Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sarabjeet Singh Sidhu | -- | 3446 | 2023-12-18 11:32:29 | | | |

| 2 | Peter Tang | + 1 word(s) | 3447 | 2023-12-19 03:26:19 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kamenskikh, A.A.; Muratov, K.R.; Shlykov, E.S.; Sidhu, S.S.; Mahajan, A.; Kuznetsova, Y.S.; Ablyaz, T.R. Electrical Discharge Machining for Surface Engineering of Biomaterials. Encyclopedia. Available online: https://encyclopedia.pub/entry/52870 (accessed on 07 February 2026).

Kamenskikh AA, Muratov KR, Shlykov ES, Sidhu SS, Mahajan A, Kuznetsova YS, et al. Electrical Discharge Machining for Surface Engineering of Biomaterials. Encyclopedia. Available at: https://encyclopedia.pub/entry/52870. Accessed February 07, 2026.

Kamenskikh, Anna A., Karim R. Muratov, Evgeny S. Shlykov, Sarabjeet Singh Sidhu, Amit Mahajan, Yulia S. Kuznetsova, Timur R. Ablyaz. "Electrical Discharge Machining for Surface Engineering of Biomaterials" Encyclopedia, https://encyclopedia.pub/entry/52870 (accessed February 07, 2026).

Kamenskikh, A.A., Muratov, K.R., Shlykov, E.S., Sidhu, S.S., Mahajan, A., Kuznetsova, Y.S., & Ablyaz, T.R. (2023, December 18). Electrical Discharge Machining for Surface Engineering of Biomaterials. In Encyclopedia. https://encyclopedia.pub/entry/52870

Kamenskikh, Anna A., et al. "Electrical Discharge Machining for Surface Engineering of Biomaterials." Encyclopedia. Web. 18 December, 2023.

Copy Citation

Electrical discharge machining (EDM) is a highly precise technology that not only facilitates the machining of components into desired shapes but also enables the alteration of the physical and chemical properties of workpieces. The complexity of the process is due to a number of regulating factors such as the material of the workpiece and tools, dielectric medium, and other process parameters. Based on the material type, electrode shape, and process configuration, various shapes and degrees of accuracy can be generated.

EDM

workpiece

electrode tool (ET)

dielectric

technology

1. Introduction

At the outset of his scientific career in the 1760s, the English chemist Joseph Priestley embarked on a journey both in England and America supported by fellow scientists John Canton, William Watson, Timothy Lane, and Benjamin Franklin to study the history of the emergence and development of electricity [1]. Their study of existing experimental results and the influence of Benjamin Franklin catalyzed their own innovative and original research [2]. One of the most interesting results of the experiments of J. Priestly was an observation of the metal erosion effect under the action of an electric charge [3][4]. With further research, the scientist abandoned the topic of electricity and became more famous for his scientific research in pneumatic chemistry. However, the effect of material erosion with electric discharge formed the basis of non-traditional technological methods. Electric arc welding, proposed in the 1800s by Vasily Petrov, remained the main method of shaping using electric discharges for quite a long time [5]. As stated in 1938 by L.A. Yutkin, the electrohydraulic effect [6] became the motivation for the development of the method of electro-spark processing of metals, founded by Boris and Natalia Lazarenko [7]. On 3 April 1943, the priority in the discovery of a fundamentally new method of metal processing was confirmed by these USSR authors. In 1946, the electro-erosion method for processing conductive materials was patented in five more countries, namely France, USA, Switzerland, Great Britain, and Sweden [8]. The scientific foundations of electroerosive machining and the main stages of development are reflected in a monograph [7]. However, the technology was widely developed after the introduction of a numerical control (NC) system to increase the accuracy of the process [9]. The studies of electro-erosive piercing were initially aimed at optimization, control, and planning of the process, as well as theoretical description and modeling of thermophysical analysis [10]. In 1989 and 1993, the first attempts were made to mathematically describe the material removal process in terms of the cathode, anode, and plasma [11][12][13]. Even later, the models of Dibitonto et al., based on the electrothermal concept of process description, contend with several modern studies regarding the description of the material removal rate (MRR) ratio [14]. According to B. Lazarenko, the reign of mechanical metal processing is over and electrical forces will take its place as a more highly organized process and the future belongs to a new material processing. Now electrical discharge machining (EDM) can be safely called one of the greatest breakthroughs of the 20th century. There are many studies aimed at reviewing the technological process and the trajectories of its development, classifying the main areas of research on EDM and existing machines, as well as the current state of the problem from various points of view [15][16][17][18][19][20][21][22][23][24]. At the same time, most studies consider new developments from the components of the process such as experimentation, optimization, processing of individual materials, surface morphology, modeling, application in science and technology, micro-electro erosive machining, surface modification, ecology, etc. [25][26][27][28][29][30][31][32].

