Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Marinella Giunta | -- | 4236 | 2023-12-16 11:36:36 | | | |

| 2 | Lindsay Dong | Meta information modification | 4236 | 2023-12-18 06:50:55 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Giunta, M. Trends and Challenges in Railway Sustainability. Encyclopedia. Available online: https://encyclopedia.pub/entry/52830 (accessed on 14 January 2026).

Giunta M. Trends and Challenges in Railway Sustainability. Encyclopedia. Available at: https://encyclopedia.pub/entry/52830. Accessed January 14, 2026.

Giunta, Marinella. "Trends and Challenges in Railway Sustainability" Encyclopedia, https://encyclopedia.pub/entry/52830 (accessed January 14, 2026).

Giunta, M. (2023, December 16). Trends and Challenges in Railway Sustainability. In Encyclopedia. https://encyclopedia.pub/entry/52830

Giunta, Marinella. "Trends and Challenges in Railway Sustainability." Encyclopedia. Web. 16 December, 2023.

Copy Citation

Rail is expected to become the backbone of future mobility in the world as the cleanest and greenest high-volume transport. Rail generates the lowest CO2 emissions and energy consumption when in operation, with respect to the other transportation modes, but during construction and maintenance phases, its environmental impacts are significant and need to be carefully assessed and properly mitigated.

railway

track

sustainability

materials

maintenance

monitoring

circular economy

life cycle assessment

1. Introduction

As it is well known, sustainability deals with “the development that meets the needs of the present without compromising the ability of future generations to meet their own needs” [1]. With growing concern for the environment, sustainable development has become one of the primary goals of all nations throughout the world.

Sustainable mobility and infrastructure are main global challenges and are important aspects of transport development. Rail transport is part of the solution to the challenge of sustainable transportation.

Railways play a structuring role in the European economy, as they facilitate the production and distribution of goods and economic services and form the basis for the provision of basic social services [2]. Indeed, rail transport is becoming increasingly important as part of the transportation system, and railway lines are an integral part of the countries’ transport networks. In addition to their central role within the mobility system, some figures demonstrate the environmental performance of the railways well. Transport systems as a whole contribute about 21% of the total emission of carbon dioxide (CO2) in the world. The main responsibility lies with road transport, which contributes about 74%, followed by aviation and marine transport, which both account for about 11%, and, lastly, rail comprises 4% [3]. Figures make clear that rail is the main pillar of transformative climate action in transport and the fastest and most cost-efficient way to decarbonize people’s daily mobility and logistics chains.

However, the evident sustainability of the rail does not exempt asset owners, researchers, or practitioners from continuing to make efforts to find solutions aimed at improving this mode of transport more and more, from the viewpoint of environmental sustainability. To this purpose, it is worthy to highlight that rail generates the lowest CO2 emissions and energy consumption during operation, with respect to the other transportation modes, but during its construction and maintenance phases, CO2 emission, energy consumption, and other environmental impacts are significant and need to be carefully assessed and properly mitigated [4][5][6]. This circumstance calls for research efforts aimed at improvements in specific aspects in all stages of railway lifespan [7], and particularly in construction and maintenance, where materials, practices, equipment, and strategies can be optimized with the aims of minimizing negative effects on the environment and society and making this transportation mode greener.

2. Trends and Challenges in Railway Sustainability

2.1. Sustainable Track Materials and Components for Construction and Maintenance

2.1.1. Ballast

The ballast layer has the following functions [8]:

-

Allows the resistance of sleepers against vertical, longitudinal, and lateral displacements, thus providing stable support for travelling trains.

-

Transfers train forces to the subgrade, according to its bearing capacity, thus reducing compressive stresses on the subgrade.

-

Keeps track geometry in the vertical and lateral directions.

-

Provides elasticity to the railway track, achieving proper riding comfort.

-

Provides effective drainage to the track and facilitates the absorption of noise and vibration.

The quality and mechanical characteristics of the ballast depend on the parent rock, petrography, size, and shape. The ballast is the weakest element of the superstructure because it is subject to the greatest deterioration; in fact, being an unbonded layer, the passage of vehicles, their speeds, and their vibrations cause geometric decay and the degeneration of the quality levels. This implies that the ballast requires more frequent maintenance interventions, specifically tamping, than other elements. The ballast quality directly influences not only track service life but also the tamping demand. Service life and tamping demand depend on loads, radii, ballast quality, and the subsoil and drainage, as demonstrated by Marschnig and Veit [9].

Various selection criteria for ballast materials and test methods for quantifying ballast quality have been applied [10][11][12]. Material properties affect the durability of the ballast layer and further the durability of the track itself.

