1. Unmanned Aerial Vehicle (UAV) Power Sources

Gas turbine engines have been widely used in aircraft propulsion systems due to their favorable power-to-weight ratio

[1] and extended operational duration

[2]. Gas turbine engines operate on the principle of air compression, combustion, and exhaust propulsion. They intake air, compress it, mix it with fuel for combustion, and then release the high-velocity exhaust gases to produce thrust. These engines are known for their high power-to-weight ratio, making them suitable for fast and agile UAVs. However, their optimal performance is limited to high-power ranges

[3], typically above 100 hp

[4]. As a result, they are not suitable for small-scale UAV applications, as they exhibit drawbacks such as inefficiency in fuel consumption, low overall efficiency, and high noise levels

[5]. In contrast, the internal combustion engine (ICE) has traditionally served as the cornerstone of aircraft propulsion systems

[6][7]. These engines are characterized by their energy density, making them suitable for long-endurance missions in UAVs. Compared to electric motors (EMs), ICEs offer advantages in terms of higher fuel energy and power densities, enabling longer flight times and larger payload capacities, which are crucial factors in flight missions. However, the multi-step energy production process in ICEs results in decreased system efficiency

[8]. EMs are the preferred choice for UAVs due to their distinct characteristics, including minimal thermal and acoustic signatures, well-established electronic control systems, adaptability to automatic control, self-starting capabilities

[9], cost-effectiveness, and higher reliability, which minimizes the risk of crashes caused by motor shutdown or failure. It should be noted that electric propulsion systems may encounter electronic speed controller (ESC) failures due to issues such as overheating and melting of the ESC casing. One potential solution to mitigate this problem is duplicating components

[10].

A research paper

[9] introduced a novel hybrid power propulsion prototype for unmanned aircraft systems (UAS), aiming to combine the advantages of thermal and electric engines. Although simulation results showed a 13% improvement in endurance, the system was considered complex and not environmentally friendly. Other researchers

[10] have also discussed hybrid parallel powertrain architectures using electric motors (EMs) and internal combustion engines (ICEs). However, the incorporation of ICEs in UAVs is currently not the preferred solution due to limitations in fuel usage and endurance optimization. Therefore, this section will solely focus on electric propulsion-based UAVs and provide a critical evaluation of available electric power sources for UAV applications. Additionally, alternative supply strategies including swapping, laser beam inflight recharging, and tethered UAVs will be discussed, particularly for UAVs relying on a single power source.

2. Battery-Based Supply Techniques

2.1. Battery-Powered Unmanned Aerial Vehicles (UAVs)

Battery power is widely utilized in small UAVs, especially quadrotors, as it offers simplicity and flexibility to the propulsion system

[6]. Battery-based platforms, particularly those using lithium batteries, such as LiPo batteries, are popular in hobbyist and commercial applications due to their flight time capabilities and cost effectiveness. However, the endurance of small battery-powered UAVs is limited by the weight constraints of the battery pack, typically allowing for a maximum flight time of around 90 min using LiPo batteries

[11]. LiPo batteries are preferred for small UAVs due to their lightweight nature and relatively high specific energy. In fact, LiPo batteries power the majority of micro aerial vehicles weighing less than 2 kg and with a length below 100 cm

[2].

In selecting the appropriate battery technology for a given UAV application and mission, various characteristics such as specific energy, energy density, and specific power are taken into consideration.

Table 1 provides detailed information on these characteristics for four different battery technologies, aiding in the battery technology selection process

[12]. Additionally, in a specific study, different battery technologies were assessed based on the state of charge (SOC) for a particular mission, further emphasizing the importance of considering mission requirements when choosing battery technologies

[13].

Table 1. Comparison of different batteries with their characteristics

[13][14].

Ref.

[15] focused on examining the factors that affect the performance of UAVs powered by batteries. Mathematical equations were developed to assess the UAV’s range and endurance, taking into consideration the discharge conditions of the battery. The study establishes relationships to estimate the range and endurance of battery-powered aircraft, considering battery discharge rate and voltage drop effects. The research demonstrates that the Peukert effect can enhance range and endurance, particularly when battery capacity significantly exceeds current demand. Conversely, when the current draw approaches the battery’s nominal capacity, effective capacity decreases. In situations with geometric constraints and a fixed battery weight as a fraction of the total aircraft weight, increasing battery capacity can lead to reduced performance due to higher power requirements and current draw.