2. EDM Processing

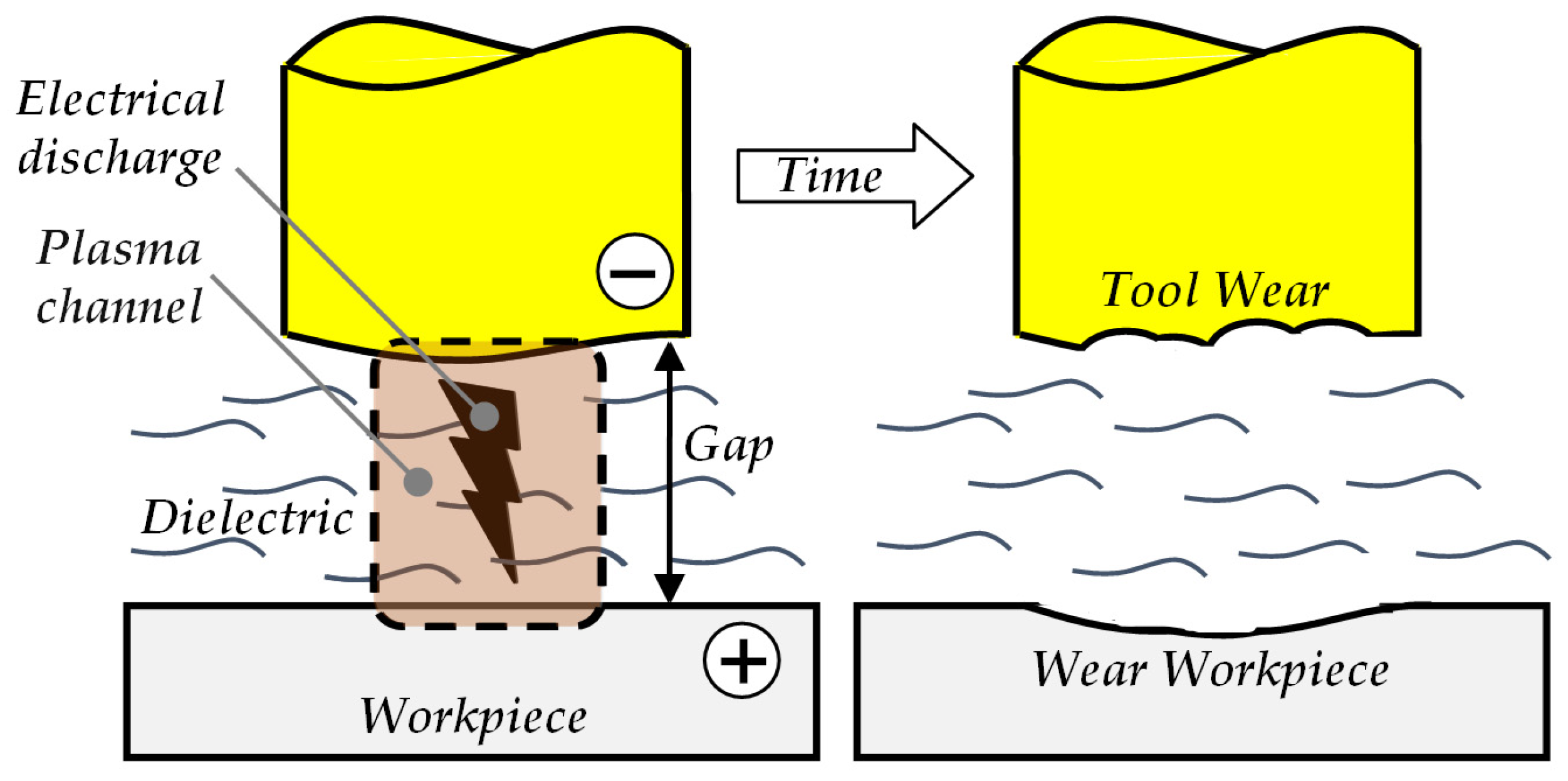

Pulsed electrophysical action involves the application of highly concentrated electrical energy to alter the shape, size, roughness, and surface properties in EDM. Figure 1 illustrates the general schematic of this process.

Figure 1. Schematic represents the basic principle and working of the EDM technology.

Initially, this technology found its application in shaping the surfaces of conductive hard-to-machine materials with complex physical and mechanical properties [7]. Over time, the scope of this technology expanded to include materials with low electrical conductivity, such as ceramics and composites [29][33]. The fundamental principle of this technology relies on non-contact material removal from both the cathode and anode in a dielectric medium, achieved through the creation of a plasma channel generated by a highly concentrated electric discharge within a specific gap [34]. The energy from the discharge transforms into thermal energy, reaching temperatures between 6000 and 12,000 °C. In this superheated state, the material melts and evaporates, and the resulting molten material is washed away by the dielectric liquid, forming craters in a phenomenon known as electrical erosion [35][36].

The final outcome is influenced by various factors, including the operational modes and types of the technological process, the processing mechanism, the experimental setup, the choice of dielectric, the electrode tool (ET), the workpiece material, and the condition of both the cathode and anode surfaces [25]. Depending on machining efficiency and surface layer requirements, the process is categorized into four types: roughing [37], semi-finishing [38], finishing [39], and super-finishing [40]. Roughing, or pre-treatment, prioritizes high productivity but may sacrifice surface quality. Semi-finishing aims for a smooth surface free from defects like peaks and valleys, scratches, and chips. Finishing results in a surface without technological allowances, often with the desired shape, dimensions, and required roughness. Superfinishing is employed to create specific micro-level surface structures or relief patterns. Achieving a particular type of surface treatment is directly tied to productivity and necessitates specialized equipment and expertise.

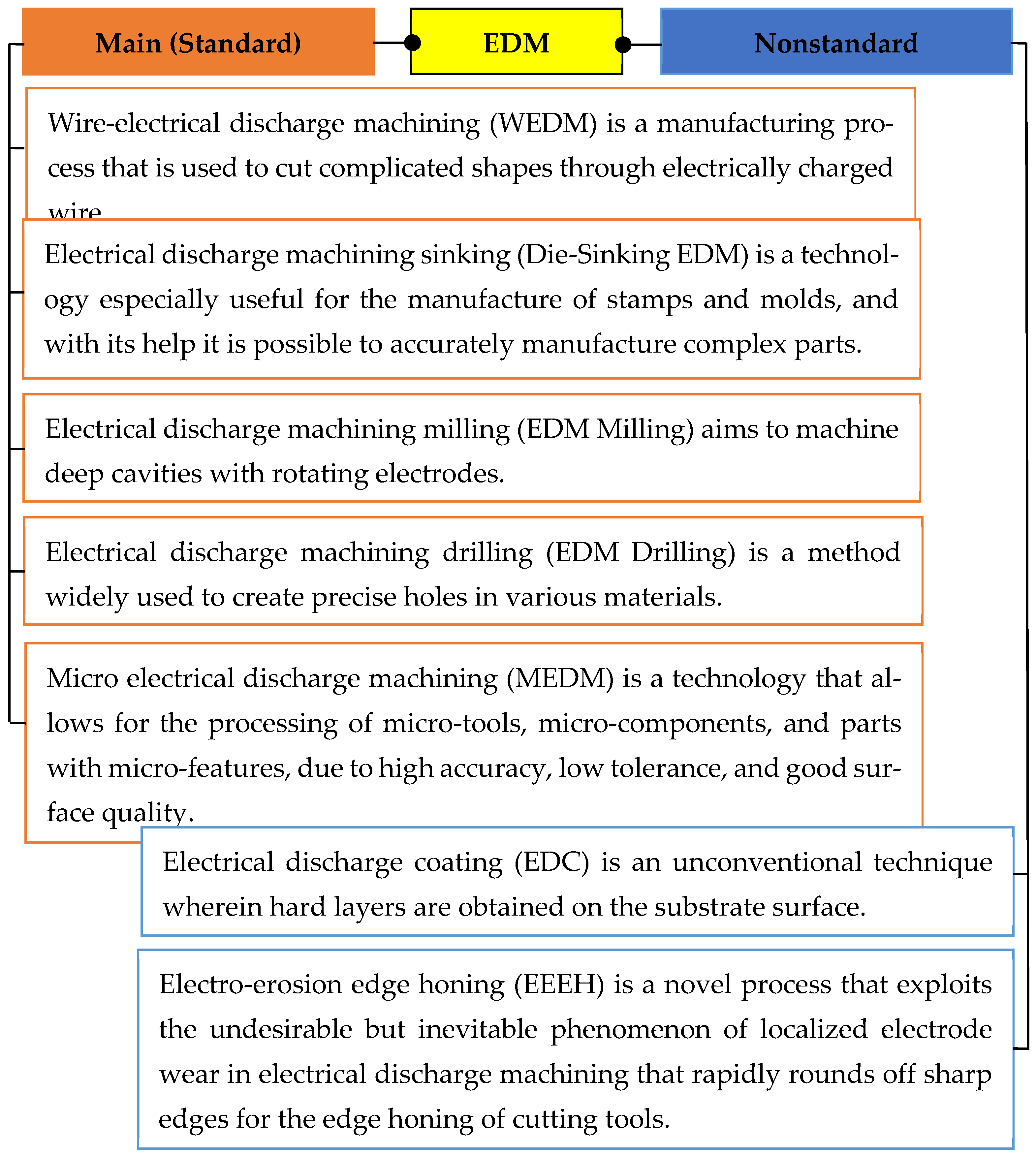

From the very beginning, EDM technology has continuously evolved. In the current landscape, EDM is no longer limited to shaping/machining alone. As part of this research, the researchers have identified five primary and two nonstandard areas of practical electro-erosion application (Figure 2).

Figure 2. Classification of the applications of EDM technology (the list is still evolving).

Wire-electrical discharge machining (WEDM) serves a dual purpose, involving both cutting and contouring processes [25][41][42]. In this method, a wire acts as the ET. WEDM is characterized by a complex iterative process that involves an unpredictable cratering mechanism [41]. The processing conditions and the physical, mechanical, and thermomechanical properties of the materials can result in wire breakage and even damage to the material itself [25][42]. Notably, WEDM offers certain advantages, such as effectively providing a constantly renewed tool in the processing zone, and relatively low tool costs [40]. However, due to the heat-affected zone, WEDM finds its primary application in roughing processes, especially in small-batch production [38].

