Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Mikhael BECHELANY | -- | 3835 | 2023-11-22 09:11:47 | | | |

| 2 | Lindsay Dong | Meta information modification | 3835 | 2023-11-23 08:47:50 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Kataya, G.; Cornu, D.; Bechelany, M.; Hijazi, A.; Issa, M. Biomass Waste Conversion Technologies for Sustainable Environmental Development. Encyclopedia. Available online: https://encyclopedia.pub/entry/51899 (accessed on 08 February 2026).

Kataya G, Cornu D, Bechelany M, Hijazi A, Issa M. Biomass Waste Conversion Technologies for Sustainable Environmental Development. Encyclopedia. Available at: https://encyclopedia.pub/entry/51899. Accessed February 08, 2026.

Kataya, Ghenwa, David Cornu, Mikhael Bechelany, Akram Hijazi, May Issa. "Biomass Waste Conversion Technologies for Sustainable Environmental Development" Encyclopedia, https://encyclopedia.pub/entry/51899 (accessed February 08, 2026).

Kataya, G., Cornu, D., Bechelany, M., Hijazi, A., & Issa, M. (2023, November 22). Biomass Waste Conversion Technologies for Sustainable Environmental Development. In Encyclopedia. https://encyclopedia.pub/entry/51899

Kataya, Ghenwa, et al. "Biomass Waste Conversion Technologies for Sustainable Environmental Development." Encyclopedia. Web. 22 November, 2023.

Copy Citation

Biomass is defined as organic matter originating from living plants that can be naturally replenished or renewed. Biomass waste can be converted into valuable resources with high efficiency and low cost, which can save money and conserve natural resources. Biomass conversion is the process of converting organic matter from biomass into usable forms of energy and high-value products.

biomass

valorization

conversion

environment

waste management

1. Biomass Waste

Biomass is defined as organic matter originating from living plants that can be naturally replenished or renewed. Pang (2016) reported that the fundamental components comprising the structural composition of biomass include cellulose, hemicellulose, and lignin [1]. Biomass waste is challenging to quantify due to its diverse and dynamic waste streams and the lack of consistent data collection methods. It consists of lignocellulosic and food materials, which vary in composition and quantity based on geographical location; climate; and economic and social conditions. Roughly 50% of global waste is organic and can be considered biomass [2].

However, biomass waste is rapidly increasing and generates approximately 140 Gt of waste globally each year as per reports, causing significant disposal and governance issues [3].

Moreover, managing biomass waste sustainably is crucial due to its significant environmental and economic impacts. The burning or disposing of biomass waste in the field or landfills has low efficiency and causes severe environmental pollution. Thus, finding sustainable ways to manage biomass waste is gaining interest [4].

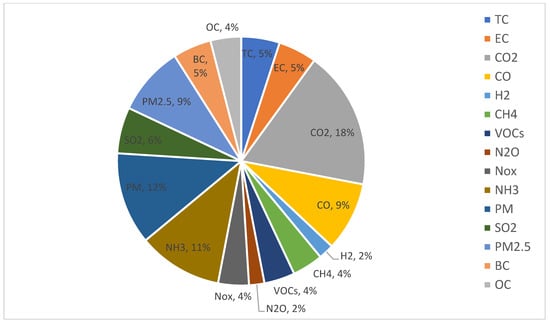

The presence of landfills gives rise to environmental concerns, primarily because they can lead to the contamination of surface and groundwater through leachate. Additionally, landfills generate greenhouse gas emissions during the decomposition of organic waste, which poses risks to air quality, human well-being, and plays a role in exacerbating climate change. Nevertheless, biomass has served as a fuel source for centuries, and while its combustion can result in the emission of pollutants, notably greenhouse gases, with CO2 being the predominant component (as illustrated in Figure 1), there exists the potential for its transformation into biofuels via thermochemical methods. These processes present a more environmentally sustainable substitute for fossil fuels [5][6][7][8].

Figure 1. Worldwide contributions of biomass burning emissions products [9].

2. Biomass Conversion Technologies

Addressing the need for a sustainable resolution to manage the increasing volume of biomass waste generated by the agri-food industry has stood as a key research focus for scholars over recent decades [10]. Biomass waste management and conversion are becoming increasingly popular due to the negative impact biomass waste has on the economy, the environment, and human health. However, recent research has shown that biomass waste can be converted into valuable resources with high efficiency and low cost, which can save money and conserve natural resources [11]. Biomass conversion is the process of converting organic matter from biomass into usable forms of energy and high-value products.

Biomass can be converted into several useful forms of energy and biochemicals using different processes and technologies [12][13]. Broadly, biomass conversion technologies fall into two categories: biochemical and thermochemical [14]. The selection of a specific conversion technology is influenced by several variables, including the type of feedstock and its moisture content, as well as the quality and quantity of biomass feedstock, its availability, the desired end products, economic considerations like profitability and market accessibility, and environmental considerations [15]. Rosendahl, L. (2010) explains that biomasses are also classified according to their water content when used for energy purposes [16]. Therefore, high-moisture biomass would not be appropriate for technologies that require prior drying, but instead would be appropriate for technologies that benefit from water content.

2.1. Biochemical Conversion

According to C. William et al. (2020), biochemical conversion is described as the process of converting biomass using enzymes from bacteria or other microorganisms to transform biomass into gaseous or liquid fuels, such as biogas or bioethanol [17]. This transformation occurs through anaerobic digestion, fermentation, or composting processes. Hydrogen, biogas, ethanol, acetone, butanol, and organic acids can be produced from biomass by selecting different microorganisms in the process of biochemical conversion as reported by Chen and wang (2016) [18]. By choosing different microorganisms, two types of butanediol can be produced, including 2,3butanediol, 1,4butanediol, isobutanol, xylitol, mannitol, and xanthan gum [19].