One of the main challenges encountered by electric vehicles relying on battery power, including UAVs, is the limited autonomy they possess. Extensive efforts have been devoted to enhancing the performance of batteries in order to prolong operational duration and enable extended missions for electric vehicles. Despite the advancements made in battery technology, the specific energy of current batteries still poses limitations on the endurance and range of UAVs, which may not meet the requirements of numerous UAV applications. Additionally, improvements in energy density can have implications for the stability and safety levels

[16]. To tackle these limitations, various solutions have been proposed in the existing body of literature. Fuel cells have emerged as a promising alternative due to their higher specific energy. Furthermore, numerous existing UAVs employ a hybrid configuration in their power supply, utilizing multiple energy sources such as batteries, fuel cells, solar cells, and supercapacitors. In practice, hybrid configurations integrate various power sources, such as batteries, fuel cells, solar cells, or generators, to work in harmony. The energy management system (EMS) plays a crucial role in optimizing power distribution among these sources to achieve enhanced efficiency and endurance

[17].

The advantages of hybrid configurations over single-source systems are numerous. They offer improved endurance, as different sources can complement each other. For example, batteries can provide immediate power for take-off, while fuel cells or generators can sustain operations for longer durations. They enhance reliability by providing redundancy—if one source fails, others can take over. Additionally, hybrid systems can be more environmentally friendly, using cleaner energy sources in combination with traditional ones

[17][18].

