Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Jia, J.; Li, Y. Deep Learning Algorithms for Structural Health Monitoring. Encyclopedia. Available online: https://encyclopedia.pub/entry/51824 (accessed on 07 February 2026).

Jia J, Li Y. Deep Learning Algorithms for Structural Health Monitoring. Encyclopedia. Available at: https://encyclopedia.pub/entry/51824. Accessed February 07, 2026.

Jia, Jing, Ying Li. "Deep Learning Algorithms for Structural Health Monitoring" Encyclopedia, https://encyclopedia.pub/entry/51824 (accessed February 07, 2026).

Jia, J., & Li, Y. (2023, November 21). Deep Learning Algorithms for Structural Health Monitoring. In Encyclopedia. https://encyclopedia.pub/entry/51824

Jia, Jing and Ying Li. "Deep Learning Algorithms for Structural Health Monitoring." Encyclopedia. Web. 21 November, 2023.

Copy Citation

Environmental effects may lead to cracking, stiffness loss, brace damage, and other damages in bridges, frame structures, buildings, etc. Structural Health Monitoring (SHM) technology could prevent catastrophic events by detecting damage early. In recent years, Deep Learning (DL) has developed rapidly and has been applied to SHM to detect, localize, and evaluate diverse damages through efficient feature extraction.

structural health monitoring

deep learning algorithms

damage detection

1. Introduction

Various damages may occur in building structures after long terms of environmental loads such as wind, earthquake, automobile, environmental vibration, etc. It could consequently impact the building’s general stability and safety and lead to serious loss of life and property [1]. For this reason, SHM is critical to the facility, whether it is the whole facility or key components of the facility. For example, a healthy concrete structure needs to maintain high strength and good durability, which is closely related to the material and ratio of mortar [2][3]. The reduction of strength and durability reflects the insecurity of the structure, which requires SHM to evaluate the durability through vibration, stress, and other parameters.

Housner et al. [4] defined SHM as using sensing technology and structural characterization to detect changes that may indicate damage or degradation. Dong et al. [5] proposed that SHM is the process of tracking operational status, assessing the condition, and detecting various types of structural damage. In summary, the primary purpose of SHM is to enable damage detection and condition assessment by sensing, recognizing, and evaluating structural operating conditions. Its core component is Damage Detection (DD), i.e., structural damage identification, localization, and assessment. Damage detection was separated into four categories in the Rytter study [6]. (1) Detection: clarification of the presence of damage. (2) Location: determination of the location and coordinates of the damage. (3) Assessment: measurement of the severity of the damage. (4) Consequence: acquisition of the actual safety information of the structure in the determined damage state. There are four critical elements of SHM: data acquisition, system identification, condition assessment, and maintenance [7]. Among them, the sensor and sensor data in the data acquisition stage are the core of SHM applications. The operational status data of the structure is obtained through contact (accelerometers, strain gauges, fiber optic sensors) and non-contact sensors (high-speed cameras, drones, smartphones). Based on the data, appropriate data processing methods (Machine Learning (ML), DL, signal processing methods) are adopted to select damage-sensitive features for damage identification and condition assessment. Finally, according to the evaluation results, necessary measures are taken to maintain the safety and service life of the structure.

Early SHM relied on visual inspection, which had the drawbacks of low efficiency, poor accuracy, susceptibility to subjective factors, and high cost of labor and time [8]. Gradually, Non-Destructive Testing (NDT) methods, such as Acoustic Emission (AE) [9], ultrasonic [10], X-ray [11], magnetic particle inspection [12], eddy current [13], and other detection methods, are frequently utilized for monitoring the key component of the structure [13]. Currently, the most commonly used SHM methods are vibration-based SHM [14][15][16][17][18], AE-based SHM [9][19][20], Guided Wave (GW) based SHM [21][22][23][24][25], and Electro-Mechanical Impedance (EMI) based SHM [26][27]. Among them, vibration-based SHM is the most popular one by analyzing the relationship between vibration characteristics and damage states. In general, DD methods for SHM can be divided into model-driven methods and data-driven methods [28]. The former uses a Finite Element Model (FEM) calibrated by sensor data and optimization algorithms to analyze structural damage. The latter uses sensor data directly to detect structural damage. Moreover, the data-driven methods, which directly obtain damage features from sensor data to estimate the structural state, are more flexible and have attracted more and more attention. Thereby, the Gaussian model, ML, and DL have emerged as popular data analysis methods.

DL is a sub-field of ML in artificial intelligence, which has become an important research topic with the development of big data, computer software, and hardware. DL comes from the research of Artificial Neural Networks (ANN), which learn the characteristics of data samples by imitating the structure of human brain neurons and then give the interpretation of data. As a multi-layer neural network, DL will feed the features of the original signal detected from the low to the high layer, which is more conducive to learning advanced features. Compared with traditional ML, DL is capable of automatic feature extraction and is suitable for processing other high-dimensional data such as images, video, and audio. Therefore, DL is used in various fields, such as speech recognition [29][30], machine translation [31][32], image classification [33][34], etc. In addition, DL has also been applied to SHM to identify, locate, and evaluate various damages by extracting advanced damage features from data such as pictures and vibration signals [15][35][36].

In the field of SHM, DL methods can be divided into image-based and vibration-based methods. The former uses the DL algorithm to extract features from the structural surface damage images and realizes image processing through classification, localization, and segmentation. First, the images are classified and labeled as damaged or undamaged. Secondly, the damaged area and damaged coordinates are located and identified. Finally, pixel-level segmentation marks image pixels as damaged or undamaged [37]. The mainstream DL algorithm applied to structural surface image damage detection is mainly a Convolutional Neural Network (CNN), which can realize image classification, object recognition, and semantic segmentation. The CNN algorithm involved includes Two-Dimensional Convolutional Neural Networks (2D-CNN), You Look Only Once (YOLO), U-Net, Region-based Convolutional Neural Networks (R-CNN), Fully Convolutional Networks (FCN), Mask Region-Based Convolutional Neural Networks (Mask R-CNN), etc. Li et al. [38] used the sliding window method to cover the image of the steel bridge and used convolution and pooling methods in CNN to classify the steel bridge’s bolts, nuts, and nut holes. Kao et al. [36] used YOLOv4 to identify bridge cracks through boundary frame selection and extracted crack contours using the edge detection method to achieve crack quantification. Panta et al. [39] proposed an iterative loop U-Net to segment crack images of levees into crack pixels and non-crack pixels to identify crack shapes accurately. Therefore, the DL algorithm can make use of structural surface defect images of bridges, frame structures, dams, tunnels, and other infrastructures for crack detection [40][41][42][43][44], bolt loosening detection [45][46][47], rebar surface defect detection [48], delamination and reinforcement exposure detection [49], displacement detection [50][51][52][53], voids detection [54], etc. The primary sensors used to acquire structural surface defect images mainly include high-resolution cameras, infrared and near-infrared cameras, mobile phones, radar systems, and so on [55]. Unmanned Air Vehicles (UAVs) can carry various sensors, hover, and fly through remote sensing technology to obtain high-definition damage images.