2.1.1. Anaerobic Digestion

Anaerobic digestion (AD), as detailed by Kumar and Ankaram (2019), is a method that transforms organic substances in an environment devoid of oxygen [20]. This process leads to the production of methane-rich biogas and involves a sequence of interrelated stages, including hydrolysis, fermentation, acetogenesis, and methanogenesis, as outlined by Sangeetha et al. (2020) [21]. During AD, microbes break down the organic components of waste to produce biogas that is composed of 40–65% methane (CH4), 35–55% CO2, and other trace gases like hydrogen (H2) and H2S. Additionally, the process yields a nutrient-rich residue known as digestate, which can be used as a soil conditioner or source of C, N, and P, as reported by Ghosh et al. (2020) and Wang and Lee (2021) [22][23].

2.1.2. Fermentation

According to Patra, D et al. (2022), fermentation is the process by which microorganisms (yeast or bacteria) convert biomolecules (glucose) into alcohol or acid under anaerobic conditions [24]. These products can yield fuels and various industrial bioproducts. Food and agricultural waste comprise a variety of sugars, with some being readily fermentable into ethanol and other products, while others, like cellulose, hemicellulose, starch, and protein, require additional processing before fermentation can commence. Conventional ethanol fermentation typically occurs within a temperature range below 35 °C, as indicated by Galbe and colleagues in their 2011 study [25].

Fermentation Products

The process of microbial fermentation converts sugars produced from biomass waste such as lignocellulosic waste, as explained by A.K. Chandel and co-authors in 2018 [26]:

-

Biofuels like ethanol (the most prevalent), butanol, acetone, iso-butanol, lipids, and more.

-

Organic acids such as lactic acid.

-

Carbon dioxide.

-

Hydrogen gas (H2).

Fermentation Feedstocks

The range of fermentation feedstocks for ethanol production is extensive and includes a variety of options. Among the most prevalent choices are cereal grains, sugar cane, and sugar beets, collectively known as first-generation feedstocks. However, due to concerns about food sustainability, lignocellulosic feedstocks, considered as a second-generation feedstock, have been developed as an alternative to overcome the limitations of first-generation bioethanol, as reported by Rodionova et al. (2022), and algal biomass as a third-generation feedstock, as reported by Timothy J. Tse et al. (2021) [27][28].

Limitations of Fermentation

There are several challenges that restrict the use of fermentation, as reported by Sindhu et al. (2016) [29] such as

-

Challenges in the process of deconstructing lignocellulosic biomass into functional components like sugars and lignin.

-

The need for energy-intensive pretreatment processes to separate the complex biomass into its individual components.

-

A significant proportion of the cost of processing lignocellulosic biomass for energy production comes from the pretreatment step, which can be more than 40%.

2.1.3. Composting

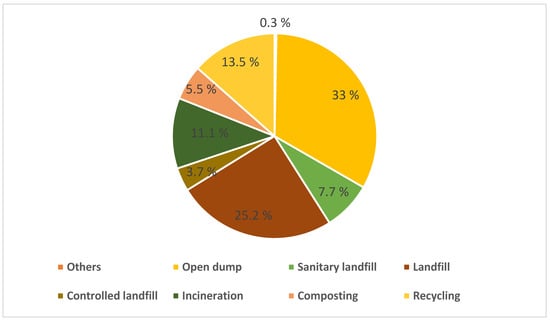

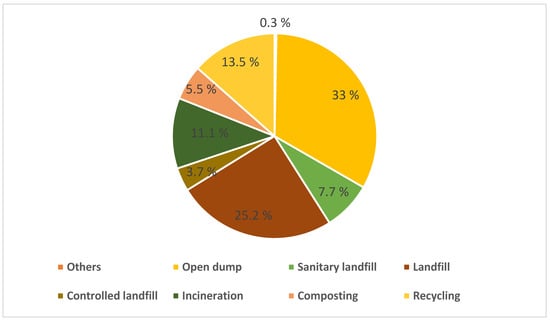

Composting comprises only 5.5% of the total waste treatment methods used globally, while open dumping comprises the largest share, of 33% (Figure 2) [30].

Figure 2. Share of the different waste management options in the global treatment and disposal of waste (%) [30].

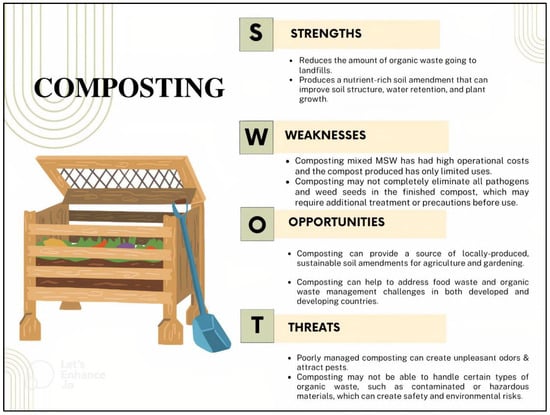

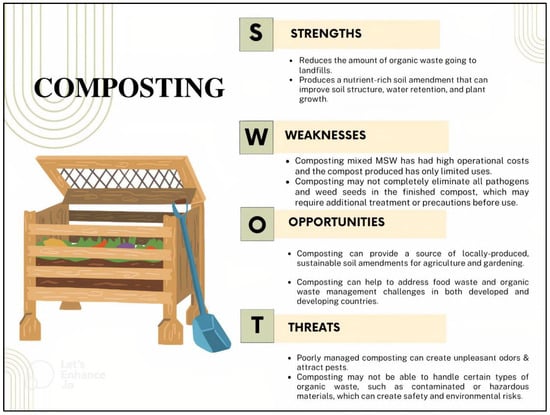

Figure 3 represents the weakness and the strength of composting in addition to the threats and opportunities. In brief, composting can be a good practice to reduce organic waste but it requires a lot of standards to be followed during the process to avoid having low quality products or causing any harm during the process.

