Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Huang, X.; Xue, Y.; Ren, S.; Wang, F. Sensor Technologies for Human Motion Monitoring. Encyclopedia. Available online: https://encyclopedia.pub/entry/51676 (accessed on 07 February 2026).

Huang X, Xue Y, Ren S, Wang F. Sensor Technologies for Human Motion Monitoring. Encyclopedia. Available at: https://encyclopedia.pub/entry/51676. Accessed February 07, 2026.

Huang, Xinxin, Yunan Xue, Shuyun Ren, Fei Wang. "Sensor Technologies for Human Motion Monitoring" Encyclopedia, https://encyclopedia.pub/entry/51676 (accessed February 07, 2026).

Huang, X., Xue, Y., Ren, S., & Wang, F. (2023, November 16). Sensor Technologies for Human Motion Monitoring. In Encyclopedia. https://encyclopedia.pub/entry/51676

Huang, Xinxin, et al. "Sensor Technologies for Human Motion Monitoring." Encyclopedia. Web. 16 November, 2023.

Copy Citation

Apart from the early video-based motion capture, the most widely used sensors for human motion capture include the traditional silicon-based sensors and the emerging flexible sensors. The former includes an accelerometer, gyroscope, magnetometer, inertial sensors, and tilt sensors; the latter involves soft strain and pressure sensors based on textile or polymer materials.

wearable sensors

motion capture

posture recognition

1. Introduction

With the continuous development of science and technology, people are paying more attention to exercise and health. Many researchers have turned their research into the human body, focusing on exploring the mystery of human movement. Human movement posture can generally be divided into gross and micro movements. Gross movements refer to large movements that require large muscle groups, which are the overall movements of the trunk and limbs, such as running, climbing, push-ups, and swimming. In contrast, micro-movements refer to small activities of small muscle groups, such as finger movements, vocal cord vibrations, and facial micro-expression changes.

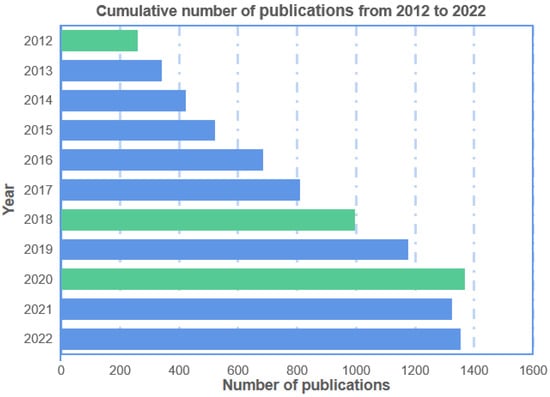

The monitoring of human motion initially adopted the dynamic monitoring method of video image processing, that is, derive the human body’s dynamic characteristics and kinematic laws from the position and state of the human object at different times [1]. However, the data acquisition of cameras is liable to be affected by weather, light, distance, orientation, and other factors. Thus, it is challenging to perform high-precision recognition of motion poses. With the advancement of technologies, many sensors are applied to constructing wearable systems and monitoring human movement, in which sensors recognize human motion data, then process and analyze the data, and finally simulate the correct human motion posture. To date, research on human motion monitoring mainly concentrates on the development of sensor devices [2][3][4], as well as the design of wearable systems by integrating sensors into textiles or clothing. The system could achieve compatibility between functionality and comfort. In the past decade, the literature related to wearable devices for human motion monitoring has been increasing year by year, as shown in Figure 1. Since Jawbone launched the first sports bracelet in 2011, many entrepreneurs have invested in the smart wearable market, and 2012 was reckoned as the first year of intelligent wearable devices. Afterward, wearable devices became the hotspot in the information industry and attracted widespread attention. In 2018, studies on human motion wearables boomed, and almost 1000 research articles were published. Further in 2020, the related research ushered in another wave with 1369 papers published annually. It can be speculated that, as a part of smart wearables, wearables for monitoring human motion have already become a hot research area.

Figure 1. Number of papers related to human motion wearables published from 2012 to 2022. (Note: the statistics of publications come from ‘Google Scholar’, ‘Web of Science’, ‘CNKI’, and ‘Baidu Scholar’. The green color represents the key years).

Due to the advantages of wearable sensors, including powerful computing, small size, and low cost [5], intelligent wearable devices are now used in various fields of human motion monitoring, the majority of which are medical and sports fields. In the medical field, motion monitoring is carried out in rehabilitation training, disease prevention and treatment, as well as movement disorder assessment. The wearables could assist doctors in evaluating the movement status of patients with Parkinson’s, amyotrophic lateral sclerosis, cerebral palsy, stroke, etc. Correspondingly, doctors could draw up a targeted rehabilitation plan and monitor the rehabilitation progress. Liang et al. [6] developed a motion capture device consisting of a wearable MEMS (Micro-Electro-Mechanical System) sensor and a mobile terminal, on which doctors can review the daily rehabilitation motion status of the patients in a remote manner and give timely guidance and advice. In the sports field, motion monitoring is commonly applied in exercise training and human kinematics studies. It can assist athletes to adjust their bodies to correct postures and rectify their movements in detail so as to develop a more scientific exercise plan and improve their performance. It can also be used in sports physiology research to help people understand the impact of sports on the body and its mechanisms. Moreover, intelligent wearable devices have excellent prospects in the areas of human-computer interaction, intelligent homes, industrial manufacturing, and virtual reality in the future [7][8][9].

To improve the comfortability of wearable devices, sensors are evolving from traditional rigid materials to emerging flexible materials. Previously, rigid materials dominated the wearable device market. Although their extensibility and compatibility are poor, the impact of rigid materials on wearing comfort is gradually reduced with the improvement of technologies such as Integrated Circuits (ICs) and MEMS (Micro-Electro-Mechanical Systems), which contribute to the miniaturization of sensor chips. In comparison, flexible materials present lightness, high extensibility, and a low loss of physical and chemical properties when stretched; therefore, wearable devices made of flexible materials have the advantages of lightness, good comfort, and a wide range of applications [10]. As a highly multidisciplinary technology, flexible electronics is promising, and many studies on flexible smart materials and sensors have increasingly emerged. By far, flexible sensors have begun to be commercialized. For example, SoftcepterTM fabric sensors developed by AdvanPro, HK, China, achieved mass production and were used in respiratory monitoring [11], muscle strength monitoring [12], and plantar pressure monitoring [13]. A fabric stretch sensor made by StretchSense, a company in Auckland, New Zealand [14], was adopted in the development of monitoring gloves to capture hand movements accurately. TekscanTM, Boston, MA, USA, produced a flexible pressure measurement system that can monitor pressure distribution in the hand [15], lower extremities [16], and soles of the feet [17]. However, there are still various problems in practical applications of these flexible wearables, including poor durability, high production costs, low stability, and a lack of consistency. Hence, most motion monitoring sensors on the market are still made of rigid materials.

