Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Domenic Klohs | -- | 1883 | 2023-11-20 08:30:35 | | | |

| 2 | Mona Zou | Meta information modification | 1883 | 2023-11-21 02:55:35 | | | | |

| 3 | Mona Zou | Meta information modification | 1883 | 2023-11-27 03:29:58 | | | | |

| 4 | Mona Zou | Meta information modification | 1883 | 2023-11-27 03:30:25 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Klohs, D.; Offermanns, C.; Heimes, H.; Kampker, A. State-of-the-Art Battery Disassembly towards Automation. Encyclopedia. Available online: https://encyclopedia.pub/entry/51791 (accessed on 08 March 2026).

Klohs D, Offermanns C, Heimes H, Kampker A. State-of-the-Art Battery Disassembly towards Automation. Encyclopedia. Available at: https://encyclopedia.pub/entry/51791. Accessed March 08, 2026.

Klohs, Domenic, Christian Offermanns, Heiner Heimes, Achim Kampker. "State-of-the-Art Battery Disassembly towards Automation" Encyclopedia, https://encyclopedia.pub/entry/51791 (accessed March 08, 2026).

Klohs, D., Offermanns, C., Heimes, H., & Kampker, A. (2023, November 20). State-of-the-Art Battery Disassembly towards Automation. In Encyclopedia. https://encyclopedia.pub/entry/51791

Klohs, Domenic, et al. "State-of-the-Art Battery Disassembly towards Automation." Encyclopedia. Web. 20 November, 2023.

Copy Citation

As the market share of electric vehicles continues to rise, the number of battery systems that are retired after their service life in the vehicle will also increase. This large growth in battery returns will also have a noticeable impact on processes such as battery disassembly. Due to the significantly increasing return volumes of traction batteries in the near future, a substantial increase in the degree of automation in battery disassembly is required, especially with regard to a stable recycling input flow.

lithium-ion battery

electric vehicles

automated battery disassembly

dismantling challenges

battery recycling

1. Introduction

The transformation in the mobility sector has reached its next phase. With the increasing market share of electrically powered vehicles, electric mobility has now fully arrived in mainstream and among customers. This has not only been recognized by manufacturers, who are now expanding their vehicle portfolios to include more and more purely electrically powered models in addition to an increasing number of hybrid vehicle models [1]. This aspect is also reflected in current political decisions. In addition to the previous financial incentives for electric vehicles, a permanent ban on most vehicles with combustion engines from 2035 onwards, approved by the EU Parliament, has set the course for a complete market diffusion of electric drives in Europe [2].

