Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Ahmed Raouf Fahmy | -- | 3740 | 2023-11-29 15:48:22 | | | |

| 2 | Rita Xu | -19 word(s) | 3721 | 2023-11-30 02:59:17 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Fahmy, A.R.; Derossi, A.; Jekle, M. Four-Dimensional Printing of Dynamic Foods. Encyclopedia. Available online: https://encyclopedia.pub/entry/52197 (accessed on 07 February 2026).

Fahmy AR, Derossi A, Jekle M. Four-Dimensional Printing of Dynamic Foods. Encyclopedia. Available at: https://encyclopedia.pub/entry/52197. Accessed February 07, 2026.

Fahmy, Ahmed Raouf, Antonio Derossi, Mario Jekle. "Four-Dimensional Printing of Dynamic Foods" Encyclopedia, https://encyclopedia.pub/entry/52197 (accessed February 07, 2026).

Fahmy, A.R., Derossi, A., & Jekle, M. (2023, November 29). Four-Dimensional Printing of Dynamic Foods. In Encyclopedia. https://encyclopedia.pub/entry/52197

Fahmy, Ahmed Raouf, et al. "Four-Dimensional Printing of Dynamic Foods." Encyclopedia. Web. 29 November, 2023.

Copy Citation

The continuous evolution of 3D food printing in the used methods, approaches, and materials has created a solid foundation for technology to process dynamic food structures. In 4D food printing, structures are engineered through material tailoring and custom designs to achieve a transformation from one configuration to another. Different engineered 4D behaviors include stimulated color change, shape morphing, and biological growth.

4D food printing

3D printing

smart materials

1. Introduction

The general interest in additive manufacturing (AM) is mainly based on its principle of operation where large structures are built in layer-based and rapid prototyping (RP) techniques. The combination of RP and layer-based fabrication provides superior accuracy and precision compared to traditional processing and structuring techniques [1][2][3][4]. For the structuring of foods, the adoption of 3D printing technologies was initially motivated by design possibilities that are either challenging or cannot be achieved using traditional food processing techniques. However, through comprehensive scientific investigations, the application of 3D printing technologies shifted towards an increase in consumer acceptance by the functional control over food structures in terms of nutrition, flavor, and textural properties.

Three-dimensional printing is a rapid prototyping technique for processing foods where 3D structures are built using a layer-based computer-aided design (CAD) approach [5]. Processing food structures using 3D printing involves multiple sequential stages. First, food constructs are modeled and designed using CAD software. Second, the model is uploaded into slicing/printing software where the material–process-dependent settings are applied. The slicing software is responsible for applying the printing settings and slicing the geometrical model for the layer-based deposition of the material. Third, through the slicing software, a G-code is generated and processed by the printer where the designed geometries are structured. Finally, a post-processing step in the form of thermal stabilization is usually applied (material-dependent) for the consumption or storage of 3D-structured foods.

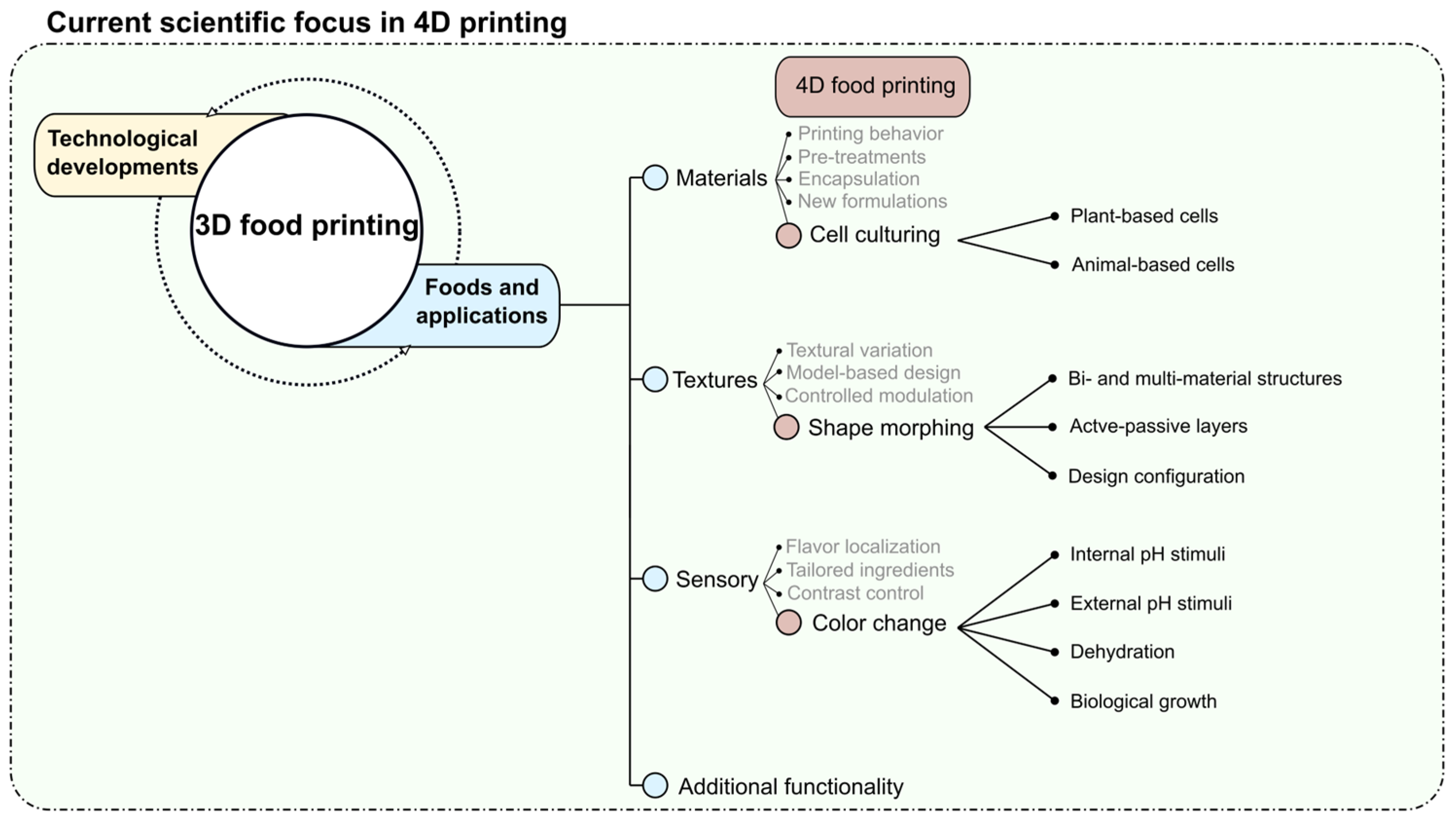

Currently, the research and investigations in the field of 3D food printing can be divided into two main categories, as shown in Figure 1, which are technological developments and applications in food. During its early adoption and development period, 3D food printing research was mainly focused on the printing applicability of different food formulations by elucidating the material–process interactions [6][7][8][9][10]. From a technological perspective, the intensive investigations into the relationship between material behavior and 3D printing led to the development of technological solutions in process monitoring, design and structuring, complementary methods (such as in-line mixing, liquid injection, and co-axial extrusion), and post-processing/stabilization techniques. Also, the native form of different food materials (powders, liquids, and solids) has motivated the adoption of different 3D printing technologies such as fused deposition modeling (FDM), binder jetting (BJ), and selective laser sintering (SLS) [11][12][13]. Consequently, technological developments have broadened the application range of 3D food printing for the structuring of customized food textures, precise localization of flavors, printing of anisotropic protein structures, and processing of food side streams, with a focus on the application of personalized nutrition in the near future [14][15][16][17][18][19][20][21][22][23][24].