2. Traditional Silicon-Based Sensors

2.1. Accelerometer

An accelerometer is a device that can measure the acceleration of an object. It is composed of a mass block, a damper, an elastic element, a sensitive element, an adaptation circuit, etc. According to the measurement principle, it can be divided into an angular accelerometer and a linear accelerometer. Accelerometers can detect deflections or stress deviations from external acceleration by means of their electrical signals [18]. Currently, the size of accelerometers is gradually decreasing [19] and becoming more wearable. They are widely used for fall recognition [20], gait monitoring [21], human motion analysis [22], elderly activity monitoring [23], children’s daily activity recognition [24], energy consumption estimation [25], and intelligent housing systems [22], etc. For example, timely recognition of the elderly falling to achieve appropriate protection [26]; being part of a smart housing system; forming an intelligent monitoring system as a part of a smart home system [22]; and assessing the type and intensity of daily activities, which is expected to improve energy consumption during exercise [25]. In recent studies, individual accelerometers have accurately distinguished abnormal motion [22][23][27]. However, reducing the number of sensors will decrease monitoring accuracy and make it difficult to identify more complex motions. Based on this, the design of monitoring systems that combine multiple accelerometers is being studied. The commercially available accelerometers commonly used in human motion monitoring are shown in Table 1. Particularly, the three-axis accelerometers in related studies are mainly from ADI and Freescale in the United States. These sensors are delicate and compact; the size is mostly 3~6 mm, and the thickness is not more than 1.5 mm. They have a wide measurement range, e.g., the accuracy is within ±2 g and the sampling rate is mostly within 50–100 Hz. In addition, in the current wearable system, triaxial accelerometers are often placed on the limbs and waist of the human body.

Table 1. Accelerometers for human motion and posture monitoring.

| Model | Company | Size (Length × Width × Thickness) (mm × mm × mm) |

Range of Measurement (g) |

Sampling Rate (Hz) | Application Areas |

|---|---|---|---|---|---|

| ADXL330 Triaxial Accelerometer [28] | ADI, Norwood, MA, USA | 4 × 4 × 1.45 | ±3 | 100 | Waist and thighs |

| ADXL345 Triaxial Accelerometer [29][30][31][32][33] | ADI, Norwood, MA, USA | 3 × 5 × 1 | ±2 | 50, 100 | Abdomen, upper limbs, thighs, and calves |

| ADXL362 Accelerometer [34] | ADI, Norwood, MA, USA | 3 × 3.25 × 1 | ±2 | 100, 400 | Waist, thighs, and calves |

| MMA7260 3-axis Accelerometer [23][35] | Freescale, Austin, TX, USA | 6 × 6 × 1.45 | ±1.5 | \ | Chest pockets, waist, left and right front pant pockets, back pant pockets, and the inside of the jacket |

| LIS3DH Triaxial Accelerometer [36] | STMicroelectronics, Geneva, Switzerland | 3 × 3 × 1 | ±2 | 100 | Android phones |

| MMA8453 3-axis Accelerometer [37] | Freescale, Austin, TX, USA | 3 × 3 × 1 | ±2 | 1.56–800 | Trunk |

2.2. Gyroscope

A gyroscope is a sensor that measures the angular variance or angular rate based on the Coriolis force [18]. It can measure the angular velocity of rotation at high speed and has a good dynamic response. Early researchers exploited a single gyroscope to measure angular acceleration. However, in order to measure the angular velocity of human motion, the accelerometer and gyroscope are often used together to decrease the error and improve the monitoring accuracy. Gyroscopes are now widely employed in electronic products such as laptops, smartphones, and navigation systems. However, long-term usage will cause it to be affected by random drift, resulting in drift errors. The commercial gyroscopes used mostly in human motion monitoring wearable systems are described in Table 2. The commonly used gyroscope is mainly from the Swiss STMicroelectronics and the United States Honeywell companies. These sensors are usually combined with accelerometers to form monitoring systems. Their assembled sizes range from 6.225 to 12,100 mm3, and the thickness is between 11 and 22 mm. Particularly, the ISM330DHCX sensor from STMicroelectronics is particularly compact, measuring less than 3 mm. These gyroscopes are available in a wide measurement range of up to 4000 dps, and the sampling rate is generally selected at 100 Hz. They are mainly used for angular acceleration monitoring of the upper limbs and trunk.

Table 2. Gyroscopes for human motion and posture monitoring.

| Model | Company | Number of Axes | Size (Length × Width × Thickness) (mm × mm × mm) | Range of Measurement (dps) |

Sampling Rate (Hz) | Application Area |

|---|---|---|---|---|---|---|

| L3G4200D | STMicroelectronics, Geneva, Switzerland [38] | 3 | 4 × 4 × 1 | ±2000 | 100, 800 | Forearms and upper arms |

| IMUZ | ZMP, Tokyo, Japan [39] | 6 | 21 × 21 × 22 | ±500 | 100 | Waist |

| 3DM-GX3-25 | Honeywell, Morris, NJ, USA [40] | 9 | 44 × 25 × 11 | ±300 | 100 | Backpack handle |

| ISM330DHCX | STMicroelectronics, Geneva, Switzerland [41] | 6 | 2.5 × 3 × 0.83 | ±4000 | 12.5–6700 | Upper arms, forearms, hands, and trunk |

2.3. Magnetometer

A magnetometer detects motion by using the earth’s magnetic field, and its measurement accuracy is high at static. It calculates the carrier orientation attitude by sensing the local magnetic field flux. Its indoor positioning results are often more accurate than GPS. When the earth’s magnetic field is constant, the magnetometer has good measurement performance at rest, and it does not drift over time. Therefore, it is often used in combination with accelerometers and gyroscopes to form an inertial measurement unit (IMU), which is used to correct the heading angle offset caused by gyroscope drift. Accordingly, the accuracy of attitude monitoring during human motion has improved.