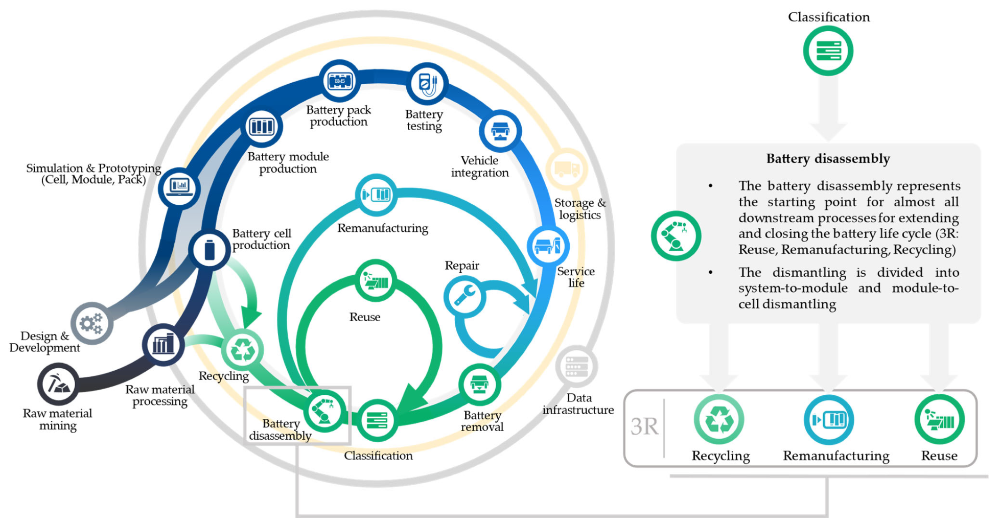

The heart of the electric powertrain is the traction battery. After an initial period in which the focus of electric vehicle and battery manufacturers was on market penetration, along with production and development topics related to increasing capacity and reducing costs of traction batteries [3], growing attention is now being paid to closing the battery lifecycle after the service life in the vehicle. Topics such as further use of traction batteries in stationary storage systems, the repair and remanufacturing of used battery systems, and recycling, including the associated recovery of essential raw materials are becoming increasingly important [4]. All in all, a multitude of paths and phases have been formed here, which the battery passes through, from the extraction of raw materials to a possible recycling. An overview of the most relevant stations is given in Figure 1, which also shows some important side processes such as the topic of logistics and the increasingly required data infrastructure.

Figure 1. Overview of the closed-loop battery life cycle with disassembly as the central branching point for the 3R paths.

2. State-of-the-Art Battery Disassembly

The present procedure for dismantling traction batteries is still characterized by relatively low return volumes, which will, however, increase significantly in the upcoming years due to the growing market share of electric vehicles. Battery disassembly is, therefore, currently carried out manually and without the support of robots [10]. The disassembly process is usually performed by multiple qualified workers [11].

Due to the manual execution, there is a high-voltage risk to the workers, especially at the beginning of the process, caused by the interconnected cells and modules. For this reason, the workers must have completed high-voltage training before being allowed to work with batteries [12]. In most cases, the battery pack, which is usually in an unknown state of charge, can only be discharged after the housing cover has been removed. The reason for this is that the battery management controller cannot be addressed without the necessary protocols, which are usually not provided by the vehicle manufacturers [13]. The manual energy extraction is done either by discharging at pack level directly at the contactors or by discharging or deactivating the modules at a later stage after removal but before shredding [14]. Deactivation means that cells or modules are placed for example, in a salt bath, whereby the stored energy is dissipated [15].

There are further potential hazards from the toxic electrolyte in the cells [16]. Here, electrolyte can already escape from the cells if the battery pack has been mechanically deformed, for example, due to an accident [17]. In addition, the disassembly operation itself can cause damage, which in turn can lead to a leakage of electrolyte. This hazard potential, as well as the high-voltage hazard, is to be emphasized especially in manual dismantling to the workers carrying out the tasks. But preventive measures should also be implemented for possible future automation.

