Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Konstantinos Tserpes | -- | 2555 | 2023-12-15 11:44:57 | | | |

| 2 | Wendy Huang | Meta information modification | 2555 | 2023-12-15 12:42:57 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Vogiantzi, C.; Tserpes, K. Enhancement of Circular Economy. Encyclopedia. Available online: https://encyclopedia.pub/entry/52807 (accessed on 14 January 2026).

Vogiantzi C, Tserpes K. Enhancement of Circular Economy. Encyclopedia. Available at: https://encyclopedia.pub/entry/52807. Accessed January 14, 2026.

Vogiantzi, Christina, Konstantinos Tserpes. "Enhancement of Circular Economy" Encyclopedia, https://encyclopedia.pub/entry/52807 (accessed January 14, 2026).

Vogiantzi, C., & Tserpes, K. (2023, December 15). Enhancement of Circular Economy. In Encyclopedia. https://encyclopedia.pub/entry/52807

Vogiantzi, Christina and Konstantinos Tserpes. "Enhancement of Circular Economy." Encyclopedia. Web. 15 December, 2023.

Copy Citation

Circular Economy (CE) is an approach and a series of processes aimed at minimizing material usage in production and consumption, enhancing material resilience, closing loops, and fostering sustainable exchanges to maximize ecological system benefits. Within a circular economy, the value of products and materials is preserved, waste is avoided, and resources are retained within the economic system once a product’s lifecycle concludes.

circular economy

Internet of Things (IoT)

Big Data Analytics (BDA)

artificial intelligence (AI)

blockchain

1. Introduction

Integrating technologies into the industrial landscape embodies the five major facets of the Fourth Industrial Revolution: digitalization, automation, human-machine interaction, value-added services and businesses, and automatic data exchange and communication. This interconnection among various systems and assets leads to several advantages over traditional CE models. These benefits include increased efficiency and resource utilization, reduced waste through enhanced traceability and optimized waste management, and extended product and equipment lifespans, ultimately contributing to more sustainable CE practices. This transition to digitalized CBMs empowers managers to align their goals with CE principles and utilize Industry 4.0 technologies to support their strategies effectively [1]. However, achieving sustainable benefits from digitalization requires innovative business models, particularly advanced service-based models [2]. In addition, ICT (Information and Communication) solutions help the transition to a circular economy. Some solutions, such as cloud manufacturing and big data, were identified as particularly crucial for supporting the principles of circularity [3].

Furthermore, resource accounting, supported by digital systems, is expected to be a key factor in achieving a circular economy. It enables continuous monitoring of resources, data-driven decisions about their lifecycle, and minimizing waste through informed choices. While waste management is vital, a CE goes beyond recycling, and waste management companies are expanding their roles upstream into business markets to prevent resources from becoming waste in the first place [4]. Moreover, Gatenholm et al. [5] explored logistical flows and trade-offs in aftermarket supply chains to enhance circularity by slowing down resource flows. It identified trade-offs in the aftermarket involving material, people, information, and knowledge, highlighting the need to extend the traditional view of logistics to include the flow of knowledge and people. Their study emphasized the importance of “slowing” as a favorable condition to improve circularity, challenging the conventional notion of time in logistics. Additionally, it provided insights for professionals and policymakers to develop environmentally sustainable aftermarket services that prioritize knowledge and customer co-creation, ultimately contributing to circular economy goals. Future research could delve into logistics gap analysis, expand the scope to complete service offerings, and explore the role of different actors in providing logistics services in the aftermarket. Last but not least, various concepts like Material Passports have emerged, enabling the digital registration of data sets describing an object’s characteristics, location, history, and ownership status. These passports are implemented and are often leveraging digital platforms to facilitate data management and circular economy practices [6].