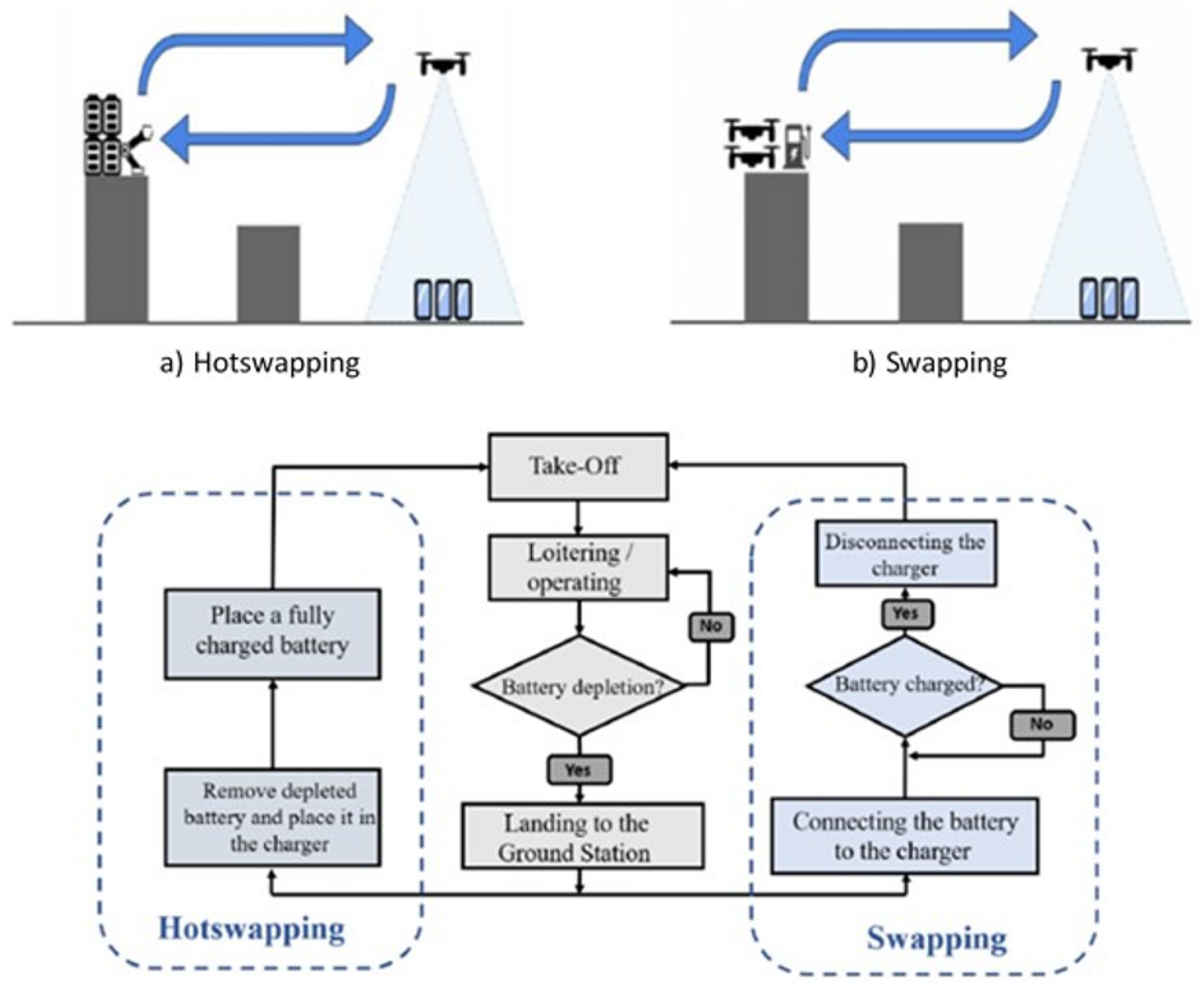

2.2. Swapping Method Algorithm

The technique known as swapping is employed to recharge the batteries of a UAV while it is in the midst of its mission. This process involves the exchange of depleted batteries with fully charged ones, which can be performed either autonomously or with human intervention. A specific type of swapping, called hot swapping, enables the immediate replacement of a depleted battery with a fully charged one, allowing the UAV to maintain power and continue its operation without interruption. Subsequently, the UAV can return to its assigned operational area and resume its tasks. By deploying multiple UAVs and coordinating their actions, a multi-agent system can ensure uninterrupted coverage of a specific area

[19]. To successfully carry out a swapping operation, three important conditions must be fulfilled: (1) the presence of a ground recharge station where UAVs can land for battery charging or replacement, (2) a group of UAVs capable of continuous operation, and (3) a management system that facilitates cooperation among the swarm of UAVs.

Figure 1 illustrates the techniques of swapping and hot swapping.

Figure 1. The swapping and hot swapping algorithms.

In the infrastructure network for UAVs, ground stations (GS), are strategically placed in various locations, such as cities or along connecting paths between cities. These GS can be installed on different structures like cell towers, streetlights, rooftops, power poles, or standalone pylons. As part of this infrastructure, battery swap stations are established, which consist of several components including ground electronics, an onboard circuit, a landing frame, and a contact mechanism. The batteries can be recharged through contact-based pathways or by utilizing inductive coupling. The docking platforms at the swap stations can be powered through a combination of power lines, large batteries, and solar cells, especially for stations located in remote areas.

There was also research that developed a multi-rotor aerial prototype specifically designed for long-duration missions using the swapping approach. The main goal of their study was to ensure the uninterrupted operation of the airborne platform by monitoring the battery’s state of charge (SOC). Their concept involved having three quadcopters in a rotating system, with one quadcopter always in a loiter position. When the SOC of a quadcopter drops below a predetermined threshold, it is replaced by another quadcopter, allowing the former to return to the ground station for battery charging. This cycle continues until all batteries are depleted or the mission is completed. The number of batteries required for sustainable operation depends on the discharge time and the duration needed for charging, rather than the number of UAVs. However, a larger number of batteries increases the system’s resilience and reliability

[19][20][21].

However, it is important to mention that the process of battery swapping and charging on the launch platform was not automated and still relied on human intervention. Additionally, the field test conducted in the study did not involve specific missions that required the use of sensors; instead, only static loitering was performed. In a separate study, researchers conducted an economic comparison of battery refilling and recharging platforms. They developed three stations based on axiomatic design principles, which allowed them to analyze and establish relationships between cost, complexity, and coverage levels

[22]. This analysis provided valuable insights into the various factors associated with the implementation of battery refilling and recharging platforms.

The comparison between refilling and exchange stations has indicated that refilling stations are suitable for low-coverage scenarios, while exchange stations are preferable when higher coverage levels are required. In

[23], research was conducted on a comparison of battery charging and replacement systems using a Petri net model. A Petri net model is a mathematical tool used to model and analyze systems with concurrent processes, making it relevant in designing efficient battery management systems. The authors also discussed in detail the design options for autonomous swapping stations, aiming to achieve precise UAV positioning for swapping regardless of landing errors. However, it is worth noting that the estimated swap time in their study was approximately one minute, which is relatively long compared to other studies researches. Moreover, the system was not fully operational, as certain modules were not prototyped or tested. In a separate study

[14], a ground recharge station was designed for battery-powered quadrotor helicopters, and an algorithm was implemented to reduce the battery recharge duration. It can significantly reduce downtime and enhance the efficiency of quadrotor helicopters in applications like search and rescue, surveillance, delivery services, agriculture, infrastructure inspection, environmental monitoring, film production, and security. The proposed autonomous charging process utilized safer electrical contacts and a balancer specifically designed for swarm applications. It is important to mention that similar to the majority of the conducted studies, no experiments or flight tests were performed, and the study did not consider battery lifetime as a factor.