Die-sinking EDM employs electrical erosion piercing technology [7][8][25][31][40]. The concept of material removal through electrical erosion was pioneered by Boris and Natalia Lazarenko [6][7]. In the die-sinking EDM process, the tool electrodes, which come in various geometric configurations ranging from canonical to complex shapes, are used to shape and machine the surface. Electroerosive piercing is a widely adopted technique, particularly for crafting molds, stamps, and other intricate systems [43][44]. In the EDM milling method [25][45][46][47], a tool is rotated and moved along a specific trajectory, somewhat resembling standard milling techniques. However, EDM milling achieves the desired part shape through non-contact electrical erosion [45]. One notable advantage of this process is the standardization of electrodes [46]. The electrode’s profile intricately depends upon various factors such as wear, tool path, gap distance, and material redistribution [47]. There is also an electro erosive analog of the drilling process [25][48][49][50]. EDM drilling is associated with the rotation of the electrode during surface treatment [48]. The main problem of this process is to create deep holes using electro-erosion [49]. In this process [25][49], low productivity of processing is noted, and poor-quality removal of material debris that arose after erosion. Surface quality and machining accuracy are also reduced due to the inaccessibility of gaps for cleaning and debris removal. The main advantage of the technology is obtaining surfaces with better accuracy and quality than with mechanical drilling [25]. Modern research considers modification of EDM drilling technology to improve surface quality and increase the depth of material removal [49][50].

The development of micro and nano systems, driven by technological progress [51][52], has a notable impact on EDM. Specifically, micro electrical discharge machining (MEDM) plays a crucial role in creating microstructures [53][54]. MEDM technology incorporates various processing methods, including wire [55][56], sinking [54][57], drilling [48][53], and milling [47][58].

The active development of electrical erosion technologies is utilized with EDM’s inherent tool wear or erosions. One such technology is electrical discharge coating (EDC), which utilizes tool wear/erosion to create functional coatings [19][26][59][60]. The quality of the coating and the percentage of the desired material depends largely on factors such as tool material and processing conditions (including dielectric flushing, electric arc, and reverse charges) [19][59][60]. Surface modification represents a new dimension of EDM [26], involving the controlled transfer of material from the tool to the workpiece as an evolving area within EDM.

Electro-erosion edge honing (EEEH) is another emerging technology aimed at altering tool geometry [61][62]. It involves rapidly rounding the sharp edges of tool electrodes to achieve the desired geometry and it can also be considered a novel aspect of EDM.

The widespread adoption and advancement of EDM is primarily driven by its diverse applications, ranging from micromachines to biomedicine and spanning various industries such as aviation and shipbuilding [17][23][32][63].

In aviation, EDM is instrumental in creating components like disks, recesses for turbofan engine blades, sealing grooves, and diffusion holes [40][64][65][66]. The automotive industry also benefits from EDM, particularly in the production of fuel injection and cooling nozzles [50]. In microelectronics, EDM is used for creating micro-holes and micro-parts [17][67].

Gears can be cut using WEDM or created from molds made through die-sinking EDM [68][69]. Over recent decades, EDM has become an integral part of industrial production processes. Beyond precision machining, EDM has found extensive applications in biomedicine. In this context, the technology is primarily used to create unique functional surfaces with desired tribological properties [63][70][71]. These materials play a crucial role in modern implantology, with surface morphology contributing to the efficient integration of materials into natural organic structures [72][73].

Despite its prevalence, EDM is a very complex process with a large number of factors and problems that affect the final result [4]. When comparing the processing of titanium alloys, Pramanik et al. [25] noted that the formation of a remelted layer, heat-affected zones, and tool wear are typically associated with EDM process parameters. Most of the studies are dedicated to the factors influencing the process, as well as the physical-mechanical, thermomechanical, electrical, and other effects associated with the process.

2.1. EDM Process Physics

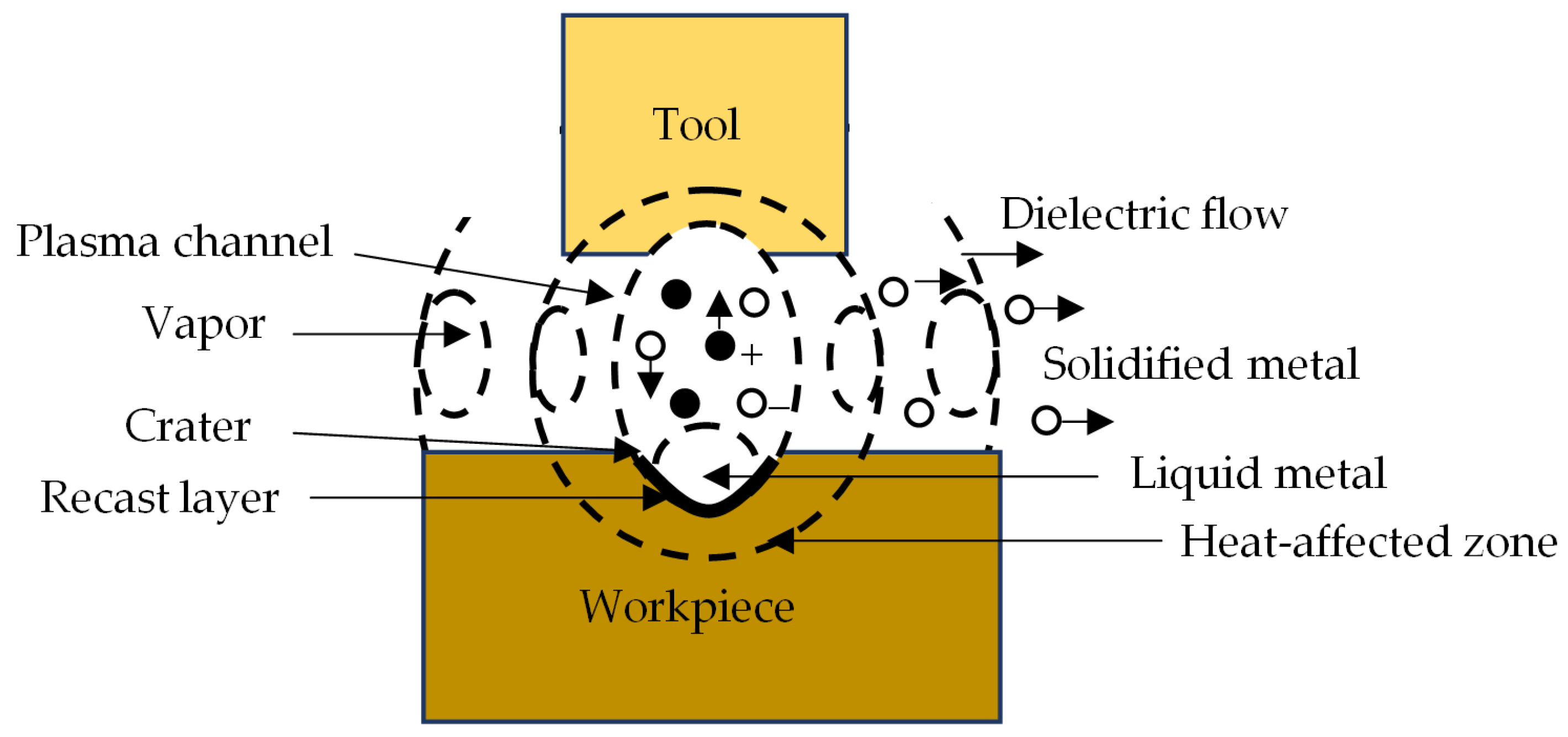

EDM is a thermoelectric process characterized by its complexity and unpredictability, influenced by numerous factors that can vary randomly [4]. Describing the material removal process solely based on empirical observations is impossible (Figure 3). Electro-erosion encompasses various intricate domains within applied mechanics, including thermo-mechanics [74], thermodynamics [75], crystal mechanics [76], mechanics of porous media [21][77], fracture mechanics [21], hardening mechanics [59][60], mechanics of liquids and hydrodynamics [75][78], tribology [63][70], etc. In addition to its connections with the physics and mechanics of materials and systems, EDM has ties to chemistry, electrical engineering, and materials science [4].