Figure 3. Strengths and weaknesses of composting according to keener (2010) [31].

2.2. Thermochemical Conversion

Thermochemical processing employs controlled heating or oxidation to convert biomass into energy and chemical products. This approach presents various benefits compared to conventional methods, such as diminished greenhouse gas emissions and the capacity to generate electricity independently of an external power source, as noted by Mahinpey and Gomez (2016) [32]. The process involves elevated temperatures ranging from 300 to 1300 °C, the utilization of cost-effective and recyclable catalysts, rapid reaction rates, short reaction durations, and adaptability regarding feedstock composition and structure. Additionally, thermochemical conversion is not affected by the recalcitrance of biomass [33]. A variety of biomass waste materials, including food waste, agricultural residues, algae, forestry residues, and more, can be employed as suitable feedstocks for thermochemical conversion. Nevertheless, the selection of the thermochemical process hinges on the moisture content of the biomass waste. Therefore, there are two main categories of thermochemical conversion: dry (not aqueous) techniques and hydrothermal techniques. In dry thermochemical conversion, as the temperature increases, the biomass primarily undergoes structural destruction, decomposing into condensable vapors and gaseous molecules. In contrast, hydrothermal techniques produce a solid product at mild conditions (below 280 °C and self-generating pressure) [34].

Three primary pathways for thermochemical conversion are combustion, gasification, and pyrolysis, in addition to hydrothermal treatment (HTT) such as hydrothermal carbonization, liquefaction, and gasification [35][36].

2.2.1. Direct Combustion

Combustion converts biomass into heat, water, and carbon dioxide through an exothermic reaction in the presence of oxygen in open air or excess air. This process, one of the earliest uses of biomass conversion, involves the hydrocarbons in biomass and oxygen reacting together. However, improper oxygen quality can lead to incomplete combustion, releasing pollutants such as CO, NOX, SO2, and particulate matter into the atmosphere [37].

In the process of combustion, a solid fuel particle is introduced into a high-temperature environment, in which it undergoes drying and devolatilization, ultimately forming a residual char. Subsequently, this residual char is oxidized by substances like O2, CO2, and H2O, leaving behind an ash residue, as discussed by Hupa, M. et al. (2017) [38]. Typically, direct combustion takes place in a furnace, steam turbine, or boiler, within a temperature range spanning from 800 to 1000 °C. This method is particularly suitable for biomass materials with a low moisture content (below 50%), as outlined by Lam, M. K et al. (2019) [39].

2.2.2. Gasification

As per the insights provided by AlNouss et al. (2019), biomass gasification (BG) is a transformative process that turns biomass into valuable products, including biofuels, biochar, syngas, power, heat, and fertilizer [40]. Simultaneously, it contributes to reducing the necessity for environmentally harmful waste disposal methods. This technology employs a controlled process that involves heat, steam, and oxygen to convert biomass into hydrogen and other products while employing a gasifying agent, which can be air, oxygen, steam, carbon dioxide, or a combination of these. The choice of gasifying agent impacts the heat content of the resulting syngas. For gasification, the optimal moisture content for biomass falls within the range of 10% to 15% according to Gao et al., 2023 [41].

2.2.3. Pyrolysis

Pyrolysis is a process that subjects molecules to high temperatures within an oxygen-free environment, causing chemical decomposition and the formation of smaller molecules, as elucidated by Palmer (2013) [42]. The thermal breakdown of biomass via pyrolysis is a complex phenomenon involving a range of reactions, including dehydration, isomerization, dehydrogenation, aromatization, charring, and oxidation, as discussed by Rasul et al. (2012) [43]. These reactions give rise to various products, including steam, carbon oxides, aliphatic and aromatic hydrocarbons, pitch (tar), polymers, hydrogen, and coal, as indicated by Saravanan et al. (2021) [44]. These products are categorized as biochar, bio-oil, and biogas/syngas.

2.2.4. Hydrothermal Carbonization

Kumar and Ankaram (2019) explain hydrothermal carbonization (HTC) as a thermochemical process that uses hot, compressed water to pretreat biomass with a high moisture percentage (75–90%) [20]. In this procedure, the temperature typically falls within the range of 180–280 °C, while the pressure is maintained between 2–6 MPa, with a duration spanning from 5 to 240 min, as noted by Arellano et al. (2016) [45]. In addition to being able to process biomass with a high moisture content without predrying, HTC also has low carbonization temperatures (180–350 °C), and it can minimize air pollution by dissolving nitrogen oxides and sulfur oxides in water [46].

3. Hydrochar and Biochar

Subcritical water activates the hydrochar production process by carbonizing it hydrothermally at temperatures between 180 °C and 260 °C [47]. Apart from its distinct physical, chemical, and biological properties, hydrochar exhibits characteristics such as an elevated specific surface area and pore volume, greater mineral content, the capacity to mitigate nitrogen oxide emissions, an enrichment of surface functional groups, and enhanced efficiency in fixing CO2, as highlighted by Sharma et al. (2021) [48]. The agronomic and environmental benefits of biochar have sparked significant interest due to its porous structure and tunable functionality [49]. Difference between hydrochar and biochar are listed in Table 1.

