Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Wenbo Han | -- | 4766 | 2023-12-18 11:24:10 | | | |

| 2 | Peter Tang | Meta information modification | 4766 | 2023-12-19 03:21:34 | | | | |

| 3 | Peter Tang | Meta information modification | 4766 | 2023-12-20 07:24:00 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Han, W.; Mu, X.; Liu, Y.; Wang, X.; Li, W.; Bai, C.; Zhang, H. Electrical Oil Wear Debris Detection Sensors. Encyclopedia. Available online: https://encyclopedia.pub/entry/52869 (accessed on 07 February 2026).

Han W, Mu X, Liu Y, Wang X, Li W, Bai C, et al. Electrical Oil Wear Debris Detection Sensors. Encyclopedia. Available at: https://encyclopedia.pub/entry/52869. Accessed February 07, 2026.

Han, Wenbo, Xiaotong Mu, Yu Liu, Xin Wang, Wei Li, Chenzhao Bai, Hongpeng Zhang. "Electrical Oil Wear Debris Detection Sensors" Encyclopedia, https://encyclopedia.pub/entry/52869 (accessed February 07, 2026).

Han, W., Mu, X., Liu, Y., Wang, X., Li, W., Bai, C., & Zhang, H. (2023, December 18). Electrical Oil Wear Debris Detection Sensors. In Encyclopedia. https://encyclopedia.pub/entry/52869

Han, Wenbo, et al. "Electrical Oil Wear Debris Detection Sensors." Encyclopedia. Web. 18 December, 2023.

Copy Citation

In the field of marine engineering, the friction and wear experienced by rotating mechanisms are recognized as significant contributors to the failure of marine machinery. In order to enhance the safety and dependability of marine ship operations, the implementation of on-line oil wear debris particle detection sensors enables the on-line monitoring of oil and facilitates the rapid identification of abnormal wear locations.

wear debris particle detection sensor

on-line oil detection

marine engineering

electrical

non-electrical

1. Introduction

The optimal functioning of marine engineering machinery and equipment plays a crucial role in ensuring the safety and efficiency of ships during their operations at sea [1]. In recent years, the rapid advancement and proliferation of smart ship and unmanned ship technology has generated a pressing demand for on-line monitoring and early warning systems to assess the operational condition of marine engineering machinery and equipment [2]. In the field of marine engineering, the occurrence of component wear and failure is a prevalent form of failure. It is of utmost importance to closely monitor the wear condition of marine engineering machinery and equipment [3]. Lubricating oil is commonly recognized as the vital fluid that enables the smooth functioning of mechanical equipment [4][5]. The oil in mechanical equipment serves multiple purposes, including power transmission, lubrication, and cooling. Additionally, the presence of metal particles in the oil provides valuable information regarding the friction and wear of the equipment [6].

Marine engineering machinery and equipment typically consist of ferromagnetic, paramagnetic, and diamagnetic materials [7][8]. The friction and wear process of mechanical equipment is a multifaceted and dynamic phenomenon that can be divided into three distinct stages: the running-in period, the stable wear period, and the severe wear period [9][10]. Different stages of friction and wear result in the generation of metal particles that possess distinct characteristic information, exhibiting variations in size, shape, and concentration [11]. When abnormal wear takes place, it disrupts the equilibrium state of metal particles present in the oil. Consequently, there is an increase in particle concentration, with the particle size typically ranging between 50 and 100 μm [12][13]. When the size of metal particles falls within the range of 150–350 μm, it typically signifies the presence of wear-induced failure [14]. According to the causes of wear failure and wear mechanisms, various types of wear can be identified, including adhesive wear, abrasive wear, fatigue wear, and corrosive wear [15]. Different types of wear result in the generation of distinct forms of metal particles, namely spherical particles, cutting particles, flake particles, fatigue-induced particles, and particles caused by severe sliding [16]. The phenomenon of friction and wear in mechanical equipment is a multifaceted and intricate process of evolution. The size of particles, magnetic characteristics, and concentration of wear debris particles present in the oil can serve as indicators of the friction and wear experienced by marine engineering machinery and equipment [17]. In the context of marine engineering machinery and equipment, the assessment of metal particle size in the oil can provide valuable insights into the friction, wear rate, and overall condition of such machinery and equipment. By effectively distinguishing between ferromagnetic metal particles and non-ferromagnetic metal particles present in oil, it is possible to accurately identify the worn parts of marine engineering machinery and equipment [18].