2.4. Inertial Sensors

Since accelerometers are susceptible to temperature and other factors, the accelerometers and gyroscopes or magnetometers are often integrated to form an inertial sensing unit ‘IMU’ to ensure monitoring accuracy, which is known as inertial sensors. Inertial sensors are increasingly used because of their small size, low cost, and ability to measure 3D knee angles with high accuracy. Besides, they are not affected by light, space, or other environmental factors. The sensors have been applied to recognizing gymnastic movements, non-invasively assessing knee function, and treating diseases such as Parkinson’s, etc. When monitoring human motion and posture, the monitoring error is mainly caused by soft tissue artifacts, sensor movement, and the relative motion of bones because the inertial sensors must be closely connected to the human body. The inertial sensors used in intelligent wearable systems are mostly nine-axis. As shown in Table 3, the commercial inertial sensors widely used are mainly produced by InvenSense, Bosch Sensortec, and Shimmer, Germany. InvenSense inertial sensors are the most popular. The size of this type of sensor is between 2.7 and 14.4 mm3, and its thickness is less than 1mm. It is primarily installed in the human chest, wrist, calf, thigh, and ankle joints.

Table 3. Inertial sensors for human motion and posture monitoring.

| Model | Company | Size (Length × Width × Thickness) (mm × mm × mm) | Application Areas |

|---|---|---|---|

| MPU6050 3-axis acceleration Gauges and Gyroscopes [31][42][43] |

InvenSense, Sunnyvale, CA, USA | 4 × 4 × 0.9 | Chest, abdomen, wrists, thighs, calves, and feet |

| Flow-MIMU 3-axis accelerometer and gyroscope [44] | \ | \ | Wrists and calves |

| YD122 Inertial Sensor [6] | Hundred Years Xukang Medical Equipment Co. Chengdu, Sichuan, China | \ | Chest, thighs, calves, upper arms, and forearms |

| MPU9250 Inertial Sensor [45] | InvenSense, Sunnyvale, CA, USA | 3 × 3 × 1 | Chest, thighs, and wrists |

| BMI160 Inertial Sensor [20] | Bosch, Stuttgart, Germany | 2.5 × 3 × 0.8 | Smart Watch |

| MPU6500 Inertial Sensor [46] | InvenSense, Sunnyvale, CA, USA | 3 × 3 × 0.9 | Thighs, wrists, and ankle joints |

2.5. Tilt Sensor

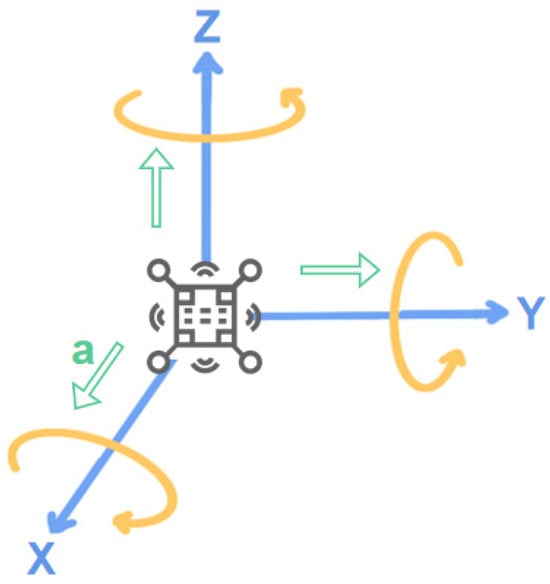

The inclination sensor is designed based on the principle of gravitational acceleration, which combines accelerometers and gyroscopes. As shown in Figure 2, the system’s inclination can be obtained by measuring the acceleration of the X, Y, and Z axes and further calculating the angle between each axis and the acceleration of gravity [33]. Inclination sensors are mostly used for lower limb posture monitoring [31][47][48]. For example, Cui et al. [31] designed a device to monitor human gait in which five inclination sensors were tied to the subject’s trunk, thigh, and calf to measure the angle with the horizontal plane. In the process of motion monitoring, the error of the inclination sensor is mainly ascribed to human factors and environmental factors. The human factors include the wearing position and installation method, and the environmental factors mainly contain temperature and surrounding noise. To solve this problem, Wang et al. [48] designed the signal processing of leg inclination sensors for footed robots. In this system, noise and temperature effects can be filtered out during measurement, and the error can be controlled within 0.75%.

Figure 2. Inclination sensor measurement principle.

3. Flexible Sensors

Flexible sensors have received a great deal of attention in the last few decades due to their excellent properties of high stretchability, biocompatibility, high compliance, and high sensitivity [49]. They are mainly used in human motion monitoring, human-computer interaction, telemedicine, and augmented reality/virtual reality. Several review articles [50][51][52] recommended flexible sensors, and they elaborated on the sensors from the perspective of sensing principles. According to the substrate materials, flexible sensors can be divided into two categories: textile sensors and thin-film sensors, both of which can include strain sensors and pressure sensors.