Table 1. Difference between hydrochar and biochar [50].

| Hydrochar | Biochar | |

|---|---|---|

| Temperature | Low: 180–260 °C [47] | High: between 300 °C and 1000 °C [51] |

| Residence time | Short | Long |

| Pressure | High: 10–25 MPa [52] | Low |

| Moisture content | >10% | <10% |

| Characteristics | Non porous—core shell, alkali rich surface | Porous and aromatic rich surface |

| Low in fixed and total carbon content Energy efficient process |

High in fixed and total carbon content High ash content |

|

| High HHV | Low HHV |

3.1. Yield Improvement

Several studies have shown that incorporating biochar into the soil can enhance plant growth and increase yield. In a study, banana peel biochar was prepared at 400 °C temperature for 2 h and was added to soil to grow plants. They found that adding 2% or 3% biochar to the soil helped the plants grow, but the difference was not significant enough to be considered meaningful. They also found that the biochar was high in potassium [53].

Moreover, Choudhary et al. (2023) found that using biochar made from invasive weeds in combination with inorganic fertilizers can improve the yield and quality of oats [54]. The biochar helped increase the plant height and number of tillers, as well as improve the nutrient availability and soil water-holding capacity. This could provide a good strategy for managing invasive weeds. Specifically, the study found that using 75% of regular fertilizer and 10 tons of biochar per hectare resulted in an 8% increase in green fodder yield, a 7.8% increase in dry fodder yield, a 6% increase in crude protein, and a reduction of 5.7% and 6% in acid detergent fiber and neutral detergent fiber, respectively, when compared to using only regular fertilizer.

Furthermore, in their study, Knoblauch et al. (2021) observed that the application of a single dose of biochar, derived from organic waste sourced from a biogas plant, at a rate of 3.4 tons per hectare and heated to 650 °C, had a positive impact on corn yield. After a two-year period, they noted a significant increase of 33–37% in the corn yield when compared to control plots [55]. Additionally, their findings indicated that the biochar application led to a reduction in the availability of potentially harmful trace elements such as Zn, Pb, Cd, and Cr in the soil. Moreover, the study revealed that the application of biochar resulted in an even more substantial increase in the yield of winter crops, with gains ranging from 52–72%. However, it is worth noting that the positive effects of biochar application diminished over time.

Furthermore, a global meta-analysis has found that the application of biochar to soils can lead to significant improvements in crop yields and reductions in pollution. Specific studies conducted in the locations of Jokioinen, Qvidja, Viikki-1, and Viikki-2 in Finland found that using biochar resulted in increases of 65% in crop yield and reductions of 43% in greenhouse gas emissions. The use of spruce biochar in Qvidja also led to increases in plant biomass, plant nitrogen uptake, and crop yield, as well as a reduction in nitrogen leaching. This is attributed to the biochar’s high specific surface area, which allows it to retain nitrogen in the soil, making it a more efficient and sustainable method of fertilization. The specific soil types in these locations were Stagnosol, Cambisol, and Umbrisol, characterized by poor drainage, a high organic matter content, and a good water-holding capacity, respectively. The biochar used in these experiments was produced by pyrolyzing chipped forest residue at 450 °C and the application rate was 30 t ha−1 with five replicates [56][57].

3.2. Nutrient Retention

Biochar possesses an extensive surface area, enabling it to effectively absorb and retain essential nutrients like nitrogen, phosphorus, and potassium. As a result, it plays a role in mitigating nutrient leaching, which occurs when these essential elements are washed away from the soil due to rainfall or irrigation. This nutrient retention property of biochar contributes to a reduction in the demand for fertilizers, which are not only costly but also carry adverse environmental consequences.

The incorporation of biochar derived from pine tree waste, produced at 650 °C, into soil has the capacity to enhance both the total carbon content and the availability of phosphorus in the soil. In specific soil types, namely, sandy clay loam and clayey soils, the introduction of biochar at a rate of 20 Mg per hectare resulted in an increase of 24.9–28.7 g per kilogram of soil in total carbon, along with a rise of 43.9–79.5 mg per kg of soil in available phosphorus. Additionally, when biochar is co-applied with NP fertilizer, it has the potential to improve short-term phosphorus availability, as indicated in the research conducted by Romero et al. (2021) [58].

3.3. Water Retention

The impact of biochar on soil properties can vary depending on the soil’s texture. Generally, it reduces bulk density (BD) by approximately 9%. However, its effect on the water-holding capacity (FC and WP) is most pronounced in coarse-textured soils, where it increases by 51% and 47%, respectively. In medium-textured soils, the increase is moderate, at 13% for FC and 9% for WP. In fine-textured soils, the effect on the water-holding capacity is minimal or slightly decreased. Furthermore, biochar substantially enhances the available water (AW) in coarse-textured soils, surpassing the improvements observed in medium- and fine-textured soils by 45%.

These findings suggest that biochar may offer greater advantages when applied to coarse-textured soils. In summary, biochar has the potential to enhance soil properties, with its effects varying based on soil texture. It generally reduces soil density, making it less compact and more porous. Soil density indicates the degree of soil particle compaction, with denser soils having less space for air and water movement. A reduction in soil density provides more room for air and water to permeate, benefiting plant growth by enabling deeper root penetration, improved access to water and nutrients, and enhanced water infiltration and drainage [59].

3.4. Reduce Greenhouse Gases (GHG) Emissions

In a global meta-analysis, it was observed that the application of biochar to soils resulted in a significant average reduction of 38% in soil N2O emissions. The study identified that the application rate of biochar was the most influential variable in determining its potential for mitigating emissions [60].

Another study has suggested that the utilization of orange peel biochar can serve as an effective means for waste disposal, while simultaneously enhancing the fertility of soil. The study found that applying 2% orange peel biochar made at 350 °C for 3 h to the soil reduced greenhouse gas emissions by 59.2% for N2O and 29.3% for CO2. It was also discovered that over time, the soil pH, organic carbon, nitrate nitrogen, and enzyme activity increased [61].

