| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Md Shaha Nur Kabir | -- | 6106 | 2023-12-12 08:07:44 | | | |

| 2 | Lindsay Dong | Meta information modification | 6106 | 2023-12-18 01:43:22 | | |

Video Upload Options

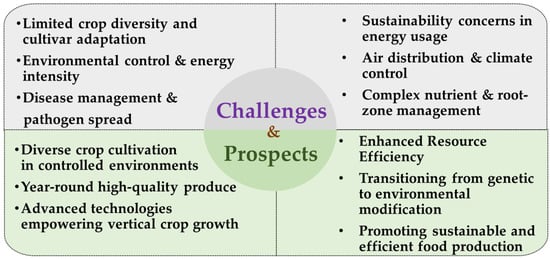

Vertical farming has emerged as a promising solution to cope with increasing food demand, urbanization pressure, and limited resources and to ensure sustainable year-round urban agriculture. Vertical farming is a modern agricultural approach that offers exceptional space efficiency, in contrast to conventional farming methods that often result in water wastage and land degradation. The key advantages of vertical farming include the recirculation of freshwater to minimize waste, the optimization of growth conditions for steady year-round harvests, and the ability to sidestep seasonal limitations. These urban-based farms employ advanced technologies to reduce costs by decreasing the need for transportation and labor expenses.