3.1. Substrates of Flexible Sensors

Textile sensors use fibers, yarns, and fabrics as substrates to enable various sensing functionalities through material improvement and structural design [53][54]. For example, Li et al. [55] developed a microfiber membrane with omnidirectional super elasticity (recovery from a 2000% strain), permeability (over 90% of cotton), and super hydrophobicity (water contact angle of 154.2°), which can identify materials and monitor hand posture. Textiles are one of the most ideal wearable materials, with both sensing characteristics and fabric properties such as excellent softness, durability, biocompatibility, and lightness. Textile sensors have undergone four generations of development. In the first and second generations, fabrics were used only as carriers. The rigid components of electronic devices were attached to or embedded in the textile. In the third generation of flexible fabric devices, flexible fabric devices and rigid microelectronic components formed a hybrid system by means of heterogeneous system integration technology, which contributed to the emerging flexible electronic components. The fourth generation used all electronic fabric devices to form an electronic system. At present, the third generation of hybrid systems has been successfully applied, and the research on the fourth generation of all-fabric electronic systems has made some achievements. However, the development still presents a bottleneck, mainly in the conflict between the functionality of electronic devices and the intrinsic properties of the fabric [49]. One typical example is the coated textile sensors, in which the sensing materials were directly coated on the fabric surface. For example, Liu [3] developed a pressure sensor using nickel-coated polyester fabric and carbon nanotubes (CNT), which has the advantages of high sensitivity, good linearity, and wide range, but the lack of adhesion of the coating affects its washing performance. Another typical example is the textile-type structure, in which the sensing materials are coated onto yarns and fibers, which are then woven into conductive lines by knitting, weaving, embroidery, or weaving processes. Afroj et al. [56] used rGO-coated cotton yarn to weave a temperature sensor via knitting, which is wear-resistant and has excellent deformability and washability. However, its conductivity is poor, and its sensitivity and response are average. Since the flexible system is different from its conventional rigid counterpart, new evaluation criteria and physical models are needed. Besides, the conductive yarns are prone to corrosion, leading to low wear resistance and low conductivity. Further research is still needed before commercialization.

Thin-film sensors are worn on the skin, with the concept of e-skin being widely known for designing thin-film sensors that can mimic the human skin. A typical example is from John A. Rogers’s research group [57]. They designed a fully elastomeric strain gauge directly attached to human skin that can be integrated with stretchable electronics. Such sensors can also be applied to treat swallowing difficulties caused by head and neck cancers, with thicknesses as low as 300 μm. They can accurately monitor the electrical signals of salivary swallowing [58], as well as the pressure monitoring of intracranial, intraocular, and intravascular cavities [59]. It can also be used for neonatal physiological signal monitoring, open (“orifice”) layout, and pre-curved design to reduce adhesion damage [60]. Thin-film sensors were initially limited to monitoring small deformations in the human body (fingers, wrists, etc.) [61][62]. Hydrogel sensors have recently been used to identify larger deformations (joints, neck, etc.) [63][64]. However, most e-skin sensors are continuous film-like structures that can only be stretched and bent in every direction, and these sensors do not allow for significant double curvature bending or in-plane shear [65]. This dramatically limits the strain forces that this type of sensor can withstand. As regards this limitation, Chen et al. [66] developed a hydrogel self-powered human motion sensor with an elongation at a break of 2800% and good strain sensitivity (GF = 4 at 200% strain). In addition, Gao et al. [67] reported a biological tissue inspired ultra-soft microfiber composite ultrathin (<5 μm) hydrogel film that can be seamlessly attached to various rough surfaces. The hydrogel has prominent mechanical strength (tensile stress~6 MPa) and anti-tearing properties.

The high conductivity and sensitivity of flexible sensors have long been the focus of research. Many scholars have integrated highly conductive nanomaterials with flexible materials. For example, Matsuhisa et al. [68] investigated the bonding process of silver particles on a fabric surface and demonstrated the feasibility of a fully printed sensor network suitable for complex and dynamic surfaces; Han et al. [69] designed a dual conductive percolation network hydrogel strain sensor; Yu et al. [70] reported an all-in-one, stretchable, and self-powered elastomer-based piezo-pressure sensor (ASPS); Zhang et al. [71] prepared a hydrogel composite containing MXene (Ti3C2TX) with a gauge factor (GF) of 25. Based on this, Bai et al. [62] found that the electrical conductivity of MXene/PAA hydrogels gradually increased from 8 to 69 mS m−1 with the increase of MXene.

3.2. Flexible Strain and Pressure Sensors

Strain sensors can convert the degree of deformation of mechanical motion into electrical signals. They are available in three categories: resistance, capacitance, and voltage [49][72]. Among them, resistive and capacitive strain sensors are most widely used as they are simple and easy to use [73][74].

Early studies of flexible strain sensors in human motion monitoring focused on fine movements, such as finger movements [72][75][76][77][78], facial expressions [62][79][80][81], and limb muscle contractions, etc. [12]. However, current research has been extended to body joints (wrist, ankle, neck, knee, elbow, etc.) [49][79][82][83] and body posture [84]. For example, Coyle S. from the University of Pisa [82] reported a sensor-printed garment for kinesthetic monitoring, in which a composite material consisting of a silicone matrix and CB (carbon black) powder is printed on Lycra®/cotton fabric to provide real-time feedback on the wearer’s limb orientation. Besides, Zhang et al. [85] designed a rose-shaped strain sensor system consisting of three graphite/silk fiber (GSF, Graphene Silk Fiber) strain sensors, which were mounted on the wrist to monitor human motion in multiple directions. Subsequently, Wang et al. [86] developed a strain sensor with a woven structure that can monitor human motion postures, including joint movements, finger movements, wrist flexion, etc. The strain sensor could detect a strain of up to 500% and maintain long-term stability. Then, Bai et al. [49] prepared a transparent, mechanically robust, environmentally stable, and versatile natural skin-derived organic hydrogel (NSD-Gel) sensor, which can recognize neck, wrist, elbow, ankle, and knee joint movements. In addition, Kong et al. [87] found that a strain sensor based on polyurethane (PU) yarn could measure up to 50% of strain stably at only 1% strain for more than 100,000 cycles. Bai et al. [62] developed an MXene/polyacrylic acid (PAA) hydrogel flexible strain sensor with high sensitivity (GF ~ 4.94), wide detection range (0–1081%), and stable output signal that can not only recognize subtle movements such as frowning, smiling, and swallowing, but also accurately monitor human motion with significant deformation.