Through its capacity to decrease greenhouse gas emissions, biochar emerges as a technology capable of mitigating climate change and mitigating its adverse effects.

3.5. Reduce Heavy Metals Availability

Joseph and Pan (2018), in their meta-analysis, found that the addition of biochar to soils resulted in a reduction in Cd, Pb, Cu, and Zn accumulation in plant tissues by approximately 38%, 39%, 25%, and 17%, respectively [62]. This reduction was particularly noticeable in coarse-textured soils. However, the impact of biochar on the uptake of heavy metals by plants varied depending on factors such as soil characteristics, the type of biochar used, plant species, and the type of contaminant. The study also revealed that the effect of biochar on Pb uptake was highly sensitive to soil pH. Specifically, decreases of 40%, 44%, and 20% in Pb uptake were observed in acidic, neutral, and alkaline soils, respectively.

Nonetheless, heavy metals do not constitute the sole category of pollutants that can be addressed through remediation. There are other pollutants, such as organic contaminants, in which biochar can serve as a remediation method. This applies to substances like pesticides, pharmaceutical products, as well as industrial products including solvents and additives. Research has shown that biochar is effective in combatting these pollutants. When biochar is introduced into agricultural soils, it can diminish the mobility, transport, and bioavailability of pesticides, while also reducing their microbial uptake. Furthermore, it has the capacity to promote soil microbiota and enhance pesticide degradation, as demonstrated by Ogura et al. (2021) [63].

3.6. Carbon Sequestration

The adverse effects of climate change, driven primarily by the emission of greenhouse gases like CO2, have significantly impacted agriculture by causing droughts and land degradation. In response to this challenge, biochar has emerged as a promising tool for carbon sequestration. Biochar effectively captures CO2 from the atmosphere and stores it in the soil. Subsequently, biochar serves as a valuable carbon source for the soil, playing a pivotal role in promoting soil health and enhancing productivity.

By capturing carbon from the atmosphere, biochar serves as a carbon storage mechanism. This process leads to an increase in soil organic carbon content, which is essential as an energy source for soil microorganisms. These microorganisms, in turn, play a crucial role in boosting plant growth and overall agricultural productivity.

In the study conducted by Yang et al. (2019), they observed a remarkable rise in the soil organic carbon levels of up to 26.7% in paddy soil [64]. Additionally, there was a substantial increase of up to 40.8% in the soil microbial biomass carbon. Moreover, Fawzy et al. (2022) reported in their study that 1 ton of biochar can embody 2.68 tCO2e [65].

3.7. Industrial Application of Biochar

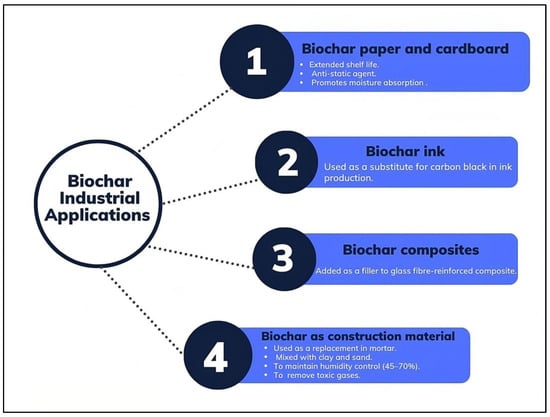

The review by Gąsior and Tic (2017) highlights the versatile nature of biochar and its potential to serve various purposes beyond its traditional applications in energy, agriculture, and wastewater treatment [66]. Its excellent insulating properties, ability to absorb moisture, and capacity to protect against electromagnetic radiation make it an ideal material for use in residential spaces, particularly as an insulating material and for moisture control. When combined with gypsum, clay, lime, or cement mortar, biochar can enhance the properties of plastering mortars due to its ability to absorb water and its low thermal conductivity.

Biochar has also captured the interest of numerous industries (Figure 4), including metallurgy, electronics, chemicals, textiles, and pharmaceuticals, due to its exceptional properties. The global market for biochar-based products includes a wide range of applications, such as microbiological preparations, animal feed supplements, paints and dyes, semiconductors, batteries, cosmetics, pharmaceuticals, food preservatives, and additives to textiles for functional clothing. Biochar can even be used as a filling material for pillows and mattresses.

Figure 4. Emerging biochar applications according to Garcia, B. et al. (2022) [67].

4. Conclusions

Biochar serves as a multifaceted solution in the realm of soil improvement. Its capacity to act as a soil amendment, preserving nutrients and moisture, immobilizing pollutants, reducing emissions, and enhancing soil structure and health, underscores its pivotal role in sustainable agriculture. Beyond its soil-enhancing benefits, biochar also emerges as a potent ally in the battle against climate change, further amplifying its significance in the agricultural and environmental sectors.

However, the thermochemical process involved in biomass conversion remains complex and time-consuming, and there is a need for further research to enhance efficiency, scalability, and economic feasibility.

Recent advances in machine learning offer a promising solution for optimizing biomass conversion processes, especially in the area of biomass pretreatment. By leveraging AI, more efficient and eco-friendly pretreatment methods have been developed, making biomass a sustainable and viable source for producing biofuels and other high-value products. Additionally, machine learning can improve the process of characterizing biochar for various applications, such as carbon sequestration and soil amendment.

Despite the progress made in assessing the economic feasibility of using agricultural biomass for energy and higher value products, there are still logistical challenges associated with biomass collection, transportation, and storage. Further analyses are needed to optimize models that account for practical issues like biomass deterioration rates and equipment availability. It is recommended to integrate economic and environmental analyses to achieve a comprehensive assessment of biomass conversion to bioenergy and higher value products.