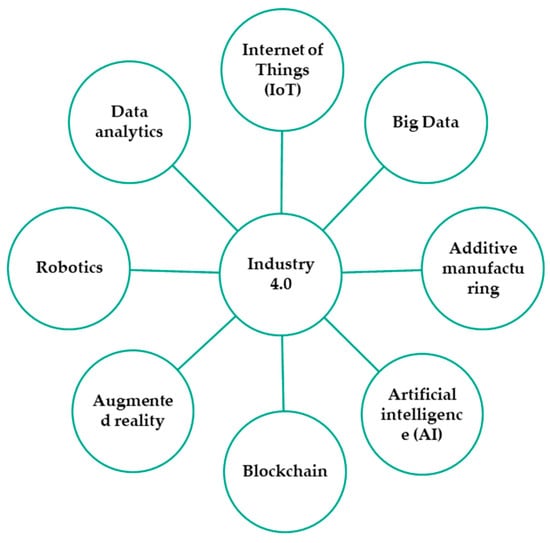

Digitalization has the potential to significantly advance the shift towards a sustainable circular economy [7]. It contributes by providing accurate data on product availability, location, and condition, thereby facilitating the closure of material loops. Additionally, digitalization streamlines processes within companies, reducing waste, extending product lifespans, and cutting transaction costs. This support from digitalization enhances CBMs by aiding loop closure, slowing the material loop, and improving resource efficiency [8]. There is a unidirectional connection, with Industry 4.0 driving circularity and a bidirectional relationship, signifying mutual benefits between these concepts. CE’s significant domains within Industry 4.0 involve recycling and reusing strategies in smart production and sustainable supply chains. The research emphasizes the relevance of applying these concepts at the company (micro) and industry (meso) levels [9]. Organizations should consider exploring emerging digital technologies to enhance their transition efforts sustainability and leverage available data across the product life cycle [10]. Many publications support the adoption of these technologies [11][12][13][14][15][16][17][18][19]. The manufacturing and consumption landscape is undergoing significant transformation due to the rise of emerging digital technologies such as the Internet of Things (IoT), big data analytics (BDA), artificial intelligence (AI) etc., as detailed in Figure 1 [20]. With these technologies, devices can seamlessly interact with each other and online services, enabling a range of goals such as automated manufacturing, smart homes and efficient waste management [21][22][23].

Figure 1. Main emerging digital technologies of Industry 4.0.

In the usage phase, digital tools (DTs), particularly IoT, transform products into “smart” entities, promoting resource efficiency and extending product lifespans by monitoring and optimizing usage. In the end-of-life stage, DTs assist in closing the loop through efficient recycling and second-life utilization, emphasizing the interconnectedness of design, end-of-life activities and end-of-life decision-making process [24][25]. The possibility of using digital technologies to help shift how products are made and used towards a circular economy is becoming more popular. This could be a helpful way to overcome the challenges of transitioning to a circular economy [26]. The application of these digital tools holds the key to overcoming barriers, facilitating resource-efficient smart factories, enhancing workforce productivity and promoting closed-loop manufacturing processes [27]. In addition, these technology-based systems enable knowledge creation, improved experiences, resource accessibility, sustainability, and data-centric decision-making, all contributing to the advancement of circular entrepreneurship [28]. These digital technologies also play a vital role in implementing advanced Circular Economy and Industrial Symbiosis solutions by enabling efficient monitoring of resource and energy flows and supporting human decision-making [29]. By incorporating responsive design techniques and digital tools, the design process can become more efficient and aligned with circular principles. Digital technology can optimize design decisions, enable circular concepts like disassembly, and facilitate efficient maintenance, thereby reducing waste [30]. Nevertheless, there is a recommendation for assessing technology implementation approaches, considering factors like ease of implementation, cost, localization, data privacy, and ethical AI use on public data [31]. Finally, the successful implementation of CE principles depends on engaging various stakeholders, including governments, international institutions, and companies, to transition toward more sustainable and digitalized processes in supply chains [32].