Figure 3. Schematic diagram of material removal in EDM.

The EDM process involves a wide range of phenomena, such as phase transitions [79][80][81], melt behavior [82][83][84], oxidation [36][50][85], residual stresses [86][87][88][89][90], energy transfer, absorption and dissipation [91][92][93][94], chemical reactions [75][95], microstructural changes [53][81][96], etc.

The EDM process is generally based on the melting and evaporation of material under the influence of highly concentrated electrical energy, which is converted into thermal energy. When the molten material comes into contact with the dielectric, it either becomes washed away as debris or solidifies, forming a crater. However, the removal processes of both the workpiece and the electrode depend on the specific materials and its work function. Furthermore, external factors like hardening or cryogenic treatment play a significant role [26][60][97][98].

The material removal mechanism can significantly differ from the standard electro-erosion process depending on the electrical resistivity and melting temperature of the material [28]. For instance, materials with high electrical resistance tend to generate additional heat, promoting melting, evaporation, and thermal exfoliation. Thermal spalling may also occur as a removal mechanism, especially in semiconductor materials.

When processing ceramics, aside from the typical removal mechanism, dissociation or spalling associated with material destruction can be observed [99]. The melting point, thermal conductivity, fracture toughness, and other thermomechanical properties of materials and composites can influence the material removal mechanisms in EDM. For example, ceramics, which are less resistant to tensile stresses, often exhibit characteristics like micro-cracking and spalling. In ceramic composites, material removal mechanisms can include oxidation and matrix dissolution [100].

Moreover, the parameters and factors of the technological process can impact not only the final result but also the material removal mechanism. In high-speed WEDM, for instance, anodic dissolution may be observed as a material removal mechanism [101]. In ceramic composites, depending on the strength of the discharge, it is possible to observe the breakage or fracture of reinforcing fibers and brittle fracture of the matrix [102].

3. EDM for Surface Engineering of Biomaterials

Cobalt-chromium, titanium, magnesium, and stainless-steel alloys are examples of metallic materials that are often chosen as candidate materials for a range of biomedical applications, such as orthopedic implants that must withstand loads and cardiovascular medical equipment. Their exceptional biomechanical, corrosion-resistant, and biocompatibility qualities, which qualify them for application in the production of biomedical devices, are the primary causes of this feature. But since these biomaterials are biomedical devices, their surfaces play a critical role in the ongoing interactions between the surface of an implanted metallic substance and the surrounding physiological environment. Therefore, in order to guarantee these metallic material’s dependability and effectiveness as biomedical devices in the body’s physiological environment, further surface treatments are essential and EDM is emerging as a potential candidate for surface alteration. Without altering the metallic material’s bulk characteristics, surface changes on these biomaterials with metallic qualities control the biological response [103][104]. The attenuated surfaces of these biomaterials are known to emit hazardous chemicals including V, Cr, Ni, Co, Al, and Fe, despite their excellent mechanical strength and resilience to wear and corrosion [105]. The solution to these adverse effects can be alleviated with applications of powder mixed EDM.

Electro-discharge treatment (also known as electro-discharge coating or EDC) is among the most recent and efficient route to alter the bio-metallic surface characteristics by mixing the bioactive powder (known as PM-EDM) in dielectric amid other developed processes such as sol-gel, electroplating, laser coating, PVD, CVD. In order to modify the surface using EDT, the fundamental principle is to choose an ideal combination of process parameters that alters the spark energy produced within the electrodes. In Pm-EDM, the most significant control variables influencing the bio-favorable surface were dielectric, pulse duration, and current for the surface treated [106].

Using nano-HAp in the PM-EDM cycle, Prakash et al. [107] examined the properties of the modified surface of the magnesium alloy. According to their research, adding HAp during machining increased the treated surface’s microhardness and corrosion resistance by 1.5 times and 90.85%, respectively. Moreover, the development of intermetallic oxides was shown to enhance the machined surface’s biocompatibility. According to S. Santosh et al. [108], adding graphite powder shortened the breakdown voltage and increased the electrical conductivity of EDM oil, which improved MRR. It was found that ZM21 magnesium alloy increased biocompatibility. The machined surface qualities of 316L stainless steel and the machining capabilities of PM-EDM with additional hydroxyapatite powder (HAp) were examined by Yubraj et al. [109]. In the case of the machined 316L stainless steel with copper electrode, the addition of additive powder, current, and pulse-on time had the greatest effects on surface roughness. The formation of oxides and intermetallic compounds, such as calcium-phosphate-zinc, iron-molybdenum, zincite, calcium carbonate (CaCO3), iron-silicate-carbide, phosphorus (P), and calcium (Ca), confirmed the presence of a biocompatible layer; however, the impact of powder concentration and other related factors were not examined. With a continuous reverse polarity of the copper electrode, Singh et al. [106] examined the impact of the HAp mixed PM-EDM process on the surface characteristics of machined 316L stainless steel. An increase in MRR of 19.01 g/min was seen in this investigation at a current of 28A, a pulse-on time of 120 μs, and a powder quantity of 15 g/L. The most influential factors for surface coating were found to be the current, followed by the pulse-off and pulse-on durations. Using the PM-EDM approach, Singh et al. [110] altered the surface of 316L stainless steel by adding TiO2 powder and tungsten (W) electrode. Due to the creation of carbides, silicides, and intermetallic alloys, the addition of TiO2 particles and subsequent current had a huge impact on improving the treated surface’s microhardness and wear resistance. The wear rate was reduced by 80% at a current of 28A with additional TiO2 particles, exhibiting an ideal hardness of 942.90 HV with an increase of 223% compared to the untreated sample. However, the quantity of added powder was not made clear. The use of a greater discharge current resulted in microcracks even with the inclusion of TiO2 powder to the process. Moreover, XRD analysis was used to assess the existence of bioactive components such as Ca, P, and CaCO3.

Using HAp in the PM-EDM process, Bains et al. [111] assessed the MRR and coarseness of the treated surface of Ti–6Al–4V. It was shown that pulse-on and pulse-off length were relatively less significant determinants for MRR, while both current and the addition of HAp were significant factors. While the addition of nano-HAp to a current of 12 A increased MRR by about two times, the response induced by rising surface hardness owing to carbide and oxide formation was partially mitigated when the current amount was shortened by 6 A. The effect of PM-EDM process parameters on Ti6Al4V alloy machining using suspended silicon powder was investigated by Nipun and Anand [112]. The three strongest arguments in favor of MRR were concentration of Si powder, pulse-on time, and current. With increases in current, pulse-on time, and Si powder concentration, MRR was shown to spike; however, beyond a certain point, MRR decreased as a result of inadequate debris flushing. The impact of carbon nanotube (CNT) powder-mixed EDM on MRR and TWR for Ti-6Al-4V alloy was investigated by Mohammadreza et al. [113]. While prior research has shown that adding CNT to the dielectric liquid may increase the machining time by 66% when it comes to steel alloy machining, this study found that adding CNT to the dielectric liquid reduced both MRR and TWR. The process parameters for machining Ti-based alloys using reverse-polarity graphite electrodes and MWCNT suspended in a dielectric liquid were optimized by Bhui et al. [114]. MRR increased by 37% in this investigation when the WMCNT suspended dielectric was used. A rise in MRR was seen at 4 A current, 60 μs pulse-on time, and MWCNT addition; however, the quantity of CNT powder added was not specified. With an increase in current, TWR rose. In the PM-EDM technique, Devgan and Sidhu [115] examined the treated surface of β-type titanium by adding MWCNT to HAp-mixed dielectric medium. While the surfaces treated with HAp and MWCNT demonstrated twice as much cell survival as the untreated surface, adding MWCNT to the HAp-mixed dielectric was preferable for improving biocompatibility. Using nano-aluminum particles in a dielectric liquid during an EDM cycle, A.M. Abdul-Rani et al. [116] investigated the surface morphology and roughness of the machined titanium alloy. Comparing this investigation to the conventional EDM technique, a little improvement in surface morphology—that is, in terms of cracks and voids—was seen. In comparison to the traditional EDM, the addition of 3 g/L of nano aluminum particles lowered SR by about 38.46%. Higher SR was caused by non-uniform distribution and agglomerated additive particles.