References

- Pang, S. Fuel flexible gas production: Biomass, coal and bio-solid wastes. In Fuel Flexible Energy Generation; Woodhead Publishing: Amsterdam, The Netherlands, 2016; pp. 241–269.

- Kaltschmitt, M.; Janczik, S. Biomass to power is on the rise globally. Renew. Energy Focus 2015, 16, 174–176.

- Tripathi, N.; Hills, C.D.; Singh, R.S.; Atkinson, C.J. Biomass waste utilisation in low-carbon products: Harnessing a major potential resource. Npj Clim. Atmos. Sci. 2019, 2, 35.

- Zhou, C.; Wang, Y. Recent progress in the conversion of biomass wastes into functional materials for value-added applications. Sci. Technol. Adv. Mater. 2020, 21, 787–804.

- Fekete, B. Biomass. In Climate Vulnerability; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2013; pp. 83–87.

- Lou, X.F.; Nair, J. The impact of landfilling and composting on greenhouse gas emissions—A review. Bioresour. Technol. 2009, 100, 3792–3798.

- Zhao, H. Biomass burning emission and impacts on air pollution in China. In Asian Atmospheric Pollution; Elsevier: Amsterdam, The Netherlands, 2022; pp. 335–347.

- Fajobi, M.O.; Lasode, O.A.; Adeleke, A.A.; Ikubanni, P.P.; Balogun, A.O. Investigation of physicochemical characteristics of selected lignocellulose biomass. Sci. Rep. 2022, 12, 2918.

- Giglio, L.; Randerson, J.T.; van der Werf, G.R. Analysis of daily, monthly, and annual burned area using the fourth-generation global fire emissions database (Gfed4): Analysis of Burned Area. J. Geophys. Res. Biogeosci. 2013, 118, 317–328.

- Wancura, J.H.; Brondani, M.; Vezaro, F.D.; Martins-Vieira, J.C.; Moreira, B.P.; Dos Santos, M.S.; Abaide, E.R.; De Castilhos, F.; Mayer, F.D. Motivations to produce biofuels from rice bran: An overview involving a recent panorama. Ind. Crops Prod. 2023, 203, 117170.

- Martín, M.; Taifouris, M.; Galán, G. Lignocellulosic biorefineries: A multiscale approach for resource exploitation. Bioresour. Technol. 2023, 385, 129397.

- Vickram, A.; Saravanan, A.; Senthil Kumar, P.; Thamarai, P.; Yasodha, S.; Jamuna, G.; Rangasamy, G. An integrated approach to the sustainable development and production of biofuel from biopolymers and algal biomass derived from wastewater. Fuel 2023, 349, 128691.

- Adams, P.; Bridgwater, T.; Lea-Langton, A.; Ross, A.; Watson, I. Biomass Conversion Technologies. In Greenhouse Gas Balances of Bioenergy Systems; Elsevier: Amsterdam, The Netherlands, 2018; pp. 107–139.

- Velvizhi, G.; Jacqueline, P.J.; Shetti, N.P.K.L.; Mohanakrishna, G.; Aminabhavi, T.M. Emerging trends and advances in valorization of lignocellulosic biomass to biofuels. J. Environ. Manag. 2023, 345, 118527.

- Garba, A. Biomass conversion technologies for bioenergy generation: An introduction. In Biotechnological Applications of Biomass; Basso, T.P., Basso, T.O., Basso, L.C., Eds.; IntechOpen: London, UK, 2020; pp. 1–18.

- Rosendahl, L. Biomass resources, fuel preparation and utilization for improving the fuel flexibility of advanced power plants. In Advanced Power Plant Materials, Design and Technology; Elsevier: Amsterdam, The Netherlands, 2010; pp. 312–331.

- Williams, C.L.; Dahiya, A.; Porter, P. Introduction to bioenergy and waste to energy. In Bioenergy, 2nd ed.; Cambridge University Press: Cambridge, UK; New York, NY, USA, 2020; pp. 5–44.

- Chen, H.; Wang, L. Technologies for Biochemical Conversion of Biomass; Academic Press: London, UK, 2016.

- Chen, H.; Qiu, W. Key technologies for bioethanol production from lignocellulose. Biotechnol. Adv. 2010, 28, 556–562.

- Kumar, S.; Ankaram, S. Waste-to-Energy Model/Tool Presentation. In Current Developments in Biotechnology and Bioengineering; Elsevier: Amsterdam, The Netherlands, 2019; pp. 239–258.

- Sangeetha, T.; Rajneesh, C.P.; Yan, W. Integration of microbial electrolysis cells with anaerobic digestion to treat beer industry wastewater. In Integrated Microbial Fuel Cells for Wastewater Treatment; Butterworth-Heinemann: Oxford, UK; Cambridge, MA, USA, 2020; pp. 313–346.

- Ghosh, P.; Sengupta, S.; Singh, L.; Sahay, A. Life cycle assessment of waste-to-bioenergy processes: A review. Bioreactors 2020, 105–122.

- Wang, W.; Lee, D. Valorization of anaerobic digestion digestate: A prospect review. Bioresour. Technol. 2021, 323, 124626.

- Patra, D.; Patra, B.R.; Pattnaik, F.; Hans, N.; Kushwaha, A. Recent evolution in green technologies for effective valorization of food and agricultural wastes. In Emerging Trends to Approaching Zero Waste; Elsevier: Amsterdam, The Netherlands, 2022; pp. 103–132.

- Galbe, M.; Wallberg, O.; Zacchi, G. Techno-economic aspects of ethanol production from lignocellulosic agricultural crops and residues. In Comprehensive Biotechnology, 3rd ed.; Elsevier: Amsterdam, The Netherlands, 2011; pp. 519–531.