2. Inductive Sensor

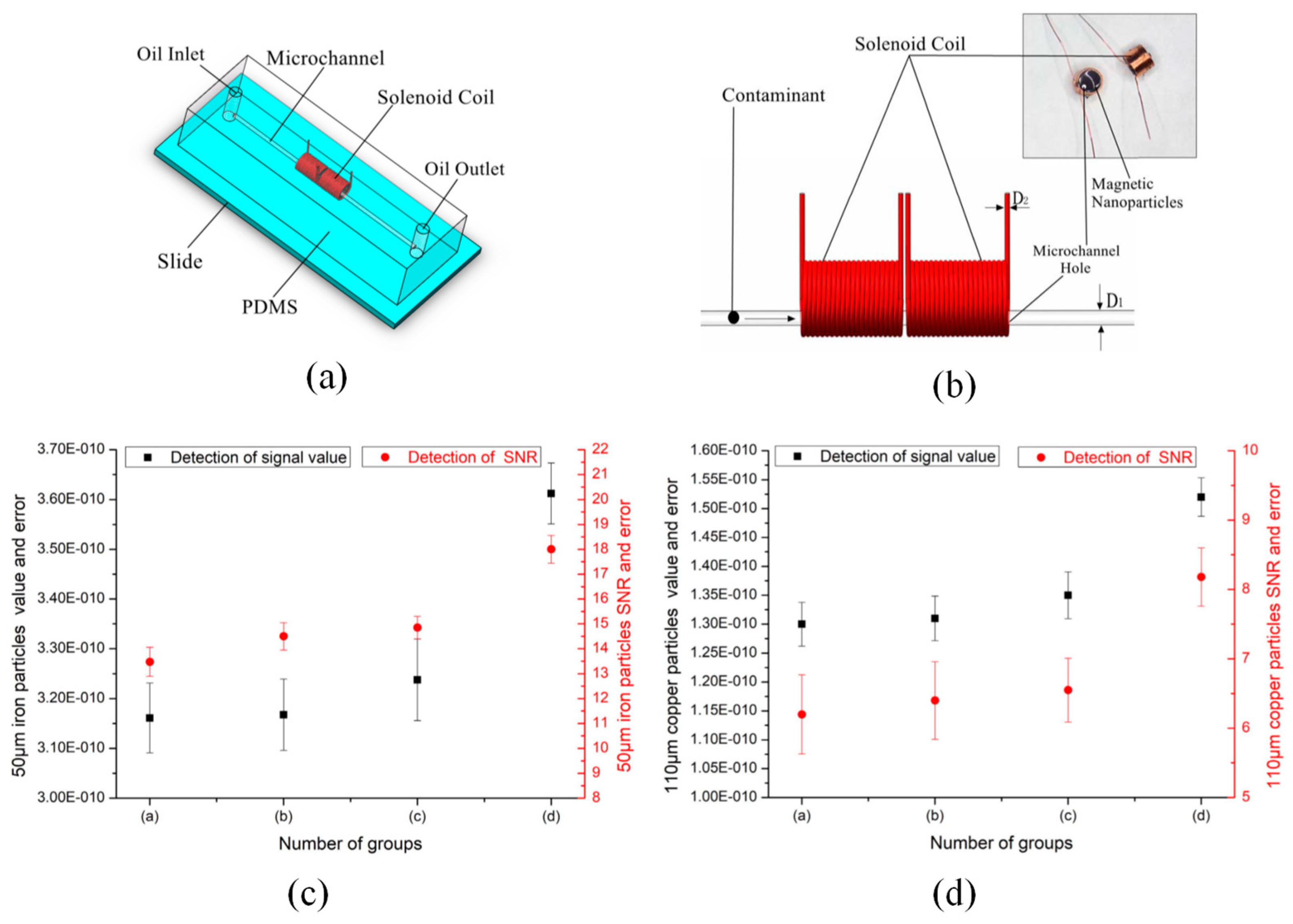

Inductive sensors function based on electromagnetic principles. They detect wear particles in the oil by monitoring alterations in electromagnetic properties as the particles traverse a magnetic field. Inductive sensors demonstrate a high level of efficacy in detecting wear particles that are ferrous in nature, primarily composed of iron. Inductive sensors, however, have a limitation in that they can only detect ferromagnetic materials, and furthermore, these materials must possess good conductivity. In 2018, Sanga et al. introduced a novel microcontroller-based inductive quasi-digital sensor that gained recognition for its cost-effectiveness, low power consumption, and remarkable precision in detecting metallic wear particles present in lubricants utilized in rotating machinery [19]. These sensors enabled continuous on-line monitoring of lubricating oils and featured an LCD display that would trigger an automatic alarm when metal particles exceeding 50 μm were detected, indicating a potentially dangerous machine state. Experimental studies have demonstrated the sensor’s efficacy in accurately detecting and monitoring iron particles as small as 30 μm, as well as non-ferrous metal particles with a diameter of 70 μm. In 2012, Du et al. successfully implemented an inductive wear particle detection sensor with seven parallel microchannels, enabling efficient high-throughput on-line monitoring of lubricant oil. This achievement was made possible by leveraging the Coulter counting principle [20]. The sensor design implemented in their study involved the integration of two layers of planar coils and microchannels. Experimental investigations highlight the impressive capability of the sensor to effectively process two milliliters of lubricating oil per minute, while simultaneously ensuring minimal interference between the seven microchannels. In contrast to single-channel systems, the utilization of a multi-channel monitoring approach has been shown to be an exceptionally effective strategy for achieving high-throughput detection. In 2017, Zhu et al. introduced a portable inductive wear debris sensor with a ferrite core as part of the ongoing efforts in the field of on-line machine health monitoring [21]. The sensor described possesses the ability to detect iron particles with diameters of 11 µm and 50 µm. This is achieved through the measurement of inductance using two planar coils that are wound around a pair of ferrite cores. The design of their sensors enables the attainment of a magnetic flux that is characterized by higher density, greater uniformity, and enhanced sensitivity in comparison to previous models. The results of the study revealed the successful achievement of high-throughput on-line monitoring, with a sampling rate of 750 milliliters per minute, using the simultaneous sampling technique. It has been demonstrated to be particularly well-suited for the on-line monitoring of wear particles of smaller sizes. Zhu et al. developed a 3 × 3 time-division multiplexed inductive sensor specifically designed for efficient high-throughput particle monitoring in 2017 [22]. The sensor employed in this study effectively addresses crosstalk issues by employing a hybrid approach that combines time division multiplexing and series diodes. This approach enables the attainment of sequential responses within each channel. The study findings emphasize the sensor’s ability to accurately monitor wear particles as small as 50 µm. The utilization of the simultaneous sampling approach in the study led to a substantial decrease in the time required for data processing. This novel design concept has the potential to be extended in order to establish an N × N sensor array mode, which would enable efficient monitoring of lubricant wear particles with high throughput. In 2020, Bai et al. developed a novel dual solenoid inductive sensor for the detection of magnetic nanoparticles. This sensor demonstrated enhanced detection accuracy in comparison to conventional single solenoid sensors, as depicted in Figure 1 [23]. Through the utilization of theoretical analysis and scanning electron microscopy, the researchers were able to identify the optimal concentration of nanoparticles and subsequently confirm that the sensitivity of this sensor in detecting magnetic nanoparticles was significantly enhanced, exhibiting a notable increase of 19–24%. Hong et al. introduced a novel hybrid detection strategy that employs a generic calibration framework based on artificial neural networks in 2020 [24]. This approach effectively reduces detection errors under different mixing conditions in inductive abrasive particle sensors. The findings of their study showcased the efficacy of the proposed scheme, as it achieved results with an error rate of less than 20% across a range of abrasive particle concentrations, from 5 mg/L to 100 mg/L. One limitation of this approach is the requirement for network redesign and retraining when implementing it with different inductive sensors or under varying operational conditions. Xiao et al. conducted a research study on an inductive sensor that was specifically designed for the purpose of detecting metal abrasive particles in large-diameter pipes in 2019 [25]. Experimental results demonstrated that the output signal obtained from the sensor in the lubricating oil circuit, which relied on a high-gradient magnetic field, displayed a linear relationship with the driving current. The sensor, however, had a limited capability in detecting debris that had a z-axis height smaller than the diameter of the pipes. Notably, the effectiveness of detection was impacted when the axial separation between two abrasive particles fell below 25 mm, leading to aliasing in the induced voltage signals of the two particles. Ren et al. developed an inductive abrasive particle sensor that incorporates multiple induction coils strategically placed around an excitation coil in 2018 [26]. Diverging from conventional sensor configurations, this particular design utilizes the simultaneous operation of multiple coils to effectively facilitate the coupling of the excitation magnetic field with the sensing end. This approach serves to increase the output voltage and improve sensitivity. Empirical evidence substantiates the sensor’s ability to precisely quantify iron particles with a diameter of 120 μm and non-ferrous metal particles measuring 210 μm in diameter. The novel methodology for sensor design effectively reduces the monitoring limit for inductive abrasive sensors.

Figure 1. Inductive wear particle detection sensor based on PDMS [23]. (a) Structural design of inductive sensor. (b) Schematic diagram of wear particles passing through the sensor. (c) The detection results of iron particles with a diameter of 50 μm in the inductive detection sensor. (d) The detection results of copper particles with a diameter of 100 μm in the inductance detection sensor.