A unique method for changing the titanium alloy’s surface using silicon additions was used in the work by Chander et al. [117]. In this work, a 15 μm thick recast layer consisting of carbides and oxides at 15 A current, 50 μs pulse-on time, and 8 g/L Si powder quantity was formed, resulting in the fabrication of a biocompatible and hard surface of 1080 HV. Furthermore, the treated surface’s wear rate increased by about 29 times and its coefficient of friction decreased by 60% as a result of the TiC, NbC, and SiC production. By combining Si powder in the PM-EDM process, Farooq et al. [118] examined the surface morphology, SR, and RLT of the titanium alloy. By 61.82% and 37.03%, respectively, the Si additive concentration helped to regulate SR and RLT. Applying 5 g/L Si powder reduced the SR by 3–3.5 μm as compared to 0 g/L; however, increasing the quantity of powder from 10 g/L to 20 g/L resulted in an increase in SR above the 5 g/L concentration. Using HAp as a dielectric, Chander and Uddin [119] investigated the surface properties of the modified Ti alloy. At 5 g/L HAp concentration, a modified surface with microcracks, voids, and ridges was detected, but at 10 g/L HAp concentration, the surface was smooth and devoid of fractures. Elevating the concentration of HAp led to a three-fold improvement in microhardness, corrosion resistance, and biocompatibility due to the faster deposition of oxides and carbides on the machined surface.

It is clear that there are still certain problems with the PM-EDM cycle that need to be addressed before bio-implants are produced in large quantities for the industries. More thorough research should be conducted on these areas.

References

- Priestley, J. The History and Present State of Electricity, with Original Experiments; Cambridge University Press: London, UK, 1767.

- Chang, H. Joseph Priestly (1733–1804). Philos. Chem. 2012, 6, 55–62.

- Ho, K.H.; Newman, S.T. State of the art electrical discharge machining (EDM). Int. J. Mach. Tools Manuf. 2003, 43, 1287–1300.

- Jibin, T.P.; Jose, M.; Basil, K. Transition from EDM to PMEDM—Impact of suspended particulates in the dielectric on Ti6Al4V and other distinct material surfaces: A review. J. Manuf. Process. 2021, 64, 1105–1142.

- Kartsev, V.P.V.V. Petrov’s Hypothetical Experiment and Electrical Experiments of the 18th Century. In Nature Mathematized; Shea, W.R., Ed.; The University of Western Ontario Series in Philosophy of Science; Springer: Dordrecht, The Netherlands, 1983; Volume 20.

- Bekaev, A.A.; Sokovikov, V.K.; Strokov, P.I. Electrohydraulic devices based on the Yutkin effect. Russ. Eng. Res. 2014, 34, 620–623.

- Livshits, A.L. Electro-Erosion Machining of Metals; Department of Scientific & Industrial Research, Butterworth & Co.: London, UK, 1960.

- Bibliography Boris Lazarenko. Available online: http://bsclupan.asm.md/src/userfiles/src/bibliografii/boris_lazarenko.pdf (accessed on 25 July 2023).

- Zia, M.K.; Pervaiz, S.; Anwar, S.; Samad, W.A. Reviewing Sustainability Interpretation of Electrical Discharge Machining Process using Triple Bottom Line Approach. Int. J. Precis. Eng. Manuf.-Green Technol. 2019, 6, 931–945.

- Tricarico, C.; Delpretti, R.; Dauw, D.F. Geometrical Simulation of the EDM Die-Sinking Process. CIRP Ann. 1988, 37, 191–196.

- DiBitonto, D.D.; Eubank, P.T.; Patel, M.R.; Barrufet, M.A. Theoretical models of the electrical discharge machining process. I. A simple cathode erosion model. J. Appl. Phys. 1989, 66, 4095–4103.

- Patel, M.R.; Barrufet, M.A.; Eubank, P.T.; DiBitonto, D.D. Theoretical models of the electrical discharge machining process. II. The anode erosion model. J. Appl. Phys. 1989, 66, 4104–4111.

- Eubank, P.T.; Patel, M.R.; Barrufet, M.A.; Bozkurt, B. Theoretical models of the electrical discharge machining process. III. The variable mass, cylindrical plasma model. J. Appl. Phys. 1993, 73, 7900–7909.

- Yeo, S.H.; Kurnia, W.; Tan, P.C. Critical assessment and numerical comparison of electro-thermal models in EDM. J. Mater. Process. Technol. 2008, 203, 241–251.

- Devgan, S.; Mahajan, A.; Singh, G.; Singh, G.; Sidhu, S.S. Surface Integrity of Powder Mixed Electrical Discharge Treated Substrate at High Discharge Energies. In Sustainable Machining Strategies for Better Performance. Lecture Notes in Mechanical Engineering; Srinivasa Pai, P., Krishnaraj, V., Eds.; Springer: Singapore, 2022.

- Sasmit, Y.; Rajesh, V. Multi Criteria Optimization Approaches in Electric Discharge Machining. Mater. Today Proc. 2019, 18, 4243–4252.

- Sidhu, A.S. Surface texturing of non-toxic, biocompatible titanium alloys via electro-discharge. Rep. Mech. Eng. 2021, 2, 51–56.

- Ming, W.; Zhang, S.; Zhang, G.; Du, J.; Ma, J.; He, W.; Cao, C.; Liu, K. Progress in modeling of electrical discharge machining process. Int. J. Heat Mass Transf. 2022, 187, 122563.

- Tyagi, R.; Mandal, A.; Das, A.K.; Tripathi, A.; Prakash, C.; Campilho, R.; Saxena, K.K. Electrical Discharge Coating a Potential Surface Engineering Technique: A State of the Art. Processes 2022, 10, 1971.

- Hasan, M.M.; Saleh, T.; Sophian, A.; Rahman, M.A.; Huang, T.; Ali, M.S.M. Experimental modeling techniques in electrical discharge machining (EDM): A review. Int. J. Adv. Manuf. Technol. 2023, 127, 2125–2150.

- Devgan, S.; Mahajan, A.; Sidhu, S.S. Multi-walled carbon nanotubes in powder mixed electrical discharge machining: An experimental study, state of the art and feasibility prospect. Appl. Phys. A Mater. Sci. Process. 2021, 127, 806.

- Jahan, M.P.; Rahman, M.; Wong, Y.S. A review on the conventional and micro-electrodischarge machining of tungsten carbide. Int. J. Mach. Tools Manuf. 2011, 51, 837–858.

- Nahak, B.; Gupta, A. A review on optimization of machining performances and recent developments in electro discharge machining. Manuf. Rev. 2019, 6, 2.

- Chen, Y.; Hu, S.; Li, A.; Cao, Y.; Zhao, Y.; Ming, W. Parameters Optimization of Electrical Discharge Machining Process Using Swarm Intelligence: A Review. Metals 2023, 13, 839.