An automated refueling station for small-scale UAVs was designed and implemented in a study

[24] to enable long-duration autonomous missions with multi-agent UAV systems. The study developed a planning and learning algorithm and tested it in a 3 h persistent flight involving 3 UAVs and over 100 battery swaps. The battery recharger mechanism used a linear sweeping motion, resulting in a simple and robust design. However, the cost of the system was not taken into account, and it should be noted that increasing the number of batteries and UAVs could potentially lead to a more expensive and complex system to manage. In a study

[25], a swapping system based on online algorithms for energy management, UAV health monitoring, and accurate landing was proposed. The system utilized a servo-based lift for battery swaps and placed the batteries onto a horizontally mounted hexagonal mat for charging. However, this swap mechanism introduced power losses in the UAVs. While individual tests were conducted for all the components, the entire system was not tested as a whole. In another study

[26], an autonomous docking platform was designed using active infrared imaging. The system operated during both day and night and incorporated a camera and an infrared filter to achieve high-precision landing.

In a study

[10], a hardware platform was introduced featuring a dual-drum structure for efficient hot swapping of batteries. The platform included a buffer of eight batteries, and experimental work provided insights into the average time required for battery swapping. A flight test was conducted, focusing on a search and track mission with communication constraints. However, the maximum operational time achieved for this mission using the developed station with three quadrotors was approximately 70 min. In a recent paper

[27], the focus was on cyclically repeated missions, such as aerial delivery services. They proposed the use of mobile battery swapping stations (MBS) that would move to designated swapping points according to a preset timetable. UAVs could then join the appropriate station for battery replacement and cargo loading/unloading. The study addressed the optimization of the number of UAVs and the distance traveled by proposing a declarative model for routing UAVs and MBS. However, it should be noted that this approach is applicable to only a limited range of missions, and the feasibility of mobile swapping stations may vary. The study primarily focused on the routing task, and no specific experiments related to swapping were conducted.

Table 1 provides a critical analysis of the various swapping approaches discussed in the literature.

Table 1. The critical evaluation of available swapping studies

[22][23][24][28].

