Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Gordon McTaggart-Cowan | -- | 2588 | 2023-10-15 10:04:39 | | | |

| 2 | Camila Xu | Meta information modification | 2588 | 2023-10-16 03:49:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Balazadeh Meresht, N.; Moghadasi, S.; Munshi, S.; Shahbakhti, M.; Mctaggart-Cowan, G. Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles. Encyclopedia. Available online: https://encyclopedia.pub/entry/50313 (accessed on 07 February 2026).

Balazadeh Meresht N, Moghadasi S, Munshi S, Shahbakhti M, Mctaggart-Cowan G. Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles. Encyclopedia. Available at: https://encyclopedia.pub/entry/50313. Accessed February 07, 2026.

Balazadeh Meresht, Navid, Sina Moghadasi, Sandeep Munshi, Mahdi Shahbakhti, Gordon Mctaggart-Cowan. "Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles" Encyclopedia, https://encyclopedia.pub/entry/50313 (accessed February 07, 2026).

Balazadeh Meresht, N., Moghadasi, S., Munshi, S., Shahbakhti, M., & Mctaggart-Cowan, G. (2023, October 15). Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles. In Encyclopedia. https://encyclopedia.pub/entry/50313

Balazadeh Meresht, Navid, et al. "Vehicle and Powertrain Efficiency of Long-Haul Commercial Vehicles." Encyclopedia. Web. 15 October, 2023.

Copy Citation

On-road transportation of freight is central to modern economic activity. However, current on-road freight vehicles emit significant amounts of greenhouse gas emissions (GHGs), on the order of 7% of global anthropogenic emissions, along with significant amounts of local and regional air pollutants. Mitigating CO2 emissions from long-haul commercial trucking is a major challenge that must be addressed to achieve substantial reductions in greenhouse gas (GHG) emissions from the transportation sector. Extensive recent research and development programs have shown how significant near-term reductions in GHGs from commercial vehicles can be achieved by combining technological advances.

long-haul truck

tractor–trailer

fuel economy

GHG and emission regulations

1. Introduction

On-road transportation of freight is central to modern economic activity. However, current on-road freight vehicles emit significant amounts of greenhouse gas emissions (GHGs), on the order of 7% of global anthropogenic emissions [1], along with significant amounts of local and regional air pollutants. The GHG emissions from commercial trucking in developed economies have been increasing over the last decades due to an increasing road freight transport demand. In North America (NA), for example, GHG emissions from heavy-duty vehicles (HDVs) have doubled over the past 25 years despite significant improvements in fuel economy (FE) [2]. Eliminating these emissions is critical to meeting global commitments to net-zero GHG emissions but must be achieved without imposing unacceptable costs on the economic activity that freight transportation underpins.

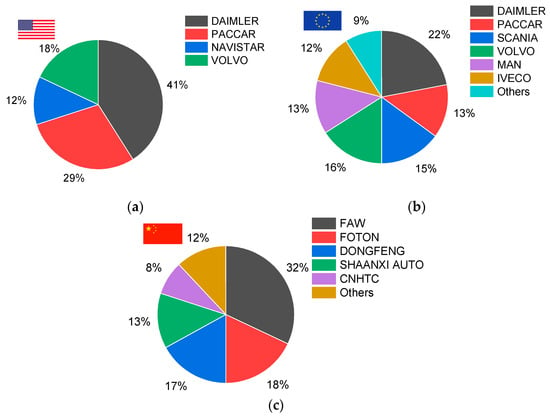

2. LHTs Make-Up and Market

Road freight transport is a critical part of economic activity worldwide. It generates a turnover of more than €334 billion in Europe and provides jobs for 3.2 million Europeans [3]. In North America, trucks are responsible for 66% of the trade between the U.S., Canada, and Mexico. All other modes, like air and rail, handle the remaining 34% of the freight [4][5]. To meet these demands, annual commercial vehicle production globally is on the order of 10 M units. Manufacturers are primarily based in China (42% of global truck and bus production from 2016 to 2022), 21% in Europe, and 13% in the U.S. [6]. There are relatively few OEMs for LHTs in all the main markets, as summarized in Figure 1 [6][7][8]. Some of the main OEMs are active in both Europe and North America, including PACCAR (DAF and Leyland in Europe; Peterbilt and Kenworth in NA); Daimler (Freightliner and Western Star in NA); and Volvo (Mack in NA).

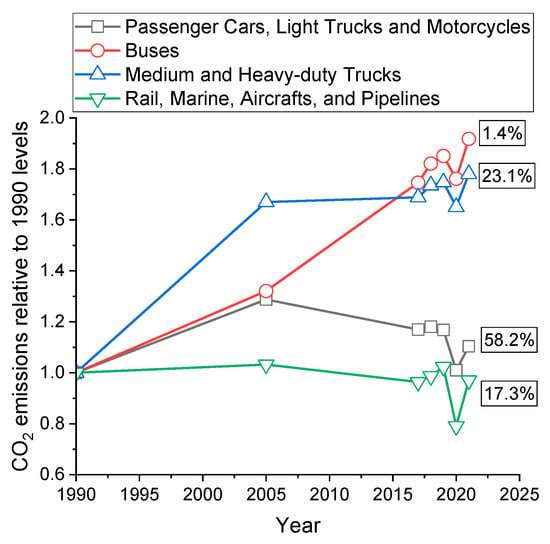

The carbon footprint of HDVs has increased considerably compared to other transportation sections. For example, in the U.S. (and similarly in Canada), as shown in Figure 2, the CO2 has almost doubled since 1990 for HDVs, showing that despite vehicle efficiency improvements, the total fuel consumption has risen due to an increasing road freight transport demand. Buses also showed a similar trend, although the GHG level of the light-duty sector has been almost stable since 1990. In Europe, CO2 emissions from HDVs increased by 25% between 1990 and 2016, stemming from growing road transport demand [9].