Image-based SHM cannot detect internal damage, while vibration-based SHM can extract natural frequencies, vibration modes, and damping ratios from vibration data to detect internal damage. However, when processing vibration signals using 2D-CNN, it is necessary to convert one-dimensional data into two-dimensional data. On this basis, One-Dimensional Convolutional Neural Networks (1D-CNN) with simple architecture and low computational complexity are applied to SHM to directly process 1D data for crack detection [56][57], corrosion detection [58], multi-type damage identification [1], abnormal data detection [59][60], etc. In addition to CNN, Recurrent Neural Networks (RNN) can identify the time features of data. Through Long Short-Term Memory (LSTM) and Gated Recurrent Unit (GRU), it can not only realize multi-type damage identification and location [61], crack detection [62][63], and dam displacement monitoring [64][65][66] but also detect data anomalies caused by sensor faults or environmental changes [67][68][69], and even predict missing data [70][71][72][73]. There are also unsupervised learning algorithms, such as auto-encoder and Generative Adversarial Networks (GAN), which directly use unlabeled data for feature extraction. They can be applied for dimensionality reduction [74][75], image generation [43][76], lost data reconstruction [77][78][79], AE source localization [80][81], crack detection [82][83][84], and so on.

2. Convolutional Neural Network

2.1. CNN

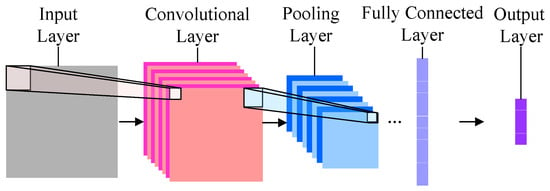

The CNN is the most popular DL network variant, mainly applied to image processing. The architecture of CNN is shown in Figure 1, including the input, output, convolution, pooling, and fully connected layers. The input layer receives the image and passes it to the convolutional layer, which convolves the image using filters to achieve feature extraction. The pooling layer, also known as the sub-sampling layer, reduces the output size of the convolutional layer by calculating statistical features such as mean and maximum values. This layer can reduce the parameters and the amount of calculation. The fully connected layer uses a classifier to classify the image by combining all the previous layer’s information and then outputs the final result with the output layer. There have been various architectures in the development of CNN. Firstly, LeNet-5 [85] is a relatively early and simple architecture with seven layers for handwritten character image classification. AlexNet [86] successfully used rectified linear units as the activation function in CNNs, enabling deeper and broader CNN development. VGG-16 [87] adds depth by stacking convolutional layers and pooling layers, including thirteen convolutional layers and three fully connected layers. GoogleNet [88] consists of several inception modules, enabling dimensionality reduction and mitigating adverse effects such as gradient disappearance due to increasing depth. ResNet [89] builds deeper models and deals with the problem of accuracy reduction due to gradient disappearance through residual learning.

Figure 1. CNN architecture diagram [90].

CNN’s processing of images can be roughly divided into three categories: image classification, object recognition, and semantic segmentation [91]. 2D-CNN is primarily used for image classification. For the input image, CNN uses a fixed-size sliding window to detect defects on each image block according to a certain stride [35]. Zhang et al. [92] applied CNN to classify bridge cracks into three categories: small, large, and serious, based on the crack images. In addition, when dealing with SHM problems based on vibration signals, GW, and AE signals, the method often adopted is transforming the signals into images in the time and frequency domains [37]. Wang et al. [93] adopted the Hilbert–Huang transform to convert the vibration signal into a time-frequency diagram as the input of a 2D-CNN for detecting seven damage modes of the IASC-ASCE benchmark structure. Chen et al. [21] processed the GW signal into a time-frequency map using a complex Gaussian wavelet transform and applied CNN to assess the length of fatigue cracks. Sikdar et al. [19] used Continuous Wavelet Transform (CWT) to process time-domain AE signals for AE source classification.

Region-based Convolutional Neural Networks (R-CNN) can solve the problem of object recognition. The traditional target detection method is the sliding window method. However, the size and stride of the sliding window are too large to reduce the detection accuracy and too small to increase the computational cost. Considering the above problems, Girshick et al. [94] proposed the R-CNN method. This method first determines the candidate region using a selective search and then extracts the defect features on the candidate region and identifies them with the bounding box to achieve object recognition. The successive introduction of Fast R-CNN [95] and Faster R-CNN [96] further improves computational efficiency. Pham et al. [97] used R-CNN to recognize bolts and backgrounds in synthetic images. Li et al. [98] realized the classification and location of coarse cracks in tunnel images through Faster R-CNN. Regarding the real-time detection problem, researchers subsequently proposed Single Shot MultiBox Detector (SSD) [99] and YOLO [100]. Hou et al. [101] employed YOLOv3-tiny and YOLOv3 to identify trucks, pickup trucks, and cars with high accuracy based on camera images of the effect of vehicle loads on bridges. Pan et al. [53] established Yolov3-tiny and Yolov3-tiny-KLT based on YOLOv3 architecture to realize vision-based structural vibration measurement.

For various defects, bounding box recognition cannot determine the shape of the defect well. In this case, pixel-level semantic segmentation can assign categories to each pixel in the image and separate the defect from the background to achieve more accurate detection and location. The models involved include FCN [102], U-net [103], FC-DenseNet [104], Deeplabv3+ [105], Mask R-CNN [106], etc. Wang et al. [41] used an FCN-based network to segment the steel beam crack splicing image to detect the size and location of the crack by the centroid coordinates, inclination, and other characteristic symbols. Zhang et al. [50] introduced a displacement monitoring method based on Mask R-CNN, which achieves the purpose of displacement detection by extracting the mask information to obtain the coordinates of the calibrated object. Qiu et al. [107] proposed that WRDeepLabV3+ combined with the class activation map could accurately identify leakage in subway tunnels, which could segment the leakage area more thoroughly.