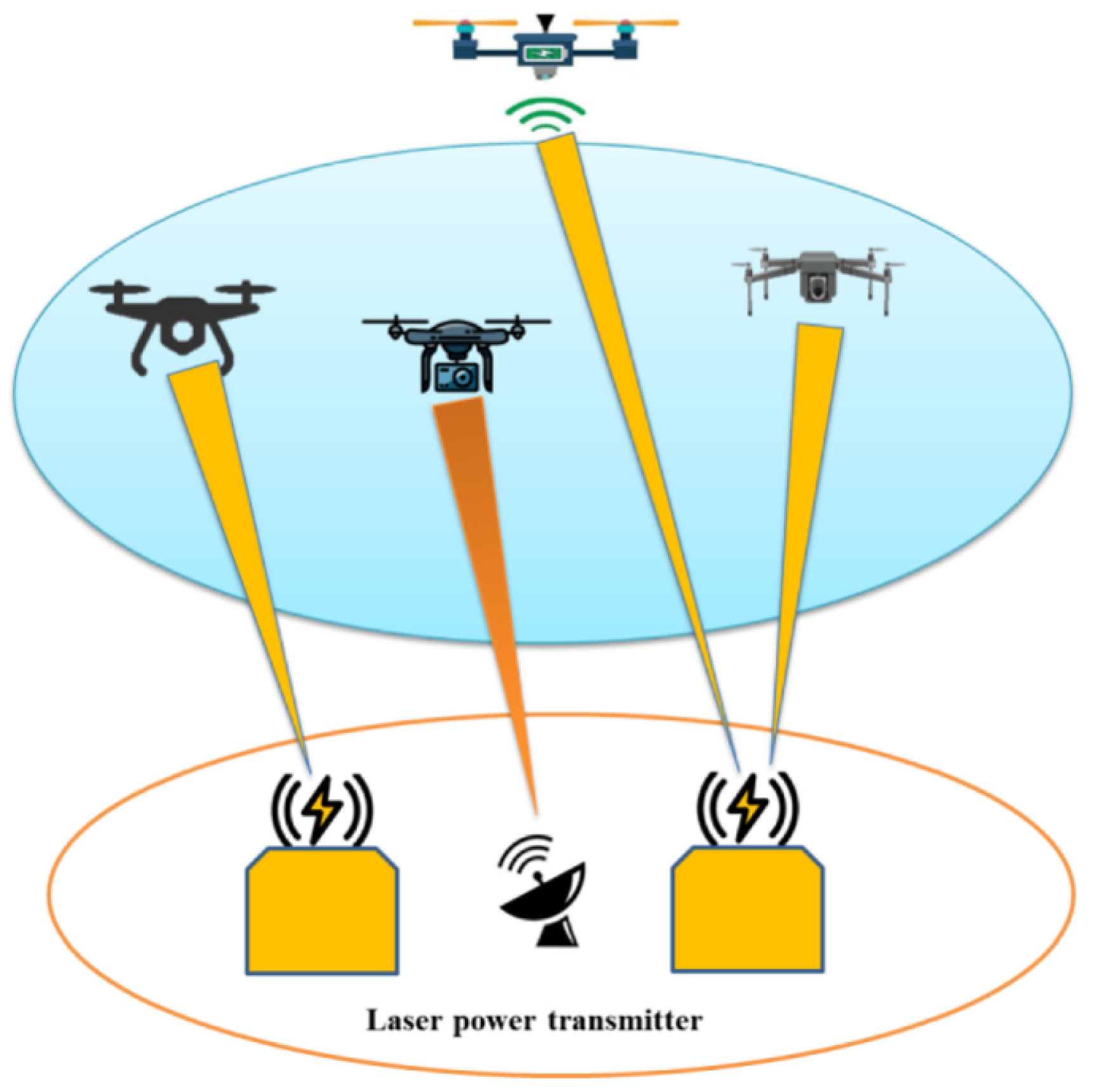

2.3. Laser Beam Inflight Recharging

The swapping approach has shown promise in extending the operational time of battery-powered UAVs by utilizing ground stations for battery replacement or recharging. However, an alternative approach that has been proposed is wireless recharging, as discussed in the previous literature

[29][30]. This method involves a ground station equipped with a primary power source, which generates a laser beam transmitted to the UAV while it is in flight. The UAV has an embedded optical receiver that converts the light into electricity, effectively powering the UAV. With wireless recharging, UAVs can remain airborne indefinitely without the need to land for battery recharging. When recharging is necessary, the UAV can access an aerial power link area to receive energy. This approach enhances safety by eliminating risks associated with take-off and landing. Laser transmitters can be strategically positioned on tall building rooftops to ensure an unobstructed laser beam path, or they can be installed on a mobile station, as depicted in

Figure 2. This establishes a radiative link between the UAV and the nearest energy source, enabling fast power transfer. Companies like LaserMotive (Washington, DC, USA) have developed working prototypes capable of transferring hundreds of watts of power

[31]. Furthermore, experiments described in

[32] have demonstrated the feasibility of this technique, achieving flight times of over 12 h for a quadcopter. Wireless recharging offers the potential for continuous operation and extended flight durations, addressing limitations associated with battery capacity and swapping cycles. However, further research and development efforts are necessary to optimize the technology and overcome challenges related to power efficiency, safety, and scalability.

Figure 2. A laser-powered UAV inflight charging system

[3][13][31].

While the laser beam inflight recharging approach offers potential benefits, it also introduces certain constraints and considerations that need to be taken into account. One such constraint is the need for UAVs to operate at reduced heights and within a limited area to maintain a reliable power transfer from the laser transmitter. This limitation is influenced by regulations, such as those imposed by the FAA, which set a maximum altitude of 400 feet for small UAVs weighing less than 26 kg. Compliance with these regulations is crucial for safe and legal operations. Another consideration is that each UAV utilizing laser beam inflight recharging requires its own dedicated laser transmitter. This can pose limitations on the number of UAVs that can be deployed in a given area, as multiple transmitters would be needed to support a larger fleet. Additionally, the individual transmitters can significantly increase the overall cost of implementing the laser beam inflight recharging system

[19]. Therefore, the scalability and economic feasibility of this approach should be carefully evaluated before widespread adoption. It is important to conduct a comprehensive assessment of the operational and regulatory aspects, as well as the economic implications, when considering the integration of laser beam inflight recharging for UAVs. This evaluation should involve a careful balance between the benefits of extended flight time and the potential limitations and costs associated with this technology. By addressing these considerations, researchers and industry professionals can make informed decisions regarding the practical implementation of laser beam inflight recharging in UAV operations.