Figure 1. Schematic representation of the current research in 3D food printing.

2. Programmed Functionality in Printed Food Structures

Regarding the inclusion criteria, published articles focusing on 4D food printing, triggered food transformations, shape morphing, and color and texture changes were considered. The search strategy led to the inclusion of 34 published articles in the 4D food printing domain. Currently, as shown in Figure 2, there are three main research directions or topics in 4D food printing that are reported in the published articles, including (1) stimulated color change; (2) stimulated shape morphing; (3) cell culturing. For the mentioned research directions, the predominant objective is to achieve programmable food transformations directed towards optimization, esthetics, and most importantly, food functionality. The concept of using a 4D approach in food applications was first introduced by Wang et al. during the proceedings of the Conference on Human Factors in Computing Systems [25]. The authors introduced the shape morphing of printed food structures through hydration-responsive food substrates. From a consumer perspective, this early approach was proposed for processing compact 2D food segments that can be transformed into 3D structures upon cooking, which saves space during packaging, storage, and shipping [25]. From the application and market perspectives, the 4D printing approach broadens the use of technology for creating appealing food products with a wide range of customization, such as the introduction of variable color gradients in foods and heat-dependent variable food shapes and textures [26][27].

Figure 2. Schematic representation of the current research on 4D food printing.

2.1. Stimulated Color Change

Time- and stimulation-driven color change is one of the most studied topics in the 4D food printing research. Such a high trend in scientific investigations is driven by two main reasons. First, the implementation of color-changing kinetics in 3D-printed structures is relatively simple compared to other 4D printing applications, such as shape morphing and cell culturing. To illustrate, the printing of color-shifting structures is driven by the introduction of plant-based bioactive compounds, which are pH stimuli-responsive inside printable food materials. The commonly introduced plant-based bioactive compounds are anthocyanins, carotenoids, betalains, and curcumin [28][29][30][31]. As an example, in alkaline conditions, anthocyanin and curcumin exhibit green and red colors, respectively. On the other hand, in acidic conditions, they exhibit red and yellow colors, respectively. The second reason for the immense focus on 4D-stimulated color change is that the color of food systems is an imperative deterministic factor in the sensory perception and consumer acceptance [32]. Currently, the research and application of stimulated color change in the 4D printing literature can be categorized into four main categories of stimulation [31][33][34][35][36][37][38][39][40][41]:

- (1)

-

Mass diffusion—internal pH stimuli;

- (2)

-

Post-processing—external pH stimuli;

- (3)

-

Post-processing—dehydration;

- (4)

-

Microbiological metabolism—internal pH stimuli.

In the application of mass diffusion, internal pH stimuli are mostly performed by the printing of multi-material composite structures. Typically, two or more materials with different hydration levels, pH conditions, and pH-responsive compounds are printed within the same structure. For reaching a pH equilibrium within the printed structure, time- and material-dependent diffusion occurs within the system, thus inducing color change. Regarding the application of post-processing, spraying with different pH solutions or dehydration methods are used to induce a spontaneous color change of the object. Dehydration methods are usually used for moisture transport, which can enhance the alkalinity of the material [38]. The fourth category using microbiological metabolism as a stimulation method, which researchers categorized earlier, is the most promising application for color change in terms of functionality. In this application, time-dependent biological growth or metabolism of microorganisms (summarized as fermentation) is used to alter the pH, thus changing the printed structure’s color [33]. At the same time, this technique can be used as an indicator of the state of cellular growth inside printed structures.