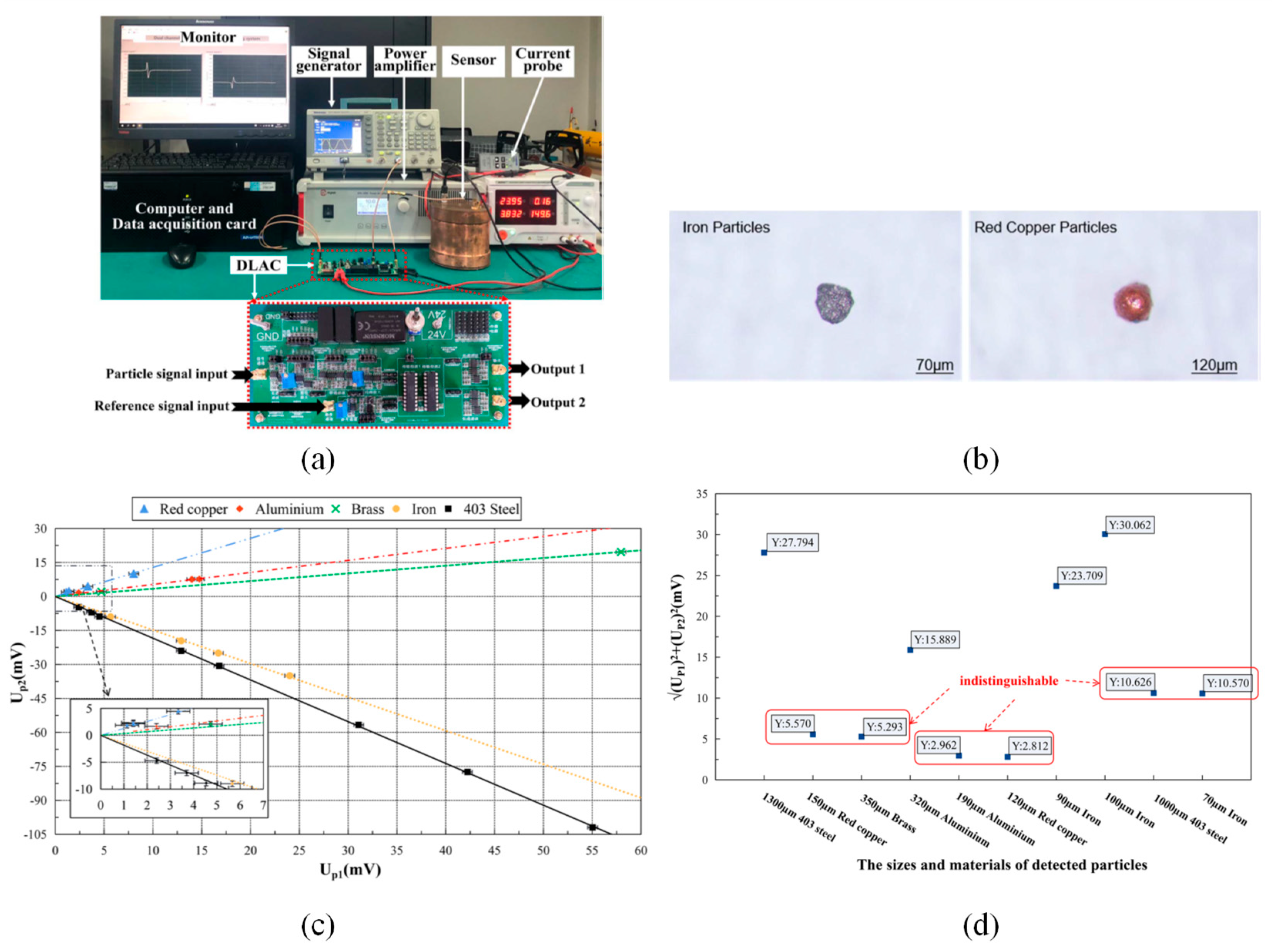

In 2020, Zeng et al. introduced a highly sophisticated micro-impedance sensor that incorporates two solenoid coils and eight silicon steel needles. This sensor is designed for the purpose of monitoring the condition of oil [27]. The inclusion of silicon steel needles serves to enhance the concentration of the magnetic field in the sensor, thereby leading to an enhancement in the intensity of magnetic induction. Research findings indicate that the sensor has the ability to accurately detect iron particles with a diameter of 18 μm and copper particles measuring 75 μm when operating in the inductive mode. Notably, the micro-impedance sensor presented in this study features a simple design and does not necessitate the use of intricate external circuits. When utilized for high-throughput wear particle detection, the sensor is susceptible to producing aliasing signals as wear particles traverse it. This has the potential to affect the evaluation of wear particle concentration and size. In 2021, Muthuvel et al. initiated the development of an innovative inductive sensor that employs a passive wireless LC sensing method. This sensor is specifically designed for monitoring wear particles in high-pressure hydraulic circuits [28]. The external coil of the sensor is energized by an alternating current (AC) signal that operates at the balanced resonant frequency of the system. As a result of wear particles passing through it, the sensor experiences a phase shift in its response. By conducting an analysis of the fluctuating direction of the output phase, this sensor demonstrates the capability to accurately differentiate between ferrous and non-ferrous metals that are present within the oil. The findings of their study demonstrated that the sensor possesses the ability to detect metal particles with a size exceeding 25 μm, while maintaining a flow rate of 40 L/min. In 2020, Wang et al. conducted a study to gain insights into the phenomenon of signal aliasing [29]. The investigation focused on examining the effects of various factors, including wear particle motion state, motion speed, spatial position, and others, on the waveform of aliasing signals within inductive sensors. A direct relationship has been discovered between the voltage induced by aliasing and the velocity of wear particles. Furthermore, the peak-to-peak voltage of the aliasing signal is also found to be proportional to the radius of the wear particles. In 2020, Li et al. conducted a comprehensive investigation on a novel inductive wear particle monitoring sensor. The sensor showcased a distinctive design, characterized by a three-coil inverted dual-excitation solenoid [30]. Using the Time Harmonic Electromagnetic Field Analysis (THEFA) method, the researchers performed finite element numerical simulations to investigate the impedance and coil characteristics of the sensor. They then conducted experimental tests to validate their theoretical findings. Their research findings revealed that the sensitivity of the sensor could be greatly improved by employing a meticulous design strategy that takes into account various factors such as the height, thickness, distance, and turn density of both the excitation and induction coils. To achieve accurate voltage output signals, a pass-band filter amplifier circuit was developed with the objective of eliminating harmonics in the output voltage signal. This approach enables high-resolution and high-sensitivity measurements of wear particles. In 2019, Feng et al. conducted a thorough investigation on an inductive wear particle sensor that utilizes a high-gradient magnetic field [31]. They have developed a mathematical model to investigate the theoretical relationship between the induced voltage and the size of wear particles that are produced when they traverse through the high-gradient magnetic field of the sensor. The experimental findings have substantiated the sensor’s efficacy in detecting ferromagnetic wear particles with a minimum diameter of 25 μm. Qian et al. conducted groundbreaking research in 2021, being the first to theoretically investigate and provide empirical evidence that the residual voltage, arising from the asymmetry of two excitation coils, is a crucial factor that constrains the potential improvement in resolution of inductive debris sensors [32]. To attain automated suppression of residual voltage, the researchers developed a three-coil inductive abrasive particle sensor that incorporates a two-stage self-asymmetric compensation circuit. Experimental results demonstrated that the sensitivity of the sensor surpassed that of a sensor lacking this compensation by a factor of more than 31. This enabled successful detection of iron abrasive particles with a diameter of 70 µm and non-ferrous abrasive particles measuring 165 µm in diameter. This experiment highlighted the notable benefits of employing the automatic asymmetric compensation circuit (AACC), specifically in attaining exceptionally high levels of resolution and sensitivity in the sensor. Wu et al. introduced a novel inductive wear particle detection sensor that incorporates dual excitation and dual induction coils in 2021 [33]. Through rigorous experimental validation, the researchers have conclusively demonstrated that the sensor exhibits exceptional sensitivity, enabling it to accurately detect ferrous metal particles measuring 115 µm and non-ferrous metal particles measuring 313 µm in size. Additionally, the study conducted by the researchers aimed to investigate the influence of variables such as excitation frequency and radial distribution of the magnetic field on the sensitivity of the inductive sensor. In their pursuit of improving the accuracy of wear level monitoring in ferromagnetic rigid friction pairs, Feng et al. developed an innovative inductive sensor that is specifically tailored for monitoring ferromagnetic particles. This sensor utilizes a high-gradient static magnetic field in 2021 [34]. The sensor configuration consists of two cylindrical magnetic rings and a magnetic housing. By employing a mathematical model and employing finite element analysis, the researchers were able to acquire the magnetic field distribution and output voltage waveform of the sensor. The numerical simulation results provided clarification on the influence of induction coil length, coil position, and particle radial position on the output voltage. Ultimately, the research findings demonstrated the sensor’s efficacy in detecting ferromagnetic particles, even at high flow rates, with a minimum diameter of 13 µm. Park et al. developed an inductive metal particle detection sensor through the utilization of an aerosol-hydrosol adoption method in 2021 [35]. The aforementioned sensor is capable of converting measurement signals into the concentration of ferrous metal particles, thereby exhibiting its capacity to differentiate between ferrous and non-ferrous metals. Research findings suggest that the sensor demonstrates a high level of effectiveness in detecting iron particles within the size range of 5 to 10 µm, as well as copper particles sized between 50 and 60 µm. Comparatively, the sensor demonstrates a commendable level of consistency when compared to high-precision commercial measuring instruments. This characteristic renders it suitable for the detection of small-size metal particles. However, its effectiveness diminishes when it comes to detecting larger-size metal particles. Wu et al. presented a novel methodology for quantifying the dimensions of non-ferrous metal particles by utilizing the impedance signal generated by an inductive sensor coil in 2021 [36]. In contrast to traditional investigations on inductive sensors, their approach solely concentrated on analyzing the imaginary component of the coil impedance signal output. Theoretical analysis has demonstrated that the coil impedance encompasses both real and imaginary components, which can be described by an elliptic function in the presence of coupled signals originating from various materials. Through conducting measurement experiments on aluminum and copper particles, the researchers were able to demonstrate that the sensor’s measurement results showed an error rate of less than 12.8% when compared to the results obtained through optical microscope measurement. In scenarios where the accurate identification of material and size of multiple mixed metal wear particles is challenging using conventional inductive mixers, Li et al. proposed a solution in 2022, as depicted in Figure 2 [37]. A triple-coil inductive sensor, integrated with a double lock-in amplifier circuit (DLAC), was utilized to detect complex-domain signals emitted by metal particles, even in the presence of noise interference. The experiments conducted on the detection of five different metal particles using complex-domain signal detection showed that the inductive sensor based on DLAC demonstrated exceptional precision, resolution, noise immunity, and minimal zero drift. These findings effectively address the identified issues.