The image processing of 2D-CNN involves a large amount of data, which has high complexity and requires special hardware equipment. Kiranyaz et al. [108] presented 1D-CNN, which had the advantages of low computational complexity, highly cost-effective, and real-time application in mobile devices compared to 2D-CNN. With the popularity of vibration signal-based SHM, vibration signals can be directly input into a 1D-CNN for damage identification, localization, and assessment. Zhang et al. [109] obtained the time-varying damage index from the Lamb wave and used the 1D-CNN to locate the damage in the plate. Sony et al. [1] divided the bridge damage into categories such as abutment settlement and tendon rupture using 1D-CNN based on vibration signals. Wu et al. [110] used 1D-CNN to process vibration signals from experiments and numerical simulations and then realized notch detection of steel beams.

2.2. The Combined Application of DL Algorithms

For vibration-based SHM, the vibration signals collected by different sensors have strong temporal and spatial correlations. To effectively extract damage-sensitive features from vibration signals, it is necessary to adopt methods to process data from time and space dimensions. The problem of data temporal and spatial feature extraction can be solved using a combination of the CNN and RNN methods, such as CNN with GRU [64][111][112], CNN with LSTM [27][113][114][115][116][117], CNN with Auto-encoder and [118], CNN with echo state networks [119], etc.

Yang et al. [112] proposed a hierarchical CNN and GRU framework called HCG, which used a CNN to extract spatial and short-term temporal features and a GRU to learn long-term temporal dependencies. Through the evaluation of the IASC-ASCE and TCRF datasets, HCG is significantly superior to other existing damage detection methods in performance. On this basis, Yang et al. [111] proposed a framework for Parallel CNN and Bidirectional GRU, which avoided the loss of time-related features of data entering CNN first through dual-channel data processing. It is verified that this framework has better recognition performance than HCG on the same two datasets. Dang et al. [113] combined CNN with LSTM to process vibration signals, and they achieved high-accuracy bridge DD with reduced time and memory complexity. Parziale et al. [118] proposed a coupling method of a CNN and autoencoder to neutralize the influence of temperature change and improve the accuracy of damage detection on a limited dataset.

3. Recurrent Neural Network

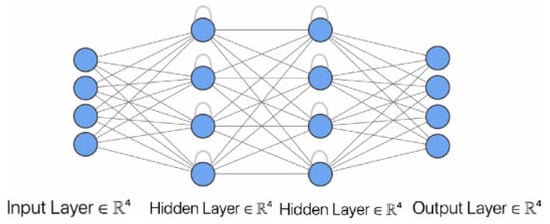

RNN allows capturing the temporal dependencies between data and is suitable for sequential data processing, such as vibration data, GW data, etc. As shown in Figure 2, the RNN consists of input, output, and hidden layers. The key is the hidden layer containing multiple units, where the production of one unit depends not only on the input of this unit but also correlates with the output of the previous unit, allowing the information above to be applied to the current state. Back-Propagation Through Time (BPTT) is the standard training algorithm for RNNs, but the problem of gradient disappearance or gradient explosion occurs when using BPTT to solve long-time dependencies. The LSTM [120] is employed to solve this problem, using forgetting, input, and output gates as threshold mechanisms to manage information. Users can decide whether to add, delete, and pass information, processing longer sequences. GRU [121] is a variant based on the LSTM, which only contains an update gate and reset gate and has a faster training speed than the LSTM with fewer parameters.

Figure 2. RNN architecture diagram [122].

Application of the RNN to SHM mainly uses time series data for damage identification, location, and evaluation. Relying on its advantage of capturing the time dependence of data, the RNN is also often adopted for missing data prediction. Based on the QUGS and Z24 bridge benchmark datasets, Sony et al. [61] first used LSTM to classify vibration signals into multiple categories. Then, the author presented the damage probability of all data through the heat map, and the area with high damage probability was the location where the damage occurred. Finally, the identification and location of multiple types of damage were realized using this method. Aiming at the random missing and continuous missing of dam data, Li et al. [123] exploited LSTM to capture the time dependence of the original sensor data to realize missing data interpolation. Deng et al. [124] used the GRU to establish a model of vehicle influence coefficient, temperature input, and deflection output, aiming to accurately predict the suspension bridge’s deflection.

4. Auto-Encoder

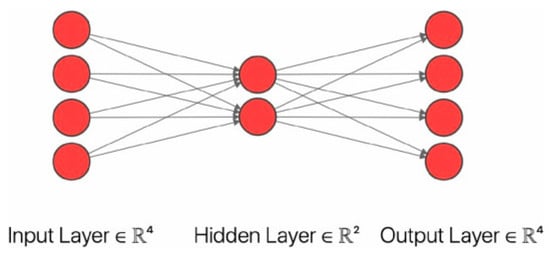

Auto-encoder is an unsupervised learning model mainly applied to data denoising, dimensionality reduction, and feature extraction. As shown in Figure 3, the auto-encoder’s most straightforward architecture includes the input, output, and hidden layers. The input layer inputs data, the mapping of the hidden layer acts as an encoder to reduce the dimension and compress the data, and the mapping of the output layer acts as a decoder to reconstruct the data. The number of neurons in the input and output layers is the same [125], which aims to reconstruct the input data. According to different application requirements, auto-encoder includes many types, such as stacked auto-encoder, variational auto-encoder, denoising auto-encoder, sparse auto-encoder, convolutional auto-encoder, etc.

Figure 3. Auto-encoder architecture diagram [122].

Auto-encoder performs data dimension reduction to eliminate unnecessary information such as data redundancy and noise in high-dimensional data and thus directly learn the necessary information. Pathirage et al. [126] introduced an autoencoder-based framework for structural damage identification, including dimensionality reduction and relational learning. The accuracy and efficiency of the framework were verified through numerical and experimental studies on the steel framework. Ebrahimkhanlou et al. [80] implemented AE source localization by stacking self-encoders with progressive compression of the input AE waveform. Coordinate localization or area localization was performed through regression or softmax layers, capable of localizing AE sources at arbitrary locations on the board. Lei et al. [127] studied a method for predicting the displacement of cable-stayed bridges using residual autoencoders. The method took temperature, wind speed, and vehicle load as input and displacement response as output, achieving more than 95% effectiveness.

5. Generative Adversarial Network

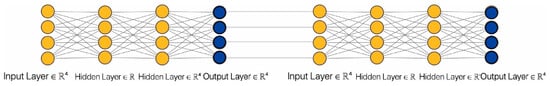

The GAN is also an unsupervised learning method proposed by Goodfellow et al. [128] in 2014, mainly for image generation and data enhancement. The architecture of the GAN is shown in Figure 4. The GAN consists of two parts: a generator, which aims to synthesize data as similar as possible to the training data, and a discriminator, which aims to distinguish the original data from the synthesized data. The two oppose each other and improve each other. Traditionally, the generator is a multilayer perceptron, and the discriminator is a binary classifier. With the development of CNN feature extraction capability, CNNs can also be used as generators and discriminators, known as Deep Convolutional GANs (DCGAN) [129], improving training stability and effectiveness.