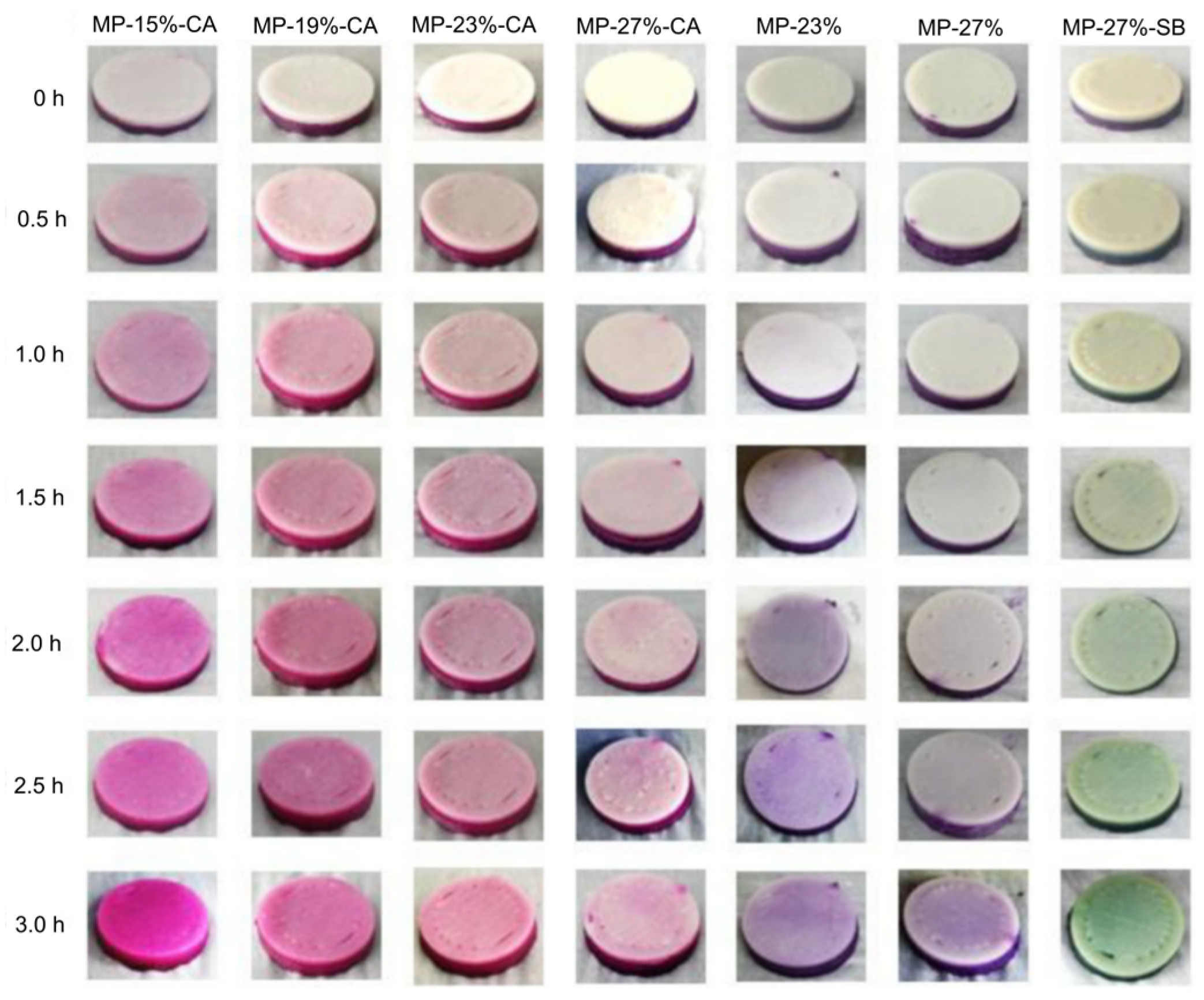

A pH-stimulated color change in the form of mass diffusion is the most studied 4D printing effect in the scientific literature. For this application, some studies have utilized extracted pH-sensitive pigments, such as anthocyanins and curcumin from plant-based sources in the printed food material systems [35][38][39]. However, most scientific investigations are performed by the 3D printing of ingredients that are natively rich with pH-responsive bioactive compounds, such as beetroot, purple sweet potato, and red cabbage [31][37]. Then, the time-dependent color change is stimulated by either spraying the printed structures with solutions prepared at different pH levels or inducing pH change by printing composite structures, which contain other materials with different pH levels. As an example, He, Zhang, and Guo (2020) investigated the color change of 3D composite structures by printing dual- and multi-materials [37]. For printing dual-material structures, a first phase of anthocyanin-containing purple sweet potato (PSP) and a second phase, with variable pH levels, of mashed potato (MP) were stacked into a disk-shaped configuration. For preparing the MP material phase at different pH levels, the authors used 1% of citric acid (CA) and 1% sodium bicarbonate (SB) of the total weight to achieve acidic (pH ≈ 2.5) and weakly alkaline (pH ≈ 7.8) phases, respectively. Without the addition of CA or SB, the MP phase was in a nearly neutral condition (pH ≈ 6.5). In addition, the authors varied the hydration level of the MP phase by changing the concentration of the potato flakes (15%, 19%, 23%, and 27% based on the weight of water) in the material system. For the printing of the disk-shaped structures, as shown in Figure 3, the PSP phase was located on the bottom, while the variable MP phase was located on the top. The results show that the structures exhibited a time-dependent color change with an increase in the color intensity depending on the MP hydration level and the pH conditions. The color change behavior occurred due to the diffusion of the anthocyanins from the PSP phase to the MP phase. As shown in Figure 3, with the increase in the MP concentration, the color intensity decreased at different times due to the slower diffusion rates. For further consideration, such an observed behavior was also dependent on the area of the diffusion boundary and the hydration discrepancy between the used material systems. Based on the results of the dual-material systems, the authors chose three MP phases (with variable hydration and pH levels) to obtain a higher color change rate for printing multi-material composites. As shown in Figure 4a, four-section composite structures were printed, consisting of PSP infill and variable pH/hydration MP perimeters. Through this approach, the study showed that depending on the distribution of the MP phase and the surface area of the diffusion boundary, the time-dependent color change kinetics can be modulated, as shown in Figure 4b. The color-changing effects shown in Figure 4 display a pre-defined and controlled transformation that is extrinsic to traditionally processed foods or typical 3D-printed food structures.

Figure 3. Time-dependent color change of printed dual-material structures composed of mashed potato and anthocyanin-containing purple sweet potato at different pH levels.

Figure 4. Four-dimensional printing of composite structures with purple sweet potato infill and mashed potato perimeter at different pH levels: (a) dual extrusion 3D printing model; (b) time-dependent mass diffusion and color change.

Stimulated color changes of 3D-printed structures, as discussed in the previous section, can be used as a primary and programmed effect to alter the perception of foods. However, this 4D printing application can also be used as a secondary effect, such as an indication of other progressing behavior, like time-dependent organic growth or fermentation processes. Several studies have focused on investigating and utilizing pH-driven color changes to monitor the microbiological metabolism in printed structures [33][42]. Chen et al. investigated the color change behavior through the incorporation of probiotics in 3D-printed food structures [33]. In their study, the authors incorporated Lactobacillus bulgaricus and Streptococcus thermophilus (lyophilized powder form) in a purple sweet potato-based material system. In addition, four different mass concentrations (0.1, 0.2, 0.3, 0.4, and 0.5%) of tea polyphenols were added to the material system to promote metabolism. Moreover, the study investigated time-dependent color changes during fermentation at 37 °C with and without the addition of the polyphenols. During incubation, the number of probiotics reached its maximum value and was saturated between 6 and 8h. Concerning the addition of tea polyphenols, the results showed that increasing the concentration of polyphenols up to 0.4% promoted the metabolism of probiotics. Most importantly, the printing and incubation results showed a significant color change for all printed formulations, from a dark purple value (after printing) to a bright red (after 10 h of fermentation). The time-dependent color shift occurred due to a reduction in the pH as a consequence of the production of lactic acid during fermentation. The authors presented this effect as 5D printing by combining color change and biological growth in one printed system. However, the combination of two time-dependent (single time domain) effects still constitutes a 4D food printing application.