2.4. Tethered UAVs

Tethered UAVs offer a unique solution for achieving unlimited autonomy by connecting to a power supply station through tethering lines. This eliminates the need for frequent recharging or battery replacement, enabling long-duration missions. Typically located on the ground, the power supply station continuously provides electricity to the UAV through the tethering lines, ensuring uninterrupted operation. Traditionally, copper wires have been used for the tethering lines of UAVs. However, there is a growing trend toward using fiber optic technology in this domain. Fiber optic cables allow for the transfer of kilowatts of power using high-intensity light, offering several advantages over copper wires. Optics-based power transfer reduces detectability by eliminating electrical signatures and significantly reduces both the payload weight of the UAV and the weight of the power lines compared to copper wires. In fact, fiber technology can reduce weight by up to eight times. Furthermore, power losses in fiber optic cables are minimal, making them more efficient for high-altitude operations.

Tethered UAVs have found applications in various fields. For instance, in maritime pollution monitoring, a tethered UAV can be deployed on a ship to detect oil spills in the sea, preventing contamination of the shoreline

[14]. In data-gathering applications, tethered UAVs equipped with sensors can be utilized to collect information in specific areas

[13]. However, one limitation of tethered UAVs is the restricted operating area imposed by the length of the connecting cable, which prevents the UAV from flying far from its ground station. To overcome this limitation, in some cases, a moving vehicle is used to carry the prime power source, allowing the UAV to cover a larger area. In missions requiring extremely long endurance, such as monitoring nuclear power plants, tethered UAVs can be deployed to provide continuous aerial surveillance for days or even months, as long as the tethered cable provides a continuous power supply

[33]. Prototypes of tethered UAVs have been designed and successfully demonstrated in outdoor environments, showcasing the feasibility and potential of this technology. The use of fiber optic cables in tethered UAV systems presents unique advantages in terms of weight reduction, power efficiency, and reduced detectability, making them an attractive option for extended-duration missions in various applications.

3. Fuel Cell Powered UAVs

Hydrogen-powered UAVs offer significant benefits compared to traditional battery-powered UAVs, particularly in terms of flight duration and refueling time

[34][35]. LiPo batteries, commonly used in UAVs, have a specific energy of up to 250 Wh/kg. In contrast, a fuel cell system with a compressed hydrogen tank can provide a specific energy of up to 1000 Wh/kg, allowing for much longer flight times

[11][36]. This substantial increase in specific energy enables hydrogen-powered UAVs to fly for hours instead of just a few minutes.

Furthermore, refueling hydrogen-powered UAVs is nearly instantaneous compared to the time-consuming recharging process required for batteries. While batteries need a significant amount of time to recharge and replenish their energy, refueling a hydrogen-powered UAV involves simply replacing the depleted hydrogen tank with a fully charged one. This enables quick turnaround times and continuous operation. These advantages make hydrogen-powered UAVs highly desirable for applications that require extended flight durations and rapid refueling, such as long-range surveillance, mapping, and monitoring missions. However, it is essential to consider the infrastructure needed for hydrogen storage, transportation, and refueling, as well as the safety considerations associated with handling hydrogen gas

[37]. Proper safety protocols and infrastructure development are necessary to ensure the efficient and secure use of hydrogen-powered UAVs.

In a study

[38], a comparison of various battery types (Li-ion, Ni-Cd, Ni-Mh) and fuel cells was conducted, considering criteria such as energy and power densities, discharging characteristics, temperature effects, efficiency, and endurance. However, it is important to note that flight tests were not conducted to evaluate the actual behavior, capabilities, and performance of these power sources in real flight conditions.

Figure 3 in the study presents a comparison of specific power versus specific energy for batteries, fuel cells, and supercapacitors. It indicates that fuel cells demonstrate higher specific energy compared to other power sources, which makes them a promising option for achieving extended endurance in UAVs while maintaining a given weight

[14]. Nevertheless, it should be acknowledged that fuel cells may have lower energy density compared to lithium batteries due to the additional volume required for hydrogen storage in the form of a tank.