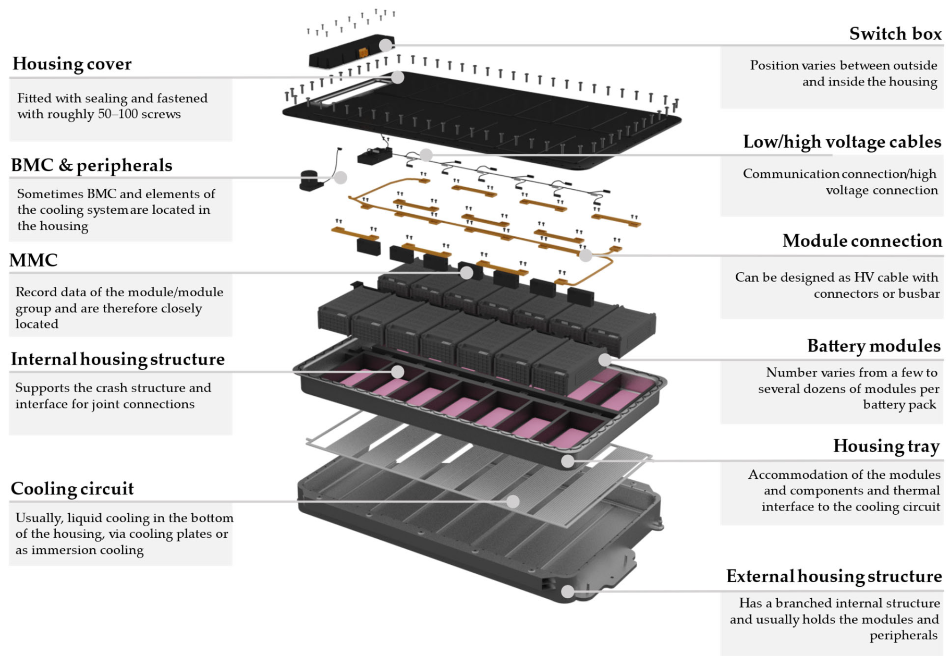

The structural design of the battery system and the joint connections are of decisive importance for the effort required for a disassembly task [18]. Even if battery packs generally have a similar functional design, the number, shape, and position of the individual components, as well as the joints used, can vary greatly [10][19]. Figure 2 shows a general battery pack structure together with details of the individual components.

In most cases, disassembly begins with opening the battery pack. Either the housing cover or the switch box is removed first, depending on whether the latter is located on the outside of the housing cover. In both cases, this is mostly done by loosening a number of screws [20]. As these screws are located in the outer area of the battery, the condition (deformation, dirt, or corrosion) plays a decisive role in the feasibility of the process step [21]. Another factor is the cover sealing used, which can have very adhesive characteristics, depending on the type and combination of materials selected [20][22].

The opened battery system can now be further processed by first removing the accessible module connections, as well as disconnecting cables and peripherals (e.g., MMCs) [23].

When the modules are completely accessible, they can be removed by loosening screw connections that are usually present [24]. In cases when the system design has integrated a floor cooling below the tray with the modules, a thermal interface material is usually still applied to the bottom of the modules. Together with the very narrow installation space, this can also lead to adhesive-like effects during removal [25].

The variation in design and the number of individual components already mentioned create certain challenges for manual disassembly. Even if this can be mostly handled by the flexibility of human workers, it results in time-consuming activities [26]. For the scaling of the process discussed in the subsequent section, together with an increase in the level of automation, this raises extensive questions.

To underline some concrete differences between functionally equivalent components, Figure 3 shows the module connections, battery/module management controllers, and battery modules from the battery systems of the VW e-Golf, BMW i3, and Audi e-tron vehicle models.

Figure 3. Differences in the design of functionally equivalent battery components for three different vehicle models.

There are two basic approaches for the module connections. Rigid busbars are used in the Audi e-tron and the VW e-Golf. The busbars differ in shape between the two models, as can be seen on the three images above. But even within one battery pack, there are several different versions of the busbars for interconnecting the total of twenty-seven modules in the Audi e-tron (71 kWh model). They vary in length and shape. In addition to bus bars, HV cables with connectors are used in the e-Golf to connect the battery modules. Those cables are also installed in the BMW i3.

With regard to the battery and module management controller, it should be mentioned that the e-tron has a total of seven Module Management Controllers (MMCs), some of which are located in an enclosure on top of the modules and others in the corners of the pack. In the BMW i3, the MMCs are located directly on the side wall of the respective module housing. Here, there are eight MMCs for the eight installed battery modules. In the VW e-Golf, there is a central control unit that is connected to the modules via a cable network.

The shape and size of the battery modules also differ in all three models. While comparatively smaller modules are installed in the e-Golf and e-tron, the i3 battery modules are significantly larger. In the BMW i3, the modules are also screwed onto cooling pipelines, whereas in the e-tron, thermal interface material is applied to the bottom side of the modules, and an additional screw connection on the four edges of every module attaches them to the inner structure of the housing.