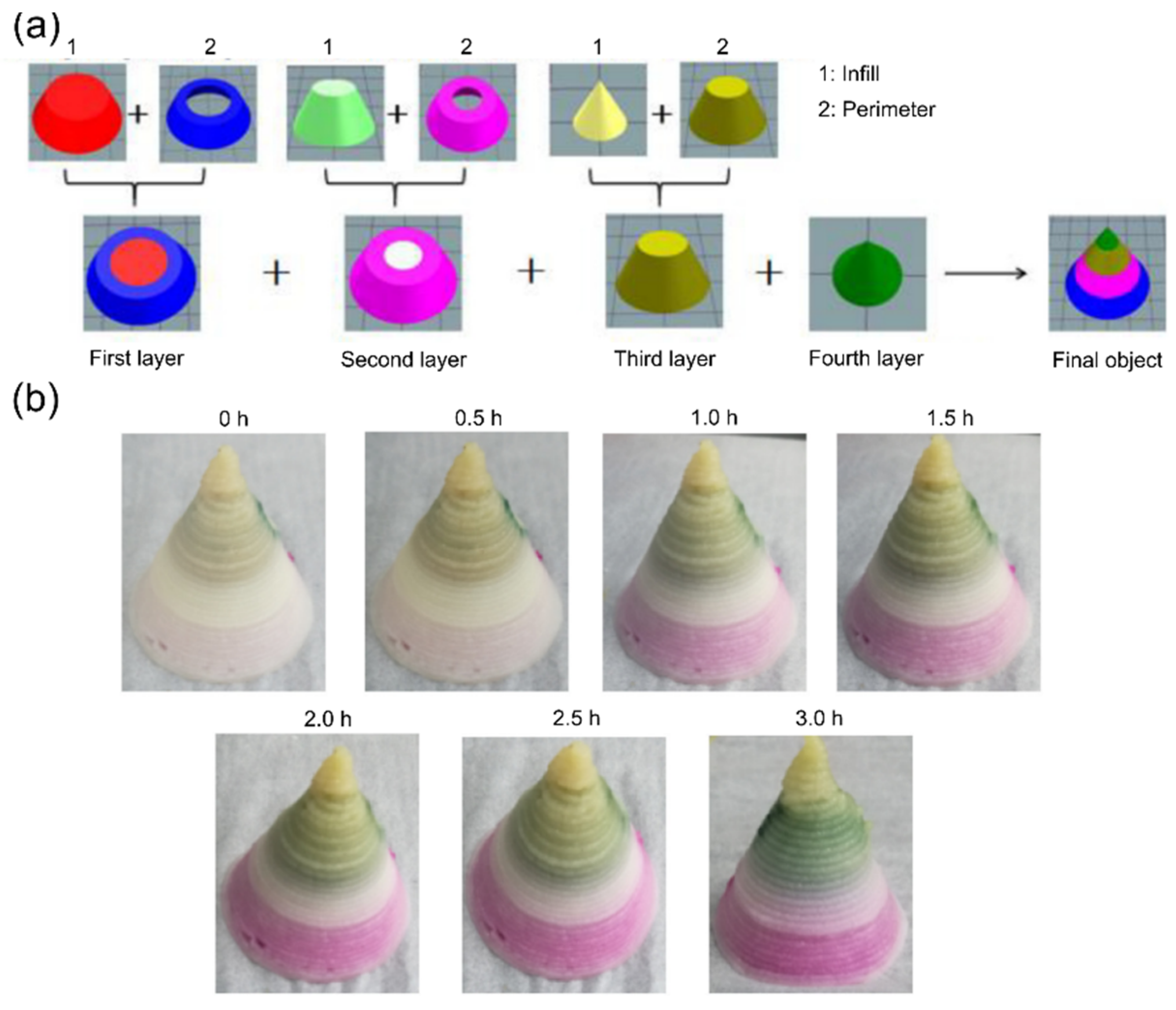

Investigating the effect of post-processing in the form of external pH stimuli, Shanthamma et al. studied the color change behavior of curcumin-based 3D-printed structures [34]. The investigation was performed on a sago flour-based material system with incorporated turmeric powder at different concentrations of 0, 0.5, 1.5, and 2.5% on a weight basis. To stimulate the time-dependent color change effect, the authors used a post-processing approach where they immersed the printed structures in solutions with varying concentrations of sodium bicarbonate (1, 3, and 5% on a weight basis). As shown in Figure 5c, time-dependent changes in the color value and intensity (from yellow to red) were observed. The observed effects mark the transition of the curcumin from a keto conformational state (fluorescent yellow) to its enol conformational state (bright red). Moreover, the authors comprehensively elucidated the resultant color changes using UV absorbance.

Figure 5. Effects of external and internal pH stimuli on the time-dependent color change behavior of printed structures: (a) color change of structures after spraying with solutions at different pH levels (2.5 and 8) after 1.5 h in relation to the structures’ thickness; (b) time-dependent color change of composite structures due to diffusion; (c) time-dependent color change of single-material structures after immersion in solutions with different concentrations of sodium bicarbonate.

Combining the effects of external and internal pH stimuli, Ghazal et al. studied the color change effects of printed structures through mass diffusion in different food models [36]. The authors used an anthocyanin- and starch-based material system composed of red cabbage and different concentrations of potato starch. First, as shown in Figure 5a, the color change effect was studied for different heights of printed single-material structures through the spraying of variable pH solutions. The printed structures were uniformly sprayed twice using 0.75 mL of the solutions (pH 2.5 and 8) and the color change behavior was observed directly after printing and after 1.5 h. As shown in Figure 5a, the color change behavior was dependent on the thickness of the printed structures due to diffusion, which is time-dependent. For all printed thicknesses (6, 8, and 10 mm), it was observed for the pH 8 solution at the vertical section that the structure’s core was darker than the perimeter after 1.5 h, indicating that the sprayed solution did not diffuse in the required time to the core. Second, Ghazal et al. studied the influence of the diffusion boundary’s geometry and the thickness of the printed structures in printed bi-material composites [36]. The investigation was performed using three models, shown in Figure 5b, using the previous material combined with an acidic material phase based on lemon and potato starch. The acidic phase is located at the bottom of Models 1 and 2 and located in the middle of Model 3. The material phases were printed at different thicknesses of 6 and 4 mm, for Models 1 and 2 respectively. The results showed that Models 2 and 3 reached an equilibrium (in color change) due to diffusion after approximately 1.5 h, while Model 1 reached an equilibrium after 3 h. Compared to Model 2, the response time of Model 1 was lower due to the higher thickness. In addition, the diffusion boundary of Model 3 had the highest surface, leading to an increased diffusion rate.

Another post-processing or external stimulation for color change is through dehydration. From a consumption perspective, this external stimulation method presents a more feasible approach to color change (compared to external pH stimulation), as inducing thermal transitions is imperative for most 3D-printed food materials. Chen et al. investigated the effect of microwave dehydration (MD) on the color change kinetics of curcumin-based 3D-printed structures [38]. The authors studied the color change with respect to the dehydration time of printed structures by the addition of curcumin emulsion and NaHCO3 (pH = 8.15) to a single-phase lotus root material. As shown in Figure 6, the colorimetry of the printed samples was characterized at different dehydration times of 1–3 min at a constant power level of 280 W. Using microwave dehydration, the NaHCO3 was decomposed into Na2CO3, which enhanced the alkalinity of the material. In addition, the authors observed (through confocal laser microscopy) that the emulsion particles aggregate during the application of MD. Thus, they inferred that some emulsion particles burst, which led to the exposure of the curcumin particulates to alkaline conditions, resulting in the deprotonation of the curcumin, denoted by the yellow to red color shift, as shown in Figure 6e.

Figure 6. Effects of curcumin-based emulsion concentration and microwave stimulation on the chroma value of a lotus root material system: (a) chroma value after 1 min of microwave stimulation; (b) chroma value after 2 min of microwave stimulation; (c) chroma value after 3 min of microwave stimulation; (d) native material without microwave stimulation; (e) printed multi-material food composites.