- Singh, T.; Sharma, S.; Sidhu, S.S.; Shlykov, E.S.; Ablyaz, T.R. Determination of Nanoindentation Behavior of HAZ on Glass Material Machined via ECSM Process through Simulation Approach. Materials 2022, 15, 5870.

- Mahajan, A.; Devgan, S.; Kalyanasundaram, D. Surface alteration of Cobalt-Chromium and duplex stainless steel alloys for biomedical applications: A concise review. Mater. Manuf. Process. 2023, 38, 260–270.

- Baroi, B.K.; Jagadish; Patowari, P.K. A review on sustainability, health, and safety issues of electrical discharge machining. J. Braz. Soc. Mech. Sci. Eng. 2022, 44, 59.

- Zhu, X.; Li, G.; Mo, J.; Ding, S. Electrical discharge machining of semiconductor materials: A review. J. Mater. Res. Technol. 2023, 25, 4354–4379.

- Grigoriev, S.N.; Hamdy, K.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V. Electrical discharge machining of oxide and nitride ceramics: A review. Mater. Des. 2021, 209, 109965.

- Shabgard, M.; Gholipoor, A.; Baseri, H. A review on recent developments in machining methods based on electrical discharge phenomena. Int. J. Adv. Manuf. Technol. 2016, 87, 2081–2097.

- Choudhary, S.K.; Jadoun, R.S. Current Advanced Research Development of Electric Discharge Machining (EDM): A Review. Int. J. Res. Advent Technol. 2014, 2, 273–297.

- Nafi, M.A.; Jahan, M.P. Functional Surface Generation by EDM—A Review. Micromachines 2023, 14, 115.

- Liu, Y.; Qu, J.; Zhao, K.; Zhang, X.; Zhang, S. Study of the High-Efficiency Ejecting-Explosion EDM of SiCp/Al Composite. Micromachines 2023, 14, 1315.

- Laperrière, L.; Reinhart, G. CIRP Encyclopedia of Production Engineering; Springer: Berlin/Heidelberg, Germany, 2014.

- Schumacher, B.M. After 60 years of EDM the discharge process remains still disputed. J. Mater. Process. Technol. 2004, 149, 376–381.

- Sidhu, S.S.; Singh, H.; Gepreel, M.A.H. A review on alloy design, biological response, and strengthening of β-titanium alloys as biomaterials. Mater. Sci. Eng. C 2021, 121, 111661.

- Oniszczuk-Świercz, D.; Świercz, R.; Kopytowski, A.; Nowicki, R. Experimental Investigation and Optimization of Rough EDM of High-Thermal-Conductivity Tool Steel with a Thin-Walled Electrode. Materials 2023, 16, 302.

- Burek, J.; Babiarz, R.; Płodzień, M.; Buk, J. The influence of electrode infeed in finishing wire electrical discharge machining process on disks fir tree slot accuracy. Mechanik 2018, 10, 915–917.

- Le, V.T. The machined performance and recast layer properties of AISI H13 steel processed by powder mixed EDM process: An investigation and comparison in fine-finishing and semi-finishing processes. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 514.

- Mahajan, A.; Devgan, S.; Kalyanasundaram, D. Electrical discharge machining—A futuristic technique for surface engineering of biomedical alloys: A concise review. Surf. Topogr. Metrol. Prop. 2022, 10, 043001.

- Borges, P.; Hensen, M.; Marra, L.; Kuffa, M.; Wegener, K. Wire-EDM geometrical simulation based on superposition of single craters. Procedia CIRP 2023, 117, 243–248.

- Grigoriev, S.N.; Volosova, M.A.; Okunkova, A.A.; Fedorov, S.V.; Hamdy, K.; Podrabinnik, P.A.; Pivkin, P.M.; Kozochkin, M.P.; Porvatov, A.N. Electrical Discharge Machining of Oxide Nanocomposite: Nanomodification of Surface and Subsurface Layers. J. Manuf. Mater. Process. 2020, 4, 96.

- Rajeswari, R.; Shunmugam, M.S. Investigations into process mechanics of rough and finish die sinking EDM using pulse train analysis. Int. J. Adv. Manuf. Technol. 2019, 100, 1945–1964.

- Kunieda, M.; Lauwers, B.; Rajurkar, K.P.; Schumacher, B.M. Advancing EDM through Fundamental Insight into the Process. CIRP Ann. 2005, 54, 64–87.

- Singh, G.; Mahajan, A.; Devgan, S.; Sidhu, S.S. Comparison of Copper and Tungsten Electrodes for the Electric Discharge Machined SUS-316L. In Sustainable Machining Strategies for Better Performance. Lecture Notes in Mechanical Engineering; Srinivasa Pai, P., Krishnaraj, V., Eds.; Springer: Singapore, 2022.

- Sidhu, S.S.; Batish, A.; Kumar, S. Fabrication and electrical discharge machining of metal–matrix composites: A review. J. Reinf. Plast. Compos. 2013, 32, 1310–1320.

- Richard, J.; Giandomenico, N. Electrode Profile Prediction and Wear Compensation in EDM-milling and Micro-EDM-Milling. Procedia CIRP 2018, 68, 819–824.

- Hou, S.; Bai, J. Electrode wear prediction and offline compensation for micro-EDM drilling through-hole array using geometry simulation. Int. J. Adv. Manuf. Technol. 2022, 120, 6877–6889.

- Jamkamon, K.; Janmanee, P. Improving Machining Performance for Deep Hole Drilling in the Electrical Discharge Machining Process Using a Step Cylindrical Electrode. Appl. Sci. 2021, 11, 2084.

- Uhlmann, E.; Polte, J.; Streckenbach, J.; Dinh, N.C.; Yabroudi, S.; Polte, M.; Börnstein, J. High-Performance Electro-Discharge Drilling with a Novel Type of Oxidized Tool Electrode. J. Manuf. Mater. Process. 2022, 6, 113.

- Ghanbarzadeh-Dagheyan, A.; Jalili, N.; Ahmadian, M.T. A holistic survey on mechatronic Systems in Micro/Nano scale with challenges and applications. J. Micro-Bio Robot. 2021, 17, 1–22.

- Ji, Y.; Yang, W.; Wang, Y.; Li, Z. Overview of Foreign Inertial Technology Development. Lect. Notes Electr. Eng. 2022, 861, 975–983.

- Fassi, I.; Modica, F. Editorial for the Special Issue on Micro-Electro Discharge Machining: Principles, Recent Advancements and Applications. Micromachines 2021, 12, 554.

- Singh, T.; Dvivedi, A.; Sidhu, S.S.; Shlykov, E.S.; Muratov, K.R.; Ablyaz, T.R. Energy Channelization Analysis of Rough Tools Developed by RM-MT-EDM Process during ECSM of Glass Substrates. Materials 2022, 15, 5598.

- Yukui, W.; Chen, X.; Gan, W.; Wang, Z.; Guo, C. Complex Rotary Structures Machined by Micro-WEDM. Procedia CIRP 2016, 42, 743–747.

- Chen, Z.; Zhou, H.; Yan, Z.; Han, F.; Yan, H. Machining characteristics of 65 vol.% SiCp/Al composite in micro-WEDM. Ceram. Int. 2021, 47, 13533–13543.

- Jahan, M.P.; Wong, Y.S.; Rahman, M. A study on the fine-finish die-sinking micro-EDM of tungsten carbide using different electrode materials. J. Mater. Process. Technol. 2009, 209, 3956–3967.

- Zhang, L.; Du, J.; Zhuang, X.; Wang, Z.; Pei, J. Geometric prediction of conic tool in micro-EDM milling with fix-length compensation using simulation. Int. J. Mach. Tools Manuf. 2015, 89, 86–94.