1. Introduction

2. Vertical Farming

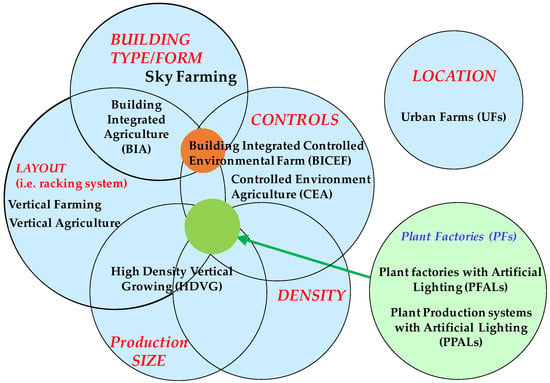

2.1. Definition and Types

2.2. General Structures and Characteristics

2.3. Key Considerations

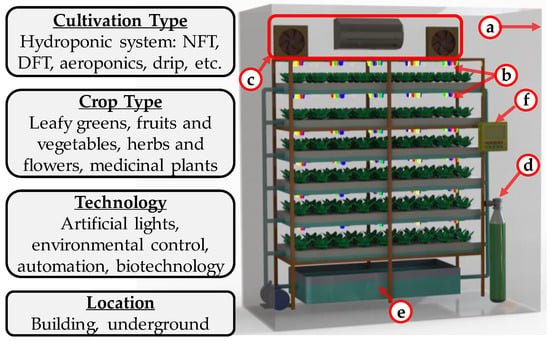

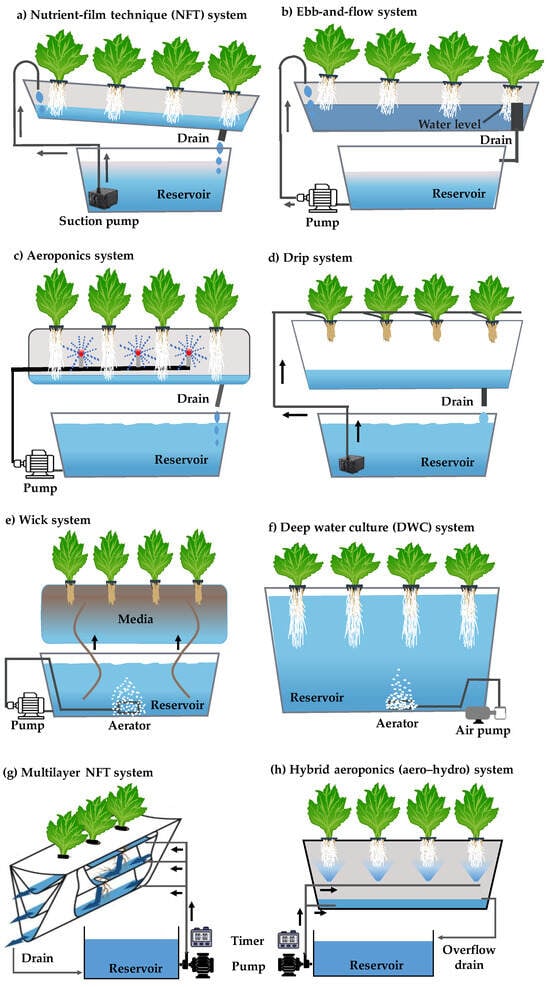

2.3.1. Crop-Cultivation System

2.3.2. Crop Selection

2.3.3. Technological Level

2.3.4. Location

3. Technological Trends

3.1. Sensing Technology

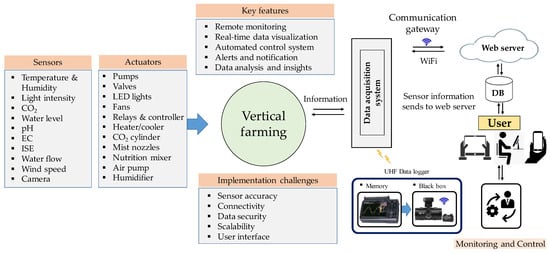

3.1.1. Sensors and Actuators

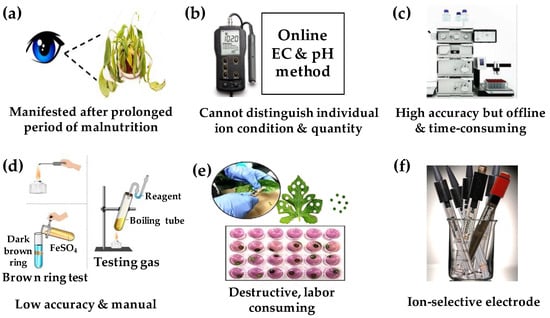

3.1.2. Nutrient-Sensing Systems

3.1.3. Plant Monitoring and Control Systems

3.2. Unmanned Vertical Farming Systems

3.2.1. Automated Vertical Farming Systems

3.2.2. Robotic Vertical Farming Systems

3.2.3. Vertical Farming with Drones

3.3. AI-Based Research Trends

4. Global Industrial and Market Trends

4.1. Global Status

4.2. Industry and Market Trends in Asia

4.3. Industry and Market Trends in the USA

4.4. Industry and Market Trends in Europe

4.5. Innovative Concepts for Upcoming Vertical Farms

5. Conclusions

References

- Ragaveena, S.; Shirly Edward, A.; Surendran, U. Smart controlled environment agriculture methods: A holistic review. Rev. Environ. Sci. Biotechnol. 2021, 20, 887–913.

- Gan, C.I.; Soukoutou, R.; Conroy, D.M. Sustainability framing of controlled environment agriculture and consumer perceptions: A review. Sustainability 2023, 15, 304.

- Engler, N.; Krarti, M. Review of energy efficiency in controlled environment agriculture. Renew. Sustain. Energy Rev. 2021, 141, 110786.

- Lee, G.O.; Jang, S.-N.; Kim, M.J.; Cho, D.Y.; Cho, K.M.; Lee, J.H.; Son, K.-H. Comparison of growth patterns and metabolite composition of different ginseng cultivars (Yunpoong and K-1) grown in a vertical farm. Horticulturae 2023, 9, 583.

- Beacham, A.M.; Vickers, L.H.; Monaghan, J.M. Vertical farming: A summary of approaches to growing skywards. J. Hortic. Sci. Biotechnol. 2019, 94, 277–283.

- Nájera, C.; Gallegos-Cedillo, V.M.; Ros, M.; Pascual, J.A. Role of spectrum-light on productivity, and plant quality over vertical farming systems: Bibliometric analysis. Horticulturae 2023, 9, 63.

- Statista. Global Vertical Farming Market Projection 2022–2032. 2023. Available online: https://www.statista.com/statistics/487666/projection-vertical-farming-market-worldwide/ (accessed on 7 August 2023).