2.2. Shape Morphing and Dynamic Textures

Textures of foods and food foams are defined as mechanical, structural, and surface properties [43]. Dynamic textures denote the time-dependent changes in the mechanical, structural, or surface properties of printed structures, causing a controlled change in the textural properties. Such dynamic textures of 3D-printed food structures can be achieved using triggered shape-morphing effects. Shape morphing denotes structural deformation causing the transition of structures between two or more different morphological states. To illustrate, defined stimuli-driven stresses are developed in the structures, and due to dimensional or material mismatch, such stresses induce specific deformations, such as bending, torsion, distortion, linear and non-linear expansion/contraction, and surface curl. Controlled deformation in the printing of food materials and structures has progressed rapidly in the last few years, as the fundamental understanding of shape change kinetics was already established for synthetic organic and inorganic materials [44][45]. In order to not trivialize the scientific progress, the published investigations remain a largely substantial scientific step when considering the challenges in geometrical designs, multi-material matching/mismatching, and tailoring of food material responses towards external stimuli. To emphasize this, the structuring of shape-morphing food assemblies is a direct adaptation of 4D printing in engineering applications, which focuses on the processing of stimuli-responsive smart materials and structures. In engineering applications, the processing of smart materials or structures is performed to achieve specific functionalities typically in sensing and actuation [46]. Compared to shape-morphing foods, a broader range of materials is used in engineering applications, including monolithic and composite material approaches (Ahmed et al., 2021; Pinho et al., 2020). With this in mind, the available literature on the 4D printing of shape-morphing food structures still encompasses a wide range of food materials, including hydrogels and fiber-, starch-, fruit-, and animal-based material systems [27][47][48].

The kinetics of shape-morphing foods are generally engineered using one or a combination of the following structure design approaches:

- (1)

-

Bi- or multi-material systems;

- (2)

-

Design configuration;

- (3)

-

Active–passive layers.

For the different structure design approaches, the dynamics of the shape-morphing process are driven by relative expansion or contraction between either different layers (materials) or repetitive/non-repetitive design patterns during hydration or dehydration. Considering hydration, the rate and capacity of water absorption control the swelling anisotropy, which causes a non-uniform distribution of stresses within the structure [49]. Such non-uniformity in the development of internal stresses is the driving force for the material transformation from one configuration to another. In dehydration-triggered stimulations, structural deformation occurs due to the relative contraction between different materials or design configurations according to their own thermal and mass transfer properties. Thus, it is mainly controlled using moisture loss through the thermal and diffusion properties of food formulations. However, mass diffusion (hydration and dehydration) is not the only approach to controlling or inhibiting shape-morphing kinetics, it can also be controlled through thermal expansion (for example, cellular structures), molecular transformations (for example, starch gelatinization), or organic growth in active-passive structures [44][50].