Figure 2. Inductive wear particle detection sensor based on dual lock-in amplifier circuit [37]. (a) Experimental system components for particle detection. (b) Microscopic images of iron particles with a diameter of 70 μm and copper particles with a diameter of 120 μm. (c) Complex plane distribution plot of particles of different sizes and materials. (d) The detection results obtained by real domain detection.

3. Capacitive Sensor

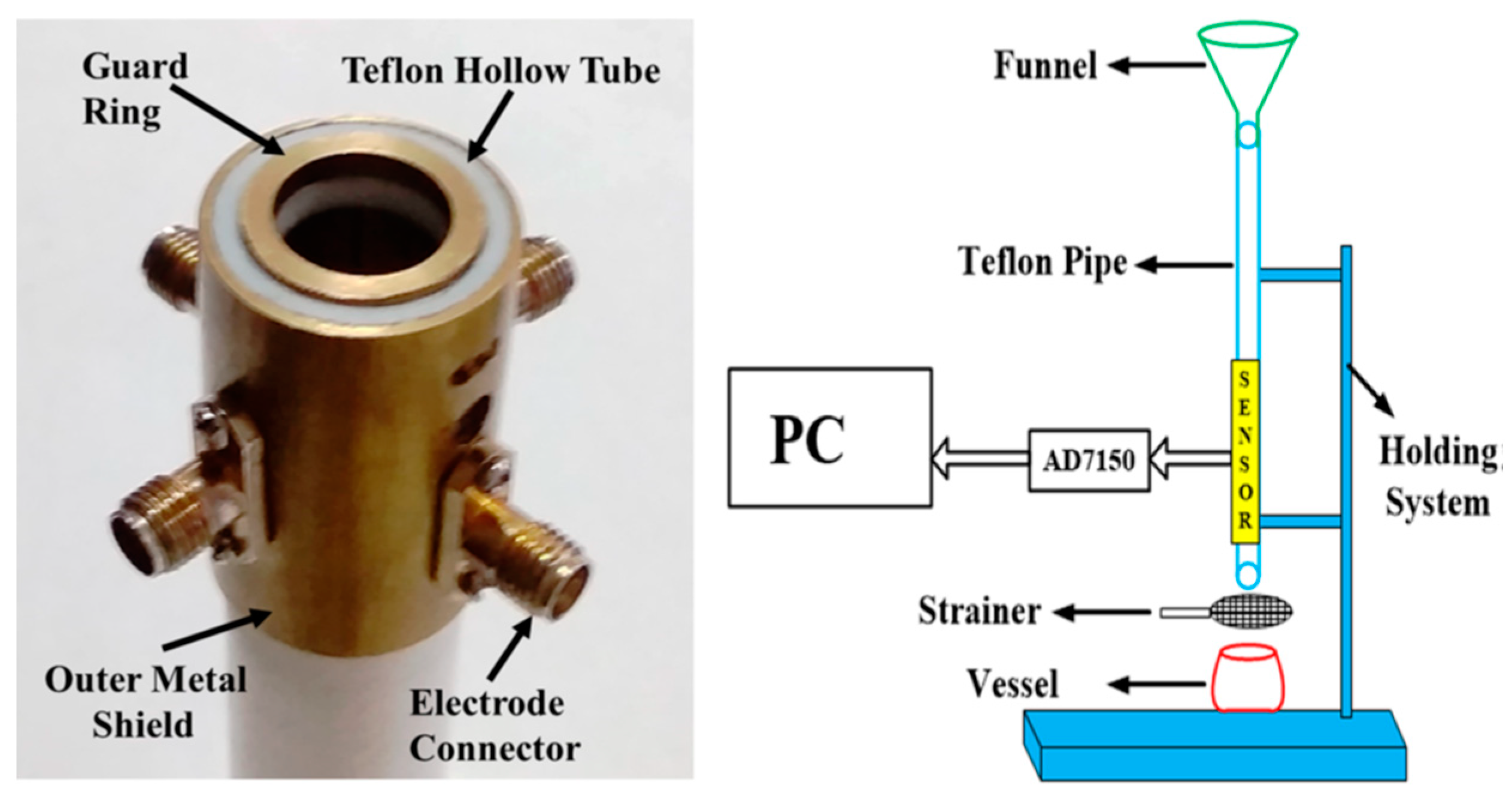

Capacitive sensors operate by detecting changes in capacitance caused by the movement of wear particles within an electric field. They depend on variations in the dielectric characteristics of the oil caused by the existence of particles. Capacitive sensors have the capability to detect particles, regardless of whether they are metallic or non-metallic. In 2005, Raadnui et al. developed a cost-effective capacitive sensor specifically designed for the purpose of monitoring suspended wear metal particles and contaminants present in lubricating oils [38]. The sensor is characterized by a grid of sensing elements that are arranged in parallel with multiple small gaps between them. It has been demonstrated that the presence of contaminants, specifically iron particles, has a significant influence on the observed variations in lubricant degradation as detected by the sensor. In the field of aero-engine health monitoring, the on-line monitoring of wear particles in lubricating oil is of utmost importance. Han et al. proposed the use of a cylindrical capacitive sensor that consists of two coaxial cylinders in 2017 [39]. They successfully incorporated this sensor into the piping of an aero-engine lubrication system in order to monitor changes in the conditions of the lubricating oil. Their methodology encompassed the establishment of mathematical models and the execution of numerical simulations in order to analyze the sensing mechanism and characteristics of capacitive sensors. Experimental validation has shown that capacitance values can be used to characterize wear particles. Additionally, compensation methods have been proposed to improve the accuracy of the sensor. Leveraging microfluidic technology, Bai et al. demonstrated the versatility of a capacitive sensor specifically designed for high-throughput hydraulic oil detection in 2019 [40]. This sensor is capable of seamlessly transitioning from capacitive to inductive working mode. This particular sensor is equipped with a set of silicon steel sheets that possess an annular microchannel. This unique feature allows for the manipulation of the magnetic field within the silicon steel sheet by modifying the connection of the coil. Consequently, the sensor enables the identification and categorization of diverse pollutants with exceptional flexibility. Liu et al. introduced a capacitive sensing system that was specifically developed to evaluate the level of wear in marine diesel engines in 2000 [41]. This system functions by detecting changes in the dielectric constant of the lubricating oil in order to assess its quality. The lubricating oil quality detector, consisting of upper and lower capacitors, is capable of accurately detecting real-time changes in oil quality caused by contaminants such as water and metal wear particles. Wang et al. proposed a novel capacitive sensor network system aimed at detecting wear particles in lubricants used in aero-engines in 2022 [42]. This system incorporates parallel curved electrodes and non-parallel planar electrodes, resulting in the formation of multiple subspaces characterized by decreased electrode distances. Each subspace comprises two distinct pairs of electrodes. As wear particles traverse these spaces, alterations occur in the dielectric constant between the electrodes and the capacitance existing between them. Experimental findings suggest that there is a correlation between the size and mass of wear particles and an increase in the capacitance value of the sensor. In 2020, Islam et al. introduced a novel non-contact cross-capacitive sensor that operates on the Thompson–Lampard principle. This sensor was designed specifically for the detection of abrasive particles in lubricating oil, as depicted in Figure 3 [43]. The sensor, consisting of four cylindrical electrodes, underwent testing using metal particles of varying weights (ranging from 10.5 mg to 27.5 mg) in a lubricating oil. Their research demonstrates that when metal particles traverse the sensor, there is a sudden alteration in the effective dielectric constant of the lubricating oil, resulting in a significant rise in capacitance value. Additionally, the capacitance peak demonstrates variation in accordance with the size of the metal particles, with the largest peak observed at 27.5 mg and the smallest peak observed at 12.2 mg. Additionally, the research findings indicate that the sensor registers capacitive pulses with more distinct peaks and shorter durations when heavier metal particles are in motion at higher velocities. Conversely, lighter particles result in longer pulse durations. The non-contact capacitive sensor described in this study is designed to preserve electrode integrity and achieve a high level of accuracy, with a tolerance of up to ±0.82%. Sun et al. developed a microsensor that integrates a 12-plate capacitance array, employing adaptive cytogenetics (SA-CGA) and morphological algorithms, in 2019 [44]. They have also proposed a novel inversion method that utilizes hyper-heuristic partial differential equations to effectively identify multiscale metal abrasive particles. Through conducting finite element simulations of the metal abrasive particle detection system, the researchers investigated the influence of abrasive particle characteristics on plate capacitance. The findings of their study showcased the efficacy of the capacitive array sensor in performing real-time detection of abrasive particles within the range of 200. This was done by comparing the results obtained from the capacitive array sensor with those obtained from an off-line detection CCD imaging system. The measurement is 900 μm. However, one limitation of this sensor is its incapability to detect metal abrasive particles with high throughput. Murali et al. conducted groundbreaking research on a novel capacitive microfluidic sensor that was specifically developed to detect metal abrasive particles in 2009 [45]. This research marked the first utilization of the Coulter counter principle. Recognizing the inherent difficulty in directly measuring alterations in electrical resistance resulting from the presence of abrasive particles, the researchers made the decision to instead monitor fluctuations in capacitance between the two polar plates situated within the microchannel. This experiment showcases the potential utilization of a microfluidic detection apparatus in the domain of identifying abrasive particles in low-conductivity lubricating oil. Zhu et al. utilized a network of coaxial capacitive sensors to evaluate and classify the morphology of metallic wear particles in 2022 [46]. They optimized the parameters of a Support Vector Machine (SVM) model and enhanced its classification accuracy through the implementation of intelligent optimization techniques. This study emphasizes the capability of the coaxial capacitive sensor network to analyze the various dimensions of wear particles. Furthermore, it demonstrates that the optimized Support Vector Machine (SVM) model can accurately classify wear particles present in lubricating oil.

Figure 3. High-precision cross-capacitive metal particle detection sensor [43].