- Li, H.; Guo, Y.; Zhao, H.; Wang, Y.; Chow, D. Towards automated greenhouse: A state of the art review on greenhouse monitoring methods and technologies based on internet of things. Comput. Electron. Agric. 2021, 191, 106558.

- Vatistas, C.; Avgoustaki, D.D.; Bartzanas, T. A systematic literature review on controlled-environment agriculture: How vertical farms and greenhouses can influence the sustainability and footprint of urban microclimate with local food production. Atmosphere 2022, 13, 1258.

- Oh, S.; Lu, C. Vertical farming—Smart urban agriculture for enhancing resilience and sustainability in food security. J. Hortic. Sci. Biotechnol. 2023, 98, 133–140.

- Kalantari, F.; Mohd Tahir, O.; Mahmoudi Lahijani, A.; Kalantari, S. A review of vertical farming technology: A guide for implementation of building integrated agriculture in cities. Adv. Eng. Forum 2017, 24, 76–91.

- Al-Kodmany, K. The Vertical Farm: A review of developments and implications for the vertical city. Buildings 2018, 8, 24.

- Sandison, F.; Yeluripati, J.; Stewart, D. Does green vertical farming offer a sustainable alternative to conventional methods of production?: A case study from Scotland. Food Energy Secur. 2023, 12, e438.

- Despommier, D. Vertical Farms in Horticulture. In Encyclopedia of Food and Agricultural Ethics; Thompson, P.B., Kaplan, D.M., Eds.; Springer: Dordrecht, The Netherlands, 2014.

- Kalantari, F.; Tahir, O.T.; Joni, R.A.; Aminuldin, N.A. The importance of the public acceptance theory in determining the success of the vertical farming projects. Manag. Res. Pract. 2018, 10, 5–16.

- Banerjee, C.; Adenaeuer, L. Up, up and away! The economics of vertical farming. J. Agric. Stud. 2014, 2, 40–60.

- Van Gerrewey, T.; Boon, N.; Geelen, D. Vertical Farming: The only way is up? Agronomy 2022, 12, 2.

- Benis, K.; Reinhart, C.; Ferrão, P. Building-Integrated Agriculture (BIA) in urban contexts: Testing a simulation-based decision support workflow. In Proceedings of the 15th International Building Performance Simulation Association (IBPSA) Conference, San Francisco, CA, USA, 7–9 August 2017.

- Shamshiri, R.R.; Kalantari, F.; Ting, K.C.; Thorp, K.R.; Hameed, I.A.; Weltzien, C.; Ahmad, D.; Shad, Z.M. Advances in greenhouse automation and controlled environment agriculture: A transition to plant factories and urban agriculture. Int. J. Agric. Biol. Eng. 2018, 11, 1–22.

- Kozai, T.; Niu, G. Introduction: Overview and concept of closed plant production system (CPPS). In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 3–6.

- Kozai, T. Resource use efficiency of closed plant production system with artificial light: Concept, estimation and application to plant factory. Proc. Jpn. Acad. Ser. B Phys. Biol. Sci. 2013, 89, 447–461.

- Waldron, D. Evolution of vertical farms and the development of a simulation methodology. WIT Trans. Ecol. Environ. 2018, 217, 975–986.

- Butturini, M.; Marcelis, L.F.M. Vertical farming in Europe: Present status and outlook. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 77–91.

- SharathKumar, M.; Heuvelink, E.; Marcelis, L.F.M. Vertical farming: Moving from genetic to environmental modification. Trends Plant Sci. 2020, 25, 724–727.

- Chole, A.S.; Jadhav, A.R.; Shinde, V. Vertical farming: Controlled environment agriculture. Just Agric. 2021, 1, 249–256. Available online: https://justagriculture.in/files/newsletter/2021/jan/055.pdf (accessed on 9 August 2023).

- Chaudhry, A.R.; Mishra, V.P. A comparative analysis of vertical agriculture systems in residential apartments. In Proceedings of the 2019 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 26 March–10 April 2019.

- Kozai, T.; Niu, G. Plant factory as a resourceefficient closed plant production system. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 93–115.

- Kozai, T. Current Status of Plant Factories with Artificial Lighting (PFALs) and Smart PFALs. In Smart Plant Factory—The Next Generation Indoor Vertical Farms; Kozai, T., Ed.; Springer: Singapore, 2018; pp. 3–13.