- Maddu, J.; Karrolla, B.; Shaik, R.U. Experimental optimization of electrical discharge coatings using conventional electrode. Mater. Sci. Eng. B 2022, 286, 116069.

- Maddu, J.; Karrolla, B.; Shaik, R.U.; Elahi, H.; Arkanti, K. Evaluation of Bronze Electrode in Electrical Discharge Coating Process for Copper Coating. Micromachines 2023, 14, 136.

- Yussefian, N.Z.; Koshy, P.; Buchholz, S.; Klocke, F. Electro-erosion edge honing of cutting tools. CIRP Ann. 2010, 59, 215–218.

- Yussefian, N.Z.; Koshy, P. Geometric simulation of electro-erosion edge honing: Insights into process mechanisms. Precis. Eng. 2017, 48, 1–8.

- Jibin, T.P.; Deepak, K.; Jose, M.; Basil, K. Experimental Investigations on the Tribological Performance of Electric Discharge Alloyed Ti-6Al-4V at 200–600 °C. J. Tribol. 2020, 142, 1–24.

- Zhao, W.; Kang, X.; GU, L.; Xi, X.; Zhang, Y.; Hu, J.; Zhao, F. Application of electrical discharge machining technology in aerospace manufacturing. Acta Aeronaut. Astronaut. Sin. 2022, 43, 525936. Available online: https://hkxb.buaa.edu.cn/CN/10.7527/S1000-6893.2021.25936 (accessed on 10 October 2023).

- Petersen, T.; Zeis, M.; Bergs, T. Tolerance-Based Optimization of Sinking EDM for Industrial Seal Slot Manufacture. In Proceedings of the ASME Turbo Expo 2021: Turbomachinery Technical Conference and Exposition, New York, NY, USA, 7–11 June 2021.

- Wang, J.; Gao, Q.; Xi, X.-C.; Zhao, W.-S. Experimental study of EDM milling of 3D-shaped diffuser for film cooling holes on turbine blades. Procedia CIRP 2022, 113, 160–165.

- Natarajan, U.; Suganthi, X.H.; Periyanan, P.R. Modeling and Multiresponse Optimization of Quality Characteristics for the Micro-EDM Drilling Process. Trans. Indian Inst. Met. 2016, 69, 1675–1686.

- Chaubey, S.K.; Gupta, K. Sustainable Manufacturing of Asymmetric Miniature-Sized Ratchet Wheels by Wire Electrical Discharge Machining. Machines 2022, 10, 506.

- Wu, B.; Zhu, L.; Zhou, Z.; Guo, C.; Cheng, T.; Wu, X. An Efficient Method to Fabricate the Mold Cavity for a Helical Cylindrical Pinion. Processes 2023, 11, 2033.

- Farooq, M.U.; Anwar, S.; Bhatti, H.A.; Kumar, M.S.; Ali, M.A.; Ammarullah, M.I. Electric Discharge Machining of Ti6Al4V ELI in Biomedical Industry: Parametric Analysis of Surface Functionalization and Tribological Characterization. Materials 2023, 16, 4458.

- Mahajan, A.; Devgan, S.; Sidhu, S.S. Surface alteration of biomedical alloys by electrical discharge treatment for enhancing the electrochemical corrosion, tribological and biological performances. Surf. Coat. Technol. 2020, 405, 126583.

- Geetha, M.; Singh, A.K.; Asokamani, R.; Gogia, A.K. Ti based biomaterials, the ultimate choice for orthopaedic implants—A review. Prog. Mater. Sci. 2009, 54, 397–425.

- Aliofkhazraei, M. Modern Surface Engineering Treatments; IntechOpen Limited: London, UK, 2013.

- Bhattacharya, S.; Mishra, A.; Singh, T.; Bandyopadhyay, S.; Kumar, S.; Dey, G.K.; Kain, V. Simulation of residual stress using thermomechanical analysis on wire EDM cut surface. Mater. Today Proc. 2019, 19, 462–467.

- Hou, S.; Bai, J.; Liu, H.; Zhou, Z.; Lu, Z. Study on material erosion mechanism of ultrasonic vibration-assisted micro-EDM based on heat-flow coupling analysis. Int. J. Adv. Manuf. Technol. 2023, 125, 465–478.

- Yue, X.; Yang, X. Molecular dynamics simulation of material removal process and mechanism of EDM using a two-temperature model. Appl. Surf. Sci. 2020, 528, 147009.

- Singh, H.; Singh, J.; Sharma, S.; Singh Chohan, J. Parametric Optimization of MRR & TWR of the Al6061/SiC MMCs Processed During Die-Sinking EDM Using Different Electrodes. Mater. Today Proc. 2021, 48, 1001–1008.

- Ablyaz, T.R.; Shlykov, E.S.; Muratov, K.R. Modeling of EDM Process Flushing Mechanism. Materials 2023, 16, 4158.

- Hess, R.; Heidemanns, L.; Herrig, T.; Klink, A.; Bergs, T. Model Based Prediction of the Heat Affected Zone in a Steel Workpiece Induced by an EDM Single Discharge. Procedia CIRP 2023, 117, 263–268.

- Salvati, E.; Korsunsky, A.M. Micro-scale measurement & FEM modelling of residual stresses in AA6082-T6 Al alloy generated by wire EDM cutting. J. Mater. Process. Technol. 2020, 275, 116373.

- Wu, H.; Ma, J.; Meng, Q.; Jahan, M.P.; Alavi, F. Numerical modeling of electrical discharge machining of Ti–6Al–4V. Procedia Manuf. 2018, 26, 359–371.

- Fazli Shahri, H.R.; Mahdavinejad, R.; Ashjaee, M.; Abdullah, A. A comparative investigation on temperature distribution in electric discharge machining process through analytical, numerical and experimental methods. Int. J. Mach. Tools Manuf. 2017, 114, 35–53.

- Yue, X.; Fan, J.; Li, Q.; Yang, X.; Xu, Z.; Chen, Z. Influence of Discharge Gap On Material Removal and Melt Pool Movement in EDM Discharge Process. Int. J. Adv. Manuf. Technol. 2021, 119, 7827–7842.

- Li, Q.; Yang, X. Thermo-hydraulic analysis of melt pool dynamics and material removal on anode in electrical discharge machining. Int. J. Heat Mass Transf. 2023, 203, 123816.

- Rizvi, S.; Agarwal, S.; Singh, A.; Bhardwaj, U.; Shukla, R. Modeling of Black Layer and Tool Wear in EDM of AISI 4340 using Cu-W electrode. Procedia CIRP 2020, 95, 389–392.

- Sidhu, S.S.; Batish, A.; Kumar, S. Analysis of residual stresses in particulate reinforced aluminium matrix composite after EDM. Mater. Sci. Technol. 2015, 31, 1850–1859.

- Philip, J.T.; Mathew, J.; Kuriachen, B. Numerical simulation of the effect of crater morphology for the prediction of surface roughness on electrical discharge textured Ti6Al4V. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 248.

- Sidhu, S.S.; Batish, A.; Kumar, S. Neural network–based modeling to predict residual stresses during electric discharge machining of Al/SiC metal matrix composites. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2013, 227, 1679–1692.

- Rajhi, W.; Alatawi, I.; Subhani, T.; Ayadi, B.; Al-Ghamdi, A.; Khaliq, A. A contribution to numerical prediction of surface damage and residual stresses on die-sinking EDM of Ti6Al4V. J. Manuf. Process. 2021, 68, 1458–1484.