Figure 4. GAN architecture diagram [122].

Chen et al. [76] employed the GAN to generate many virtual crack images similar to real images, which were applied to train CNN models for crack detection. Gao et al. [130] presented a balanced semi-supervised GAN that solved low data and imbalance class problems using balanced batch sampling during training. Rastin et al. [82] proposed a two-stage damage detection method. The DCGAN learned structural health data to obtain the probability of data from the structural integrity state, which was used to evaluate the severity of the damage. A conditional GAN classified the data into different accelerometer sources to achieve damage localization. Lei et al. [79] exploited the DCGAN to learn the features of the pre-loss data to reconstruct the lost data. Then, they distinguished the actual and reconstructed data using discriminators to improve the reconstruction accuracy.

6. Others

A Multi-Layer Perceptron (MLP) is an artificial neural network containing an input, hidden, and output layer. It is capable of performing classification and regression tasks. Due to the small number of hidden layers, it can only solve simple problems. Mariani et al. [10] adopted various methods of 1D-CNN, LSTM, and MLP for plate hole detection, among which the performance of the MLP method was slightly inferior. Deep Neural Networks (DNNs) are deep neural networks with more hidden layers than MLP, thus improving the performance of feature recognition. Kohiyama et al. [131] fully exploited the powerful DNN damage pattern classification capability and combined it with an SVM to achieve unlearned damage pattern classification.

Sabour et al. [132] proposed capsule neural networks, where each capsule consists of a set of neurons and is activated by a routing algorithm. It can solve the problem that the CNN cannot recognize the hierarchical structure in the image and has been applied to many fields to perform classification and regression tasks. Barraza et al. [133] employed CapsNets to localize and quantify the stiffness reduction damage in beams, showing that the method achieved better results than CNNs. Son et al. [134] proposed that a Graph Neural Network (GNN) can learn graph structure data, which overcame the limitation that a CNN can only learn grid structure data. Finally, using graph sensor data, the GNN was trained to successfully detect cable damage on cable-stayed bridges. Li et al. [135] proposed a transformer-based time series prediction framework, verified by bridge strain data, and was found to have a more minor error than LSTM.

References

- Sony, S.; Gamage, S.; Sadhu, A.; Samarabandu, J. Multiclass Damage Identification in a Full-Scale Bridge Using Optimally Tuned One-Dimensional Convolutional Neural Network. J. Comput. Civil Eng. 2022, 36, 14.

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629.

- Wu, H.; Hu, R.; Yang, D.; Ma, Z. Micro-macro characterizations of mortar containing construction waste fines as replacement of cement and sand: A comparative study. Constr. Build. Mater. 2023, 383, 131328.

- Housner, G.W.; Bergman, L.A.; Caughey, T.K.; Chassiakos, A.G.; Claus, R.O.; Masri, S.F.; Skelton, R.E.; Soong, T.T.; Spencer, B.F.; Yao, J.T.P. Structural control: Past, present, and future. J. Eng. Mech. 1997, 123, 897–971.

- Dong, C.-Z.; Catbas, F.N. A review of computer vision-based structural health monitoring at local and global levels. Struct. Health Monit. 2021, 20, 692–743.

- Rytter, A. Vibrational Based Inspection of Civil Engineering Structures. Ph.D. Thesis, Aalborg University, Aalborg, Denmark, 1993.

- Sony, S.; Laventure, S.; Sadhu, A. A literature review of next-generation smart sensing technology in structural health monitoring. Struct. Control Health Monit. 2019, 26, e2321.

- Wang, R.H.; Li, J.; Chencho; An, S.J.; Hao, H.; Liu, W.Q.; Li, L. Densely connected convolutional networks for vibration based structural damage identification. Eng. Struct. 2021, 245, 14.

- Guo, S.F.; Ding, H.; Li, Y.H.; Feng, H.W.; Xiong, X.H.; Su, Z.Q.; Feng, W. A hierarchical deep convolutional regression framework with sensor network fail-safe adaptation for acoustic-emission-based structural health monitoring. Mech. Syst. Signal Proc. 2022, 181, 17.

- Mariani, S.; Rendu, Q.; Urbani, M.; Sbarufatti, C. Causal dilated convolutional neural networks for automatic inspection of ultrasonic signals in non-destructive evaluation and structural health monitoring. Mech. Syst. Signal Proc. 2021, 157, 22.

- Sakurai, H.; Suzuki, K.; Ishii, S.; Hoshi, K.; Nozawa, T.; Ozaki, H.; Haga, H.; Tanigawa, H.; Someya, Y.; Tsuchiya, M.; et al. Development of non-destructive testing (NDT) technique for HIPed interface by Compton scattering X-ray spectroscopy. Nucl. Mater. Energy 2022, 31, 101171.

- Sacarea, A.I.; Oancea, G.; Parv, L. Magnetic Particle Inspection Optimization Solution within the Frame of NDT 4.0. Processes 2021, 9, 1067.

- Sophian, A.; Tian, G.; Fan, M. Pulsed Eddy Current Non-destructive Testing and Evaluation: A Review. Chin. J. Mech. Eng. 2017, 30, 500–514.

- Shao, Y.; Li, L.; Li, J.; An, S.; Hao, H. Computer vision based target-free 3D vibration displacement measurement of structures. Eng. Struct. 2021, 246, 113040.

- Hurtado, A.C.; Kaur, K.; Alamdari, M.M.; Atroshchenko, E.; Chang, K.; Kim, C.W. Unsupervised learning-based framework for indirect structural health monitoring using adversarial autoencoder. J. Sound Vibr. 2023, 550, 23.

- Xiao, H.T.; Ogai, H.; Wang, W.J. A new deep transfer learning method for intelligent bridge damage diagnosis based on muti-channel sub-domain adaptation. Struct. Infrastruct. Eng. 2023, 16.

- He, Y.Y.; Huang, Z.H.; Liu, D.; Zhang, L.K.; Liu, Y. A Novel Structural Damage Identification Method Using a Hybrid Deep Learning Framework. Buildings 2022, 12, 2130.

- Sandhu, H.K.; Bodda, S.S.; Gupta, A. Post-hazard condition assessment of nuclear piping-equipment systems: Novel approach to feature extraction and deep learning. Int. J. Pressure Vessels Pip. 2023, 201, 16.

- Sikdar, S.; Liu, D.Z.; Kundu, A. Acoustic emission data based deep learning approach for classification and detection of damage-sources in a composite panel. Compos. Pt. B-Eng. 2022, 228, 9.