- Wong, C.E.; Teo, Z.W.N.; Shen, L.; Yu, H. Seeing the lights for leafy greens in indoor vertical farming. Trends Food Sci. Technol. 2020, 106, 48–63.

- Son, J.E.; Kim, H.J.; Ahn, T.I. Hydroponic systems. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 273–283.

- van Delden, S.H.; SharathKumar, M.; Butturini, M.; Graamans, L.J.A.; Heuvelink, E.; Kacira, M.; Kaiser, E.; Klamer, R.S.; Klerkx, L.; Kootstra, G.; et al. Current status and future challenges in implementing and upscaling vertical farming systems. Nat. Food 2021, 2, 944–956.

- Maucieri, C.; Nicoletto, C.; Os, E.V.; Anseeuw, D.; Havermaet, R.V.; Junge, R. Hydroponic technologies. In Aquaponics Food Production Systems; Goddek, S., Joyce, A., Kotzen, B., Burnell, G.M., Eds.; Springer: Cham, Switzerland, 2019; pp. 77–110.

- Eldridge, B.M.; Manzoni, L.R.; Graham, C.A.; Rodgers, B.; Farmer, J.R.; Dodd, A.N. Getting to the roots of aeroponic indoor farming. New Phytol. 2020, 228, 1183–1192.

- Yuan, G.N.; Marquez, G.P.B.; Deng, H.; Iu, A.; Fabella, M.; Salonga, R.B.; Ashardiono, F.; Cartagena, J.A. A review on urban agriculture: Technology, socio-economy, and policy. Heliyon 2022, 8, e11583.

- Aerofarms. Available online: https://aerofarms.com/ (accessed on 26 August 2023).

- Plenty. Available online: https://www.plenty.ag/ (accessed on 26 August 2023).

- Bowery. Available online: https://bowery.co/ (accessed on 26 August 2023).

- Lakhiar, I.A.; Gao, J.M.; Syed, T.N.; Chandio, F.A.; Tunio, M.H.; Ahmad, F. Overview of the aeroponic agriculture—An emerging technology for global food security. Int. J. Agric. Biol. Eng. 2020, 13, 1–10.

- Pala, M.; Mizenko, L.; Mach, M.; Reed, T. Aeroponic greenhouse as an autonomous system using intelligent space for agriculture robotics. In Robot Intelligence Technology and Applications 2: Results from the 2nd International Conference on Robot Intelligence Technology and Applications; Kim, J.H., Matson, E., Myung, H., Xu, P., Karray, F., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 83–93.

- Lakhiar, I.A.; Gao, J.; Syed, T.N.; Chandio, F.A.; Buttar, N.A. Modern plant cultivation technologies in agriculture under controlled environment: A review on aeroponics. J. Plant Interact. 2018, 13, 338–352.

- NGS. New Growing System. Available online: https://ngsystem.com (accessed on 8 April 2023).

- Omega Garden™. Hydroponics Design. Available online: https://omegagarden.com/ (accessed on 10 July 2023).

- Farmdominium™. The Farmdominium™ Concept. Available online: https://omegagarden.com/the-farmdominium/ (accessed on 10 July 2023).

- Sananbio. Indoor Vertical Hydroponic Vegetation Cultivation Module. Available online: https://www.sananbiofarm.com/product/indoor-vertical-hydroponic-vegetation-cultivation-module (accessed on 10 July 2023).

- Pocock, T. Light-emitting diodes and the modulation of specialty crops: Light sensing and signaling networks in plants. HortScience 2015, 50, 1281–1284.

- Pattison, P.; Tsao, J.; Brainard, G.; Bugbee, B. LEDs for photons, physiology and food. Nature 2018, 563, 493–500.

- Rehman, A.-U.; Abbasi, A.Z.; Islam, N.; Shaikh, Z.A. A review of wireless sensors and networks’ applications in agriculture. Comput. Stand. Interfaces 2014, 36, 263–270.

- Singh, N.; Singh, A.N. Odysseys of agriculture sensors: Current challenges and forthcoming prospects. Comput. Electron. Agric. 2020, 171, 105328.