As train speed and axle load increase, there are more demanding requirements for particles in the ballast layer, such as a tighter particle size distribution (PSD), higher particle strength, and higher particle densities. Note that the use of crushed stones as ballast material increases the difficulty of maintenance. Several studies have summarized the test methods for determining the mechanical, physical, environmental, and geometric properties of ballast materials. The two traditional and commonly used tests are the Los Angeles abrasion test (LAA) and the Micro-Deval abrasion test (MDA). The LAA test is performed only on dry ballast particles, while the MDA test can be performed on dry or impregnated particles. Based on the properties of the ballast and the corresponding tests, the quality of the ballast can be classified. It is inferred that the quality is classified according to degradation and weathering.

Some alternative recycled materials, listed below, are proved to increase the lifetime and performance of the ballast, in addition to which, being recycled materials, they also make it possible to pursue economic and environmental benefits, according to the criteria of the circular economy [8]. In fact, the application of recycled waste materials in transport infrastructure developments is an efficient way to minimize waste accumulation in stockpiles.

-

Steel slag as rail ballast exhibits interesting technical properties, such as a higher modulus of elasticity, lower vertical stress, and lower permanent deformation under high train loads. These observations imply that the use of steel slag ballast (SSB) can potentially reduce track maintenance costs, owing to its lower settlement and breakage, its ability to enhance the lateral resistance due to its higher density, and its ability to provide better riding comfort because of its higher resilient modulus [13][14].

-

Steel slag and crushed rocks: the mixture of crushed rocks with steel slag, by 50% (or lower), allow for the creation of a material that meets the standard for special class ballast, in terms of abrasion resistance, and improves the shear strength of the slag–rock ballast, compared to a pure steel slag ballast layer [15].

-

Steel slag and tire-derived aggregate (TDA): a study demonstrated that the settlement and damping ratio increased with an increase in the TDA percentage, whereas the breakage index and the stiffness of the ballast decreased. A TDA of 10% by weight (16.5% by volume) was selected as the optimum percentage for the mixture for a good balance between the dynamic stiffness and the damping ratio [16].

-

Crumb rubber (from end of life tires): a low percentage of this material (10%) brings significant improvements to the ballast’s behavior, in terms of its settlement and deterioration, mechanical properties, capacity to dissipate energy, and contributions to extending the service life of a railway track [17][18]. The main disadvantages are drainage interference, potential contamination, low resilience, performance uncertainties due to limited use, interference in ballast–ballast contact, and uncertainty over movement in the ballast layer [8].

-

Asphalt: the use of asphalt in the ballast layer improves the ballast layer’s stiffness, by bonding the discrete ballast into a form of track between a slab track and a ballasted track. The asphalt can be recycled and decomposed after heating, making it easier to maintain and repair. Conversely, asphalt in ballast is costly and creates a high maintenance cost, producing maintenance difficulties, and is also subject to temperature deformation, posing the problem of long-term creep control [8].

-

Polyethylene fibers: studies demonstrated that, when narrow fibers were used, the fiber-reinforced ballast significantly reduced the settlement, because the fibers in granular materials reduced the lateral expansion of the mixture (with smaller principal strains) and mobilized a higher stress ratio [19].

-

Polyurethane, cement, and geopolymer: these binders act like asphalt; the differences entail with costs, working principles, and installation. Geopolymer is a promising material with a low carbon footprint but suffers with the problem of thermal expansion and contraction. A glued ballast layer is subject to rapid degradation, due to fouling in the ballast layer [20].

-

Bitumen-stabilized ballast (BSB): it represents an innovative solution, designed to increase ballast service life and reduce overall maintenance burdens. This technology, which can be used for new track beds, as well as for reinforcing existing ones, consists of the use of bitumen emulsion (BE) poured or sprayed at ambient temperatures onto the ballast. The main advantage resulting from the use of BSB is its long-term use (between 40 and 60 years) [21].

-

Geogrids: several studies and experiments have shown how the inclusion of a geogrid in the ballast increases the service life of the track, improving the strength properties and, particularly, the resilient modulus of the railway ballast. Geogrids also reduce the extent of the dynamic amplification factor (DAF) [22][23].

For the application of new materials and technologies aimed at improving track response and durability, it is necessary to provide a set of recommendations and guidelines, distinguishing between design-based solutions and maintenance-based solutions. Design-based solutions include the use of elastic elements, the development of alternative elastic elements, the use of geogrids, and the use of bituminous layers. Maintenance-based solutions include conventional tamping, the use of stone blowing, and ballast stabilization, including polyurethane-based stabilization techniques [24].