Unlike strain sensors, pressure sensors convert pressure into an electrical signal [88]. Most current pressure sensors have a sensing range of more than 10 kPa and can be used for finger motion monitoring, such as finger bending force, pressure, twisting, and extension force [3], as well as for human joint motion recognition. For example, in 2020, Zhu et al. [89] developed a novel highly shape-adaptive, self-powered piezo electronic skin that can be mounted coordinately on arbitrarily curved surfaces (e.g., twisted human skin) or moving surfaces (e.g., curved joints). However, it is currently mainly used for gait monitoring. In 2012, Shu [90] integrated it into a fabric insole to develop an intelligent wearable system for plantar pressure distribution measurement and gait analysis; Wang et al. [91] developed a textile capacitive pressure-sensing insole for gait pattern analysis; and Zhou et al. [92] developed a brilliant motion array with an 8 × 16 pressure sensing array that can monitor calf muscles during daily exercise and perform motion quality evaluation. In addition, pressure sensors are also widely used for early screening of diseases. For instance, Shu et al. [13] developed iShoe, a pair of shoes that can map foot pressure anytime and anywhere, and the system has been successfully tested in local hospitals in Hong Kong for the prognosis of diabetic foot syndrome. Cheng et al. [93] reported a piezoresistive pressure sensor based on PPy/rGO/FSF (nylon fabric-latex foam-nylon fabric (FSF), reduced graphene oxide (rGO), and in situ molded polypyrrole (PPy)) composite for Parkinson’s disease detection by monitoring the time of head lift and elevation. However, pressure sensors can also be applied to smart homes. Yu et al. [94] reported an all-in-one conformal pressure sensor (ACPS) that can be deployed in the human body and the room to care for the elderly living alone.

References

- Rafi, M.; Hamid, M.E.; Khan, M.S.; Wahidabanu, R.S.D. A Parametric Approach to Gait Signature Extraction for Human Motion Identification. Int. J. Image Process. 2011, 5, 2011–2185.

- Liu, R.; Li, J.M.; Li, M.; Zhang, Q.H.; Shi, G.Y.; Li, Y.G.; Hou, C.Y.; Wang, H.Z. MXene-Coated Air-Permeable Pressure-Sensing Fabric for Smart Wear. ACS Appl. Mater. Int. 2020, 12, 46446–46454.

- Liu, M.; Pu, X.; Jiang, C.; Liu, T.; Huang, X.; Chen, L.; Du, C.; Sun, J.; Hu, W.; Wang, Z.L. Large-Area All-Textile Pressure Sensors for Monitoring Human Motion and Physiological Signals. Adv. Mater. 2017, 29, 1703700.

- Xiong, Y.; Hu, Y.; Zhu, P.; Sun, R.; Wong, C. Fabrication and Application of Flexible Pressure Sensors with Micro/Nano-Structures. Prog. Chem. 2019, 31, 800–810.

- Perez, A.J.; Labrador, M.A.; Barbeau, S.J. G-Sense: A Scalable Architecture for Global Sensing and Monitoring. IEEE Netw. 2010, 24, 57–64.

- Liang, D.; Qu, Y. Design and application of motion capture algorithm for wearable sensors in remote rehabilitation. China Med. Devices 2021, 36, 32–35+39.

- Meng, Z.; Zhang, M.; Guo, C.; Fan, Q.; Zhang, H.; Gao, N.; Zhang, Z. Recent progress in sensing and computing techniques for human activity recognition and motion analysis. Electronics 2020, 9, 1357.

- Munro, B.J.; Campbell, T.E.; Wallace, G.G.; Steele, J.R. The intelligent knee sleeve: A wearable biofeedback device. Sens. Actuators B Chem. 2008, 131, 541–547.

- Helmer, R.J.N.; Mestrovic, M.A.; Farrow, D.; Lucas, S.; Spratford, W. Smart Textiles: Position and Motion Sensing for Sport, Entertainment and Rehabilitation. Adv. Sci. Technol. 2008, 60, 144–153.

- Pang, C.; Lee, C.; Suh, K.Y. Recent advances in flexible sensors for wearable and implantable devices. J. Appl. Polym. Sci. 2013, 130, 1429–1441.

- Wang, F.; Liu, S.; Shu, L.; Tao, X.M. Low-dimensional carbon based sensors and sensing network for wearable health and environmental monitoring. Carbon 2017, 121, 353–367.

- Wang, X.; Tao, X.; So, R.C.; Shu, L.; Yang, B.; Li, Y. Monitoring elbow isometric contraction by novel wearable fabric sensing device. Smart Mater. Struct. 2016, 25, 125022.

- Shu, L.; Hua, T.; Wang, Y.; Li, Q.; Feng, D.D.; Tao, X. In-Shoe Plantar Pressure Measurement and Analysis System Based on Fabric Pressure Sensing Array. IEEE Trans. Inf. Technol. Biomed. 2010, 14, 767–775.

- StretchSense. Available online: https://stretchsense.com/ (accessed on 28 September 2023).

- Zhang, J.; Bader, D.; Twycross-Lewis, R.; Padhiar, N. A prospective cohort study of vertical pressure on hands of sitting volleyball players using tekscan pressure mat. Br. J. Sports Med. 2011, 45, e1.

- Wilharm, A.; Hurschler, C.; Dermitas, T.; Bohnsack, M. Use of Tekscan K-Scan Sensors for Retropatellar Pressure Measurement Avoiding Errors during Implantation and the Effects of Shear Forces on the Measurement Precision. BioMed Res. Int. 2013, 2013, 829171.

- Zammit, G.V.; Menz, H.B.; Munteanu, S.E. Reliability of the TekScan MatScan®system for the measurement of plantar forces and pressures during barefoot level walking in healthy adults. J. Foot Ankle Res. 2010, 3, 11.

- Zhu, J.; Liu, X.; Shi, Q.; He, T.; Sun, Z.; Guo, X.; Liu, W.; Sulaiman, O.B.; Dong, B.; Lee, C. Development trends and perspectives of future sensors and MEMS/NEMS. Micromachines 2019, 11, 7.

- Sun, C. Research on Human Motion Monitonng Based on Acceleration Sensor. Master’s Thesis, Suzhou University, Suzhou, China, 2019.

- Chen, L.; Li, R.; Zhang, H.; Tian, L.L.; Chen, N. Intelligent fall detection method based on accelerometer data from a wrist-worn smart watch. Measurement 2019, 140, 215–226.

- Avvenuti, M.; Carbonaro, N.; Cimino, M.G.C.A.; Cola, G.; Tognetti, A.; Vaglini, G. Smart Shoe-Assisted Evaluation of Using a Single Trunk/Pocket-Worn Accelerometer to Detect Gait Phases. Sensors 2018, 18, 3811.

- Jala, A.; Quaid, M.A.K.; Kim, K. A Wrist Worn Acceleration Based Human Motion Analysis and Classification for Ambient Smart Home System. J. Electr. Eng. Technol. 2019, 14, 1733–1739.