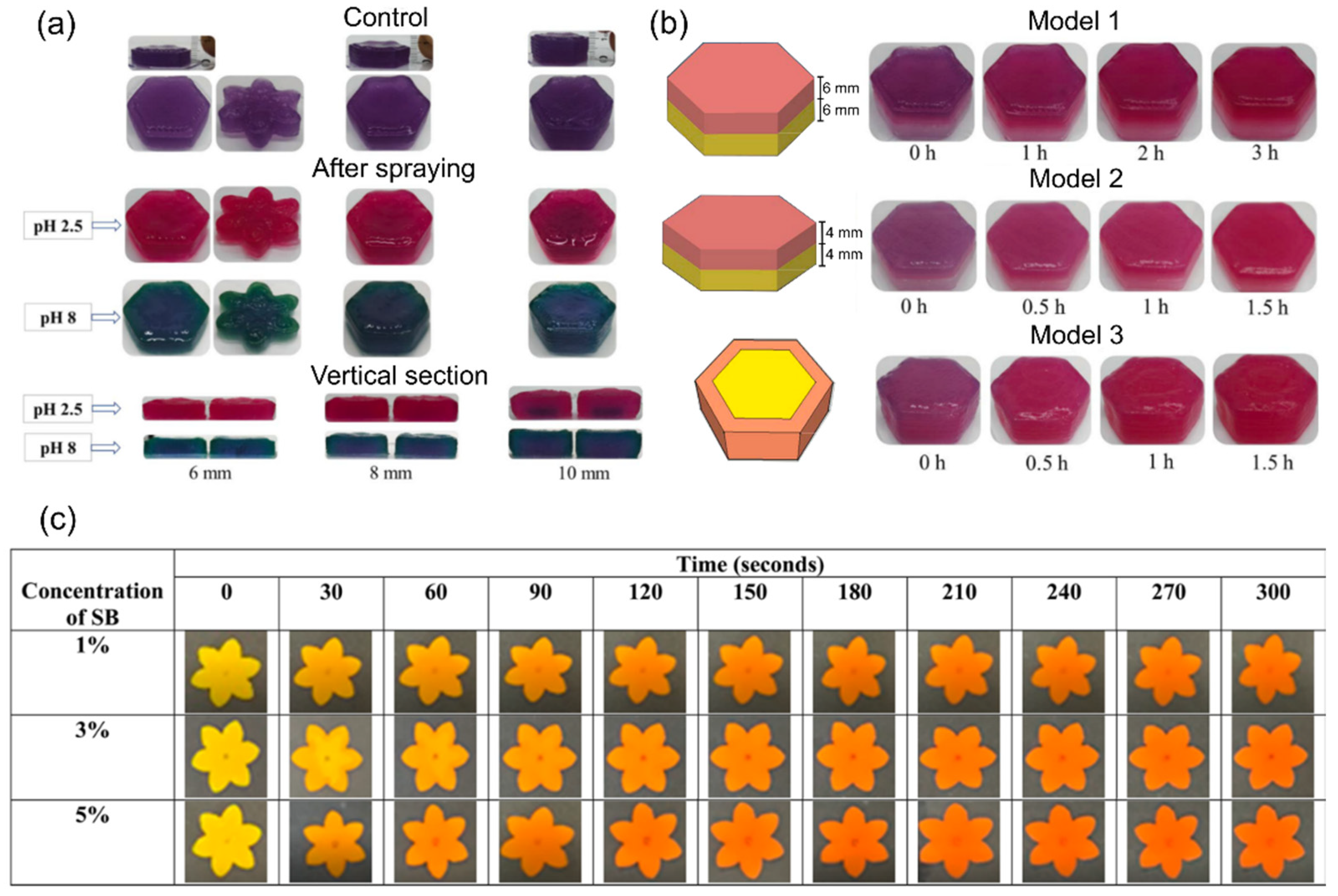

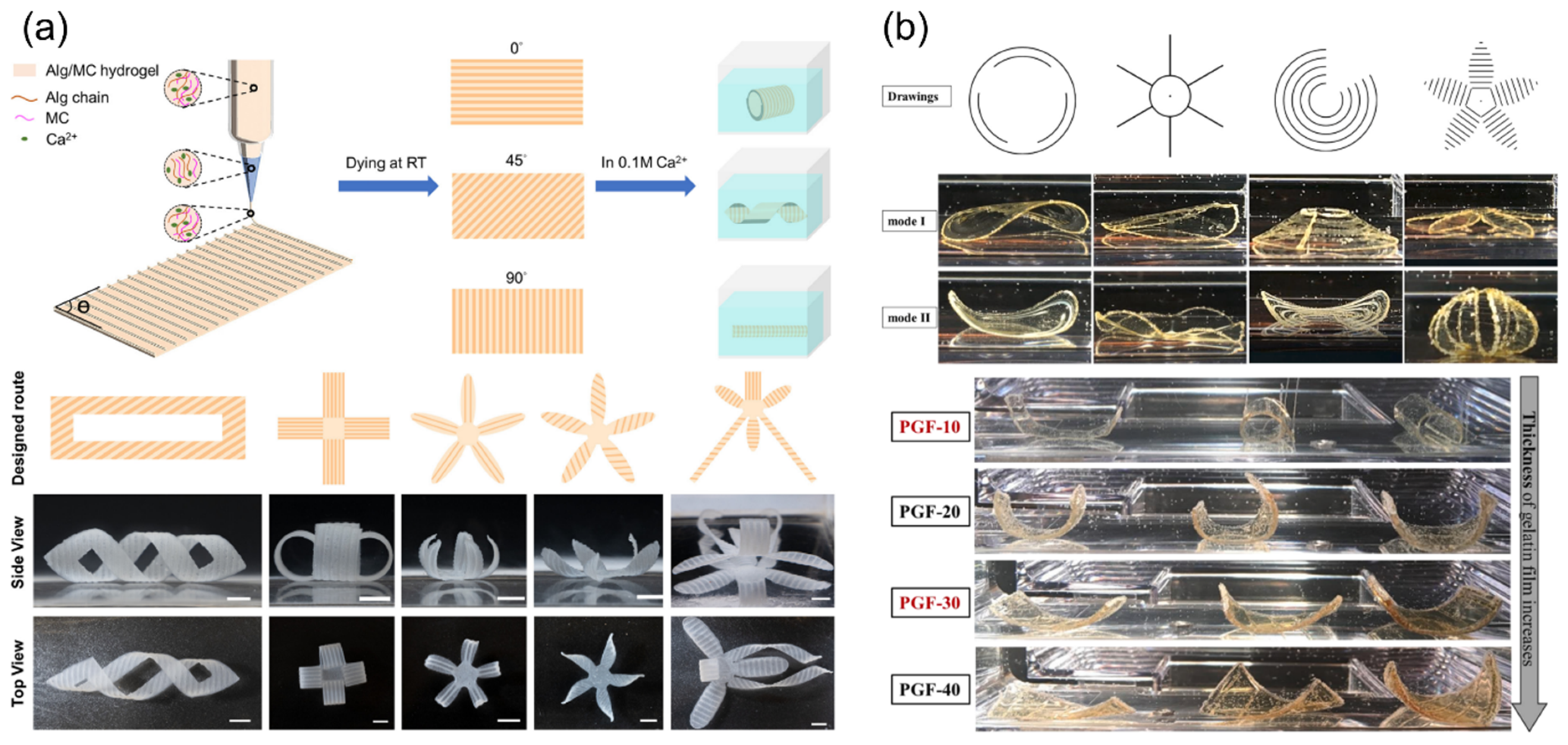

Currently, the available literature on the 4D printing of shape-morphing food structures encompasses a range of imperative research directions, such as investigating the design-driven deformation effects in multi-material structures, the deformation kinetics by using different drying mechanisms, and the effects of fats, salts, and other additives (variable thermal and diffusion properties) on deformation kinetics [51][52][53][54][55][56][57][58]. Scientific studies presented by Pulatsu et al. and Lai et al. investigated the swelling and shape-morphing behaviors of hydration-triggered 4D-printed edible food composites [51][59]. As shown in Figure 7a, the study by Lai et al. showed the design-controlled morphing of printed alginate/methylcellulose (Alg/MC) hydrogel structures. The shape-morphing effects were engineered by inducing a network density gradient across the printing plane. To illustrate, the density gradient resulted in a non-uniform swelling behavior, leading to relative expansion across the printing plane and the transformation of 3D-printed flat structures from one configuration to another, forming complex 3D morphologies. Moreover, the pre-defined deformations were triggered by the immersion of the printed flat sheets in calcium chloride solutions (CaCl2). The authors introduced a novel approach for inducing such hydration-triggered transformations using network gradient discrepancies. This was achieved by printing three-layered sheets, the first layer of which was a uniform film. The second and third layers were printed as a strip pattern uniformly interspaced at different angles. Furthermore, to create the network density gradient, the authors dried the printed structures at room temperature to create a compressed network and dense regions of the three-layered areas, while the single-layer areas produced lower network densities. Using a different approach to induce hydration-triggered transformations in food structures, the study presented by Pulatsu et al. investigated shape-morphing effects and configurations using multi-materials or composite systems by the 3D printing of ethyl cellulose (EC) patterns on pure gelatin and glycerol–gelatin films, as shown in Figure 7b. The presented study showed a novel approach for achieving shape-morphing effects using swelling anisotropy driven by the hydrophilic behavior of gelatin in relation to the hydrophobicity of EC. The authors investigated the effects of film thickness, aspect ratio, swelling properties, and printing patterns on the shape-morphing properties when subjecting the films to water as a stimulus. One of the most important metrics the authors used to quantify the dependencies of the shape-morphing properties was the response capacity of the patterned structures [59]. In the study, the response capacity was considered to be high when flat structures reached their maximum deformation in a shorter period of time in response to the applied hydration stimulus. Regarding the dependency of the response capacity on the film thickness, as shown in Figure 7b, the authors observed an inverse relationship between the film thickness and the final curvature of the structures. To induce simple bending, the authors printed parallel EC strips on gelatin films. Upon hydration of the patterned films, curvatures (defined as the reciprocal of a circle’s radius) ranging from 0.045 to 0.576 mm−1 were obtained, depending of the film’s thickness. The authors presented promising shape-morphing effects using different distributions of the EC on the gelatin film, which proved to be an imperative method for elucidating hydration-dependent shape-morphing kinetics. However, 3D printing was only used for the deposition of EC patterns on pre-prepared gelatin films. Therefore, the application of dual extrusion can be a step forward for the processing of hydration-triggered morphing food structures.

Figure 7. Hydration-triggered shape-morphing multi-material structures: (a) illustration and pictures of shape-morphing configurations using 3D-printed Alg/MC hydrogels; (b) effect of 3D-printed EC pattern and gelatin film thickness on shape-morphing behavior of patterned structures.

References

- Sun, J.; Peng, Z.; Zhou, W.; Fuh, J.Y.H.; Hong, G.S.; Chiu, A. A Review on 3D Printing for Customized Food Fabrication. In Proceedings of the Procedia Manufacturing; Elsevier B.V.: Amsterdam, The Netherlands, 2015; Volume 1, pp. 308–319.

- Chen, Y.; Zhang, M.; Sun, Y.; Phuhongsung, P. Improving 3D/4D Printing Characteristics of Natural Food Gels by Novel Additives: A Review. Food Hydrocoll. 2022, 123, 107160.

- Zhao, L.; Zhang, M.; Chitrakar, B.; Adhikari, B. Recent Advances in Functional 3D Printing of Foods: A Review of Functions of Ingredients and Internal Structures. Crit. Rev. Food Sci. Nutr. 2021, 61, 3489–3503.

- Derossi, A.; Caporizzi, R.; Ricci, I.; Severini, C. Critical Variables in 3D Food Printing. In Fundamentals of 3D Food Printing and Applications; Elsevier: Amsterdam, The Netherlands, 2018; pp. 41–91. ISBN 9780128145647.