2.1.2. Sub-Ballast

Regarding the sub-ballast layer, the literature shows that sustainable solutions are related to the use of the following: non-conventional bituminous mixtures made with recycled materials [5], which are able to ensure great layer stability; and geocell-reinforced coal mine overburden waste materials [25], which have been proved to ensure a decrease in vertical settlements, lateral deformations, and subgrade stresses. A recent study [26] demonstrated that the use of recycled rubber products, such as CWRC mixtures (i.e., mixtures of coal wash (CW) and rubber crumbs (RC)) and SEAL mixtures (i.e., mixtures of steel furnace slag, CW and RC), to replace sub-ballast, tire cell reinforcements for sub-ballast and under-ballast mats increases the energy dissipation effect of the track, hence reducing the ballast degradation efficiently and increasing the track stability.

2.1.3. Sleepers

Another important component of the track is the sleeper. Several kinds of sleepers are in use: timber, steel, and concrete. Timber was the earliest material used, due to its excellent dynamic, electrical, and sound-insulating properties. The scarcity of timber and the growing environmental sensitivity, as well as problems related to timber rotting, splitting, insect attacks, and a limited service life (20 years), have led to the progressive disuse of this material.

Steel has been used as alternative material to timber. Steel sleepers are highly economical from the viewpoint of maintenance costs with respect to the concrete ones, and, in addition, the old ballast can remain in place, reducing new ballast requirements. The main drawbacks associated with their use are higher transportation costs, due to the heavy weight, being difficult to handle and requiring expensive and extensive equipment for installation, risk of corrosion, high electrical conductivity, fatigue cracking in the rail seat region, and difficulty of packing them within the ballast [27]. Mono-block pre-stressed concrete sleepers, since 1943, have been a widely used solution throughout the world in heavy haul and high-speed rail track constructions. This extensive application is due to their durability and lateral resistance [28]. Their main shortcomings can be summarized as the low impact resistance and susceptibility to chemical attack, together with the higher costs for transportation and handling due to the weight.

Research on sustainable solutions for this component has led to innovative projects based on the use of composites which, when engineered according to specific requirements, can ensure a high strength-to-weight ratio, excellent resistance against corrosion, moisture, and insects, and thermal and electrical non-conductivity. Different sleeper technologies have been developed with composites (Tietek, Axion, I-Plas, KLP, MPW, Wood core), mainly to replace the timber ones. Limits to the extensive use of these technologies are due to their low strength and stiffness properties, low anchorage capability, formation of material voids, creep deformation, and the high price of composites, especially for the use of fibers.

2.1.4. Rails

As for the rails, higher axle loads and speeds can lead to excessive wear, rolling contact fatigue (RCF), and ultimately fracture of the steel rails, depending on the type of steel. To withstand these phenomena and increase the rail service life, different strategies can be put into action. Higher strength steel grades have proven to be an optimal solution which significantly elongates the service life of the rails and reduces maintenance needs. Steel alloying and heat treatment are widely used to improve the lifespan of rails [29]. The use of harder steel poses the problem of wheel wear. In Europe, rail steels typically range in hardness from 260 to 440 Brinell hardness (HB), while wheel grades range in hardness from 225 HB to 255 HB. It has been demonstrated that, when the rail is harder than the wheel, there is no influence of increasing rail hardness on wheel wear [30]. Rail wear decreases with increasing hardness, and wheel wear remains unchanged, resulting in a reduction in overall system wear. Rail–wheel contact is a key aspect in the durability and service life of these two components.

Since the production of steel is an emission process, increasing the durability and the service life of the rails and reducing the need for maintenance positively affects the rails’ environmental sustainability. Further, it is worth noting that steel is a material that can be 100% endlessly recycled. Due to the high recyclability and relatively high value of scrap steel, this option often seems more attractive, as well as sustainable, and is in line with the principles of a circular economy. The reuse of these components poses the following technical challenges: a lack of standardization of components, uncertainty regarding the efficiency of reused components, lack of knowledge regarding fatigue history and product composition, and possibly inappropriate decomposition handling. The criteria for reuse are established as follows: if the components are “as good as new”, they can be reinstalled in all lines; if they are “almost as good as new” they meet the criteria for less frequent lines and can be repurposed and used in secondary lines; if neither is possible the material is sold as scrap, used as fence posts or supports for railway equipment such as signals, or sold to produce designer furniture [31].