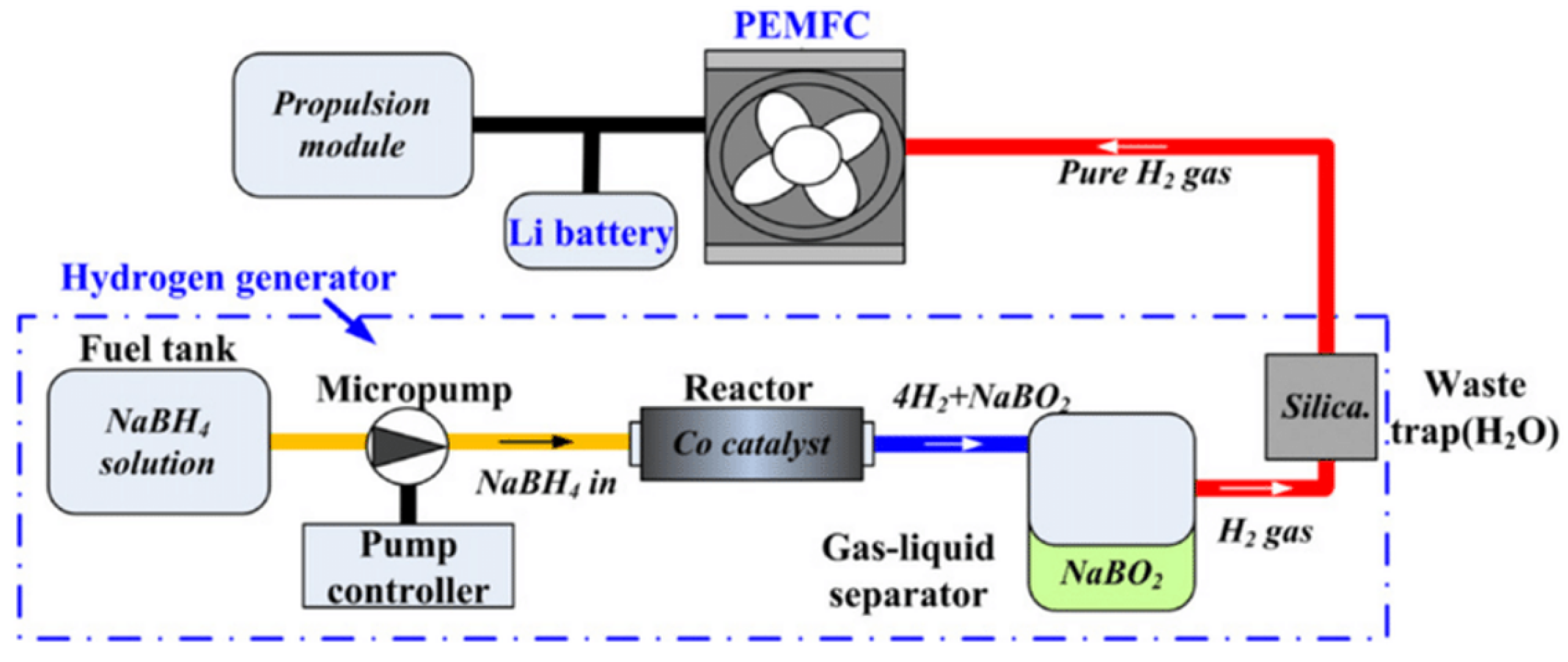

Figure 3. The fuel cell system auxiliaries.

In a separate study, the development of a UAV for mobile crane inspection was explored, with a focus on proton exchange membrane fuel cells

[39] and lithium-ion batteries

[40]. The research involved an economic analysis and a life cycle assessment to compare the two power sources. One of the main conclusions drawn from the study was that from a commercial standpoint, fuel cells, being a niche product, tend to be more expensive compared to lithium-ion batteries. This fact emphasizes the trade-offs between fuel cells and batteries in terms of specific energy, energy density, cost, and commercial viability. The selection of the appropriate power source for UAV applications relies on specific requirements, mission profiles, and considerations such as flight endurance, weight limitations, cost constraints, and the availability of infrastructure.

3.1. Fuel Cell Efficiency Issues

The process of electricity generation from fuel cells involves certain elements. Fuel cells can achieve an efficiency level of up to 60%

[38]. However, this efficiency is lower compared to lithium batteries, which can exceed 90%. One of the reasons for the lower efficiency of fuel cells is the presence of auxiliary equipment required for the operation of the fuel cell stack. These auxiliary components add complexity to the system and can contribute to energy losses, thus reducing overall efficiency

[24]. Additionally, the onboard hydrogen generation system, which is necessary for fuel cell operation, can also introduce complexity and potentially decrease efficiency. While fuel cells may have lower efficiency compared to lithium batteries, they offer advantages in terms of specific energy and longer operational duration. While proton exchange Membrane fuel cells (PEMFCs) hold promises for enhancing the endurance of drones and hydrogen–lithium composite energy storage systems prove adaptable to specialized working conditions, certain challenges must be addressed for their large-scale commercialization. Notably, PEMFCs require higher power and current densities to meet the demands of commercial applications. However, at elevated operating current densities, issues such as the accumulation of liquid water in the Gas Diffusion Layer (GDL) can lead to flooding and impede gas diffusion, resulting in a rapid degradation of cell performance