- Saad, M.H.M.; Hamdan, N.M.; Sarker, M.R. State of the art of urban smart vertical farming automation system: Advanced topologies, issues and recommendations. Electronics 2021, 10, 1422.

- Sivamani, S.; Bae, N.; Cho, Y. A smart service model based on ubiquitous sensor networks using vertical farm ontology. Int. J. Distrib. Sens. Netw. 2013, 9, 161495.

- Lakhiar, I.A.; Jianmin, G.; Syed, T.N.; Chandio, F.A.; Buttar, N.A.; Qureshi, W.A. Monitoring and control systems in agriculture using intelligent sensor techniques: A review of the aeroponic system. J. Sens. 2018, 2018, 8672769.

- Kato, K.; Yoshida, R.; Kikuzaki, A.; Hirai, T.; Kuroda, H.; Hiwasa-Tanase, K.; Takane, K.; Ezura, H.; Mizoguchi, T. Molecular breeding of tomato lines for mass production of miraculin in a plant factory. J. Agric. Food Chem. 2010, 58, 9505–9510.

- Borgognone, D.; Colla, G.; Rouphael, Y.; Cardarelli, M.; Rea, E.; Schwarz, D. Effect of nitrogen form and nutrient solution pH on growth and mineral composition of self-grafted and grafted tomatoes. Sci. Hortic. 2013, 149, 61–69.

- Trejo-Téllez, L.I.; Gómez-Merino, F.C. Nutrient solutions for hydroponic systems. In Hydroponics—A Standard Methodology for Plant Biological Researches; Toshiki, A., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 1–22.

- Bamsey, M.; Graham, T.; Thompson, C.; Berinstain, A.; Scott, A.; Dixon, M. Ion-specific nutrient management in closed systems: The necessity for ion-selective sensors in terrestrial and space-based agriculture and water management systems. Sensors 2012, 12, 13349–13392.

- Kim, H.J.; Kim, W.K.; Roh, M.Y.; Kang, C.I.; Park, J.M.; Sudduth, K.A. Automated sensing of hydroponic macronutrients using a computer-controlled system with an array of ion-selective electrodes. Comput. Electron. Agric. 2013, 93, 46–54.

- Chowdhury, M.; Jang, B.E.; Kabir, M.S.N.; Kim, Y.J.; Na, K.D.; Park, S.B.; Chung, S.O. Factors affecting the accuracy and precision of ion-selective electrodes for hydroponic nutrient supply systems. Acta Hortic. 2020, 1296, 997–1004.

- Chowdhury, M.; Jang, B.E.; Kabir, M.S.N.; Lee, D.H.; Kim, H.T.; Park, T.S.; Chung, S.O. Performance evaluation of commercial ion-selective electrodes for hydroponic cultivation system. Acta Hortic. 2020, 1296, 831–838.

- Jung, D.H.; Kim, H.J.; Choi, G.L.; Ahn, T.I.; Son, J.E.; Sudduth, K.A. Automated lettuce nutrient solution management using an array of ion-selective electrodes. Trans. ASABE 2015, 58, 1309–1319.

- Asaduzzaman, M.; Asao, T. Autotoxicity in strawberry under recycled hydroponics and its mitigation methods. Hortic. J. 2020, 89, 124–137.

- Gutiérrez, M.; Alegret, S.; Caceres, R.; Casadesús, J.; Marfa, O.; Del Valle, M. Application of a potentiometric electronic tongue to fertigation strategy in greenhouse cultivation. Comput. Electron. Agric. 2007, 57, 12–22.

- Dhanaraju, M.; Chenniappan, P.; Ramalingam, K.; Pazhanivelan, S.; Kaliaperumal, R. Smart farming: Internet of things (IoT)-based sustainable agriculture. Agriculture 2022, 12, 1745.

- Crisnapati, P.N.; Wardana, I.N.K.; Aryanto, I.K.A.A.; Hermawan, A. Hommons: Hydroponic management and moni-toring system for an IOT based NFT farm using web technology. In Proceedings of the 2017 5th International Conference on Cyber and IT Service Management (CITSM), Denpasar, Indonesia, 8–10 August 2017; pp. 1–6.