- Khan, A.M.; Lee, Y.K.; Lee, S.; Kim, T.S. Accelerometer’s position independent physical activity recognition system for long-term activity monitoring in the elderly. Med. Biol. Eng. Comput. 2010, 48, 1271–1279.

- Nam, Y.; Park, J.W. Child Activity Recognition Based on Cooperative Fusion Model of a Triaxial Accelerometer and a Barometric Pressure Sensor. IEEE J. Biomed. Health Inf. 2013, 17, 420–426.

- Bonomi, A.G.; Plasqui, G.; Goris, A.H.C.; Westerterp, K.R. Improving assessment of daily energy expenditure by identifying types of physical activity with a single accelerometer. J. Appl. Physiol. 2009, 107, 655–661.

- Ye, Z.; Li, Y.; Zhao, Q.; Liu, X. A Falling Detection System with wireless sensor for the Elderly People Based on Ergnomics. Int. J. Smart Home 2014, 8, 187–196.

- Wen-Sheng, H.; Jia-Man, D.; Xiao-Lin, Z.; Qin, Y.; Xiao-Ying, W.U.; Rong, X.U. Detection of human upper limb motion gesture based on acceleration sensor. Transducer Microsyst. Technol. 2009, 28, 106–108.

- Chen, Y.; Wang, Z.; Li, Z.; Li, H. Human daily activity recognition method based on BSN and neural network. J. Dalian Univ. Technol. 2013, 53, 893–897.

- Li, J.; Chi, Z.; Li, Z. Human fall detection system based on threshold analysis method. Transducer Microsyst. Technol. 2019, 38, 80–82+86.

- Hong, J.; Zhao, Z. A Research Method of Human Upper Limb Motion Recognition Based on Acceleration Signal. Mach. Tool Hydraul. 2014, 42, 50–53.

- Cui, J.; Cao, H.; Zhu, J.; Jiang, J.; Zhang, Y. Human gait monitoring system based on MEMS tilt sensors and thin film pressure sensors. China Meas. Test. 2018, 44, 70–75.

- Ji, T.; Cong, S. Research Progress and Development Trend of Smart Health Monitoring Clothing. Knitt. Ind. 2021, 3, 82–85.

- Guo, T.; Wei, M.; Wang, C. Design of Portable Wireless Angle Sensor Measurement System. Instrum. Tech. Sens. 2016, 8, 5–8+13.

- Chen, J. Research and Design of Wearable Body Posture Monitoring System. Master’s Thesis, Central South University, Changsha, China, 2014.

- Su, B. The Design and Implementation of Human Posture Monitoring System Based on Accelerometer. Master’s Thesis, Northeastern University, Liaoning, China, 2011.

- Xue, Y. Research on Human Posture Recognition System Based on Accelerometer. Master’s Thesis, Hebei University of Science & Technology, Shijiazhuang, China, 2014.

- Chen, T.; Zhang, X.; Xu, J.; Li, J. System for Fall Monitoring Based on 3-Axis Accelerometer and Electronic Compass. Meas. Control Technol. 2015, 34, 16–19.

- Hsu, Y.L.; Wang, J.S.; Lin, Y.C.; Chen, S.M.; Tsai, Y.J.; Chu, C.L.; Chang, C.W. A wearable inertial-sensing-based body sensor network for shoulder range of motion assessment. In Proceedings of the 2013 1st International Conference on Orange Technologies (ICOT), Tainan, Taiwan, 12–16 March 2013; IEEE: New York, NY, USA, 2013; pp. 328–331.

- Ngo, T.T.; Makihara, Y.; Nagahara, H.; Mukaigawa, Y.; Yagi, Y. The largest inertial sensor-based gait database and performance evaluation of gait-based personal authentication. Pattern Recognit. 2014, 47, 228–237.

- Trung, N.T.; Makihara, Y.; Nagahara, H.; Sagawa, R.; Mukaigawa, Y.; Yagi, Y. Phase registration in a gallery improving gait authentication. In Proceedings of the 2011 International Joint Conference on Biometrics (IJCB), Washington, DC, USA, 11–13 October 2011; IEEE: New York, NY, USA, 2011; pp. 1–7.

- Slade, P.; Habib, A.; Hicks, J.L.; Delp, S.L. An open-source and wearable system for measuring 3D human motion in real-time. IEEE Trans. Biomed. Eng. 2021, 99, 678–688.

- Wang, Y.; Zhang, X.; Mu, X.; Han, H. Research on the prediction method of elderly fall-down for elderly-assistant and walking-assistant robot. J. Electron. Meas. Instrum. 2018, 32, 1–7.

- Lu, P.; Jia, F.; Qie, J. MEMS-based human-body posture classification and monitoring system for patients suffering from Parkinson’s disease. Acta Autom. Sin. 2017, 40, 161–164+169.

- Liu, S.Q.; Zhang, J.C.; Li, G.Z.; Zhu, R. A Wearable Flow-MIMU Device for Monitoring Human Dynamic Motion. IEEE Trans. Neural Syst. Rehabil. Eng. 2020, 99, 637–645.

- Gochoo, M.; Tahir, S.B.U.D.; Jalal, A.; Kim, K. Monitoring Real-Time Personal Locomotion Behaviors Over Smart Indoor-Outdoor Environments Via Body-Worn Sensors. IEEE Access 2021, 9, 70556–70570.

- Sun, J.; Meng, X.; Liang, H.; Duan, H.; Zhan, Z. Gymnastics motion recognition based on MEMS sensor. J. Electron. Meas. Instrum. 2020, 34, 94–99.

- Motoi, K.; Taniguchi, S.; Baek, M.; Wakugawa, M.; Sonoda, T.; Yuji, T.; Higashi, Y.; Fujimoto, T.; Ogawa, M.; Tanaka, S. Development of a wearable gait monitoring system for evaluating efficacy of walking training in rehabilitation. Sens. Mater. 2012, 24, 59–373.

- Wang, Z.; Li, L. Study on Signal Processing of Leg Tilt Sensor of Legged Robot. Chin. J. Sens. Actuators 2018, 31, 710–714.

- Bai, Z.; Wang, X.; Zheng, M.; Yue, O.; Huang, M.; Zou, X.; Cui, B.; Xie, L.; Dong, S.; Shang, J. Mechanically Robust and Transparent Organohydrogel-Based E-Skin Nanoengineered from Natural Skin. Adv. Funct. Mater. 2023, 33, 2212856.