2.1.5. Fastening System

The fastening system is a key component of track structures, because it fixes the rail to sleepers and retains it in the required position, whilst permitting any necessary vertical, lateral, and longitudinal movements. An additional key function is reducing the noise related to high-speed trains and track structures. Fastening systems include a variety of components such as clips, bolts, screws, and plates. There are various type of fastenings: with and without plate, elastic, tree screw with plates, Pandrol E-clip, and Pandrol Fastclip, etc. Different types present different elasticities and suitability for timber sleepers, concrete sleepers, and slabs. Given the important function they perform, understanding the external and internal mechanisms of rail fastener failures and the potential detrimental consequences to railway operation safety is very important.

2.1.6. Resilient Components

Under sleeper pads (USPs) and under ballast mats (UBMs) are two important resilient components in tracks.

USPs, usually made of polyurethane elastomer with a foam structure including air voids, are installed underneath sleepers to provide additional track resiliency between the sleepers and ballast. The main objectives for using USPs are to moderate track stiffness, to reduce ground-borne vibrations, and to reduce ballast breakage. The stiffness is a key aspect of this component, because it affects the degradation speed of the infrastructure. In fact, high pad stiffness could increase the dynamic loads and stresses on the substructure, whereas a low stiffness could cause damages in the rail track, increasing their stress state even more. Engineering properties in recent years have been merged with environmental concerns, and the suitability of rail pads with recycled polymers and crumb rubber has been studied [32][33]. The use of plastics and crumb rubber allow mats to enact different solutions and can reduce the stiffness more than 50%, even if softer solutions lead to higher plastic deformations during fatigue tests, reducing their durability, in comparison to the pads made from high-density polyethylene. From an environmental standpoint, plastics offer a reduced carbon footprint, compared to conventional pads.

UBMs, usually made with elastomeric materials like polyurethane or rubber, are used in ballasted track to reduce rail vibrations and protect the ballast against fast degradation generated by the abrasion and breakage of its particles. Also, for this component, recent studies demonstrated the suitability of the use of rubber from end-of-life tires, with the double benefits of reducing both the cost and environmental impacts [34].

2.2. Maintenance Strategies: Environment-Related Effects

Maintenance is constantly required in ballasted track to ensure the efficiency, reliability, availability, functionality, and safety of the railways. The replacement of the components and renewal of the track are needed at the end of the service life (Table 1).

Table 1. Service life of ballasted track components.

| Component | Service Life [Years] |

|---|---|

| Rail replacement | 28 |

| Sleepers’ replacement | 40 |

| Fastenings replacement | 40 |

| Ballast recovery | 30 |

| Tamping/levelling | 1–5 |

The component towards which maintenance is mainly addressed is the ballast, which needs periodic interventions to maintain its alignment and restore its geometry to an acceptable condition [35][36].

Maintenance activities include renewal and re-construction, as well as ballast cleaning, resurfacing, rail-head grinding, and re-railing. From an environmental standpoint, all these activities require the use of resources and diesel power machineries, such as: tamping machines (which have a diesel engine), used for packing, lifting, and lining the track bed; ballast regulators, used for replenishing ballast and rebuilding shoulder profiles; and dynamic stabilizers, which, when passing through the track, consolidate the ballast aggregate to a uniform fit, ensuring a good interlocking between the crushed aggregates.

The environmental aspects of maintenance cannot be underestimated, with respect to cost-effective issues. The optimization of maintenance activity from technical, economic, and environmental standpoints requires the awareness that this is a critical activity in managing railway infrastructure assets. Maintenance management covers a wide range of themes [37]:

-

Maintenance policy: preventive maintenance, corrective maintenance, or improvement;

-

Maintenance operation: activities and equipment;

-

Degree of maintenance: perfect, imperfect, or minimal;

-

Decision-making level: strategical, tactical, or operational;

-

Maintenance planning: action intervention and prioritization, intervention timing, and inspection interval planning;

-

Maintenance scheduling: possession time of the track for maintenance, maintenance sequencing, vehicle routing, and crew scheduling.

Another important theme is related to the decision-making process. In this sense, track degradation modelling is the basis for estimating the appropriate time for condition-based maintenance interventions in railway track maintenance. The literature on this topic has been gathered and deeply analyzed. Track degradation behavior is affected by uncertainties about heterogeneous influencing factors, such as weather conditions, train axle loads, track-bed settlements, and construction materials [38].

2.3. Devices for Monitoring the State of the Track

Monitoring the state of the track is a core activity for implementing the correct maintenance strategies in terms of sites, time, and modes of interventions. Intervening on the track at the correct time and in the correct mode allows for an increase in its lifetime and, therefore, a reduction of the need for reconstruction/rehabilitation that results in significant environmental impacts.