- Ullah, R.; Asghar, I.; Griffiths, M.G.; Stacey, C.; Stiles, W.; Whitelaw, C. Internet of things based sensor system for vertical farming and controlled environment agriculture. In Proceedings of the 2023 6th Conference on Cloud and Internet of Things (CIoT), Lisbon, Portugal, 20–22 March 2023; pp. 136–140.

- Kaur, G.; Upadhyaya, P.; Chawla, P. Comparative analysis of IoT-based controlled environment and uncontrolled environment plant growth monitoring system for hydroponic indoor vertical farm. Environ. Res. 2023, 222, 115313.

- Morella, P.; Lambán, M.P.; Royo, J.; Sánchez, J.C. Vertical farming monitoring: How does it work and how much does it cost? Sensors 2023, 23, 3502.

- Chowdhury, M.E.H.; Khandakar, A.; Ahmed, S.; Al-Khuzaei, F.; Hamdalla, J.; Haque, F.; Reaz, M.B.I.; Al Shafei, A.; Al-Emadi, N. Design, construction and testing of IoT based automated indoor vertical hydroponics farming test-bed in Qatar. Sensors 2020, 20, 5637.

- Quy, V.K.; Hau, N.V.; Anh, D.V.; Quy, N.M.; Ban, N.T.; Lanza, S.; Randazzo, G.; Muzirafuti, A. IoT-enabled smart agriculture: Architecture, applications, and challenges. Appl. Sci. 2022, 12, 3396.

- Dutta, M.; Gupta, D.; Sahu, S.; Limkar, S.; Singh, P.; Mishra, A.; Kumar, M.; Mutlu, R. Evaluation of growth responses of lettuce and energy efficiency of the substrate and smart hydroponics cropping system. Sensors 2023, 23, 1875.

- Rezk, N.G.; Hemdan, E.E.-D.; Attia, A.-F.; El-Sayed, A.; El-Rashidy, M.A. An efficient IoT based smart farming system using machine learning algorithms. Multimed. Tools Appl. 2021, 80, 773–797.

- Grinblat, G.L.; Uzal, L.C.; Larese, M.G.; Granitto, P.M. Deep learning for plant identification using vein morphological patterns. Comput. Electron. Agric. 2016, 127, 418–424.

- Mehra, M.; Saxena, S.; Sankaranarayanan, S.; Tom, R.J.; Veeramanikandan, M. IoT based hydroponics system using deep neural networks. Comput. Electron. Agric. 2018, 155, 473–486.

- Franchetti, B.; Ntouskos, V.; Giuliani, P.; Herman, T.; Barnes, L.; Pirri, F. Vision based modeling of plants phenotyping in vertical farming under artificial lighting. Sensors 2019, 19, 4378.

- Schima, R.; Mollenhauer, H.; Grenzdörffer, G.; Merbach, I.; Lausch, A.; Dietrich, P.; Bumberger, J. Imagine all the plants: Evaluation of a light-field camera for on-site crop growth monitoring. Remote Sens. 2016, 8, 823.

- Paulus, S.; Behmann, J.; Mahlein, A.-K.; Plümer, L.; Kuhlmann, H. Low-cost 3D systems: Suitable tools for plant phenotyping. Sensors 2014, 14, 3001–3018.

- Paul, K.; Chatterjee, S.S.; Pai, P.; Varshney, A.; Juikar, S.; Prasad, V.; Bhadra, B.; Dasgupta, S. Viable smart sensors and their application in data driven agriculture. Comput. Electron. Agric. 2022, 198, 107096.

- Pérez-Bueno, M.L.; Pineda, M.; Barón, M. Phenotyping plant responses to biotic stress by chlorophyll fluorescence imaging. Front. Plant Sci. 2019, 10, 1135.

- Zahir, S.A.D.M.; Omar, A.F.; Jamlos, M.F.; Azmi, M.A.M.; Muncan, J. A review of visible and near-infrared (Vis-NIR) spectroscopy application in plant stress detection. Sens. Actuator A Phys. 2022, 338, 113468.