For instance, Bag and Pretorius [33] proposed an integrative research framework that outlines key pathways for adoption. This framework highlights the significance of Industry 4.0 technology adoption, particularly big data analytics-powered artificial intelligence, in enhancing sustainable manufacturing practices and circular economy capabilities. Islam et al. [34] and Bressanelli et al. [35] explored the role of IoT, Big Data, and analytics in facilitating the transition toward a CE through usage-focused Business Models (BMs). It identifies eight key functionalities enabled by these digital technologies that align with the three fundamental CE value drivers: resource efficiency improvement, product lifespan extension, and closing the loop. The study emphasized the importance of coupling IoT with Big Data and analytics. It highlighted that while IoT is instrumental in tracking product usage and preventing premature wear, functions related to the product’s lifecycle stages are critical for achieving CE, particularly in extending product lifespan and closing the loop. In addition, the home appliance industry, the textile and clothing industry and the food supply chain present a promising opportunity for the adoption of Industry 4.0 technologies such as the Internet of Things (IoT), Big Data, Blockchain and the Cloud in facilitating serviceable business models within the context of the CE [35][36][37][38][39]. More specifically, combining IoT, machine learning, robotics, transportation management systems, and 3D printing can enhance the link between technology and sustainable practices while improving business performance in Circular Supply Chains [10][40][41]. Agrawal et al. [42] investigated the transition in supply chains from a linear economy to CE and eventually to a net-zero economy (NZE). It identifies 19 key drivers, such as high automation, manufacturing process flexibility, and real-time sensing, through DEMATEL analysis. In addition, Magrini et al. [43] and Joshi et al. [44] focused on the utilization of the Internet of Things (IoT) and Blockchain, using the case study of Electrical and Electronic Equipment (EEE). IoT and blockchain can enable producers to maintain control over products until their end-of-life, promoting circular strategies and aiding decision-making. Liu et al. [45] investigated the role of DTs in advancing CE strategies through a systematic literature review. The findings highlight 13 key digital functions categorized into three groups, along with their mechanisms, resulting in a proposed Digital Function for Circular Economy (DF4CE) framework. The research contributes theoretical understanding, practical insights for collaboration and data security, managerial implications for DT implementation, and outlines avenues for future research, acknowledging the need for wider technology inclusion and validation in subsequent studies, including a focus on specific digital tools like IoT, BDA, and AI, while overlooking other technologies that could offer insights for Circular Economy strategies. Additionally, the literature review did not adequately address the potential energy-related implications of digitalization.

2. Internet of Things (IoT)

The officially recognized definition of the Internet of Things (IoT) was provided by the International Telecommunication Union (ITU) as follows: “Internet of Things is defined as a global infrastructure for the information society, which activates advanced services, connecting physical and digital components, based on existing and evolving interoperable information and communication technologies” [46]. The combination of Artificial Intelligence (AI) and the Internet of Things (IoT) presents great prospects for the circular economy. This collaboration enables a manufacturing model with reduced costs, enhanced efficiency, and individualized production. For instance, IoT’s incorporation of low-cost sensors into reusable products facilitates efficient asset management and recycling in the circular economy. The link between CE principles and IoT strengthens efficiency, enabling institutions to achieve profitability and conservation goals through data analysis and AI. IoT’s monitoring of manufacturing and product lifecycles enhances the efficiency of the entire value chain. Moreover, IoT-driven leasing models can transition conventional value chains toward circular economy practices, emphasizing asset durability and reducing waste. The potential of digital transformation and big data to support circular economy models underscores the transformative impact of IoT in promoting sustainability [47].

Voulgaridis et al. [48] explored the relationship between IoT technologies and Digital CE principles through a review of academic papers. It investigates the application fields, architectural models, and features of IoT technologies, as well as the integration of Digital CE concepts. The findings indicate a connection between Digital CE and IoT within the context of Industry 4.0, with a focus on lifecycle and use-cycle monitoring. Ingemarsdotter et al. [49] used a two-step approach to analyze how companies implement IoT for circular strategies compared to expected opportunities. Akbari and Hopkins [50] proved through a survey of 223 supply chain experts that a relatively low adoption rate of I4.0 technologies, with the Internet of Things (IoT) being the most prevalent. Kazancoglu et al. [51] investigated the significance of IoT-enabled technologies in enhancing supply chain visibility, particularly in food supply chains. The application of IoT technologies aids in the collection and analysis of data in real time, enabling quicker decision-making and minimizing food waste within the supply chain. Garcia-Muiña et al. [52] noticed that the ready access to production data facilitated by IoT technologies has combined with the Canvas Business Model to enable the re-evaluation of the existing linear business model. The integration of concepts such as environmental conservation, social advancement, and economic robustness has led to the creation of a new business model. The fusion of eco-design prediction and real-time digital assessment transforms sustainability analysis into dynamic corporate social responsibility strategies, encouraging long-term managerial perspectives and facilitating the application of circular economy principles by reshaping business models and value creation processes. Chau et al. [53] underscored the significant impact of IoT, emphasizing the need for both policymakers and businesses to adopt this technology for real-time control and optimization of end-of-life product lifecycles. In order to fully utilize the potential of IoT, it is essential to increase the automation of manual remanufacturing procedures. Creating strong and unified laws that align with the trends of Industry 4.0 is crucial for the growth of developing nations. Particularly in significant fields, it becomes crucial when they aim to enact measures to enhance their domestic industries.