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d Printing Technologies Applied for Food Design: Status and Prospects. J. Food Eng. 2016, 179, 44–54.

- Severini, C.; Azzollini, D.; Albenzio, M.; Derossi, A. On Printability, Quality and Nutritional Properties of 3D Printed Cereal Based Snacks Enriched with Edible Insects. Food Res. Int. 2018, 106, 666–676.

- Fahmy, A.R.; Becker, T.; Jekle, M. 3D Printing and Additive Manufacturing of Cereal-Based Materials: Quality Analysis of Starch-Based Systems Using a Camera-Based Morphological Approach. Innov. Food Sci. Emerg. Technol. 2020, 63, 102384.

- Severini, C.; Derossi, A.; Azzollini, D. Variables Affecting the Printability of Foods: Preliminary Tests on Cereal-Based Products. Innov. Food Sci. Emerg. Technol. 2016, 38, 281–291.

- Liu, Z.; Bhandari, B.; Prakash, S.; Mantihal, S.; Zhang, M. Linking Rheology and Printability of a Multicomponent Gel System of Carrageenan-Xanthan-Starch in Extrusion Based Additive Manufacturing. Food Hydrocoll. 2019, 87, 413–424.

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the Printability of Selected Food for 3D Printing: Development of an Assessment Method Using Hydrocolloids as Reference Material. J. Food Eng. 2017, 215, 23–32.

- Holland, S.; Tuck, C.; Foster, T. Selective Recrystallization of Cellulose Composite Powders and Microstructure Creation through 3D Binder Jetting. Carbohydr. Polym. 2018, 200, 229–238.

- Jonkers, N.; van Dommelen, J.A.W.; Geers, M.G.D. Experimental Characterization and Modeling of the Mechanical Behavior of Brittle 3D Printed Food. J. Food Eng. 2020, 278, 109941.

- Zhang, M.; Liu, Z.; Bhandari, B.; Wang, Y. 3D Printing: Printing Precision and Application in the Food Sector. Trends Food Sci. Technol. 2017, 69, 83–94.

- Fahmy, A.R.; Amann, L.S.; Dunkel, A.; Frank, O.; Dawid, C.; Hofmann, T.; Becker, T.; Jekle, M. Sensory Design in Food 3D Printing—Structuring, Texture Modulation, Taste Localization, and Thermal Stabilization. Innov. Food Sci. Emerg. Technol. 2021, 72, 102743.

- Maniglia, B.C.; Fahmy, A.R.; Jekle, M.; Le-Bail, P.; Le-Bail, A. Three-Dimensional (3D) Food Printing Based on Starch-Based Inks: Crucial Factors for Printing Precision. In Food Printing: 3D Printing in Food Industry; Sandhu, K., Singh, S., Eds.; Springer: Singapore, 2022; pp. 101–140. ISBN 9789811681219.

- Vancauwenberghe, V.; Delele, M.A.; Vanbiervliet, J.; Aregawi, W.; Verboven, P.; Lammertyn, J.; Nicolai, B. Model-Based Design and Validation of Food Texture of 3D Printed Pectin-Based Food Simulants. J. Food Eng. 2018, 231, 72–82.

- Ko, H.J.; Wen, Y.; Choi, J.H.; Park, B.R.; Kim, H.W.; Park, H.J. Meat Analog Production through Artificial Muscle Fiber Insertion Using Coaxial Nozzle-Assisted Three-Dimensional Food Printing. Food Hydrocoll. 2021, 120, 106898.

- Escalante-Aburto, A.; Trujillo-de Santiago, G.; Álvarez, M.M.; Chuck-Hernández, C. Advances and Prospective Applications of 3D Food Printing for Health Improvement and Personalized Nutrition. Compr. Rev. Food Sci. Food Saf. 2021, 20, 5722–5741.

- Fahmy, A.R.; Jekle, M.; Becker, T. Texture Modulation of Starch-Based Closed-Cell Foams Using 3D Printing: Deformation Behavior beyond the Elastic Regime. J. Texture Stud. 2022, 54, 153–169.

- Fahmy, A.R.; Vogt, U.T.; Jekle, M.; Becker, T. Hardness Targeted Design and Modulation of Food Textures in the Elastic-Regime Using 3D Printing of Closed-Cell Foams in Point Lattice Systems. J. Food Eng. 2022, 320, 110942.

- Pereira, T.; Barroso, S.; Gil, M.M. Food Texture Design by 3d Printing: A Review. Foods 2021, 10, 320.

- Vancauwenberghe, V.; Baiye Mfortaw Mbong, V.; Vanstreels, E.; Verboven, P.; Lammertyn, J.; Nicolai, B. 3D Printing of Plant Tissue for Innovative Food Manufacturing: Encapsulation of Alive Plant Cells into Pectin Based Bio-Ink. J. Food Eng. 2019, 263, 454–464.

- Park, S.M.; Kim, H.W.; Park, H.J. Callus-Based 3D Printing for Food Exemplified with Carrot Tissues and Its Potential for Innovative Food Production. J. Food Eng. 2020, 271, 109781.

- Shahbazi, M.; Jäger, H.; Ettelaie, R. Application of Pickering Emulsions in 3D Printing of Personalized Nutrition. Part II: Functional Properties of Reduced-Fat 3D Printed Cheese Analogues. Colloids Surf. A Physicochem. Eng. Asp. 2021, 624, 126760.

- Wang, W.; Yao, L.; Zhang, T.; Cheng, C.Y.; Levine, D.; Ishii, H. Transformative Appetite: Shape-Changing Food Transforms from 2D to 3D by Water Interaction through Cooking. In Proceedings of the 2017 CHI Conference on Human Factors in Computing Systems, Denver, CO, USA, 6–11 May 2017; Association for Computing Machinery: New York, NY, USA, 2017; Volume 2017-May, pp. 6123–6132.

- Teng, X.; Zhang, M.; Mujumdar, A.S. 4D Printing: Recent Advances and Proposals in the Food Sector. Trends Food Sci. Technol. 2021, 110, 349–363.

- Navaf, M.; Sunooj, K.V.; Aaliya, B.; Akhila, P.P.; Sudheesh, C.; Mir, S.A.; George, J. 4D Printing: A New Approach for Food Printing; Effect of Various Stimuli on 4D Printed Food Properties. A Comprehensive Review. Appl. Food Res. 2022, 2, 100150.

- Tsaplev, Y.B.; Lapina, V.A.; Trofimov, A.V. Curcumin in Dimethyl Sulfoxide: Stability, Spectral, Luminescent and Acid-Base Properties. Dye Pigment. 2020, 177, 108327.

- Tena, N.; Asuero, A.G. Up-To-Date Analysis of the Extraction Methods for Anthocyanins: Principles of the Techniques, Optimization, Technical Progress, and Industrial Application. Antioxidants 2022, 11, 286.

- Rodriguez-Saona, L.E.; Wrolstad, R.E. Extraction, Isolation, and Purification of Anthocyanins. Curr. Protoc. Food Anal. Chem. 2001, 00, F1.1.1–F1.1.11.