These design variations from conversion to purpose designs, from PHEV to BEV approaches, from an increasing number of models and capacities and the characteristics of their individual components result in very diverse disassembly procedures [26]. In addition to the flexibility required, the disassembly times for different battery models in particular vary due to the numerous components. An overview of these time variations and the associated estimated dismantling costs are shown in Table 1 for various regions. The information shown comprises a mixture of measured and calculated values from the literature.

Table 1. Overview of disassembly times and costs for different disassembly scenarios.

| Battery Description | Disassembly Time | Disassembly Costs |

Region | Year | Disassembly Depth |

Source |

|---|---|---|---|---|---|---|

| Audi A3 Sportback | 30 min. | €170 | EU | 2020 | Module level | [27] |

| e-tron hybrid | 31.2 min. | 2021 | [25] | |||

| Tesla Model S (85 kWh) | - | $0.25∙kWh−1 | $21.25 | China | 2021 | Cell level | [28] |

| $0.84∙kWh−1 | $71.4 | South Korea | |||||

| $1.68∙kWh−1 | $142.8 | US | |||||

| $4.04∙kWh−1 | $343.4 | Belgium | |||||

| $2.84∙kWh−1 | $241.4 | UK | |||||

| Mercedes PHEV (13.5 kWh) | 20–31.5 min. | €80–100 | EU | 2022 | Module level | [20] |

| Renault ZOE (52 kWh) | 323.8 min. | 2.58 $∙kWh−1| $134.3 | UK | 2023 | Cell level | [29] |

| Nissan Leaf (40 kWh) | 468.1 min. | 4.85 $∙kWh−1 | $194.1 | ||||

| Peugeot 208 (50 kWh) | 449.4 min. | 3.73 $∙kWh−1 | $186.3 | ||||

| BAIC BJEV (51 kWh) | 198.5 min. | 1.61 $∙kWh−1 | $82.3 | ||||

| BYD Han (77 kWh) | 173.6 min. | 0.94 $∙kWh−1 | $72.0 | ||||

| Battery pack (40 kWh) | 121.8 min. | ¥60.3 | China | 2023 | Module level | [30] |

Even if the individual values are based on different approaches, the dismantling times listed show that each battery model must be considered individually and may be dismantled in a timeframe ranging from about 30 min to several hours. Particularly in regions with high hourly wages, these sometimes very extensive processes result in dismantling costs of several hundred euros for a single battery pack. Compared to China or South Korea, the dismantling process in the European region cannot be economically scaled up with a manual approach for future increases in return volumes. This is particularly caused by the significantly higher labor costs. An increase in the degree of automation in battery disassembly is therefore essential for Europe. In order to achieve shorter cycle times in battery disassembly and to increase the flexibility and robustness, it is necessary to push the use of robots and the development of intelligent and digitized process controls [31][32].

Even though the current standard is the dismantling of systems down to module level, it is worth mentioning that an even deeper dismantling and fractionation is beneficial for the downstream recycling processes in terms of effort and quality of the black mass [33]. The reasons why disassembly down to cell level is often not carried out are due to the similar or greater efforts involved in separating individual components. Modules can contain gap fillers between the cells. The contacting is usually welded and the module housings can often only be separated destructively [34].

References

- Barkenbus, J.N. Prospects for Electric Vehicles. Sustainability 2020, 12, 5813.

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Golke, D. Energy assessment of the ageing phenomenon in Li-Ion batteries and its impact on the vehicle range efficiency. Energy Convers. Manag. 2023, 276, 116530.

- McGinnis, R. CO2-to-Fuels Renewable Gasoline and Jet Fuel Can Soon Be Price Competitive with Fossil Fuels. Joule 2020, 4, 509–511.

- Rajaeifar, M.; Rajaeifar, M.A.; Ghadimi, P.; Raugei, M.; Wu, Y.; Heidrich, O. Challenges and recent developments in supply and value chains of electric vehicle batteries: A sustainability perspective. Resour. Conserv. Recycl. 2022, 180, 106144.