3. Big Data Analytics

Big Data Analytics (BDA) holds transformative potential for effective decision-making within organizations, offering significant implications for driving and supporting CE efforts [54][55]. BDA is seen as a vital facilitator for obtaining decision-making information in the CE context, with collaborative relationships with stakeholders enhancing access to relevant data. Gupta et al. [56] proposed a model linking CE and BDA, emphasizing proactive management of the entire system through collective stakeholder engagement, suggesting implications for researchers and practitioners in these fields. They also offer a theoretical foundation for future empirical research in this field. Combining CE principles, network-oriented thinking, and digitalization can provide a significant competitive advantage in business facilitated by digitalization and big data technologies. Salminen et al. [57] presented a conceptual tool for responsible business leadership, utilizing Evolute, an intelligent web-based system, to analyze co-evolution throughout the lifecycle of a business’s transition to a circular economy. Giudice et al. [58] contributed significantly by empirically confirming the positive impact of circular economy practices, including design, relationship management, and HR management, on firm performance. They also underscored the vital role of a big data-driven supply chain, particularly in enhancing HR management, leading to overall improved firm performance.

4. Artificial Intelligence

Artificial intelligence (AI) includes a range of technologies focused on mimicking human cognitive functions like learning and reasoning [59]. By utilizing data from diverse sources such as videos, images, audio, text, and numerical data, AI aids in problem-solving through tasks like pattern recognition, prediction, optimization, and generating recommendations. AI holds the potential to facilitate and accelerate the transition towards a circular economy. Ellen MacArthur Foundation demonstrated that AI can be effectively leveraged across three pivotal domains of the CE: designing circular materials, products and components, operationalizing CBMs and optimizing infrastructures for seamless circular product and material flows. While the global economic prospects of AI are projected at USD 13 trillion by 2030, its substantial application in the circular economy remains largely underexplored [60].

In particular, AI is becoming essential for achieving data-driven circular product design, minimizing biases in testing and prototyping, and enhancing overall efficiency. Ghoreishi and Happonen [61] identified key circular design tools and strategies that enhance product design while highlighting how AI contributes to circularity by facilitating real-time data analysis, reducing time and energy consumption, enabling rapid prototyping, and supporting effective material and product management, maintenance, and reuse. Awan et al. [62] discussed the integration of AI and big data analytics in supply chain management. They highlighted the need for research to identify the most suitable AI and data analytics approaches, underscoring the importance of informed decision-making and its potential for enhancing performance in the circular economy and sustainability.

5. Blockchain

Blockchain technology involves a shared database (distribution of information) that continuously records transactions and their chronological sequence. It functions as a decentralized ledger containing digital transactions, data records, and executables shared among participants [63].

Juszczyk and Shahzad [64] investigated the impact of blockchain technology on promoting a CE. Significant effects were observed in sectors like spare parts management, where real-time quality, repair, and reuse status data were enhanced. Additionally, blockchain improved transparency in the manufacturing stage and verified ethical work practices. Furthermore, blockchain’s capacity to provide impartial and auditable data about energy sources validated whether energy sold to customers originated from renewable sources. Rehman Khan et al. [65] emphasized that blockchain positively impacts the circular economy, subsequently benefiting green supply chain activities like recycling, remanufacturing, green design, and green manufacturing. In addition, highlights the capability of blockchain to enhance transparency, security, and effectiveness in supply chains while promoting the integration of circular economy strategies for enduring sustainability and economic advantages. Teisserenc and Sepasgozar [16] proposed a conceptual model for integrating blockchain technology and digital twin(s) (DT) in the building, engineering, construction, operations, and mining (BECOM) industry. This model aims to enhance trust, security, efficiency, and transparency by addressing key challenges such as fragmented data and lack of trust in the industry.