- Hesser, D.F.; Mostafavi, S.; Kocur, G.K.; Markert, B. Identification of acoustic emission sources for structural health monitoring applications based on convolutional neural networks and deep transfer learning. Neurocomputing 2021, 453, 1–12.

- Chen, J.; Wu, W.; Ren, Y.; Yuan, S. Fatigue Crack Evaluation with the Guided Wave-Convolutional Neural Network Ensemble and Differential Wavelet Spectrogram. Sensors 2022, 22, 307.

- Liao, Y.L.; Qing, X.L.; Wang, Y.H.; Zhang, F.H. Damage localization for composite structure using guided wave signals with Gramian angular field image coding and convolutional neural networks. Compos. Struct. 2023, 312, 14.

- Sawant, S.; Sethi, A.; Banerjee, S.; Tallur, S. Unsupervised learning framework for temperature compensated damage identification and localization in ultrasonic guided wave SHM with transfer learning. Ultrasonics 2023, 130, 10.

- Zhang, Z.; Tang, F.J.; Cao, Q.; Pan, H.; Wang, X.Y.; Lin, Z.B. Deep Learning-Enriched Stress Level Identification of Pretensioned Rods via Guided Wave Approaches. Buildings 2022, 12, 1772.

- Lomazzi, L.; Fabiano, S.; Parziale, M.; Giglio, M.; Cadini, F. On the explainability of convolutional neural networks processing ultrasonic guided waves for damage diagnosis. Mech. Syst. Signal Proc. 2023, 183, 18.

- Alazzawi, O.; Wang, D.S. Damage identification using the PZT impedance signals and residual learning algorithm. J. Civ. Struct. Health Monit. 2021, 11, 1225–1238.

- Parida, L.; Moharana, S.; Ferreira, V.M.; Giri, S.K.; Ascensao, G. A Novel CNN-LSTM Hybrid Model for Prediction of Electro-Mechanical Impedance Signal Based Bond Strength Monitoring. Sensors 2022, 22, 26.

- Rosafalco, L.; Torzoni, M.; Manzoni, A.; Mariani, S.; Corigliano, A. Online structural health monitoring by model order reduction and deep learning algorithms. Comput. Struct. 2021, 255, 18.

- Zhen, W. Research on English Vocabulary and Speech Corpus Recognition Based on Deep Learning. Wirel. Commun. Mob. Comput. 2022, 2022, 2882964.

- Dokuz, Y.; Tufekci, Z. Feature-based hybrid strategies for gradient descent optimization in end-to-end speech recognition. Multimed. Tools Appl. 2022, 81, 9969–9988.

- Zhang, W. An Automatic Error Detection Method for Machine Translation Results via Deep Learning. IEEE Access 2023, 11, 53237–53248.

- Chen, M. A Deep Learning-Based Intelligent Quality Detection Model for Machine Translation. IEEE Access 2023, 11, 89469–89477.

- Liu, B.; Zuo, X.; Yu, A.; Sun, Y.; Wang, R. Semi-supervised classification of hyperspectral images based on multi-view consistency. Remote Sens. Lett. 2023, 14, 479–490.

- Chen, W.; Su, L.; Chen, X.; Huang, Z. Rock image classification using deep residual neural network with transfer learning. Front. Earth Sci. 2023, 10, 1079447.

- Hou, L.; Chen, H.S.; Zhang, G.M.; Wang, X.Y. Deep Learning-Based Applications for Safety Management in the AEC Industry: A Review. Appl. Sci. 2021, 11, 821.

- Kao, S.P.; Chang, Y.C.; Wang, F.L. Combining the YOLOv4 Deep Learning Model with UAV Imagery Processing Technology in the Extraction and Quantization of Cracks in Bridges. Sensors 2023, 23, 2572.

- Sony, S.; Dunphy, K.; Sadhu, A.; Capretz, M. A systematic review of convolutional neural network-based structural condition assessment techniques. Eng. Struct. 2021, 226, 16.

- Li, Z.J.; Adamu, K.; Yan, K.; Xu, X.L.; Shao, P.; Li, X.H.; Bashir, H.M. Detection of Nut-Bolt Loss in Steel Bridges Using Deep Learning Techniques. Sustainability 2022, 14, 10837.

- Panta, M.; Hoque, M.T.; Abdelguerfi, M.; Flanagin, M.C. IterLUNet: Deep Learning Architecture for Pixel-Wise Crack Detection in Levee Systems. IEEE Access 2023, 11, 12249–12262.

- Zhang, L.X.; Shen, J.K.; Zhu, B.J. A research on an improved Unet-based concrete crack detection algorithm. Struct. Health Monit. 2021, 20, 1864–1879.

- Wang, S.; Liu, C.; Zhang, Y.H. Fully convolution network architecture for steel-beam crack detection in fast-stitching images. Mech. Syst. Signal Proc. 2022, 165, 20.

- Gao, X.J.; Huang, C.S.; Teng, S.; Chen, G.F. A Deep-Convolutional-Neural-Network-Based Semi-Supervised Learning Method for Anomaly Crack Detection. Appl. Sci. 2022, 12, 9244.

- Dunphy, K.; Fekri, M.N.; Grolinger, K.; Sadhu, A. Data Augmentation for Deep-Learning-Based Multiclass Structural Damage Detection Using Limited Information. Sensors 2022, 22, 6193.

- Wang, L.L.; Li, J.J.; Kang, F. Crack Location and Degree Detection Method Based on YOLOX Model. Appl. Sci. 2022, 12, 12572.

- Pal, J.; Sikdar, S.; Banerjee, S. A deep-learning approach for health monitoring of a steel frame structure with bolted connections. Struct. Control Health Monit. 2022, 29, e2873.

- Zhang, T.; Biswal, S.; Wang, Y. SHMnet: Condition assessment of bolted connection with beyond human-level performance. Struct. Health Monit. 2020, 19, 1188–1201.

- Lu, Q.Z.; Jing, Y.C.; Zhao, X.F. Bolt Loosening Detection Using Key-Point Detection Enhanced by Synthetic Datasets. Appl. Sci. 2023, 13, 2020.

- Li, Z.Q.; Li, D.S. A high-frequency feature enhancement network for the surface defect detection of welded rebar. Struct. Control Health Monit. 2022, 29, 13.

- Rubio, J.J.; Kashiwa, T.; Laiteerapong, T.; Deng, W.; Nagai, K.; Escalera, S.; Nakayama, K.; Matsuo, Y.; Prendinger, H. Multi-class structural damage segmentation using fully convolutional networks. Comput. Ind. 2019, 112, 103121.