- Wang, X.; Yu, H.; Kold, S.; Rahbek, O.; Bai, S. Wearable sensors for activity monitoring and motion control: A review. Biomim. Intell. Robot. 2023, 3, 100089.

- Duan, L.; D’Hooge, D.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Mater. Sci. 2019, 114, 100617.

- Yang, T.; Xie, D.; Li, Z.; Zhu, H. Recent advances in wearable tactile sensors: Materials, sensing mechanisms, and device performance. Mater. Sci. Eng. R Rep. 2017, 115, 1–37.

- Li, X.; Hu, H.; Hua, T.; Xu, B.; Jiang, S. Wearable strain sensing textile based on one-dimensional stretchable and weavable yarn sensors. Nano Res. 2018, 11, 5799–5811.

- Roh, J.S. Wearable Textile Strain Sensors. Fash. Text. Res. J. 2016, 18, 733–745.

- Li, Y.; Xiao, S.; Zhang, X.; Jia, P.; Tian, S.S.; Pan, C.; Zeng, F.P.; Chen, D.C.; Chen, Y.Y.; Tang, J.; et al. Silk inspired in-situ interlocked superelastic microfibers for permeable stretchable triboelectric nanogenerator. Nano Energy 2022, 98, 107347.

- Afroj, S.; Karim, N.; Wang, Z.; Tan, S.; He, P.; Holwill, M.; Ghazaryan, D.; Fernando, A.; Novoselov, K.S. Engineering graphene flakes for wearable textile sensors via highly scalable and ultrafast yarn dyeing technique. ACS Nano 2019, 13, 3847–3857.

- Lu, N.; Chi, L.; Yang, S.; Rogers, J. Highly Sensitive Skin-Mountable Strain Gauges Based Entirely on Elastomers. Adv. Funct. Mater. 2012, 22, 4044–4050.

- Madhvapathy, S.R.; Ma, Y.; Patel, M.; Krishnan, S.; Wei, C.; Li, Y.; Xu, S.; Feng, X.; Huang, Y.; Rogers, J.A. Epidermal Electronic Systems for Measuring the Thermal Properties of Human Skin at Depths of up to Several Millimeters. Adv. Funct. Mater. 2018, 28, 1802083.

- Yang, Q.; Lee, S.; Xue, Y.; Yan, Y.; Rogers, J.A. Materials, Mechanics Designs, and Bioresorbable Multisensor Platforms for Pressure Monitoring in the Intracranial Space. Adv. Funct. Mater. 2020, 30, 1910718.

- Kwak, S.S.; Yoo, S.; Avila, R.; Chung, H.U.; Jeong, H.; Liu, C.; Vogl, J.L.; Kim, J.; Yoon, H.J.; Park, Y.; et al. Skin-Integrated Devices with Soft, Holey Architectures for Wireless Physiological Monitoring, With Applications in the Neonatal Intensive Care Unit. Adv. Mater. 2021, 33, 2103974.

- Shi, L.; Li, Z.; Chen, M.; Zhu, T.; Wu, L. Ultrasensitive and Ultraprecise Pressure Sensors for Soft Systems. Adv. Mater. 2023, 35, e2210091.

- Bai, Y.; Lu, Y.; Bi, S.; Wang, W.; Lin, F.; Zhu, F.; Yang, P.; Ding, N.; Liu, S.; Zhao, W. Stretchable and Photothermal MXene/PAA Hydrogel in Strain Sensor for Wearable Human-Machine Interaction Electronics. Adv. Mater. Technol. 2023, 8, 2201767.

- Wang, H.; Sun, X.; Wang, Y.; Li, K.; Wang, J.; Dai, X.; Chen, B.; Chong, D.; Zhang, L.; Yan, J. Acid enhanced zipping effect to densify MWCNT packing for multifunctional MWCNT films with ultra-high electrical conductivity. Nat. Commun. 2023, 14, 380.

- Liu, X.; Huang, Z.; Ye, C.M. Graphene-Based Hydrogel Strain Sensors with Excellent Breathability for Motion Detection and Communication. Macromol. Mater. Eng. 2022, 8, 307.

- Benight, S.J.; Wang, C.; Tok, J.B.H.; Bao, Z. Stretchable and self-healing polymers and devices for electronic skin. Prog. Polym. Sci. 2013, 38, 1961–1977.

- Chen, J.; Zhang, L.; Tu, Y.; Zhang, Q.; Peng, F.; Zeng, W.; Zhang, M.; Tao, X. Wearable self-powered human motion sensors based on highly stretchable quasi-solid state hydrogel. Nano Energy 2021, 88, 106272.

- Gao, Q.; Sun, F.Q.; Li, Y.; Li, L.H.; Liu, M.Y.; Wang, S.Q.; Wang, Y.F.; Li, T.; Liu, L.; Feng, S.M.; et al. Biological Tissue-Inspired Ultrasoft, Ultrathin, and Mechanically Enhanced Microfiber Composite Hydrogel for Flexible Bioelectronics. Nano-Micro Lett. 2023, 15, 139.

- Matsuhisa, N.; Inoue, D.; Zalar, P.; Jin, H.; Matsuba, Y.; Itoh, A.; Yokota, T.; Hashizume, D.; Someya, T. Printable elastic conductors by in situ formation of silver nanoparticles from silver flakes. Nat. Mater. 2017, 16, 834–840.

- Han, S.; Liu, C.; Lin, X.; Zheng, J.; Wu, J.; Liu, C. Dual conductive network hydrogel for a highly conductive, self-healing, anti-freezing, and non-drying strain sensor. ACS Appl. Polym. Mater. 2020, 2, 996–1005.

- Yu, J.B.; Xian, S.; Zhang, Z.P.; Hou, X.J.; He, J.; Mu, J.L.; Geng, W.P.; Qiao, X.J.; Zhang, L.; Chou, X.J. Synergistic piezoelectricity enhanced BaTiO3/polyacrylonitrile elastomer-based highly sensitive pressure sensor for intelligent sensing and posture recognition applications. Nano Res. 2023, 16, 5490–5502.