Research carried out on the devices for monitoring showed that there are several devices that enable European railroad companies to perform track diagnostics to support maintenance activities. The main geometric parameters monitored are as follows: gauge, alignment, longitudinal level, transverse level, and twist. Various other parameters related to the track components can be monitored with manual devices (e.g., hand-driven trolley measuring systems) or with equipment mounted on the board of vehicles (e.g., track recording vehicles) [39]. The first type of inspection is labor-intensive, prone to human error, time-consuming, expensive for railroad companies, and also poses safety issues for maintenance staff.

These include:

-

RSMV, rolling stiffness measuring vehicle, is a technique used in Sweden that is based on measurements of track stiffness. It is used to identify areas where action is needed.

-

FWD, falling weight deflectometer, is a non-destructive test (NDT) used in the United Kingdom. The data obtained, after the test is carried out, allow the elastic modulus of the lower zone of the track to be calculated.

-

GPR, ground-penetrating radar, is a tool that allows for fast, non-destructive inspection to estimate the integrity of the railway substructure. It provides continuous measurements of the thicknesses of the layers of ballast, sub-ballast, and subgrade. The measurements are sensitive to water content and material density. It is also capable of distinguishing dirty ballast from clean ballast.

-

Acoustics, electromagnetics, and machine vision are NDTs for rail. Each of these tests has advantages and limitations. Acoustic tests, and particularly ultrasonic tests, and electromagnetic tests are suitable for detecting the internal defects of the rail but cannot accurately detect the surface damage; on the contrary, visual inspection is suitable for the detection of cracks, deformation, and corrosion on the rail surface but cannot detect internal damage. Combined NDT techniques allow personnel to overcome these limitations and reach a greater accuracy in defect detection [40].

-

The Archimede train is the most important diagnostic tool in Italy. It consists of a locomotive, four coaches, and a driving trailer. It can simultaneously measure 119 primary parameters and more than 200 derived parameters at 200 km/h. The on-board equipment comprises 57 computers, capable of globally processing data, which are designed to be able to withstand electromagnetic interference. An innovative positioning system enables the accurate localization of each measurement at a specific point on the network. This train, which has the ability to measure track, ride quality, overhead line, signaling, and telecommunications conditions, has made it possible to:

-

Make measurements that were not possible before its introduction (2003);

-

Carry out line monitoring without interruption;

-

Increase the frequency of visiting operations;

-

Carry out different measurements simultaneously;

-

Increase the maximum diagnostic speed from 160 to 200 km/h.

-

-

ETR500Y2 Dia.man.te (acronym for diagnostics, maintenance and technology) is an innovative train used in Italy to periodically monitor the conditions of the infrastructure, track, contact lines, signaling equipment, and telecommunications facilities of high-speed high-capacity railway lines. It consists of two driving trailers and height coaches, where 16 diagnostic systems, with 98 cameras and over 200 sensors, are installed on board. These are placed on the roof rail, in the underbody, and on the trolleys near the wheels, to monitor data and values aimed at analyzing the conditions of the railway infrastructure, such as, for example, the geometry and wear of the track, the interaction between the wheel and the rail, the quality of energy collection from the overhead power line, signaling, and telecommunications. The train is able to measure 500 parameters at 300 Km/h.

Furthermore, different types of sensors are used today [41][42][43][44]. The inclusion of sensors in railway track components permits the automated and real-time monitoring of track behavior and traffic conditions, which is necessary for adopting preventive maintenance strategies. Various types of accelerometer, piezoresistive, and piezoelectric sensors were evaluated, to determine their viability for smart rail pads. The piezoelectric sensor presented the highest implementation potential for this application, considering its low cost and clear ability to monitor variations in traffic and/or track state. Some of these sensors are as follows:

-

Fiber optic sensors: in the last two decades, a significant number of innovative sensing technologies, based on fiber optic sensors (FOS), have been utilized for structural health monitoring (SHM) due to their inherent distinctive advantages, such as their small size, light weight, immunity to electromagnetic interference (EMI) and corrosion, and embedding capability. Fiber optic-based monitoring systems use quasi-distributed and continuously distributed sensing techniques for the real-time measurement and long-term assessment of structural properties. This allows for early stage damage detection and characterization, leading to timely remediation and the prevention of catastrophic failure.

-

Force sensing resistors (FSR), or piezoelectric sheets, work by measuring voltage changes due to variations in the stress levels to which they are subjected.