References

- Rossi, J.; Bianchini, A.; Guarnieri, P. Circular Economy Model Enhanced by Intelligent Assets from Industry 4.0: The Proposition of an Innovative Tool to Analyze Case Studies. Sustainability 2020, 12, 7147.

- Parida, V.; Sjödin, D.; Reim, W. Reviewing Literature on Digitalization, Business Model Innovation, and Sustainable Industry: Past Achievements and Future Promises. Sustainability 2019, 11, 391.

- Demestichas, K.; Daskalakis, E. Information and Communication Technology Solutions for the Circular Economy. Sustainability 2020, 12, 7272.

- Jørgensen, S.; Pedersen, L.J.T.; Skard, S. Resource Accounting for a Circular Economy: Evidence from a Digitalised Waste Management System. In Accounting Forum; Routledge: Oxfordshire, UK, 2023; pp. 1–30.

- Gatenholm, G.; Halldórsson, Á.; Bäckstrand, J. Enhanced Circularity in Aftermarkets: Logistics Tradeoffs. Int. J. Phys. Distrib. Logist. Manag. 2021, 51, 999–1021.

- Çetin, S.; De Wolf, C.; Bocken, N. Circular Digital Built Environment: An Emerging Framework. Sustainability 2021, 13, 6348.

- Tseng, M.-L.; Tran, T.P.T.; Ha, H.M.; Bui, T.-D.; Lim, M.K. Sustainable Industrial and Operation Engineering Trends and Challenges Toward Industry 4.0: A Data Driven Analysis. J. Ind. Prod. Eng. 2021, 38, 581–598.

- Antikainen, M.; Uusitalo, T.; Kivikytö-Reponen, P. Digitalisation as an Enabler of Circular Economy. Procedia CIRP 2018, 73, 45–49.

- Ćwiklicki, M.; Wojnarowska, M. Circular Economy and Industry 4.0: One-Way or Two-Way Relationships? Eng. Econ. 2020, 31, 387–397.

- Khan, S.A.R.; Shah, A.S.A.; Yu, Z.; Tanveer, M. A Systematic Literature Review on Circular Economy Practices: Challenges, Opportunities and Future Trends. J. Entrep. Emerg. Econ. 2022, 14, 754–795.

- Hoosain, M.S.; Paul, B.S.; Ramakrishna, S. The Impact of 4IR Digital Technologies and Circular Thinking on the United Nations Sustainable Development Goals. Sustainability 2020, 12, 10143.

- Rosário, A.; Dias, J. Sustainability and the Digital Transition: A Literature Review. Sustainability 2022, 14, 4072.

- Nandi, S.; Hervani, A.A.; Helms, M.M.; Sarkis, J. Conceptualising Circular Economy Performance with Non-Traditional Valuation Methods: Lessons for a Post-Pandemic Recovery. Int. J. Logist. Res. Appl. 2023, 26, 662–682.

- Elghaish, F.; Matarneh, S.T.; Edwards, D.J.; Pour Rahimian, F.; El-Gohary, H.; Ejohwomu, O. Applications of Industry 4.0 Digital Technologies towards a Construction Circular Economy: Gap Analysis and Conceptual Framework. Constr. Innov. 2022, 22, 647–670.

- Tavana, M.; Shaabani, A.; Raeesi Vanani, I.; Kumar Gangadhari, R. A Review of Digital Transformation on Supply Chain Process Management Using Text Mining. Processes 2022, 10, 842.

- Teisserenc, B.; Sepasgozar, S. Adoption of Blockchain Technology through Digital Twins in the Construction Industry 4.0: A PESTELS Approach. Buildings 2021, 11, 670.

- De Felice, F.; Petrillo, A. Green Transition: The Frontier of the Digicircular Economy Evidenced from a Systematic Literature Review. Sustainability 2021, 13, 11068.

- Rusch, M.; Schöggl, J.; Baumgartner, R.J. Application of Digital Technologies for Sustainable Product Management in a Circular Economy: A Review. Bus. Strat. Environ. 2023, 32, 1159–1174.