- Zhang, Y.; Liu, P.; Zhao, X.F. Structural displacement monitoring based on mask regions with convolutional neural network. Constr. Build. Mater. 2021, 267, 8.

- Song, Q.S.; Wu, J.R.; Wang, H.L.; An, Y.S.; Tang, G.W. Computer vision-based illumination-robust and multi-point simultaneous structural displacement measuring method. Mech. Syst. Signal Proc. 2022, 170, 14.

- Lydon, D.; Kromanis, R.; Lydon, M.; Early, J.; Taylor, S. Use of a roving computer vision system to compare anomaly detection techniques for health monitoring of bridges. J. Civ. Struct. Health Monit. 2022, 12, 1299–1316.

- Pan, X.; Yang, T.Y.; Xiao, Y.F.; Yao, H.C.; Adeli, H. Vision-based real-time structural vibration measurement through deep-learning-based detection and tracking methods. Eng. Struct. 2023, 281, 12.

- Zhao, S.Z.; Kang, F.; Li, J.J. Concrete dam damage detection and localisation based on YOLOv5s-HSC and photogrammetric 3D reconstruction. Autom. Constr. 2022, 143, 18.

- Azimi, M.; Eslamlou, A.D.; Pekcan, G. Data-Driven Structural Health Monitoring and Damage Detection through Deep Learning: State-of-the-Art Review. Sensors 2020, 20, 2778.

- Wuttke, F.; Lyu, H.; Sattari, A.S.; Rizvi, Z.H. Wave based damage detection in solid structures using spatially asymmetric encoder-decoder network. Sci. Rep. 2021, 11, 20968.

- Geetha, G.K.; Yang, H.J.; Sim, S.H. Fast Detection of Missing Thin Propagating Cracks during Deep-Learning-Based Concrete Crack/Non-Crack Classification. Sensors 2023, 23, 1419.

- Sattarifar, A.; Nestorovi, T. Damage localization and characterization using one-dimensional convolutional neural network and a sparse network of transducers. Eng. Appl. Artif. Intell. 2022, 115, 13.

- Jian, X.; Zhong, H.; Xia, Y.; Sun, L. Faulty data detection and classification for bridge structural health monitoring via statistical and deep-learning approach. Struct. Control Health Monit. 2021, 28, e2824.

- Zhao, J. Efficient Detection of Large-Scale Multimedia Network Information Data Anomalies Based on the Rule-Extracting Matrix Algorithm. Adv. Multimed. 2021, 2021, 3299891.

- Sony, S.; Gamage, S.; Sadhu, A.; Samarabandu, J. Vibration-based multiclass damage detection and localization using long short-term memory networks. Structures 2022, 35, 436–451.

- Siracusano, G.; Garesci, F.; Finocchio, G.; Tomasello, R.; Lamonaca, F.; Scuro, C.; Carpentieri, M.; Chiappini, M.; La Corte, A. Automatic Crack Classification by Exploiting Statistical Event Descriptors for Deep Learning. Appl. Sci. 2021, 11, 12059.

- Zhang, B.; Hong, X.B.; Liu, Y. Distribution adaptation deep transfer learning method for cross-structure health monitoring using guided waves. Struct. Health Monit. 2022, 21, 853–871.

- Li, Y.; Bao, T.; Gao, Z.; Shu, X.; Zhang, K.; Xie, L.; Zhang, Z. A new dam structural response estimation paradigm powered by deep learning and transfer learning techniques. Struct. Health Monit. 2022, 21, 770–787.

- Li, Y.; Bao, T.; Gong, J.; Shu, X.; Zhang, K. The Prediction of Dam Displacement Time Series Using STL, Extra-Trees, and Stacked LSTM Neural Network. IEEE Access 2020, 8, 94440–94452.

- Huang, B.; Kang, F.; Li, J.J.; Wang, F. Displacement prediction model for high arch dams using long short-term memory based encoder-decoder with dual-stage attention considering measured dam temperature. Eng. Struct. 2023, 280, 15.

- Son, H.; Jang, Y.; Kim, S.-E.; Kim, D.; Park, J.-W. Deep Learning-Based Anomaly Detection to Classify Inaccurate Data and Damaged Condition of a Cable-Stayed Bridge. IEEE Access 2021, 9, 124549–124559.

- Li, L.; Liu, G.; Zhang, L.; Li, Q. FS-LSTM-Based Sensor Fault and Structural Damage Isolation in SHM. IEEE Sens. J. 2021, 21, 3250–3259.

- Liu, B.; Xu, Q.; Chen, J.Y.; Li, J.; Wang, M.M. A New Framework for Isolating Sensor Failures and Structural Damage in Noisy Environments Based on Stacked Gated Recurrent Unit Neural Networks. Buildings 2022, 12, 1286.

- Zhang, R.Y.; Meng, L.B.; Mao, Z.; Sun, H. Spatiotemporal Deep Learning for Bridge Response Forecasting. J. Struct. Eng. 2021, 147, 9.

- Hou, J.L.; Jiang, H.C.; Wan, C.F.; Yi, L.T.; Gao, S.; Ding, Y.L.; Xue, S.T. Deep learning and data augmentation based data imputation for structural health monitoring system in multi-sensor damaged state. Measurement 2022, 196, 17.

- Deng, Y.; Ju, H.W.; Li, Y.H.; Hu, Y.A.; Li, A.Q. Abnormal Data Recovery of Structural Health Monitoring for Ancient City Wall Using Deep Learning Neural Network. Int. J. Archit. Herit. 2022, 19.

- Ju, H.W.; Deng, Y.; Zhai, W.Q.; Li, A.Q. Recovery of Abnormal Data for Bridge Structural Health Monitoring Based on Deep Learning and Temporal Correlation. Sens. Mater. 2022, 34, 4491–4505.

- Rosafalco, L.; Manzoni, A.; Mariani, S.; Corigliano, A. An Autoencoder-Based Deep Learning Approach for Load Identification in Structural Dynamics. Sensors 2021, 21, 32.

- Zhang, B.; Hong, X.B.; Liu, Y. Deep Convolutional Neural Network Probability Imaging for Plate Structural Health Monitoring Using Guided Waves. IEEE Trans. Instrum. Meas. 2021, 70, 10.

- Chen, G.F.; Teng, S.; Lin, M.S.; Yang, X.M.; Sun, X.L. Crack Detection Based on Generative Adversarial Networks and Deep Learning. KSCE J. Civ. Eng. 2022, 26, 1803–1816.

- Jiang, H.; Wan, C.; Yang, K.; Ding, Y.; Xue, S. Continuous missing data imputation with incomplete dataset by generative adversarial networks-based unsupervised learning for long-term bridge health monitoring. Struct. Health Monit. 2022, 21, 1093–1109.