- Rebelo, J.C.; Morao Dias, A.; Kremer, D.; Lebrun, J.L. Influence of EDM pulse energy on the surface integrity of martensitic steels. J. Mater. Process. Technol. 1998, 84, 90–96.

- Shabgard, M.; Ahmadi, R.; Seyedzavvar, M.; Oliaei, S.N.B. Mathematical and numerical modeling of the effect of inputparameters on the flushing efficiency of plasma channel in EDM process. Int. J. Mach. Tools Manuf. 2013, 65, 79–87.

- Singh, H. Experimental study of distribution of energy during EDM process for utilization in thermal models. Int. J. Heat Mass Transf. 2012, 55, 5053–5064.

- Sahoo, R.; Singh, N.K.; Bajpai, V. A novel approach for modeling MRR in EDM process using utilized discharge energy. Mech. Syst. Signal Process. 2023, 185, 109811.

- Gostimirovic, M.; Kovac, P.; Sekulic, M. An inverse optimal control problem in the electrical discharge machining. Sādhanā 2018, 43, 70.

- Yushchishina, A.N.; Kuskova, N.I.; Malyushevskaya, A.P. Study of chemical reactions during electric discharge in water and aqueous solutions of inorganic substances. Surf. Eng. Appl. Electrochem. 2007, 43, 347–349.

- Gopal, R.; Thangadurai, K.R.; Thirunavukkarasu, K. Behavior of ECAP processed copper electrodes in electrical discharge machining of AISI H13 steel. Mater. Today Proc. 2020, 21, 295–298.

- Shastri, R.K.; Mohanty, C.P.; Dash, S.; Gopal, K.M.P.; Annamalai, A.R.; Jen, C.-P. Reviewing Performance Measures of the Die-Sinking Electrical Discharge Machining Process: Challenges and Future Scopes. Nanomaterials 2022, 12, 384.

- Ishfaq, K.; Sana, M.; Mahmood, M.A.; Anwar, S.; Waseem, M.U. Evaluating Surface Quality of Inconel 617 by Employing Deep Cryogenically Treated Electrodes in Surfactant-Added Dielectrics of Transformer Oil. Metals 2023, 13, 1092.

- Patel, K.M.; Pulak, M.; Pandey, P.; Venkateswara, R. Surface integrity and material removal mechanisms associated with the EDM of Al2O3 ceramic composite. Int. J. Refract. Met. Hard Mater. 2009, 27, 892–899.

- Lauwers, B.; Kruth, J.P.; Liu, W.; Eeraerts, W.; Schacht, B.; Bleys, P. Investigation of material removal mechanisms in EDM of composite ceramic materials. J. Mater. Process. Technol. 2004, 149, 347–352.

- Oßwald, K.; Brandl, L.; Lochmahr, I. Experimental investigation into material removal mechanisms in High Speed Wire EDM. Int. J. Adv. Manuf. Technol. 2020, 111, 2163–2170.

- Yue, X.; Li, Q.; Yang, X. Influence of thermal stress on material removal of Cf_SiC composite in EDM. Ceram. Int. 2020, 46, 7998–8009.

- Shen, X.Y.; Xu, H.Q.; Gerdroodbary, M.B.; Valiallah Mousavi, S.; Musa Abazari, A.; Imani, S.M. Numerical simulation of blood flow effects on rupture of aneurysm in middle cerebral artery. Int. J. Mod. Phys. C 2021, 33, 1–18.

- Munir, K.; Biesiekierski, A.; Wen, C.; Li, Y. Surface modifications of metallic biomaterials. Met. Biomater. Process. Med. Device Manuf. 2020, 2020, 387–424.

- Devgan, S.; Sidhu, S.S. Evolution of surface modification trends in bone related biomaterials: A review. Mater. Chem. Phys. 2019, 233, 68–78.

- Al-Amin, M.; Abdul-Rani, A.M.; Danish, M.; Thompson, H.M.; Abdu Aliyu, A.A.; Hastuty, S.; Tuj Zohura1, F.; Bryant, M.G.; Rubaiee, S.; Rao, T.V.V.L.N. Assessment of PM-EDM cycle factors influence on machining responses and surface properties of biomaterials: A comprehensive review. Precis. Eng. 2020, 66, 531–549.

- Santosh, S.; Ibrahim, S.J.S.; Saravanamuthukumar, P.; Rajkumar, K.; Harikrishna, K.L. Nano Graphite Powder Assisted Electric Discharge Machining Characteristics of ZM21 Magnesium Alloy. Appl. Mech. Mater. 2015, 787, 406–410.

- Lamichhane, Y.; Singh, G.; Bhui, A.S.; Mukhiya, P.; Kumar, P.; Thapa, B. Surface modification of 316L SS with HAp nano-particles using PMEDM for enhanced Biocompatibility. Mater. Today Proc. 2019, 15, 336–343.

- Singh, G.; Lamichhane, Y.; Bhui, A.S.; Sidhu, S.S.; Bains, P.S.; Mukhiya, P. Surface morphology and microhardness behavior of 316L in hap-pmedm. Facta Univ. Ser. Mech. Eng. 2019, 17, 445–454.

- Singh, G.; Singh Sidhu, S.; Singh Bains, P.; Singh Bhui, A. Improving microhardness and wear resistance of 316L by TiO2 powder mixed electro-discharge treatment. Mater. Res. Express 2019, 6, 086501.

- Bains, P.S.; Bahraminasab, M.; Sidhu, S.S.; Singh, G. On the machinability and properties of Ti–6Al–4V biomaterial with n-HAp powder–mixed ED machining. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2020, 234, 232–242.

- Gosai, N.D.; Joshi, A.Y. Experimental Investigation and Optimization of Process Parameters Used in the Silicon Powder Mixed Electro Discharge Machining of Ti-6Al-4V Alloy Using Response Surface Methodology. J. Manuf. Sci. Prod. 2016, 16, 21–32.

- Shabgard, M.; Khosrozadeh, B. Investigation of carbon nanotube added dielectric on the surface characteristics and machining performance of Ti–6Al–4V alloy in EDM process. J. Manuf. Process. 2017, 25, 212–219.

- Bhui, A.S.; Bains, P.S.; Sidhu, S.S.; Singh, G. Parametric optimization of ED machining of Ti-6Al-4V in CNTs mixed dielectric medium. Mater. Today Proc. 2019, 18, 1532–1539.

- Devgan, S.; Sidhu, S.S. Surface modification of β-type titanium with multi-walled CNTs/ μ-HAp powder mixed Electro Discharge Treatment process. Mater. Chem. Phys. 2020, 239, 122005.

- Abdul-Rani, A.M.; Nanimina, A.M.; Ginta, T.L.; Razak, M.A. Machined Surface Quality in Nano Aluminum Mixed Electrical Discharge Machining. Procedia Manuf. 2017, 7, 510–517.

- Prakash, C.; Kansal, H.K.; Pabla, B.S.; Puri, S. Potential of Silicon Powder-Mixed Electro Spark Alloying for Surface Modification of β-Phase Titanium Alloy for Orthopedic Applications. Mater. Today Proc. 2017, 4, 10080–10083.

- Farooq, M.U.; Mughal, M.P.; Ahmed, N.; Mufti, N.A.; Al-Ahmari, A.M.; He, Y. On the Investigation of Surface Integrity of Ti6Al4V ELI Using Si-Mixed Electric Discharge Machining. Materials 2020, 13, 1549.

- Prakash, C.; Uddin, M.S. Surface modification of β-phase Ti implant by hydroaxyapatite mixed electric discharge machining to enhance the corrosion resistance and in-vitro bioactivity. Surf. Coat. Technol. 2017, 326, 134–145.

More

Information

Subjects:

Engineering, Manufacturing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

19 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No