[41]. Consequently, the improvement of water management capabilities is imperative to unlock the full potential of PEMFCs and achieve better cell output performance. The choice between fuel cells and batteries depends on specific application requirements, taking into account factors such as flight endurance, weight limitations, cost considerations, and the availability of infrastructure. The cost of implementing fuel cells in drones varies based on factors such as fuel cell type, size, and specific application requirements. While fuel cells offer advantages in terms of extended endurance and reduced environmental impact, their cost is a significant consideration in the adoption of this technology. Cost reduction efforts, advancements in research and development, and economies of scale are expected to make fuel cells more cost-effective in the future. The decision to use fuel cells as the primary means of power generation and energy supply in drones will depend on the specific drone applications, regulatory support, competition with evolving battery technology, and a comprehensive evaluation of the total cost of ownership, taking into account initial purchase, maintenance, and operational costs.

3.2. Fuel Storage

Hydrogen has a low density at standard temperature and pressure, which poses a challenge for storing a sufficient amount of fuel for UAV missions. The low density means that hydrogen tanks need to be bulky to accommodate the required amount of fuel, which can impact the size and weight of the UAV. In addition to the size and weight considerations, safety is also a significant concern when it comes to storing hydrogen. Pure hydrogen cannot be stored under extremely high pressure and low temperatures due to safety reasons. Therefore, alternative techniques are employed for hydrogen storage in UAVs.

The three main techniques currently used for hydrogen storage in UAVs are as follows:

-

Compressed hydrogen gas: Hydrogen gas is stored in tanks under high pressure. This method allows for easier storage and refueling compared to other techniques. However, it requires high-pressure tanks, which can add weight and volume to the UAV.

-

Liquid hydrogen: Hydrogen is stored in a liquid state at very low temperatures. This method provides a higher energy density compared to compressed gas storage. However, it requires specialized cryogenic storage systems and insulation, which can add complexity and weight to the UAV.

-

Chemical hydrogen generation: Hydrogen is generated onboard the UAV through chemical reactions, such as the reaction between a metal hydride and water. This method offers the advantage of generating hydrogen as needed, eliminating the need for storing large quantities of hydrogen. However, it requires additional components and can have limitations in terms of hydrogen generation rate.

4. Hybrid Power Sources (Fuel Cell and Battery)

Fuel cells face limitations when used as the sole power source for UAVs. Their time constant is relatively long, typically in the range of seconds, due to the requirements of fuel and air supply facilitated by pumps, valves, and compressors. This sluggish response is primarily attributed to the mechanical characteristics of the pumps, flow delay, thermodynamic properties, and the effect of capacitance

[42]. Consequently, when there are significant fluctuations in current demand, there is a potential risk of fuel shortage, which can negatively impact the fuel cell system’s lifetime, reliability, and efficiency

[43]. To tackle these challenges, researchers have explored the integration of fuel cells with batteries to form hybrid power supply systems, which have emerged as a promising solution. By harnessing the strengths of both power sources and mitigating their weaknesses, hybrid systems can deliver enhanced performance and efficiency for UAV propulsion

[36][44][45]. The battery can swiftly provide power for sudden changes in demand, while the fuel cell can supply sustained power for extended durations. This approach enables superior power management, heightened system dependability, and overall improved UAV performance.

In a hybrid UAV propulsion system, the battery plays a crucial role in supplying power during high-demand maneuvers, like take-off and climbing. Its higher power density, quicker response time, and greater efficiency make it well-suited for such tasks compared to a fuel cell. On the other hand, the fuel cell takes over as the primary power source during cruise or descent phases, providing sustained power and also recharging the battery to maintain its state of charge (SOC) above a certain threshold. To evaluate the performance of hybrid UAV propulsion systems, researchers have employed hardware-in-the-loop (HIL) simulations. These simulations analyze the behavior of each power source in various test scenarios, considering factors such as endurance and hydrogen consumption.

The role of the battery in the hybrid system has been extensively considered in studies, such as

[46]. These experiments have specifically focused on analyzing the battery’s performance during different flight mission phases and under varying demands. Additionally, ref.

[16] provides a comprehensive characterization of the hybrid propulsion system using diverse mission profiles and speeds. However, it should be noted that these studies mainly concentrated on passive power-splitting methods and did not delve into the development of an active energy management strategy. The implementation of an energy management strategy is a crucial aspect of hybrid UAV propulsion systems. It involves actively regulating the power flow between the fuel cell and battery to optimize the overall performance, efficiency, and longevity of the system. This strategy determines the appropriate utilization of each power source based on the prevailing flight conditions, load requirements, and the battery’s state of charge. By employing intelligent power management algorithms, the hybrid system can achieve enhanced efficiency and prolong the UAV’s mission endurance.