- Brzychczyk, B.; Hebda, T.; Fitas, J.; Giełżecki, J. The follow-up photobioreactor illumination system for the cultivation of photosynthetic microorganisms. Energies 2020, 13, 1143.

- Bagha, H.; Yavari, A.; Georgakopoulos, D. IoT-based plant health analysis using optical sensors in precision agriculture. In Proceedings of the 2021 Digital Image Computing: Techniques and Applications (DICTA), Gold Coast, Australia, 29 November–1 December 2021; pp. 1–8.

- Wang, T.; Xu, X.; Wang, C.; Li, Z.; Li, D. From smart farming towards unmanned farms: A new mode of agricultural production. Agriculture 2021, 11, 145.

- Avgoustaki, D.D.; Avgoustakis, I.; Miralles, C.C.; Sohn, J.; Xydis, G. Autonomous mobile robot with attached multispectral camera to monitor the development of crops and detect nutrient and water deficiencies in vertical farms. Agronomy 2022, 12, 2691.

- Kozai, T.; Niu, G. Role of the plant factory with artificial lighting (PFAL) in urban areas. In Plant Factory: An Indoor Vertical Farming System for Efficient Quality Food Production, 2nd ed.; Kozai, T., Niu, G., Takagaki, M., Eds.; Academic Press: Cambridge, MA, USA, 2019; pp. 7–34.

- Eagle Technologies. Use Cases of Factory Automation in Vertical Farming. Factory Automation Food Processing. 2020. Available online: https://eagletechnologies.com/2020/08/03/6-use-cases-of-factory-automation-in-vertical-farming/ (accessed on 12 January 2023).

- CityCrop. Automated Indoor Farming. Available online: https://citycrop.io/ (accessed on 13 February 2023).

- Eponic Agriculture Co. Ltd. A Fully Automated Three-Dimensional Vertical Farm Comes into Operation. Available online: https://www.igrowpreowned.com/igrownews/a-fully-automated-three-dimensional-vertical-farm-comes-into-operation (accessed on 16 June 2023).

- iFarm. iFarm StackGrow Vertical Farming Automation Technology. Available online: https://ifarm.fi/technologies/stack-grow (accessed on 16 July 2023).

- Allinson, M. Future of Agriculture: What Does Automated Vertical Farming Look Like? 2023. Available online: https://roboticsandautomationnews.com/2023/03/10/future-of-agriculture-what-does-automated-vertical-farming-look-like/64840/ (accessed on 16 July 2023).

- Marchant, W.; Tosunoglu, S. Robotic implementation to automate a vertical farm system. In Proceedings of the 30st Florida Conference on Recent Advances in Robotics, Florida Atlantic University, Boca Raton, FL, USA, 11–12 May 2107; Available online: https://public.eng.fau.edu/design/fcrar2017/papers/RoboticImplementation.pdf (accessed on 12 February 2023).

- AgritechTomorrow, Future Crops Brings Vertical Farming Closer to the Land. 2021. Available online: https://www.agritechtomorrow.com/story/2021/12/future-crops-brings-vertical-farming-closer-to-the-land/13356/ (accessed on 10 January 2023).

- iFarm. Available online: https://ifarm.fi/ (accessed on 2 March 2023).

- iFarm. Autonomous Drones Will Help to Observe Plants. Available online: https://ifarm.fi/dron_on_farm (accessed on 18 August 2023).

- Corvus Drones. Available online: https://www.corvusdrones.com/ (accessed on 20 May 2023).

- Siropyan, M.; Celikel, O.; Pinarer, O. Artificial Intelligence Driven Vertical Farming Management System. In Proceedings of the World Congress on Engineering, London, UK, 6–8 July 2022; Available online: https://www.iaeng.org/publication/WCE2022/WCE2022_pp108-113.pdf (accessed on 15 April 2023).

- Talaviya, T.; Shah, D.; Patel, N.; Yagnik, H.; Shah, M. Implementation of artificial intelligence in agriculture for optimisation of irrigation and application of pesticides and herbicides. Artif. Intell. Agric. 2020, 4, 58–73.