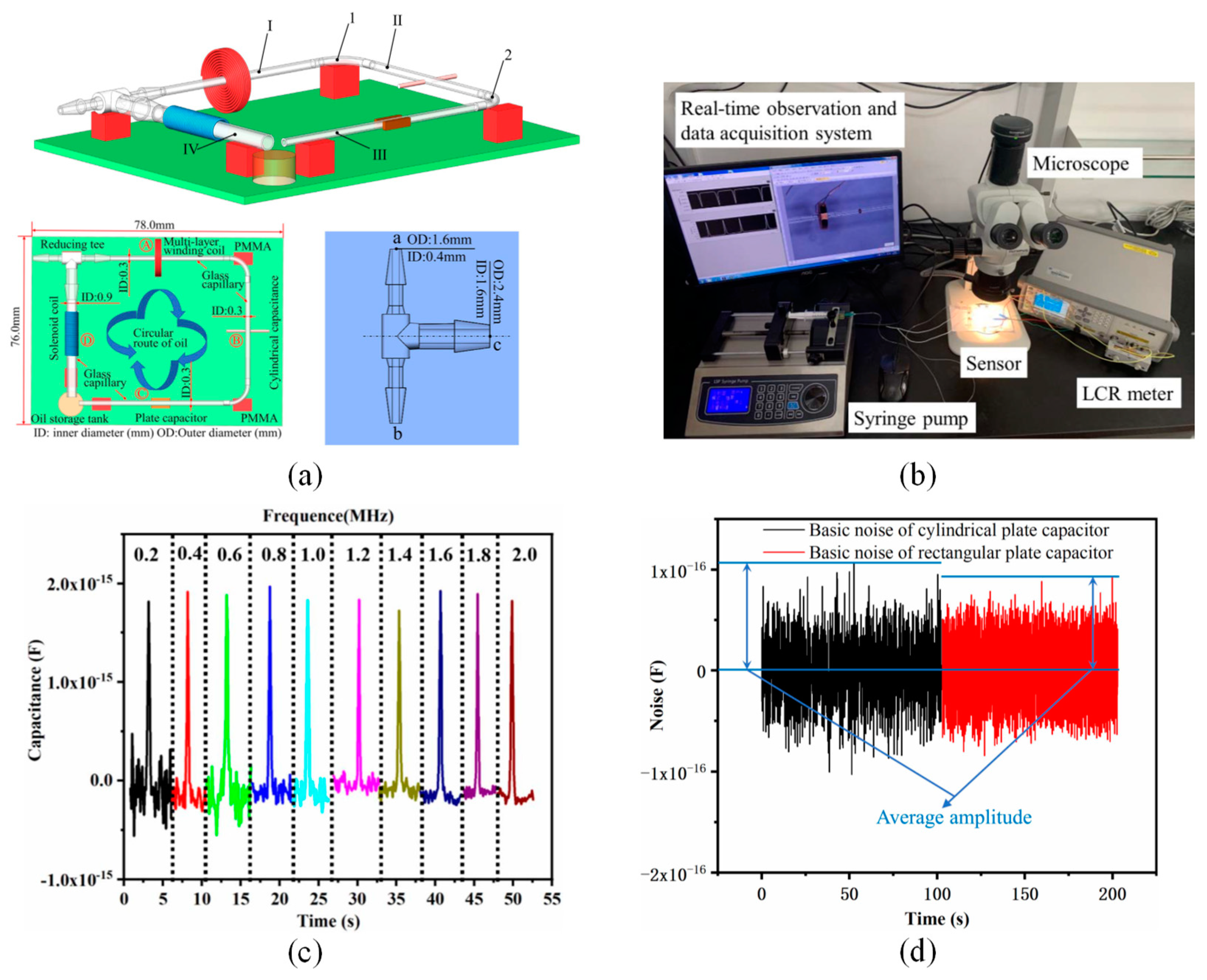

Liu et al. conducted a study on the optimization of parallel resonant circuits in capacitive abrasive sensors. The researchers employed a method that involved adjusting the parallel capacitance to enhance the performance of the sensors in 2022 [47]. The evaluation of the detection quality was conducted through the measurement of the relative impedance change of the LC resonant circuit. The conducted experiments involved the utilization of both ferrous and non-ferrous metal particles and demonstrated a significant level of concurrence between the experimental outcomes and the calculated results. A significant advantage of capacitive devices lies in their ease of replacement in experimental setups, allowing for the adjustment of parallel capacitance as a viable method to optimize abrasive particle sensors in comparison to other types of sensing system devices. In 2022, Wang et al. investigated a high-sensitivity, multi-channel, multi-modal capacitive sensor that was specifically developed for the purpose of detecting wear particles in a high-throughput manner. This sensor is illustrated in Figure 4 [48]. The sensor comprises four glass capillary channels, a planar coil, a solenoid coil, a cylindrical parallel-plate capacitor, and a rectangular parallel-plate capacitor. The system has the capability to achieve high-throughput on-line monitoring of a wide range of pollutants, such as ferromagnetic particles, non-ferromagnetic particles, air, water, and other substances. The detection throughput of the sensor has undergone a substantial improvement, exhibiting a twelve-fold increase compared to its initial value. In 2022, Gao et al. presented a novel capacitive sensor that was specifically developed for real-time monitoring of the mean velocity of metal particle flow in narrow pipes [49]. This sensor employs double triangular electrodes for both numerical simulations and experimental investigations. Importantly, it has been found that the axial position of the metal particles does not have a significant impact on velocity measurements. In the initial experiments, the researchers confirmed the viability of the sensor for measuring the velocity of metal particles, demonstrating a repeatability error of less than 7%. It is important to highlight that the metal particles examined in their study had a relatively large diameter and flow velocity, and the fluid flow was predominantly influenced by gravity. In 2018, Muthuvel et al. conducted a study on an efficient and cost-effective capacitive sensor that was specifically designed for the detection of abrasive particles in hydraulic systems [50]. The methodology entails the utilization of a permanent magnet to attract iron-containing abrasive particles towards the sensor. Subsequently, a capacitive sensor is employed to monitor the presence of iron-containing abrasive particles with a diameter exceeding 200 μm in the lubricating oil. The findings of the research demonstrated that the implementation of the capacitive sensor, employing the differential sensing technique, presented significant benefits such as enhanced sensitivity, cost-effectiveness, and operational efficiency. Additionally, the utilization of permanent magnets effectively attracted ferrous abrasive particles towards the sensor, thereby guaranteeing the absence of any abrasive particles within the hydraulic system’s circuit. It is crucial to acknowledge that the current capability of the sensor is limited to monitoring abrasive particles made of ferrous metal. In 2022, Shi et al. presented an innovative integrated multi-unit capacitive sensing microsensor. This microsensor was specifically designed to achieve ultrasensitive detection and comprehensive analysis of various contaminants in oil, including metal wear particles, air bubbles, and moisture [51]. By employing impedance parameters, this sensor exhibits the capability to accurately distinguish between iron filings with sizes ranging from 16 µm to 500 µm, copper filings with sizes ranging from 60 µm to 500 µm, as well as detect air bubbles and moisture in oil that are larger than 170 µm.

Figure 4. High-sensitivity, high-throughput capacitive detection sensor for oil contamination [48]. (a) The overall structure design of the sensor. (b) Capacitive sensor experimental test system. (c) The detection signals obtained by the cylindrical capacitive sensor under different excitation frequencies. (d) Basic noise of different types of capacitive sensors.