- Zhang, Y.Z.; Lee, K.H.; Anjum, D.H.; Sougrat, R.; Jiang, Q.; Kim, H.; Alshareef, H.N. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv. 2018, 4, eaat0098.

- Wang, J.; Lu, C.; Zhang, K. Textile-based strain sensor for human motion detection. Energy Environ. Mater. 2020, 3, 80–100.

- Sun, Q.; Seung, W.; Kim, B.J.; Seo, S.; Kim, S.W.; Cho, J.H. Active matrix electronic skin strain sensor based on piezopotential-powered graphene transistors. Adv. Mater. 2015, 27, 3411–3417.

- Zhou, J.; Gu, Y.; Fei, P.; Mai, W.; Gao, Y.; Yang, R.; Bao, G.; Wang, Z.L. Flexible piezotronic strain sensor. Nano Lett. 2008, 8, 3035–3040.

- Ryu, S.; Lee, P.; Chou, J.B.; Xu, R.; Zhao, R.; Hart, A.J.; Kim, S.G. Extremely elastic wearable carbon nanotube fiber strain sensor for monitoring of human motion. ACS Nano 2015, 9, 5929–5936.

- Cheng, Y.; Wang, R.; Sun, J.; Gao, L. A stretchable and highly sensitive graphene-based fiber for sensing tensile strain, bending, and torsion. Adv. Mater. 2015, 27, 7365–7371.

- Yan, C.; Wang, J.; Kang, W.; Cui, M.; Wang, X.; Foo, C.Y.; Chee, K.J.; Lee, P.S. Highly stretchable piezoresistive graphene–nanocellulose nanopaper for strain sensors. Adv. Mater. 2014, 26, 2022–2027.

- Yuan, W.; Zhou, Q.; Li, Y.; Shi, G. Small and light strain sensors based on graphene coated human hairs. Nanoscale 2015, 7, 16361–16365.

- Wang, Z.; Huang, Y.; Sun, J.; Huang, Y.; Hu, H.; Jiang, R.; Gai, W.; Li, G.; Zhi, C. Polyurethane/cotton/carbon nanotubes core-spun yarn as high reliability stretchable strain sensor for human motion detection. ACS Appl. Mater. Int. 2016, 8, 24837–24843.

- Wu, X.; Han, Y.; Zhang, X.; Lu, C. Highly sensitive, stretchable, and wash-durable strain sensor based on ultrathin conductive layer@ polyurethane yarn for tiny motion monitoring. ACS Appl. Mater. Int. 2016, 8, 9936–9945.

- Zhang, H.; Liu, N.; Shi, Y.; Liu, W.; Yue, Y.; Wang, S.; Ma, Y.; Wen, L.; Li, L.; Long, F. Piezoresistive sensor with high elasticity based on 3D hybrid network of sponge@ CNTs@ Ag NPs. ACS Appl. Mater. Int. 2016, 8, 22374–22381.

- Coyle, S.; Wu, Y.; Lau, K.T.; Rossi, D.; Wallace, G.; Diamond, D. Smart nanotextiles: A review of materials and applications. MRS Bull. 2007, 32, 434–442.

- Yamada, T.; Hayamizu, Y.; Yamamoto, Y.; Yomogida, Y.; Izadi-Najafabadi, A.; Futaba, D.N.; Hata, K. A stretchable carbon nanotube strain sensor for human-motion detection. Nat. Nanotechnol. 2011, 6, 296–301.

- Mattmann, C.; Clemens, F.; Tröster, G. Sensor for measuring strain in textile. Sensors 2008, 8, 3719–3732.

- Zhang, M.; Wang, C.; Wang, Q.; Jian, M.; Zhang, Y. Sheath–core graphite/silk fiber made by dry-meyer-rod-coating for wearable strain sensors. ACS Appl. Mater. Int. 2016, 8, 0894–20899.

- Wang, C.; Li, X.; Gao, E.; Jian, M.; Xia, K.; Wang, Q.; Xu, Z.; Ren, T.; Zhang, Y. Carbonized silk fabric for ultrastretchable, highly sensitive, and wearable strain sensors. Adv. Mater. 2016, 28, 6640–6648.

- Kong, J.H.; Jang, N.S.; Kim, S.H.; Kim, J.M. Simple and rapid micropatterning of conductive carbon composites and its application to elastic strain sensors. Carbon 2014, 77, 199–207.

- Liu, S.; Ma, K.; Yang, B.; Li, H.; Tao, X. Textile electronics for VR/AR applications. Adv. Funct. Mater. 2021, 31, 2007254.

- Zhu, M.; Lou, M.; Abdalla, I.; Yu, J.; Li, Z.; Ding, B. Highly shape adaptive fiber based electronic skin for sensitive joint motion monitoring and tactile sensing. Nano Energy 2020, 69, 104429.

- Shu, L. Wearable Body Area Sensor Networks for Continuous Dynamic Health Monitoring in Daily Activities: Case Study of Intelligent Footwear System. Ph.D. Thesis, The Hong Kong Polytechnic University, Hong Kong, 2012.

- Wang, C.; Kim, Y.; Shin, H.; Min, S.D. Preliminary clinical application of textile insole sensor for hemiparetic gait pattern analysis. Sensors 2019, 19, 3950.

- Zhou, B.; Sundholm, M.; Cheng, J.; Cruz, H.; Lukowicz, P. Measuring muscle activities during gym exercises with textile pressure mapping sensors. Pervasive Mob. Comput. 2017, 38, 331–345.

- Cheng, H.; Xu, B.; Yang, K.; Yin, Y.J.; Wang, C. High-Sensitivity, Long-Durability, and Wearable Pressure Sensor Based on the Polypyrrole/Reduced Graphene Oxide/(Fabric–Sponge–Fabric) for Human Motion Monitoring. Macromol. Mater. Eng. 2022, 307, 2100801.

- Yu, J.B.; Xian, S.; Mu, J.B.; Wang, M.; Wang, Y.; Hou, X.J.; Zhang, L.; He, J.; Mu, J.L.; Chou, X.J. Hybrid electromechanical properties of hetero-doped and homogeneously bonded dual-mode pressure sensor for indoor body area network node. Sci. China Inf. Sci. 2023, 67, 112401.

More

Information

Subjects:

Instruments & Instrumentation

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

17 Nov 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No