- Cagno, E.; Neri, A.; Negri, M.; Bassani, C.A.; Lampertico, T. The Role of Digital Technologies in Operationalizing the Circular Economy Transition: A Systematic Literature Review. Appl. Sci. 2021, 11, 3328.

- Lasi, H.; Fettke, P.; Kemper, H.-G.; Feld, T.; Hoffmann, M. Industry 4.0. Bus. Inf. Syst. Eng. 2014, 6, 239–242.

- Whitmore, A.; Agarwal, A.; Da Xu, L. The Internet of Things—A Survey of Topics and Trends. Inf. Syst. Front. 2015, 17, 261–274.

- Talamo, C.; Pinto, M.R.; Viola, S.; Atta, N. Smart Cities and Enabling Technologies: Influences on Urban Facility Management Services. IOP Conf. Ser. Earth Environ. Sci. 2019, 296, 012047.

- Baiardi, L.; Ciaramella, A.; Bellintani, S. A Development and Management Model for “Smart” Temporary Residences. In Regeneration of the Built Environment from a Circular Economy Perspective; Della Torre, S., Cattaneo, S., Lenzi, C., Zanelli, A., Eds.; Research for Development; Springer International Publishing: Cham, Switzerland, 2020; pp. 337–346. ISBN 978-3-030-33255-6.

- Han, Y.; Shevchenko, T.; Yannou, B.; Ranjbari, M.; Shams Esfandabadi, Z.; Saidani, M.; Bouillass, G.; Bliumska-Danko, K.; Li, G. Exploring How Digital Technologies Enable a Circular Economy of Products. Sustainability 2023, 15, 2067.

- Abruzzini, A.; Abrishami, S. Integration of BIM and Advanced Digital Technologies to the End of Life Decision-Making Process: A Paradigm of Future Opportunities. J. Eng. Des. Technol. 2022, 20, 388–413.

- World Economic Forum and Ellen MacArthur Foundation, Intelligent Assets: Unlocking the Circular Economy Potential, 2016. Available online: https://www.ellenmacarthurfoundation.org/intelligent-assets-unlocking-the-circular-economy-potential (accessed on 5 August 2023).

- Stock, T.; Seliger, G. Opportunities of Sustainable Manufacturing in Industry 4.0. Procedia CIRP 2016, 40, 536–541.

- Saura, J.R.; Ribeiro-Soriano, D.; Palacios-Marqués, D. Adopting Digital Reservation Systems to Enable Circular Economy in Entrepreneurship. Manag. Decis. 2022.

- Colla, V.; Pietrosanti, C.; Malfa, E.; Peters, K. Environment 4.0: How Digitalization and Machine Learning Can Improve the Environmental Footprint of the Steel Production Processes. Matériaux Tech. 2020, 108, 507.

- Talla, A.; McIlwaine, S. Industry 4.0 and the Circular Economy: Using Design-Stage Digital Technology to Reduce Construction Waste. Smart Sustain. Built Environ. 2022.

- Choudhuri, B.; Srivastava, P.R.; Mangla, S.K.; Kazancoglu, Y. Enterprise Architecture as a Responsible Data Driven Urban Digitization Framework: Enabling Circular Cities in India. Ann. Oper. Res. 2023, 1–29.

- Ciliberto, C.; Szopik-Depczyńska, K.; Tarczyńska-Łuniewska, M.; Ruggieri, A.; Ioppolo, G. Enabling the Circular Economy Transition: A Sustainable Lean Manufacturing Recipe for Industry 4.0. Bus. Strat. Environ. 2021, 30, 3255–3272.

- Bag, S.; Pretorius, J.H.C. Relationships between Industry 4.0, Sustainable Manufacturing and Circular Economy: Proposal of a Research Framework. Int. J. Organ. Anal. 2022, 30, 864–898.

- Islam, M.T.; Iyer-Raniga, U.; Trewick, S. Recycling Perspectives of Circular Business Models: A Review. Recycling 2022, 7, 79.

- Bressanelli, G.; Saccani, N.; Perona, M.; Baccanelli, I. Towards Circular Economy in the Household Appliance Industry: An Overview of Cases. Resources 2020, 9, 128.

- Alves, L.; Ferreira Cruz, E.; Lopes, S.I.; Faria, P.M.; Rosado Da Cruz, A.M. Towards Circular Economy in the Textiles and Clothing Value Chain through Blockchain Technology and IoT: A Review. Waste Manag. Res. 2022, 40, 3–23.