- Chandel, A.K.; Garlapati, V.K.; Singh, A.K.; Antunes, F.A.F.; da Silva, S.S. The path forward for lignocellulose biorefineries: Bottlenecks, solutions, and perspective on commercialization. Bioresour. Technol. 2018, 264, 370–381.

- Rodionova, M.V.; Bozieva, A.M.; Zharmukhamedov, S.K.; Leong, Y.K.; Chi-Wei Lan, J.; Veziroglu, A.; Veziroglu, T.N.; Tomo, T.; Chang, J.; Allakhverdiev, S.I. A comprehensive review on lignocellulosic biomass biorefinery for sustainable biofuel production. Int. J. Hydrogen Energy 2022, 47, 1481–1498.

- Tse, T.J.; Wiens, D.J.; Reaney, M.J.T. Production of Bioethanol—A Review of Factors Affecting Ethanol Yield. Fermentation 2021, 7, 268.

- Sindhu, R.; Binod, P.; Pandey, A. Biological pretreatment of lignocellulosic biomass–An overview. Bioresour. Technol. 2016, 199, 76–82.

- Ghisellini, P.; Santagata, R.; Zucaro, A.; Ulgiati, S. Circular patterns of waste prevention and recovery. E3S Web Conf. 2019, 119, 00003.

- Keener, H.M. Challenges and Opportunities in Composting Organic Waste. In Climate Change and Food Security in South Asia; Lal, R., Sivakumar, M., Faiz, S., Mustafizur Rahman, A., Islam, K., Eds.; Springer: Dordrecht, The Netherlands, 2010.

- Mahinpey, N.; Gomez, A. Review of gasification fundamentals and new findings: Reactors, feedstock, and kinetic studies. Chem. Eng. Sci. 2016, 148, 14–31.

- Mussatto, S.I.; Motta, I.L.; Filho, R.M.; van der Wielen, L.; Capaz, R.; Seabra, J.; Osseweijer, P.; Posada, J.; de Freitas Gonçalves, M.; Scorza, P.R.; et al. Sustainable Aviation Fuels: Production, Use and Impact on Decarbonization. In Comprehensive Renewable Energy, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 348–371.

- Zhang, J.; Zhang, X. The thermochemical conversion of biomass into biofuels. In Biomass, Biopolymer-Based Materials, and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2019; pp. 327–368.

- Sadhwani, N.; Liu, Z.; Eden, M.R.; Adhikari, S. Simulation, Analysis, and Assessment of CO2 Enhanced Biomass Gasification. Comput. Aided Chem. Eng. 2013, 32, 421–426.

- Zhang, W.; Chen, Q.; Chen, J.; Xu, D.; Zhan, H.; Peng, H.; Pan, J.; Vlaskin, M.; Leng, L.; Li, H. Machine learning for hydrothermal treatment of biomass: A review. Bioresour. Technol. 2022, 370, 128547.

- Yang, W.; Pudasainee, D.; Gupta, R.; Li, W.; Wang, B.; Sun, L. An overview of inorganic particulate matter emission from coal/biomass/MSW combustion: Sampling and measurement, formation, distribution, inorganic composition and influencing factors. Fuel Process. Technol. 2021, 213, 106657.

- Hupa, M.; Karlström, O.; Vainio, E. Biomass combustion technology development–It is all about chemical details. Proc. Combust. Inst. 2017, 36, 113–134.

- Lam, M.K.; Loy AC, M.; Yusup, S.; Lee, K.T. Biohydrogen Production from Algae. In Biohydrogen, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2019; pp. 219–245.

- Alnouss, A.; McKay, G.; Al-Ansari, T. Superstructure Optimization for the Production of Fuels, Fertilizers and Power using Biomass Gasification. In Computer Aided Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2019; Volume 46, pp. 301–306.

- Gao, Y.; Wang, M.; Raheem, A.; Wang, F.; Wei, J.; Xu, D.; Song, X.; Bao, W.; Huang, A.; Zhang, S.; et al. Syngas Production from Biomass Gasification: Influences of Feedstock Properties, Reactor Type, and Reaction Parameters. ACS Omega 2023, 8, 31620–31631.

- Palmer, R. Identification and Comparison. In Encyclopedia of Forensic Sciences; Academic Press: San Diego, CA, USA, 2013; pp. 129–137.

- Rasul, M.G.; Jahirul, M.I. Recent developments in biomass pyrolysis for bio-fuel production: Its potential for commercial applications. In Proceedings of the Recent Research in Environmental and Geological Sciences, 7th WSEAS International Conference on Energy & Environment (EE’12), Kos Island, Greece, 14–17 July 2012; pp. 256–264, ISBN 978-1-61804-110-4.

- Saravanan, A.; Senthil Kumar, P.; Khoo, K.S.; Show, P.; Femina Carolin, C.; Fetcia Jackulin, C.; Jeevanantham, S.; Karishma, S.; Show, K.; Lee, D.; et al. Biohydrogen from organic wastes as a clean and environment-friendly energy source: Production pathways, feedstock types, and future prospects. Bioresour. Technol. 2021, 342, 126021.

- Arellano, O.; Flores, M.; Guerra, J.; Hidalgo, A.; Rojas, D.; Strubinger, A. Hydrothermal carbonization of corncob and characterization of the obtained hydrochar. Chem. Eng. Trans. 2016, 50, 235–240.

- Nasrollahzadeh, M.; Nezafat, Z.; Shafiei, N. Lignin chemistry and valorization. In Biopolymer-Based Metal Nanoparticle Chemistry for Sustainable Applications; Elsevier: Amsterdam, The Netherlands, 2021; pp. 145–183.