- Fan, G.; Li, J.; Hao, H.; Xin, Y. Data driven structural dynamic response reconstruction using segment based generative adversarial networks. Eng. Struct. 2021, 234, 111970.

- Lei, X.M.; Sun, L.M.; Xia, Y. Lost data reconstruction for structural health monitoring using deep convolutional generative adversarial networks. Struct. Health Monit. 2021, 20, 2069–2087.

- Ebrahimkhanlou, A.; Dubuc, B.; Salamone, S. A generalizable deep learning framework for localizing and characterizing acoustic emission sources in riveted metallic panels. Mech. Syst. Signal Proc. 2019, 130, 248–272.

- Ebrahimkhanlou, A.; Salamone, S. Single-sensor acoustic emission source localization in plate-like structures: A deep learning approach. In Proceedings of the SPIE Conference on Health Monitoring of Structural and Biological Systems XII, Denver, CO, USA, 5–8 March 2018.

- Rastin, Z.; Amiri, G.G.; Darvishan, E. Generative Adversarial Network for Damage Identification in Civil Structures. Shock Vib. 2021, 2021, 12.

- Qi, Y.Z.; Yuan, C.; Li, P.Z.; Kong, Q.Z. Damage analysis and quantification of RC beams assisted by Damage-T Generative Adversarial Network. Eng. Appl. Artif. Intell. 2023, 117, 11.

- Dunphy, K.; Sadhu, A.; Wang, J.F. Multiclass damage detection in concrete structures using a transfer learning-based generative adversarial networks. Struct. Control Health Monit. 2022, 29, 20.

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324.

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2017, 60, 84–89.

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556.

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Boston, MA, USA, 7–12 June 2015; pp. 1–9.

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 27–30 June 2016; pp. 770–778.

- Peng, M.; Wang, C.; Chen, T.; Liu, G. Nirfacenet: A convolutional neural network for near-infrared face identification. Information 2016, 7, 61.

- Hamishebahar, Y.; Guan, H.; So, S.P.; Jo, J. A Comprehensive Review of Deep Learning-Based Crack Detection Approaches. Appl. Sci. 2022, 12, 1374.

- Zhang, L.Y.; Zhou, G.C.; Han, Y.; Lin, H.L.; Wu, Y.Y. Application of Internet of Things Technology and Convolutional Neural Network Model in Bridge Crack Detection. IEEE Access 2018, 6, 39442–39451.

- Wang, X.W.; Zhang, X.N.; Shahzad, M.M. A novel structural damage identification scheme based on deep learning framework. Structures 2021, 29, 1537–1549.

- Girshick, R.; Donahue, J.; Darrell, T.; Malik, J. Rich feature hierarchies for accurate object detection and semantic segmentation. In Proceedings of the 27th IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Columbus, OH, Italy, 23–28 June 2014; pp. 580–587.

- Girshick, R. Fast r-cnn. In Proceedings of the IEEE International Conference on Computer Vision, Santiago, Chile, 7–13 December 2015; pp. 1440–1448.

- Ren, S.; He, K.; Girshick, R.; Sun, J. Faster R-CNN: Towards Real-Time Object Detection with Region Proposal Networks. arXiv 2016, arXiv:1506.01497.s, s.

- Pham, H.C.; Ta, Q.B.; Kim, J.T.; Ho, D.D.; Tran, X.L.; Huynh, T.C. Bolt-Loosening Monitoring Framework Using an Image-Based Deep Learning and Graphical Model. Sensors 2020, 20, 19.

- Li, C.; Xu, P.; Niu, L.; Chen, Y.; Sheng, L.; Liu, M. Tunnel crack detection using coarse-to-fine region localization and edge detection. Wiley Interdiscip. Rev. -Data Min. Knowl. Discov. 2019, 9, e1308.

- Liu, W.; Anguelov, D.; Erhan, D.; Szegedy, C.; Reed, S.; Fu, C.-Y.; Berg, A.C. Ssd: Single shot multibox detector. In Proceedings of the Computer Vision–ECCV 2016: 14th European Conference, Amsterdam, The Netherlands, 11–14 October 2016; pp. 21–37.

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You only look once: Unified, real-time object detection. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Seattle, WA, USA, 27–30 June 2016; pp. 779–788.

- Hou, R.; Jeong, S.; Lynch, J.P.; Law, K.H. Cyber-physical system architecture for automating the mapping of truck loads to bridge behavior using computer vision in connected highway corridors. Transp. Res. Part C-Emerg. Technol. 2020, 111, 547–571.

- Ding, L.; Fang, W.; Luo, H.; Love, P.E.; Zhong, B.; Ouyang, X. A deep hybrid learning model to detect unsafe behavior: Integrating convolution neural networks and long short-term memory. Autom. Constr. 2018, 86, 118–124.

- Ronneberger, O.; Fischer, P.; Brox, T. U-net: Convolutional networks for biomedical image segmentation. In Proceedings of the Medical Image Computing and Computer-Assisted Intervention–MICCAI, Munich, Germany, 5–9 October 2015; pp. 234–241.

- Jégou, S.; Drozdzal, M.; Vazquez, D.; Romero, A.; Bengio, Y. The one hundred layers tiramisu: Fully convolutional densenets for semantic segmentation. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition Workshops, Honolulu, HI, USA, 21–26 July 2017; pp. 11–19.

- Chen, L.-C.; Zhu, Y.; Papandreou, G.; Schroff, F.; Adam, H. Encoder-Decoder with Atrous Separable Convolution for Semantic Image Segmentation. In Proceedings of the 15th European Conference on Computer Vision (ECCV), Munich, Germany, 8–14 September 2018; pp. 833–851.

- He, K.; Gkioxari, G.; Dollár, P.; Girshick, R. Mask r-cnn. In Proceedings of the IEEE international conference on computer vision, Venice, Italy, 22–29 October 2017; pp. 2961–2969.

- Qiu, D.W.; Liang, H.R.; Wang, Z.L.; Tong, Y.C.; Wan, S.S. Hybrid-Supervised-Learning-Based Automatic Image Segmentation for Water Leakage in Subway Tunnels. Appl. Sci. 2022, 12, 11799.

- Kiranyaz, S.; Ince, T.; Hamila, R.; Gabbouj, M. Convolutional Neural Networks for Patient-Specific ECG Classification. In Proceedings of the 37th Annual International Conference of the IEEE-Engineering-in-Medicine-and-Biology-Society (EMBC), Milan, Italy, 25–29 August 2015; pp. 2608–2611.