- Rejeb, A.; Rejeb, K.; Abdollahi, A.; Zailani, S.; Iranmanesh, M.; Ghobakhloo, M. Digitalization in Food Supply Chains: A Bibliometric Review and Key-Route Main Path Analysis. Sustainability 2021, 14, 83.

- Huynh, P.H. Enabling Circular Business Models in the Fashion Industry: The Role of Digital Innovation. Int. J. Product. Perform. Manag. 2022, 71, 870–895.

- Akram, S.V.; Malik, P.K.; Singh, R.; Gehlot, A.; Juyal, A.; Ghafoor, K.Z.; Shrestha, S. Implementation of Digitalized Technologies for Fashion Industry 4.0: Opportunities and Challenges. Sci. Program. 2022, 2022, 7523246.

- Romagnoli, S.; Tarabu’, C.; Maleki Vishkaei, B.; De Giovanni, P. The Impact of Digital Technologies and Sustainable Practices on Circular Supply Chain Management. Logistics 2023, 7, 1.

- Hettiarachchi, B.D.; Seuring, S.; Brandenburg, M. Industry 4.0-Driven Operations and Supply Chains for the Circular Economy: A Bibliometric Analysis. Oper. Manag. Res. 2022, 15, 858–878.

- Agrawal, R.; Priyadarshinee, P.; Kumar, A.; Luthra, S.; Garza-Reyes, J.A.; Kadyan, S. Are Emerging Technologies Unlocking the Potential of Sustainable Practices in the Context of a Net-Zero Economy? An Analysis of Driving Forces. Environ. Sci. Pollut. Res. 2023, 1–19.

- Magrini, C.; Nicolas, J.; Berg, H.; Bellini, A.; Paolini, E.; Vincenti, N.; Campadello, L.; Bonoli, A. Using Internet of Things and Distributed Ledger Technology for Digital Circular Economy Enablement: The Case of Electronic Equipment. Sustainability 2021, 13, 4982.

- Joshi, S.; Sharma, M.; Barve, A. Implementation Challenges of Blockchain Technology in Closed-Loop Supply Chain: A Waste Electrical and Electronic Equipment (WEEE) Management Perspective in Developing Countries. Supply Chain. Forum Int. J. 2023, 24, 59–80.

- Liu, Q.; Trevisan, A.H.; Yang, M.; Mascarenhas, J. A Framework of Digital Technologies for the Circular Economy: Digital Functions and Mechanisms. Bus. Strat. Environ. 2022, 31, 2171–2192.

- Y.2060: Overview of the Internet of Things. Available online: https://www.itu.int/rec/T-REC-Y.2060-201206-I (accessed on 28 August 2023).

- Ramadoss, T.S.; Alam, H.; Seeram, R. Artificial Intelligence and Internet of Things Enabled Circular Economy. Int. J. Eng. Sci. 2018, 7, 55–63.

- Voulgaridis, K.; Lagkas, T.; Angelopoulos, C.M.; Nikoletseas, S.E. IoT and Digital Circular Economy: Principles, Applications, and Challenges. Comput. Netw. 2022, 219, 109456.

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular Strategies Enabled by the Internet of Things—A Framework and Analysis of Current Practice. Sustainability 2019, 11, 5689.

- Akbari, M.; Hopkins, J.L. Digital Technologies as Enablers of Supply Chain Sustainability in an Emerging Economy. Oper. Manag. Res. 2022, 15, 689–710.

- Kazancoglu, Y.; Ozbiltekin-Pala, M.; Sezer, M.D.; Kumar, A.; Luthra, S. Circular Dairy Supply Chain Management through Internet of Things-Enabled Technologies. Environ. Sci. Pollut. Res. 2022, 1–13.

- Garcia-Muiña, F.E.; González-Sánchez, R.; Ferrari, A.M.; Volpi, L.; Pini, M.; Siligardi, C.; Settembre-Blundo, D. Identifying the Equilibrium Point between Sustainability Goals and Circular Economy Practices in an Industry 4.0 Manufacturing Context Using Eco-Design. Soc. Sci. 2019, 8, 241.