- Basu, P. Hydrothermal Conversion of Biomass. In Biomass Gasification, Pyrolysis and Torrefaction, 3rd ed.; Demirbas, A., Ed.; Academic Press: London, UK, 2018; pp. 331–371.

- Sharma, H.B.; Venna, S.; Dubey, B.K. Resource recovery and circular economy approach in organic waste management using hydrothermal carbonization. Clean Energy Resour. Recovery 2021, 1, 313–326.

- Wang, Y.; Wu, P.; Bolan, N.S.; Wang, H. The potential agronomic and environmental applications of biochar: Prospects and challenges. In Reference Module in Earth Systems and Environmental Sciences; Elsevier: Amsterdam, The Netherlands, 2022.

- Kumar, A.; Saini, K.; Bhaskar, T. Hydochar and biochar: Production, physicochemical properties and techno-economic analysis. Bioresour. Technol. 2020, 310, 123442.

- Zhang, J.; Liu, J.; Liu, R. Effects of pyrolysis temperature and heating time on biochar obtained from the pyrolysis of straw and lignosulfonate. Bioresour. Technol. 2015, 176, 288–291.

- Masoumi, S.; Borugadda, V.B.; Nanda, S.; Dalai, A.K. Hydrochar: A Review on Its Production Technologies and Applications. Catalysts 2021, 11, 939.

- Islam, M.; Halder, M.; Siddique, M.A.B.; Razir, S.A.A.; Sikder, S.; Joardar, J.C. Banana peel biochar as alternative source of potassium for plant productivity and sustainable agriculture. Int. J. Recycl. Org. Waste Agricult. 2019, 8 (Suppl. S1), 407–413.

- Choudhary, P.; Prasad, M.; Choudhary, M.; Kumar, A.; Kumar, S.; Srinivasan, R.; Mahawer, S.K. Exploring invasive weed biochar as soil amendment: A study on fodder oats productivity and soil biological properties. Environ. Res. 2023, 216, 114527.

- Knoblauch, C.; Renuka Priyadarshani, S.H.; Haefele, S.M.; Schröder, N.; Pfeiffer, M. Impact of biochar on nutrient supply, crop yield and microbial respiration on sandy soils of northern Germany. Eur. J. Soil Sci. 2021, 72, 1885–1901.

- Kalu, S.; Simojoki, A.; Karhu, K.; Tammeorg, P. Long-Term Effects of Softwood Biochar on Soil Physical Properties, Greenhouse Gas Emissions and Crop Nutrient Uptake in Two Contrasting Boreal Soils. Agric. Ecosyst. Environ. 2021, 316, 107454.

- Soinne, H.; Keskinen, R.; Heikkinen, J.; Hyväluoma, J.; Uusitalo, R.; Peltoniemi, K.; Velmala, S.; Pennanen, T.; Fritze, H.; Kaseva, J.; et al. Are There Environmental or Agricultural Benefits in Using Forest Residue Biochar in Boreal Agricultural Clay Soil? Sci. Total Environ. 2020, 731, 138955.

- Romero, C.M.; Hao, X.; Li, C.; Owens, J.; Schwinghamer, T.; McAllister, T.A.; Okine, E. Nutrient retention, availability and greenhouse gas emissions from biochar-fertilized Chernozems. Catena 2021, 198, 105046.

- Razzaghi, F.; BilsonObour, P.; Arthur, E. Does biochar improve soil water retention? A systematic review and meta-analysis. Geoderma 2020, 361, 114055.

- Zhang, Q.; Xiao, J.; Xue, J.; Zhang, L. Quantifying the effects of biochar application on greenhouse gas emissions from agricultural soils: A global meta-analysis. Sustainability 2020, 12, 3436.

- Sial, T.A.; Lan, Z.; Khan, M.N.; Zhao, Y.; Kumbhar, F.; Liu, J.; Zhang, A.; Hill, R.L.; Lahori, A.H.; Memon, M. Evaluation of orange peel waste and its biochar on greenhouse gas emissions and soil biochemical properties within a loess soil. Waste Manag. 2019, 87, 125–134.

- Joseph, S.; Pan, G. Effects of biochar on availability and plant uptake of heavy metals–A meta-analysis. J. Environ. Manag. 2018, 222, 76–85.

- Ogura, A.P.; Lima, J.Z.; Marques, J.P.; Massaro Sousa, L.; Rodrigues, V.G.S.; Espíndola, E.L.G. A review of pesticides sorption in biochar from maize, rice, and wheat residues: Current status and challenges for soil application. J. Environ. Manag. 2021, 300, 113753.

- Yang, S.; Chen, X.; Jiang, Z.; Ding, J.; Sun, X.; Xu, J. Effects of Biochar Application on Soil Organic Carbon Composition and Enzyme Activity in Paddy Soil under Water-Saving Irrigation. Int. J. Environ. Res. Public Health 2019, 17, 333.

- Fawzy, S.; Osman, A.I.; Mehta, N.; Moran, D.; Al-Muhtaseb, A.H.; Rooney, D.W. Atmospheric carbon removal via industrial biochar systems: A techno-economic-environmental study. J. Clean. Prod. 2022, 371, 133660.

- Gąsior, D.; Tic, W. Application of the biochar-based technologies as the way of realization of the sustainable development strategy. Econ. Environ. Stud. 2017, 17, 597–611.

- Garcia, B.; Alves, O.; Rijo, B.; Lourinho, G.; Nobre, C. Biochar: Production, applications, and market prospects in Portugal. Environments 2022, 9, 95.

More

Information

Subjects:

Agricultural Engineering

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

793

Revisions:

2 times

(View History)

Update Date:

23 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No