2.4. Sustainablity Assessment Methods

2.4.1. Life Cycle Assessment

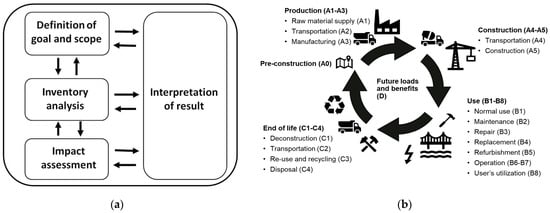

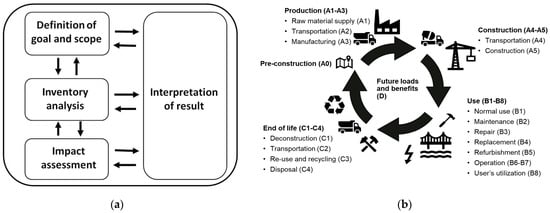

Life cycle assessment (LCA) is a methodology defined by ISO 14040, 2006 a, b [45][46], and applied to evaluate the environmental impacts of a product/material over its entire life cycle. A LCA aims to analyze the “environmental profile” of a rail infrastructure project or construction process, and it is a useful operational tool for integrating sustainability into project development and for measuring the environmental and energy loads. The LCA framework encompasses four stages: (i) goal and scope definition; (ii) life cycle inventory analysis (LCI); (iii) life cycle impact assessment (LCIA); and (iv) interpretation, as shown in Figure 2.

Figure 2. (a) The phases of the LCA, ISO 14040, 2006a; (b) schematic illustration of the life cycle stages of a civil engineering works project and their classification in modules, ISO 21931-2.

2.4.2. Circularity Metrics

Considering the quantity of the materials in the construction and maintenance of the rail track, one of the strategies for sustainability deals with reducing, reusing, and recycling materials and extending a product’s useful life through maintenance and repair. This is the concept of the circular economy (CE), intended in sensu stricto, and focusing on the technological cycle of resources and, therefore, on slowing (for the extended period of utilization) and closing (for the circular flow) resource loops [47][48]. There is another definition of CE, in sensu latu, which refers to a sustainable economic system where economic growth is decoupled from resource use. According to this broad concept, CE “is an economic model wherein planning, resourcing, procurement, production and reprocessing are designed and managed, as both process and output, to maximize ecosystem functioning and human well-being” [49][50]. The transition to a circular economy, as stated by the European Commission [51], “is a tremendous opportunity to transform our economy and make it more sustainable, contribute to climate goals and the preservation of the world’s resources, create local jobs and generate competitive advantages for Europe in a world that is undergoing profound changes”.

References

- Brundtland, G.; Khalid, M.; Agnelli, S.; Al-Athel, S.; Chidzero, B.; Fadika, L.; Singh, M. Our Common Future ‘Brundt-Land Report’; Oxford University Press: Oxford, UK, 1987.

- European Commission. Adapting Infrastructures to Climate Change; The European Commission: Brussels, Belgium, 2013.

- Ritchie, H. Cars, Planes, Trains: Where Do CO2 Emissions from Transport Come from? 2020. Available online: https://ourworldindata.org/co2-emissions-from-transport (accessed on 26 October 2023).

- Lawrence, M.; Bullock, R. The Role of Rail in Decarbonizing Transport in Developing Countries; Mobility and Transport Connectivity Series; World Bank: Washington, DC, USA, 2022; Available online: http://hdl.handle.net/10986/38214 (accessed on 26 October 2023).

- Bressi, S.; Santos, J.; Giunta, M.; Pistonesi, L.; Lo Presti, D. A comparative life cycle assessment of asphalt mixtures for railway sub-ballast containing alternative materials. Resour. Conserv. Recycl. 2018, 137, 76–88.

- Olugbenga, O.; Kalyviotis, N.; Shoshanna Saxe, S. Embodied emissions in rail infrastructure: A critical literature review. Environ. Res. Lett. 2019, 14, 123002.

- Milewicz, J.; Mokrzan, D.; Szymanski, G.M. Environmental Impact Evaluation as a Key Element in Ensuring Sustainable Development of Rail Transport. Sustainability 2023, 15, 13754.

- Guo, Y.; Xie, J.; Fan, Z.; Markine, V.; Connolly, D.P.; Jing, G. Railway ballast material selection and evaluation: A review. Constr. Build. Mater. 2022, 344, 128218.

- Marschnig, S.; Veit, P. Assessing Average Maintenance Frequencies and Service Lives of Railway Tracks: The Standard Element Approach. In New Research on Railway Engineering and Transport; IntechOpen: Rijeka, Croatia, 2023.

- Nalsund, R. Railway Ballast Characteristics, Selection Criterion and Performance. Ph.D. Thesis, Norwegian University of Science and Technology, Department of Civil and Transport Engineering, Trondheim, Norway, 2014.

- Indraratna, B. 1st Proctor Lecture of ISSMGE: Railroad performance with special reference to ballast and substructure characteristics. Transp. Geotech. 2016, 7, 74–114.