4. Resistance Sensor

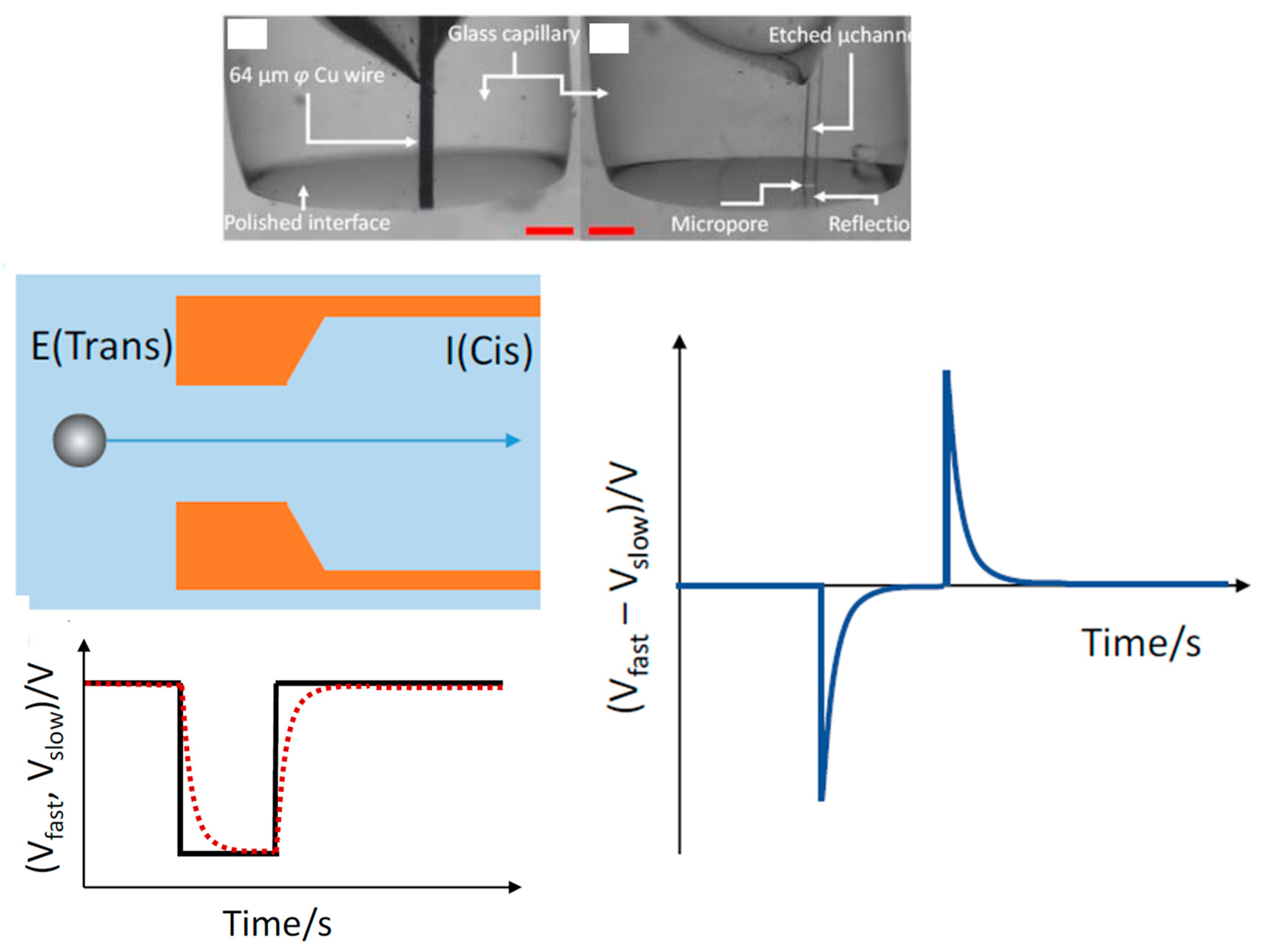

The resistance detection method is employed to identify particulate matter by utilizing the disparity in conductivity among different substances. Resistance sensors are utilized to measure fluctuations in the electrical resistance of the oil. When wear particles are present, they generate conductive pathways that modify the resistance of the oil. These sensors have the capability to detect a diverse array of wear particle types. In 2019, Birkin et al. conducted an experiment to evaluate the performance of a newly developed differential resistive pulse sensor for particle size analysis. The results showed that this sensor had a higher signal-to-noise ratio compared to traditional current sensing techniques, especially when applied to Coulter counting. These findings are illustrated in Figure 5 [52]. The sensitivity of the resistive sensor is contingent upon various factors, including the selection of the resistor and the voltage applied. Song et al. developed a microfluidic-based differential resistive pulse sensor for the purpose of monitoring nanoparticles in 2011 [53]. This sensor is capable of detecting particles through the observation of resistive pulses that are generated when particles pass through a designated sensing region. By implementing differential amplification techniques, the researchers are able to improve the signal-to-noise ratio of the sensor. The aforementioned sensor is highly regarded for its uncomplicated data processing capabilities and exceptional sensitivity. Santilli et al. developed a resistive sensor that is capable of monitoring wear particles by measuring the rate of fluid wear in 1989 [54]. The response of this sensor is influenced by the size and wear properties of both ferromagnetic and non-ferromagnetic particles. The objective is accomplished through the integration of two layers of metal film on its outer surface. When particles in rapid motion collide with the metal film, it undergoes gradual erosion, resulting in an elevation of resistance. Monitoring the change in resistance allows for the identification of wear particles.

Figure 5. Detection principle of resistive particle detection sensor [52].

References

- Shi, H.; Huo, D.; Zhang, H.; Li, W.; Sun, Y.; Li, G.; Chen, H. An Impedance Sensor for Distinguishing Multi-Contaminants in Hydraulic Oil of Offshore Machinery. Micromachines 2021, 12, 1407.

- Zhang, X.; Cao, Y.; Xue, B.; Hua, G.; Zhang, H. Method for Identifying Materials and Sizes of Particles Based on Neural Network. JMSE 2023, 11, 541.

- Zhu, X.; Zhong, C.; Zhe, J. Lubricating oil conditioning sensors for online machine health monitoring—A review. Tribol. Int. 2017, 109, 473–484.

- Urban, A.; Zhe, J. A microsensor array for diesel engine lubricant monitoring using deep learning with stochastic global optimization. Sens. Actuators A 2022, 343, 113671.

- Hong, W.; Cai, W.; Wang, S.; Tomovic, M.M. Mechanical wear debris feature, detection, and diagnosis: A review. Chin. J. Aeronaut. 2018, 31, 867–882.

- Fu, C.; Lu, K.; Li, Q.; Xu, Y.; Gu, F.; Ball, A.D.; Zheng, Z. Physics-Based Modelling for On-Line Condition Monitoring of a Marine Engine System. JMSE 2023, 11, 1241.

- Chuma, E.L.; Iano, Y.; Roger, L.L.B.; De Oliveira, G.G.; Vaz, G.C. Novelty Sensor for Detection of Wear Particles in Oil Using Integrated Microwave Metamaterial Resonators With Neodymium Magnets. IEEE Sens. J. 2022, 22, 10508–10514.