- Phuhongsung, P.; Zhang, M.; Devahastin, S. Influence of Surface PH on Color, Texture and Flavor of 3D Printed Composite Mixture of Soy Protein Isolate, Pumpkin, and Beetroot. Food Bioprocess Technol. 2020, 13, 1600–1610.

- Spence, C. On the Changing Colour of Food & Drink. Int. J. Gastron. Food Sci. 2019, 17, 100161.

- Chen, J.; Teng, X.; Zhang, M.; Bhandari, B.; Adhikari, B.; Yu, D. 5D Food Printing with Color Change Induced by Probiotic Growth in a Starch-Protein-Based Gel System. Food Bioprocess. Technol. 2023, 16, 2304–2314.

- Shanthamma, S.; Preethi, R.; Moses, J.A.; Anandharamakrishnan, C. 4D Printing of Sago Starch with Turmeric Blends: A Study on PH-Triggered Spontaneous Color Transformation. ACS Food Sci. Technol. 2021, 1, 669–679.

- Ghazal, A.F.; Zhang, M.; Liu, Z. Spontaneous Color Change of 3D Printed Healthy Food Product over Time after Printing as a Novel Application for 4D Food Printing. Food Bioprocess Technol. 2019, 12, 1627–1645.

- Ghazal, A.F.; Zhang, M.; Bhandari, B.; Chen, H. Investigation on Spontaneous 4D Changes in Color and Flavor of Healthy 3D Printed Food Materials over Time in Response to External or Internal PH Stimulus. Food Res. Int. 2021, 142, 110215.

- He, C.; Zhang, M.; Guo, C. 4D Printing of Mashed Potato/Purple Sweet Potato Puree with Spontaneous Color Change. Innov. Food Sci. Emerg. Technol. 2020, 59, 102250.

- Chen, C.; Zhang, M.; Guo, C.; Chen, H. 4D Printing of Lotus Root Powder Gel: Color Change Induced by Microwave. Innov. Food Sci. Emerg. Technol. 2021, 68, 102605.

- Wang, R.; Li, Z.; Shi, J.; Holmes, M.; Wang, X.; Zhang, J.; Zhai, X.; Huang, X.; Zou, X. Color 3D Printing of Pulped Yam Utilizing a Natural PH Sensitive Pigment. Addit. Manuf. 2021, 46, 102062.

- Chen, C.; Zhang, M.; Mujumdar, A.S.; Phuhongsung, P. Investigation of 4D Printing of Lotus Root-Compound Pigment Gel: Effect of PH on Rapid Colour Change. Food Res. Int. 2021, 148, 110630.

- Guo, C.; Zhang, M.; Devahastin, S. Color/Aroma Changes of 3D-Printed Buckwheat Dough with Yellow Flesh Peach as Triggered by Microwave Heating of Gelatin-Gum Arabic Complex Coacervates. Food Hydrocoll. 2021, 112, 106358.

- Zhan, J.; Fu, J.; Jin, D.; Yuan, Y.; Shen, S.; Li, G.; Chen, Y. Surimi Freshness Monitoring of 4D Printing Material with Anthocyanin. J. Food Eng. 2023, 358, 111678.

- Szczesniak, A.S. Texture Is a Sensory Property. Food Qual. Prefer. 2002, 13, 215–225.

- Momeni, F.; Ni, J. Laws of 4D Printing. Engineering 2020, 6, 1035–1055.

- Megdich, A.; Habibi, M.; Laperrière, L. A Review on 4D Printing: Material Structures, Stimuli and Additive Manufacturing Techniques. Mater. Lett. 2023, 337, 133977.

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From Innovation to Evolution. Adv. Colloid Interface Sci. 2021, 294, 102482.

- Ghazal, A.F.; Zhang, M.; Mujumdar, A.S.; Ghamry, M. Progress in 4D/5D/6D Printing of Foods: Applications and R&D Opportunities. Crit. Rev. Food Sci. Nutr. 2022.

- Oral, M.O.; Derossi, A.; Caporizzi, R.; Severini, C. Analyzing the Most Promising Innovations in Food Printing. Programmable Food Texture and 4D Foods. Future Foods 2021, 4, 100093.

- Gao, B.; Yang, Q.; Zhao, X.; Jin, G.; Ma, Y.; Xu, F. 4D Bioprinting for Biomedical Applications. Trends Biotechnol. 2016, 34, 746–756.

- Fahmy, A.R.; Kant, J.; Marius Knorz; Jekle, M. 4D Printing of Shape-Morphing Foods: Control of Stimulus-Driven Deformations through Protein-Starch Thermal Transitions. In Proceedings of the ICEF14 International Congress on Engineering and Food, Nantes, France, 19–23 June 2023.

- Lai, J.; Ye, X.; Liu, J.; Wang, C.; Li, J.; Wang, X.; Ma, M.; Wang, M. 4D Printing of Highly Printable and Shape Morphing Hydrogels Composed of Alginate and Methylcellulose. Mater. Des. 2021, 205, 109699.

- He, C.; Zhang, M.; Devahastin, S. Investigation on Spontaneous Shape Change of 4D Printed Starch-Based Purees from Purple Sweet Potatoes As Induced by Microwave Dehydration. ACS Appl. Mater. Interfaces 2020, 12, 37896–37905.

- Chen, F.; Zhang, M.; Liu, Z.; Bhandari, B. 4D Deformation Based on Double-Layer Structure of the Pumpkin/Paper. Food Struct. 2021, 27, 100168.

- He, C.; Zhang, M.; Devahastin, S. Microwave-Induced Deformation Behaviors of 4D Printed Starch-Based Food Products as Affected by Edible Salt and Butter Content. Innov. Food Sci. Emerg. Technol. 2021, 70, 102699.

- Shi, Y.; Zhang, M.; Phuhongsung, P. Microwave-Induced Spontaneous Deformation of Purple Potato Puree and Oleogel in 4D Printing. J. Food Eng. 2022, 313, 110757.

- Dick, A.; Gao, Y.; Bhandari, B.; Prakash, S. Influence of Drying Method and 3D Design on the 4D Morphing of Beef Products. Appl. Food Res. 2021, 1, 100017.

- Guo, J.; Zhang, M.; Li, J.; Fang, Z. Using Soy Protein Isolate to Improve the Deformation Properties of 4D-Printed Oat Flour Butterfly. Food Bioprocess Technol. 2023, 16, 1165–1176.

- Nishihara, Y.; Kakehi, Y. Magashi: Fabrication of Shape-Changing Edible Structures by Extrusion-Based Printing and Baking. In Proceedings of the Creativity and Cognition; ACM: New York, NY, USA, 2021; pp. 1–12.

- Pulatsu, E.; Su, J.W.; Lin, J.; Lin, M. Utilization of Ethyl Cellulose in the Osmotically-Driven and Anisotropically-Actuated 4D Printing Concept of Edible Food Composites. Carbohydr. Polym. Technol. Appl. 2022, 3, 100183.

More

Information

Subjects:

Others

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

764

Revisions:

2 times

(View History)

Update Date:

30 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No