- Alabbasi, Y.; Hussein, M. Large-scale triaxial and box testing on railroad ballast: A review. SN Appl. Sci. 2019, 1, 1592.

- Guimaraes Delgado, B.; Viana da Fonseca, A.; Fortunato, E.; Maia, P. Mechanical behavior of inert steel slag ballast for heavy haul rail track: Laboratory evaluation. Transp. Geotech. 2019, 20, 100243.

- Hussain, A.; Hussaini, S.K.K. Use of steel slag as railway ballast: A review. Transp. Geotech. 2022, 35, 100779.

- Jing, G.; Wang, J.; Wang, H.; Siahkouhi, M. Numerical investigation of the behavior of stone ballast mixed by steel slag in ballasted railway track. Constr. Build. Mater. 2020, 262, 120015.

- Mehran Khoshoei, S.; Mortazavi Bak, H.; Mahdi Abtahi, S.; Mahdi Hejazi, S.; Shahbodagh, B. Experimental Investigation of the Cyclic Behavior of Steel-Slag Ballast Mixed with Tire-Derived Aggregate. J. Mater. Civ. Eng. 2021, 33, 04020468.

- Sol-Sanchez, M.; Thom, N.H.; Moreno-Navarro, F.; Rubio-Gamez, M.C.; Airey, G.D. A study into the use of crumb rubber in railway ballast. Constr. Build. Mater. 2015, 75, 19–24.

- Fathali, M.; Nejad, F.M.; Esmaeili, M. Influence of Tire-Derived Aggregates on the Properties of Railway Ballast Material. J. Mater. Civ. Eng. 2017, 29, 04016177.

- Ajayi, O.; Le Pen, L.; Zervos, A.; Powrie, V. Feasibility Study of Random Fibre Reinforced Railway Ballast. In Proceedings of the 23rd European Young Geotechnical Engineers Conference, Barcelona, Spain, 2–5 September 2014.

- Jing, G.; Qie, L.; Markine, V.L.; Jia, W. Polyurethane reinforced ballasted track: Review, innovation and challenge. Constr. Build. Mater. 2019, 208, 734–774.

- D’Angelo, G.; Bressi, S.; Giunta, M.; Presti, D.; Thom, N. Novel performance-based technique for predicting maintenance strategy of bitumen stabilised ballast. Constr. Build. Mater. 2018, 161, 1–8.

- Sweta, K.; Hussaini, S.K.K. Effect of geogrid on deformation response and resilient modulus of railroad ballast under cyclic loading. Constr. Build. Mater. 2020, 264, 120690.

- Leonardi, G. Analysis of railway tracks reinforced with geogrids. ARPN J. Eng. Appl. Sci. 2021, 16, 2722–2728.

- Sol-Sanchez, M.; D’Angelo, G. Review of the design and maintenance technologies used to decelerate the deterioration of ballasted railway tracks. Constr. Build. Mater. 2017, 157, 402–415.

- Banerjee, L.; Chawla, S.; Kumar Dash, S. Application of geocell reinforced coal mine overburden waste as subballast in railway tracks on weak subgrade. Constr. Build. Mater. 2020, 265, 120774.

- Indraratna, B.; Qi, Y.; Sai Malisetty, R.; Navaratnarajah, S.K.; Fatima Mehmood, F.; Tawk Rail, M. Recycled materials in railroad substructure: An energy perspective. Rail. Eng. Sci. 2022, 30, 304–322.

- Ferdous, W.; Manalo, A.; Van Erp, G.; Aravinthan, T.; Kaewunruen, S.; Remennikov, A. Composite railway sleepers—Recent developments, challenges and future prospects. Compos. Struct. 2015, 134, 158–168.

- Mansouri, P.; Zakeri, J.-A.; Esmaeili, M.; Ghahremani, S. Discrete element method analysis of lateral resistance of different sleepers under different support conditions. Constr. Build. Mater. 2022, 327, 126915.

- Babachenko, O.I.; Kononenko, H.A.; Podolskyi, R.V.; Safronova, O.A. Steel for railroad rails with improved operating properties. Mater. Sci. 2021, 56, 814–819.

- Tuzik, J. Steel Hardness and Wear at the Wheel/Rail Interface: Perception vs Reality. Interface J. Wheel/Rail Interact. 2023. Available online: https://interfacejournal.com/archives/21462 (accessed on 30 October 2023).

- International Union of Railway. UIC SUSTAINABILITY Circular Practices in the Railway and Ways Forward REUSE Project Final Report 2021. Available online: https://uic.org/IMG/pdf/reuse_project_final_report.pdf (accessed on 31 October 2023).