- Zhang, S.Y.; Li, C.M.; Ye, W.J. Damage localization in plate-like structures using time-varying feature and one-dimensional convolutional neural network. Mech. Syst. Signal Proc. 2021, 147, 15.

- Wu, C.S.; Peng, Y.X.; Zhuo, D.B.; Zhang, J.Q.; Ren, W.; Feng, Z.Y. Energy Ratio Variation-Based Structural Damage Detection Using Convolutional Neural Network. Appl. Sci. 2022, 12, 10220.

- Yang, J.; Yang, F.; Zhou, Y.; Wang, D.; Li, R.; Wang, G.; Chen, W. A data-driven structural damage detection framework based on parallel convolutional neural network and bidirectional gated recurrent unit. Inf. Sci. 2021, 566, 103–117.

- Yang, J.; Zhang, L.; Chen, C.; Li, Y.; Li, R.; Wang, G.; Jiang, S.; Zeng, Z. A hierarchical deep convolutional neural network and gated recurrent unit framework for structural damage detection. Inf. Sci. 2020, 540, 117–130.

- Dang, H.V.; Tran-Ngoc, H.; Nguyen, T.V.; Bui-Tien, T.; De Roeck, G.; Nguyen, H.X. Data-Driven Structural Health Monitoring Using Feature Fusion and Hybrid Deep Learning. IEEE Trans. Autom. Sci. Eng. 2021, 18, 2087–2103.

- Ma, Z.R.; Gao, L. Predicting Mechanical State of High-Speed Railway Elevated Station Track System Using a Hybrid Prediction Model. KSCE J. Civ. Eng. 2021, 25, 2474–2486.

- Shin, R.; Okada, Y.; Yamamoto, K. Application of C-LSTM Networks to Automatic Labeling of Vehicle Dynamic Response Data for Bridges. Sensors 2022, 22, 12.

- Du, B.W.; Lin, C.M.; Sun, L.L.; Zhao, Y.P.; Li, L.C. Response Prediction Based on Temporal and Spatial Deep Learning Model for Intelligent Structural Health Monitoring. IEEE Internet Things J. 2022, 9, 13364–13375.

- Yue, Z.X.; Ding, Y.L.; Zhao, H.W.; Wang, Z.W. Ultra-high precise Stack-LSTM-CNN model of temperature-induced deflection of a cable-stayed bridge for detecting bridge state driven by monitoring data. Structures 2022, 45, 110–125.

- Parziale, M.; Lomazzi, L.; Giglio, M.; Cadini, F. Vibration-based structural health monitoring exploiting a combination of convolutional neural networks and autoencoders for temperature effects neutralization. Struct. Control Health Monit. 2022, 29, 20.

- He, Y.Y.; Zhang, L.K.; Chen, Z.S.; Li, C.Y. A framework of structural damage detection for civil structures using a combined multi-scale convolutional neural network and echo state network. Eng. Comput. 2023, 39, 1771–1789.

- Graves, A.; Graves, A. Long short-term memory. In Supervised Sequence Labelling with Recurrent Neural Networks; Springer: Berlin/Heidelberg, Germany, 2012; pp. 37–45.

- Cho, K.; van Merrienboer, B.; Gulcehre, C.; Bahdanau, D.; Bougares, F.; Schwenk, H.; Bengio, Y. Learning Phrase Representations using RNN Encoder-Decoder for Statistical Machine Translation. arXiv 2014, arXiv:1406.1078.

- Akinosho, T.D.; Oyedele, L.O.; Bilal, M.; Ajayi, A.O.; Delgado, M.D.; Akinade, O.O.; Ahmed, A.A. Deep learning in the construction industry: A review of present status and future innovations. J. Build. Eng. 2020, 32, 14.

- Li, Y.; Bao, T.; Chen, H.; Zhang, K.; Shu, X.; Chen, Z.; Hu, Y. A large-scale sensor missing data imputation framework for dams using deep learning and transfer learning strategy. Measurement 2021, 178, 109377.

- Deng, Y.; Ju, H.W.; Zhai, W.Q.; Li, A.Q.; Ding, Y.L. Correlation model of deflection, vehicle load, and temperature for in-service bridge using deep learning and structural health monitoring. Struct. Control Health Monit. 2022, 29, 20.

- Ai, L.; Soltangharaei, V.; Ziehl, P. Evaluation of ASR in concrete using acoustic emission and deep learning. Nucl. Eng. Des. 2021, 380, 10.

- Pathirage, C.S.N.; Li, J.; Li, L.; Hao, H.; Liu, W.Q.; Ni, P.H. Structural damage identification based on autoencoder neural networks and deep learning. Eng. Struct. 2018, 172, 13–28.

- Lei, X.M.; Siringoringo, D.M.; Sun, Z.; Fujino, Y. Displacement response estimation of a cable-stayed bridge subjected to various loading conditions with one-dimensional residual convolutional autoencoder method. Struct. Health Monit. 2022, 22, 1790–1806.

- Goodfellow, I.; Pouget-Abadie, J.; Mirza, M.; Xu, B.; Warde-Farley, D.; Ozair, S.; Courville, A.; Bengio, Y. Generative adversarial networks. Commun. ACM 2020, 63, 139–144.

- Radford, A.; Metz, L.; Chintala, S.J.a.p.a. Unsupervised representation learning with deep convolutional generative adversarial networks. arXiv 2015, arXiv:1511.06434.

- Gao, Y.; Zhai, P.; Mosalam, K.M. Balanced semisupervised generative adversarial network for damage assessment from low-data imbalanced-class regime. Comput.-Aided Civ. Infrastruct. Eng. 2021, 36, 1094–1113.

- Kohiyama, M.; Oka, K.; Yamashita, T. Detection method of unlearned pattern using support vector machine in damage classification based on deep neural network. Struct. Control Health Monit. 2020, 27, 23.

- Sabour, S.; Frosst, N.; Hinton, G.E. Dynamic routing between capsules. In Proceedings of the 31st Annual Conference on Neural Information Processing Systems, Long Beach, CA, USA, 4–9 December 2017; pp. 3856–3866.

- Barraza, J.F.; Droguett, E.L.; Naranjo, V.M.; Martins, M.R. Capsule Neural Networks for structural damage localization and quantification using transmissibility data. Appl. Soft. Comput. 2020, 97, 106732.

- Son, H.; Pham, V.T.; Jang, Y.; Kim, S.E. Damage Localization and Severity Assessment of a Cable-Stayed Bridge Using a Message Passing Neural Network. Sensors 2021, 21, 3118.

- Li, Z.Q.; Li, D.S.; Sun, T.S. A Transformer-Based Bridge Structural Response Prediction Framework. Sensors 2022, 22, 3100.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

22 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No