- Gerlitz, E.; Greifenstein, M.; Kaiser, J.-P.; Mayer, D.; Lanza, G.; Fleischer, J. Systematic Identification of Hazardous States and Approach for Condition Monitoring in the Context of Li-ion Battery Disassembly. Procedia CIRP 2022, 107, 308–313.

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249.

- Rallo, H.; Sánchez, A.; Canals, L.; Amante, B. Battery dismantling centre in Europe: A centralized vs decentralized analysis. Resour. Conserv. Recycl. Adv. 2022, 15, 200087.

- Zhou, Z.; Ran, A.; Chen, S.; Zhang, X.; Wei, G.; Li, B.; Kang, F.; Zhou, X.; Sun, H. A fast screening framework for second-life batteries based on an improved bisecting K-means algorithm combined with fast pulse test. J. Energy Storage 2020, 31, 101739.

- Li, R.; Zhang, H.; Li, W.; Zhao, X.; Zhou, Y. Toward Group Applications: A Critical Review of the Classification Strategies of Lithium-Ion Batteries. WEVJ 2020, 11, 58.

- Zorn, M.; Ionescu, C.; Klohs, D.; Zähl, K.; Kisseler, N.; Daldrup, A.; Hams, S.; Zheng, Y.; Offermanns, C.; Flamme, S.; et al. An Approach for Automated Disassembly of Lithium-Ion Battery Packs and High-Quality Recycling Using Computer Vision, Labeling, and Material Characterization. Recycling 2022, 7, 48.

- Hellmuth, J.F.; DiFilippo, N.M.; Jouaneh, M.K. Assessment of the automation potential of electric vehicle battery disassembly. J. Manuf. Syst. 2021, 59, 398–412.

- Shahjalal, M.; Roy, P.K.; Shams, T.; Fly, A.; Chowdhury, J.I.; Ahmed, M.R.; Liu, K. A review on second-life of Li-ion batteries: Prospects, challenges, and issues. Energy 2022, 241, 122881.

- Villagrossi, E.; Dinon, T. Robotics for electric vehicles battery packs disassembly towards sustainable remanufacturing. Res. Sq. 2023.

- Sheth, R.P.; Ranawat, N.S.; Chakraborty, A.; Mishra, R.P.; Khandelwal, M. The Lithium-Ion Battery Recycling Process from a Circular Economy Perspective—A Review and Future Directions. Energies 2023, 16, 3228.

- Mossali, E.; Picone, N.; Gentilini, L.; Rodrìguez, O.; Pérez, J.M.; Colledani, M. Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. J. Environ. Manag. 2020, 264, 110500.

- Wu, X.; Ma, J.; Wang, J.; Zhang, X.; Zhou, G.; Liang, Z. Progress, Key Issues, and Future Prospects for Li-Ion Battery Recycling. Glob. Chall. 2022, 6, 2200067.

- Christensen, P.A.; Anderson, P.A.; Harper, G.D.J.; Lambert, S.M.; Mrozik, W.; Rajaeifar, M.A.; Wise, M.S.; Heidrich, O. Risk management over the life cycle of lithium-ion batteries in electric vehicles. Renew. Sustain. Energy Rev. 2021, 148, 111240.

- Mossali, E.; Gentilini, L.; Merati, G.; Colledani, M. Methodology and Application of Electric Vehicles Battery Packs Redesign for Circular Economy. Procedia CIRP 2020, 91, 747–751.

- Thompson, D.L.; Hartley, J.M.; Lambert, S.M.; Shiref, M.; Harper, G.D.J.; Kendrick, E.; Anderson, P.; Ryder, K.S.; Gaines, L.; Abbott, A.P. The importance of design in lithium-ion battery recycling—A critical review. Green Chem. 2020, 22, 7585–7603.