- Sol-Sanchez, M.; Moreno-Navarro, F.; Rubio-Gamez, M.C. The use of deconstructed tire rail pads in railroad tracks: Impact of pad thickness. Mater. Des. 2014, 58, 198–203.

- Castillo-Mingorance, J.M.; Sol-Sanchez, M.; Mattinzioli, T.; Moreno-Navarro, F.; Rubio-Gamez, M.C. Development of rail pads from recycled polymers for ballasted railway tracks. Constr. Build. Mater. 2022, 337, 127479.

- Kraskiewicz, C.; Zbiciak, A.; Pełczynski, J.; Al Sabouni-Zawadzka, A. Experimental and numerical testing of prototypical under ballast mats (UBMs) produced from deconstructed tires—The effect of mat thickness. Constr. Build. Mater. 2023, 369, 130559.

- Giunta, M.; Praticò, F.G. Design and maintenance of high-speed rail tracks: A comparison between ballasted and ballast-less solutions based on Life Cycle Cost Analysis. In Proceedings of the International Congress on Transport Infrastructure and System, Rome, Italy, 10–12 April 2017.

- Italferr. LCA Life Cycle Assessment, Line Guida per la Valutazione LCA di Infrastrutture Ferroviarie; Italferr: Rome, Italy, 2019.

- Sedghi, M.; Kauppila, O.; Bergquista, B.; Vanhataloa, E.; Kulahcia, M. A taxonomy of railway track maintenance planning and scheduling: A review and research trends. Reliab. Eng. Syst. Saf. 2021, 215, 107827.

- Bressi, S.; Santos, J.; Losa, M. Optimization of maintenance strategies for railway track-bed considering probabilistic degradation models and different reliability levels. Reliab. Eng. Syst. Saf. 2021, 207, 107359.

- Kostrzewski, M.; Melnik, R. Condition Monitoring of Rail Transport Systems: A Bibliometric Performance Analysis and Systematic Literature Review. Sensors 2021, 21, 4710.

- Gong, W.; Akbar, M.F.; Jawad, G.N.; Mohamed, M.F.P.; Wahab, M.N.A. Nondestructive Testing Technologies for Rail Inspection: A Review. Coatings 2022, 12, 1790.

- Du, C.; Dutta, S.; Kurup, P.; Yu, T.; Wang, X. A review of railway infrastructure monitoring using fiber optic sensors. Sens. Actuators A 2020, 303, 111728.

- Sol-Sanchez, M.; Castillo-Mingorance, J.M.; Moreno-Navarro, F.; Rubio-Gamez, M.C. Smart rail pads for the continuous monitoring of sensored railway tracks: Sensors analysis. Autom. Constr. 2021, 132, 103950.

- Sol-Sanchez, M.; Castillo-Mingorance, J.M.; Moreno-Navarro, F.; Mattinzioli, T.; Rubio-Gamez, M.C. Piezoelectric-sensored sustainable pads for smart railway traffic and track state monitoring: Full-scale laboratory tests. Constr. Build. Mater. 2021, 301, 124324.

- Antognoli, M.; Marinacci, C.; Ricci, S.; Rizzetto, L. Requirement specifications for track measuring and monitoring systems. Ing. Ferrov. 2020, 11, 841–864.

- ISO 14040; Environmental Management—Life-Cycle Assessment—Principles and Framework. International Organization for Standardization: Geneva, Switzerland, 2006.

- ISO 14044; Environmental Management—Life-Cycle Assessment—Requirements and Guidelines. International Organization for Standardization: Geneva, Switzerland, 2006.

- Bocken, N.M.P.; de Pauw, I.; Bakker, C.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320.

- Moraga, G.; Huysveld, S.; Mathieux, F.; Blengini, G.A.; Alaerts, L.; Van Acker, K.; de Meester, S.; Dewulf, J. Circular economy indicators: What do they measure? Resour. Conserv. Recycl. 2019, 146, 452–461.

- Murray, A.; Skene, K.; Haynes, K. The circular economy: An interdisciplinary exploration of the concept and application in a global context. J. Bus. Ethics 2017, 140, 369–380.

- Corona, B.; Shen, L.; Reike, D.; Rosales Carreón, J.; Worrell, E. Towards sustainable development through the circular economy—A review and critical assessment on current circularity metrics. Resour. Conserv. Recycl. 2019, 151, 104498.

- European Commission. A Monitoring Framework for the Circular Economy, Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions; European Commission: Brussels, Belgium, 2018.

More

Information

Subjects:

Engineering, Civil

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

661

Revisions:

2 times

(View History)

Update Date:

18 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No