-Blodgett P(VDF-TrFE) films. J. Phys. D Appl. Phys. 2007, 40, 4571.

- Petty, M.; Tsibouklis, J.; Davis, F.; Hodge, P.; Petty, M.C.; Feast, W.J. Pyroelectric Langmuir-Blodgett films prepared using preformed polymers. J. Phys. D Appl. Phys. 1992, 25, 1032.

- Newnham, R.E. Properties of Materials. In Anisotropy, Symmetry, Structure; University Press: Oxford, NY, USA, 2004.

- Lindemann, W.R.; Philiph, R.L.; Chan, D.W.W.; Ayers, C.T.; Perez, E.M.; Beckman, C.P.; Strzalka, J.; Chaudhary, S.; Vaknin, D. Oriented Polyvinylidene Fluoride-Trifluoroethylene films by Langmuir-Blodgett deposition:A synchrotron X ray diffraction study. Phys. Chem. Chem. Phys. 2015, 17, 29335–29339.

- Breitenbach, J. Melt Extrusion: From process to drug delivery technology. Eur. J. Pharm. Biopharm. 2002, 54, 107–117.

- Nelson, K.D. Absorbable, drug-loaded, extruded fiber for implantation. In Biomedical Textiles for Orthopedic and Surgical Applications; Woodhead Publishing: Sawston, UK, 2005; pp. 119–143.

- Meng, N.; Zhu, X.; Mao, R.; Reece, M.J.; Bilotti, E. Nanoscale Interfacial Electroactivity in PVDF/PVDF-TrFE Blended Films with Enhanced Dielectric and Ferroelectric. J. Mater. Chem. C 2017, 13, 3296–3305.

- Meng, N.; Ren, X. Multiscale understanding of electric polarization in PVDF based ferroelectric Polymers. J. Mater. Chem. C 2020, 46, 16436–16442.

- Beringar, L.T.; Xu, X.; Shih, W.; Shih, W.; Habas, R.; Schauer, C. An electrospun PVDF-TrFE fiber sensor platform for biological applications. Sens. Actuators A 2015, 222, 293–300.

- Kim, Y.; Wu, X.; Lee, C.; Oh, J.H. Characterization of PI/PVDF-TrFE composite nanofiber based Triboelectric nanogenerators depending on the type of the electrospinning system. ASC Appl. Mater. Interfaces 2021, 13, 31.

- Pourbafrani, M.; Azimi, S.; Nia, N.Y.; Zendehdel, M.; Abolhasani, M.M. The effect of electrospinning parameters on piezoelectric PVDF-TrFE nanofibers:Experimental and simulation study. Energies 2023, 16, 37.

- Jiang, Y.G.; Sun, X.J.; Zhang, D.Y. Highly allignedP(VDF-TrFE) nano fibers with anisotropic piezoelectricity fabricated by electrospinning for physical sensing device. In Proceedings of the IEEE International Conference on Solid State Sensors, Actuators and Micro Systems, Anchorage, AK, USA, 21–25 June 2015; IEEE: Piscataway, NJ, USA, 2015.

- Ico, G.; Showalter, A.; Bosze, W.; Gott, S.C.; Kim, B.S.; Rao, M.P.; Myung, N.V.; Nam, J. Size dependent piezoelectric and mechanical properties of electrospun P(VDF-TrFE) nanofibers for enhanced energy harvesting. J. Mater. Chem. A 2016, 4, 2293–2304.

- Kibria, F.; Rahman, W. Electrospinning based high sensitive PVDF-TrFE nanofiber sensor with sensitivity dependence on pore diameter. Curr. Sci. 2020, 119, 5.

- Kang, H.B.; Han, C.S.; Pyun, J.C.; Ryu, W.H.; Kang, C.Y.; Cho, Y.S. (Na, K)NbO3 nanoparticle-embedded piezoelectric nanofiber composites for flexible nanogenerators. Compos. Sci. Technol. 2015, 111, 1–8.

- Liu, K.; Choi, H.J.; Kim, B.K.; Kim, D.B.; Han, C.S.; Kim, S.W.; Kang, H.B.; Park, J.W.; Chao, Y.S. Piezoelectric energy harvesting and charging performance of Pb(Zn1/3Nb2/3)O3–Pb(Zr0.5Ti0.5)O3 nanoparticle-embedded P(VDF-TrFE) nanofiber composite sheets. Compos. Sci. Technol. 2018, 168, 296–302.

- Wang, X.; Yang, B.; Liu, J.; Zhu, Y.; Yang, C.; He, Q. A flexible triboelectric piezoelectric hybrid nanogenerator based on PVDF-TrFE nanofibers and PDMS/MWCNT for wearable device. Sci. Rep. 2006, 6, 36409.

- Turdakyn, N.; Bekezhankyzy, Z.; Araby, S.; Montazami, R.; Bakenov, Z.; Kalimuldina, G. Investigation of electrospun piezoelectric P(VDF-TrFE) nanofiber-based nanogenerators for energy harvesting. Energy Rep. 2023, 10, 628–636.

- Serairi, L.; Gu, L.; Qin, Y.; Lu, Y.; Basset, P.; Wang, Y.L. Flexible piezoelectric nanogenerators based on PVDF-TrFE nanofibers. Eur. Phys. J. Appl. Phys. 2017, 80, 30901.

- Zhang, Q.Q.; Chan, H.L.W.; Ploss, B.; Choy, C.L. PCLT/P(VDF-TrFE) nanocomposite pyroelectric sensors. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 2001, 48, 154–160.

- Pecora, A.; Maiolo, L.; Maita, F.; Minotti, A. Flexible PVDF-TrFE pyroelectric sensor driven by polysilicon thin film transistor fabricated on ultra-thin polyimide substrate. Sens. Actuators Rep. 2012, 185, 39–43.

- Nazir, N.A.; Kim, N.; Iglesias, W.G.; Jakli, A.; Kyu, T. Conductive behavior in relation to domain morphology and phase diagram of Nafion/poly (vinylidene-co-trifluoroethylene) blends. Polymer 2012, 53, 196–204.

- Simoes, R.D.; Rodriguez-Perez, M.A.; De Saja, J.A.; Constantino, C.J.L. Tailoring, the structural properties of PVDF and P(VDF-TrFE) by using natural polymers as additives. Poly. Eng. Sci. 2009, 49, 2150–2157.

- Li, Y.; Liao, C.; Tjnog, S.C. Electrospun polyvinylidene fluoride based fibrous scaffolds with piezoelectric characteristics for bone and neural tissue engineering. Nanaomaterials 2019, 9, 952.

- Ohigashi, H.; Koyama, H.K.; Takahashi, S.; Ishizaki, A.; Maida, Y. Piezoelectric Properties of P(VDF-TrFE) Thin Films at Low Temperatures and Their Application to Ultrasonic Transducers for Scanning Acoustic Microscopy Operating in a Wide Temperature Range. Jpn. J. Appl. Phys. 1989, 28, 28–66.

- Ducrot, P.H.; Dufour, I.; Ayela, C. Optimization of PVDF-TrFE Processing Conditions for The Fabrication of Organic MEMS Resonators. Sci. Rep. 2016, 6, 19426.