- Chau, M.Q.; Nguyen, X.P.; Huynh, T.T.; Chu, V.D.; Le, T.H.; Nguyen, T.P.; Nguyen, D.T. Prospects of Application of IoT-Based Advanced Technologies in Remanufacturing Process towards Sustainable Development and Energy-Efficient Use. Energy Sources Part A Recovery Util. Environ. Eff. 2021, 1–25.

- Awan, U.; Shamim, S.; Khan, Z.; Zia, N.U.; Shariq, S.M.; Khan, M.N. Big Data Analytics Capability and Decision-Making: The Role of Data-Driven Insight on Circular Economy Performance. Technol. Forecast. Soc. Chang. 2021, 168, 120766.

- Edwin Cheng, T.C.; Kamble, S.S.; Belhadi, A.; Ndubisi, N.O.; Lai, K.; Kharat, M.G. Linkages between Big Data Analytics, Circular Economy, Sustainable Supply Chain Flexibility, and Sustainable Performance in Manufacturing Firms. Int. J. Prod. Res. 2022, 60, 6908–6922.

- Gupta, S.; Chen, H.; Hazen, B.T.; Kaur, S.; Santibañez Gonzalez, E.D.R. Circular Economy and Big Data Analytics: A Stakeholder Perspective. Technol. Forecast. Soc. Chang. 2019, 144, 466–474.

- Salminen, V.; Ruohomaa, H.; Kantola, J. Digitalization and Big Data Supporting Responsible Business Co-Evolution. In Advances in Human Factors, Business Management, Training and Education; Kantola, J.I., Barath, T., Nazir, S., Andre, T., Eds.; Advances in Intelligent Systems and Computing; Springer International Publishing: Cham, Switzerland, 2017; Volume 498, pp. 1055–1067. ISBN 978-3-319-42069-1.

- Del Giudice, M.; Chierici, R.; Mazzucchelli, A.; Fiano, F. Supply Chain Management in the Era of Circular Economy: The Moderating Effect of Big Data. Int. J. Logist. Manag. 2021, 32, 337–356.

- Fraga-Lamas, P.; Lopes, S.I.; Fernández-Caramés, T.M. Green IoT and Edge AI as Key Technological Enablers for a Sustainable Digital Transition towards a Smart Circular Economy: An Industry 5.0 Use Case. Sensors 2021, 21, 5745.

- Artificial Intelligence and the Circular Economy. Available online: https://ellenmacarthurfoundation.org/artificial-intelligence-and-the-circular-economy (accessed on 30 August 2023).

- Ghoreishi, M.; Happonen, A. New Promises AI Brings into Circular Economy Accelerated Product Design: A Review on Supporting Literature. E3S Web Conf. 2020, 158, 06002.

- Awan, U.; Kanwal, N.; Alawi, S.; Huiskonen, J.; Dahanayake, A. Artificial Intelligence for Supply Chain Success in the Era of Data Analytics. In The Fourth Industrial Revolution: Implementation of Artificial Intelligence for Growing Business Success; Hamdan, A., Hassanien, A.E., Razzaque, A., Alareeni, B., Eds.; Studies in Computational Intelligence; Springer International Publishing: Cham, Switzerland, 2021; Volume 935, pp. 3–21. ISBN 978-3-030-62795-9.

- Andoni, M.; Robu, V.; Flynn, D.; Abram, S.; Geach, D.; Jenkins, D.; McCallum, P.; Peacock, A. Blockchain Technology in the Energy Sector: A Systematic Review of Challenges and Opportunities. Renew. Sustain. Energy Rev. 2019, 100, 143–174.

- Juszczyk, O.; Shahzad, K. Blockchain Technology for Renewable Energy: Principles, Applications and Prospects. Energies 2022, 15, 4603.

- Rehman Khan, S.A.; Yu, Z.; Sarwat, S.; Godil, D.I.; Amin, S.; Shujaat, S. The Role of Block Chain Technology in Circular Economy Practices to Improve Organisational Performance. Int. J. Logist. Res. Appl. 2022, 25, 605–622.

More

Information

Subjects:

Engineering, Mechanical

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

538

Revisions:

2 times

(View History)

Update Date:

15 Dec 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No