- Rosenberg, S.; Huster, S.; Baazouzi, S.; Glöser-Chahoud, S.; Al Assadi, A.; Schultmann, F. Field Study and Multimethod Analysis of an EV Battery System Disassembly. Energies 2022, 15, 5324.

- Blankemeyer, S.; Wiens, D.; Wiese, T.; Raatz, A.; Kara, S. Investigation of the potential for an automated disassembly process of BEV batteries. Procedia CIRP 2021, 98, 559–564.

- Mulcahy, K.R.; Kilpatrick, A.F.R.; Harper, G.D.J.; Walton, A.; Abbott, A.P. Debondable adhesives and their use in recycling. Green Chem. 2022, 24, 36–61.

- Kay, I.; Farhad, S.; Mahajan, A.; Esmaeeli, R.; Hashemi, S.R. Robotic Disassembly of Electric Vehicles’ Battery Modules for Recycling. Energies 2022, 15, 4856.

- Poschmann, H.; Brüggemann, H.; Goldmann, D. Fostering End-of-Life Utilization by Information-driven Robotic Disassembly. Procedia CIRP 2021, 98, 282–287.

- Baazouzi, S.; Rist, F.P.; Weeber, M.; Birke, K.P. Optimization of Disassembly Strategies for Electric Vehicle Batteries. Batteries 2021, 7, 74.

- Hossain, R.; Sarkar, M.; Sahajwalla, V. Technological options and design evolution for recycling spent lithium-ion batteries: Impact, challenges, and opportunities. WIREs Energy Environ. 2023, 161, e481.

- Alfaro-Algaba, M.; Ramirez, F.J. Techno-economic and environmental disassembly planning of lithium-ion electric vehicle battery packs for remanufacturing. Resour. Conserv. Recycl. 2020, 154, 104461.

- Lander, L.; Cleaver, T.; Rajaeifar, M.A.; Nguyen-Tien, V.; Elliott, R.J.R.; Heidrich, O.; Kendrick, E.; Edge, J.S.; Offer, G. Financial viability of electric vehicle lithium-ion battery recycling. iScience 2021, 24, 102787.

- Lander, L.; Tagnon, C.; Nguyen-Tien, V.; Kendrick, E.; Elliott, R.J.R.; Abbott, A.P.; Edge, J.S.; Offer, G.J. Breaking it down: A techno-economic assessment of the impact of battery pack design on disassembly costs. Appl. Energy 2023, 331, 120437.

- Cong, L.; Zhou, K.; Liu, W.; Li, R. Retired Lithium-Ion Battery Pack Disassembly Line Balancing Based on Precedence Graph Using a Hybrid Genetic-Firework Algorithm for Remanufacturing. J. Manuf. Sci. Eng. 2023, 145, 108035.

- Montes, T.; Etxandi-Santolaya, M.; Eichman, J.; Ferreira, V.J.; Trilla, L.; Corchero, C. Procedure for Assessing the Suitability of Battery Second Life Applications after EV First Life. Batteries 2022, 8, 122.

- Choux, M.; Marti Bigorra, E.; Tyapin, I. Task Planner for Robotic Disassembly of Electric Vehicle Battery Pack. Metals 2021, 11, 387.

- Gerlitz, E.; Greifenstein, M.; Hofmann, J.; Fleischer, J. Analysis of the Variety of Lithium-Ion Battery Modules and the Challenges for an Agile Automated Disassembly System. Procedia CIRP 2021, 96, 175–180.

- Graner, M.; Heieck, F.; Fill, A.; Birke, P.; Hammami, W.; Litty, K. Requirements for a Process to Remanufacture EV Battery Packs Down to Cell Level and Necessary Design Modifications. In Proceedings of the Stuttgart Conference on Automotive Production, Stuttgart, Germany, 16–18 November 2022; pp. 376–386.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

4 times

(View History)

Update Date:

27 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No