- Hwang, Y.; Lee, S.; Kim, T.; Baik, K.; Choi, Y. Crop growth monitoring system in vertical farms based on region-of-interest prediction. Agriculture 2022, 12, 656.

- Story, D.; Kacira, M.; Kubota, C.; Akoglu, A.; An, L. Lettuce calcium deficiency detection with machine vision computed plant features in controlled environments. Comput. Electron. Agric. 2010, 74, 238–243.

- Hao, X.; Jia, J.; Gao, W.; Guo, X.; Zhang, W.; Zheng, L.; Wang, M. MFC-CNN: An automatic grading scheme for light stress levels of lettuce (Lactuca sativa L.) leaves. Comput. Electron. Agric. 2020, 179, 105847.

- Wu, Z.; Yang, R.; Gao, F.; Wang, W.; Fu, L.; Li, R. Segmentation of abnormal leaves of hydroponic lettuce based on DeepLabV3+ for robotic sorting. Comput. Electron. Agric. 2021, 190, 106443.

- Hendrawan, Y.; Damayanti, R.; Al Riza, D.F.; Hermanto, M.B. Classification of water stress in cultured Sunagoke moss using deep learning. TELKOMNIKA Telecommun. Comput. Electron. Control 2021, 19, 1594–1604.

- Avgoustaki, D.D.; Xydis, G. Indoor vertical farming in the urban nexus context: Business growth and resource savings. Sustainability 2020, 12, 1965.

- Mitchell, C.A. History of controlled environment horticulture: Indoor farming and its key technologies. HortScience 2022, 57, 247–256.

- Despommier, D. Vertical farms, building a viable indoor farming model for cities. Field Actions Sci. Rep. 2019, 20, 68–73. Available online: http://journals.openedition.org/factsreports/5737 (accessed on 15 January 2023).

- Armanda, D.T.; Guinée, J.B.; Tukker, A. The second green revolution: Innovative urban agriculture’s contribution to food security and sustainability—A review. Glob. Food Sec. 2019, 22, 13–24.

- Hardy, K.; Orridge, T.; Heynes, X.; Gunasena, S.; Grundy, S.; Lu, C. Farming the future: Contemporary innovations enhancing sustainability in the agri-sector. Annu. Plant Rev. 2021, 4, 263–294.

- Piechowiak, M. Countries Using Vertical Farming, Vertical Farming Planet. Available online: https://verticalfarmingplanet.com/countries-using-vertical-farming/#:~:text=There%20are%20currently%20over%20200,that%20focus%20on%20producing%20vegetables (accessed on 2 September 2023).

- Wen, X. Vertical Farming Reaches New Heights. 13 April 2023. Available online: https://www.chinadaily.com.cn/a/202304/13/WS64373a55a31057c47ebb9cb0_3.html (accessed on 20 February 2023).

- Yan, X. Chinese Startup Gets in on Ground Floor of High-Rise Farms. 17 August 2020. Available online: https://asia.nikkei.com/Business/Startups/Chinese-startup-gets-in-on-ground-floor-of-high-rise-farms (accessed on 20 February 2023).

- Ning, S.; Xydis, G. PEST analysis of the future Chinese vertical farming market: Environmental sustainability and energy savings. AIMS Agric. Food 2023, 8, 496–512.

- Mordor Intelligence. Vertical Farming Market Size & Share Analysis-Growth Trends & Forecasts (2023–2028). Available online: https://www.mordorintelligence.com/industry-reports/vertical-farming-market (accessed on 2 April 2023).

- den Besten, J. Vertical farming development; the Dutch approach. In Plant Factory Using Artificial Light; Anpo, M., Fukuda, H., Wada, T., Eds.; Elsevier: Cambridge, MA, USA, 2019; pp. 307–317.

- Benis, K.; Ferrão, P. Commercial farming within the urban built environment–Taking stock of an evolving field in northern countries. Glob. Food Sec. 2018, 17, 30–37.

- Architects, S. A New Model for Urban Farming for the World’s Largest Agricultural Producer and Consumer: China, Sunqiao Urban Agricultural District. Available online: https://www.sasaki.com/projects/sunqiao-urban-agricultural-district/ (accessed on 12 July 2023).