- Wang, F.; Liu, Z.; Ren, X.; Wu, S.; Meng, M.; Wang, Y.; Pan, X. A Novel Method for Detecting Ferromagnetic Wear Debris with High Flow Velocity. Sensors 2022, 22, 4912.

- Jiao, D.; Urban, A.; Zhu, X.; Zhe, J. Oil property sensing array based on a general regression neural network. Tribol. Int. 2021, 164, 107221.

- Rao, X.; Sheng, C.; Guo, Z.; Yuan, C. A review of online condition monitoring and maintenance strategy for cylinder liner-piston rings of diesel engines. Mech. Syst. Sig. Process. 2022, 165, 108385.

- Wang, J.; Maw, M.M.; Yu, X.; Dai, B.; Wang, G.; Jiang, Z. Applications and perspectives on microfluidic technologies in ships and marine engineering: A review. Microfluid. Nanofluid. 2017, 21, 39.

- Zhang, Y.; Hong, J.; Shi, H.; Xie, Y.; Zhang, H.; Zhang, S.; Li, W.; Chen, H. Magnetic Plug Sensor with Bridge Nonlinear Correction Circuit for Oil Condition Monitoring of Marine Machinery. JMSE 2022, 10, 1883.

- Sun, J.; Wang, L.; Li, J.; Li, F.; Li, J.; Lu, H. Online oil debris monitoring of rotating machinery: A detailed review of more than three decades. Mech. Syst. Sig. Process. 2021, 149, 107341.

- Li, W.; Bai, C.; Wang, C.; Zhang, H.; Ilerioluwa, L.; Wang, X.; Yu, S.; Li, G. Design and Research of Inductive Oil Pollutant Detection Sensor Based on High Gradient Magnetic Field Structure. Micromachines 2021, 12, 638.

- Zamorano, M.; Avila, D.; Marichal, G.N.; Castejon, C. Data Preprocessing for Vibration Analysis: Application in Indirect Monitoring of ‘Ship Centrifuge Lube Oil Separation Systems’. JMSE 2022, 10, 1199.

- Gebarin, S. On-line and In-line Wear Debris Detectors: What’s Out There? Available online: https://www.machinerylubrication.com/Read/521/in-line-wear-debris-detectors (accessed on 8 December 2023).

- Zeng, L.; Chen, X.; Zhang, R.; Hu, S.; Zhang, H.; Zhang, Y.; Yang, H. High-Resolution Separation of Nanoparticles Using a Negative Magnetophoretic Microfluidic System. Micromachines 2022, 13, 377.

- Wu, X.; Liu, H.; Qian, Z.; Qian, Z.; Liu, D.; Li, K.; Wang, G. On the Investigation of Frequency Characteristics of a Novel Inductive Debris Sensor. Micromachines 2023, 14, 669.

- Sanga, R.; Srinivasan, V.S.; Sivaramakrishna, M.; Prabhakara Rao, G. Deployment of an inductance-based quasi-digital sensor to detect metallic wear debris in lubricant oil of rotating machinery. Meas. Sci. Technol. 2018, 29, 075102.

- Du, L.; Zhe, J. Parallel sensing of metallic wear debris in lubricants using undersampling data processing. Tribol. Int. 2012, 53, 28–34.

- Zhu, X.; Zhong, C.; Zhe, J. A high sensitivity wear debris sensor using ferrite cores for online oil condition monitoring. Meas. Sci. Technol. 2017, 28, 075102.

- Zhu, X.; Du, L.; Zhe, J. A 3×3 wear debris sensor array for real time lubricant oil conditioning monitoring using synchronized sampling. Mech. Syst. Sig. Process. 2017, 83, 296–304.

- Bai, C.; Zhang, H.; Wang, W.; Zhao, X.; Chen, H.; Zeng, N. Inductive-Capacitive Dual-Mode Oil Detection Sensor Based on Magnetic Nanoparticle Material. IEEE Sens. J. 2020, 20, 12274–12281.

- Hong, W.; Li, T.; Wang, S.; Zhou, Z. A General Framework for Aliasing Corrections of Inductive Oil Debris Detection Based on Artificial Neural Networks. IEEE Sens. J. 2020, 20, 10724–10732.

- Xiao, H.; Wang, X.; Li, H.; Luo, J.; Feng, S. An Inductive Debris Sensor for a Large-Diameter Lubricating Oil Circuit Based on a High-Gradient Magnetic Field. Appl. Sci. 2019, 9, 1546.

- Ren, Y.J.; Li, W.; Zhao, G.F.; Feng, Z.H. Inductive debris sensor using one energizing coil with multiple sensing coils for sensitivity improvement and high throughput. Tribol. Int. 2018, 128, 96–103.

- Zeng, L.; Wang, W.; Rogers, F.; Zhang, H.; Zhang, X.; Yang, D. A High Sensitivity Micro Impedance Sensor Based on Magnetic Focusing for Oil Condition Monitoring. IEEE Sens. J. 2020, 20, 3813–3821.

- Muthuvel, P.; George, B.; Ramadass, G.A. A Highly Sensitive In-Line Oil Wear Debris Sensor Based on Passive Wireless LC Sensing. IEEE Sens. J. 2021, 21, 6888–6896.

- Wang, X.; Chen, P.; Luo, J.; Yang, L.; Feng, S. Characteristics and Superposition Regularity of Aliasing Signal of an Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2020, 20, 10071–10078.

- Li, Y.; Wu, J.; Guo, Q. Electromagnetic Sensor for Detecting Wear Debris in Lubricating Oil. IEEE Trans. Instrum. Meas. 2020, 69, 2533–2541.

- Feng, S.; Yang, L.; Qiu, G.; Luo, J.; Li, R.; Mao, J. An Inductive Debris Sensor Based on a High-Gradient Magnetic Field. IEEE Sens. J. 2019, 19, 2879–2886.

- Qian, M.; Ren, Y.; Zhao, G.; Feng, Z. Ultrasensitive Inductive Debris Sensor With a Two-Stage Autoasymmetrical Compensation Circuit. IEEE Trans. Ind. Electron. 2021, 68, 8885–8893.

- Wu, X.; Zhang, Y.; Li, N.; Qian, Z.; Liu, D.; Qian, Z.; Zhang, C. A New Inductive Debris Sensor Based on Dual-Excitation Coils and Dual-Sensing Coils for Online Debris Monitoring. Sensors 2021, 21, 7556.

- Feng, S.; Yang, L.; Fan, B.; Li, R.; Luo, J.; Mao, J. A Ferromagnetic Wear Particle Sensor Based on a Rotational Symmetry High-Gradient Magnetostatic Field. IEEE Trans. Instrum. Meas. 2021, 70, 9504709.

- Park, J.; Yoo, S.-J.; Yoon, J.; Kim, Y.-J. Inductive particle detection system for real-time monitoring of metals in airborne particles. Sens. Actuators A 2021, 332, 113153.

- Wu, Y.; Wang, F.; Zhao, M.; Wang, B.; Yang, C. A Method for Measurement of Nonferrous Particles Sizes in Lubricant Oil Independent of Materials Using Inductive Sensor. IEEE Sens. J. 2021, 21, 17723–17731.

- Li, Y.; Yu, C.; Xue, B.; Zhang, H.; Zhang, X. A Double Lock-in Amplifier Circuit for Complex Domain Signal Detection of Particles in Oil. IEEE Trans. Instrum. Meas. 2022, 71, 3503710.

- Raadnui, S.; Kleesuwan, S. Low-cost condition monitoring sensor for used oil analysis. Wear 2005, 259, 1502–1506.

- Han, Z.; Wang, Y.; Qing, X. Characteristics Study of In-Situ Capacitive Sensor for Monitoring Lubrication Oil Debris. Sensors 2017, 17, 2851.

- Bai, C.; Zhang, H.; Zeng, L.; Zhao, X.; Yu, Z. High-Throughput Sensor to Detect Hydraulic Oil Contamination Based on Microfluidics. IEEE Sens. J. 2019, 19, 8590–8596.

- Liu, Y.; Liu, Z.; Xie, Y.; Yao, Z. Research on an on-line wear condition monitoring system for marine diesel engine. Tribol. Int. 2000, 33, 829–835.

- Wang, Y.; Lin, T.; Wu, D.; Zhu, L.; Qing, X.; Xue, W. A New In Situ Coaxial Capacitive Sensor Network for Debris Monitoring of Lubricating Oil. Sensors 2022, 22, 1777.

- Islam, T.; Yousuf, M.; Nauman, M. A highly precise cross-capacitive sensor for metal debris detection in insulating oil. Rev. Sci. Instrum. 2020, 91, 025005.

- Sun, Y.; Jia, L.; Zeng, Z. Hyper-Heuristic Capacitance Array Method for Multi-Metal Wear Debris Detection. Sensors 2019, 19, 515.

- Murali, S.; Xia, X.; Jagtiani, A.V.; Carletta, J.; Zhe, J. Capacitive Coulter counting: Detection of metal wear particles in lubricant using a microfluidic device. Smart Mater. Struct. 2009, 18, 037001.

- Zhu, L.; Xiao, X.; Wu, D.; Wang, Y.; Qing, X.; Xue, W. Qualitative Classification of Lubricating Oil Wear Particle Morphology Based on Coaxial Capacitive Sensing Network and SVM. Sensors 2022, 22, 6653.

- Liu, Z.; Wu, S.; Raihan, M.K.; Zhu, D.; Yu, K.; Wang, F.; Pan, X. The Optimization of Parallel Resonance Circuit for Wear Debris Detection by Adjusting Capacitance. Energies 2022, 15, 7318.

- Wang, C.; Zheng, Y.; Zhang, H.; Li, W.; Zhang, S.; Hong, J.; Li, G.; Sun, Y. An Oil Multipollutant Detection Sensor With High Sensitivity and High Throughput. IEEE Trans. Instrum. Meas. 2022, 71, 6003611.

- Gao, H.; Min, Y.; Chang, Q. Metal Particles Velocity Measurement Based on Capacitance Sensor With Double Triangular-Shaped Electrodes. IEEE Sens. J. 2022, 22, 11827–11834.

- Muthuvel, P.; George, B.; Ramadass, G.A. Magnetic-Capacitive Wear Debris Sensor Plug for Condition Monitoring of Hydraulic Systems. IEEE Sens. J. 2018, 18, 9120–9127.

- Shi, H.; Zhang, H.; Huo, D.; Yu, S.; Su, J.; Xie, Y.; Li, W.; Ma, L.; Chen, H.; Sun, Y. An Ultrasensitive Microsensor Based on Impedance Analysis for Oil Condition Monitoring. IEEE Trans. Ind. Electron. 2022, 69, 7441–7450.

- Birkin, P.R.; Linfield, S.; Denuault, G.; Jones, R.; Youngs, J.J.; Wain, E. An Analytical Differential Resistance Pulse System Relying on a Time Shift Signal Analysis–Applications in Coulter Counting. ACS Sens. 2019, 4, 2190–2195.

- Song, Y.; Zhang, H.; Chon, C.H.; Pan, X.; Li, D. Nanoparticle detection by microfluidic Resistive Pulse Sensor with a submicron sensing gate and dual detecting channels-two stage differential amplifier. Sens. Actuators B 2011, 155, 930–936.

- Santilli, R. The Fulmer Method of Monitoring Fluid Abrasivity as an Indication of Fluid Condition and Machine Health. In COMADEM 89 International; Rao, R.B.K.N., Hope, A.D., Eds.; Springer: Boston, MA, USA, 1989; pp. 55–67. ISBN 978-1-4684-8907-1.

More

Information

Subjects:

Engineering, Marine

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

632

Revisions:

3 times

(View History)

Update Date:

20 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No