HDVs are categorized as light heavy-duty (GVWR of 8500 to 19,500 lbs), medium heavy-duty (GVWR of 19,501 to 33,000 lbs), and heavy heavy-duty (LHTs with GVWR exceeding 33,000 lbs). As seen in Table 1, HDVs form only 2% of vehicles on the road in Europe and are responsible for one-fourth of the road transport CO2 in the EU (and almost 6% of total EU GHG) and 31% of transport-related NOx emissions [9][12][13]. HDVs show a similar GHG share in the U.S. [14], and although they represent only 7.8% of the total road transport market, HDVs in China are responsible for 74% of transport NOx, 52.4% of road PM and 6.1% of all GHG emissions [15].

| Jurisdiction |  |

|

|

|---|---|---|---|

| HDV share in road transportation |  5% 5% |

2% 2% |

7.8% 7.8% |

| HDV GHG and emission share in road transportation |  23.1% of transport CO2 |

25% of transport CO2  6% of total GHG |

6.1% of total GHG  74% of transport NOx  52.4% of transport PM |

Although light commercial vehicles in HDVs account for the largest market share, tractor–trailers, or LHTs, emit a major part of GHG and NOx emissions. For example, LHTs form 9% of the HDV fleet in the U.S. but emit almost half of the NOx emissions and half of the GHGs. Similarly, RHTs make up 5% of the HDV fleet and are responsible for 12% and 13% of the GHGs and NOx emissions, respectively [17]. Moreover, in particular, LHTs emit 65% of the CO2 emissions within HDVs in Europe [16][18].

Moreover, LHTs are responsible for hauling almost 65% of goods (regarding the weight of the shipment) [19] in the U.S. while using 28 billion gallons of fuel per year (22% of total transportation energy usage). Also, HDVs’ GHG emissions in the U.S. are almost 430 MMT CO2 equivalent per year. Similarly, in Europe, these trucks account for almost two-thirds of road freight transport in vehicle kilometers [20]. As a result, there is a significant opportunity for technology improvement to reduce emissions and fuel costs in this key sector. One of the main driving factors for these engine, powertrain, and vehicle parts improvements is stringent emission regulations, which will be discussed in the next section.

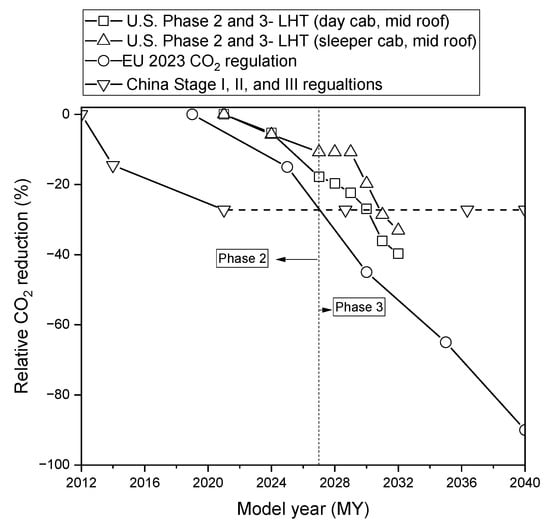

3. Drivers of LHT Fuel Consumption Reduction

Regulatory push and cost savings from fuel consumption reduction are the main drivers for the technology upgrades in commercial vehicles. The emission regulations for LHTs are categorized as GHG and meet the criteria for pollutant emissions. Regulatory limits aiming to reduce GHG emissions in LHTs vary between jurisdictions. Requirements for the U.S., EU, and China are summarized in Figure 3. The U.S. Phase 2 and 3 regulations, when combined, require an almost 40% CO2 reduction in LHTs in 2032 compared to 2021 levels [21]. In February 2023, the European Union announced more ambitious fleet average targets for CO2 reduction in HDVs, with 45% in 2030, 65% in 2035, and 90% in 2040 compared to 2019 levels [12][22]. Finally, China is in phase 3 of the fuel consumption standard, which applies to all new 2021 heavy commercial vehicles with a 15% lower fuel consumption limit than the previous phase.

In all cases, the regulations target vehicle tailpipe (not fuel-cycle) emissions reductions and are based on manufacturer sales-weighted annual new vehicle averages. The wide variety of HDVs means that type approval for individual vehicles, common in LDVs, would be prohibitively expensive. Instead, regulations combine ICE emissions and performance test results with vehicle simulations to provide consistent assessments across HDV platforms. European regulation uses a modeling tool called the Vehicle Energy Consumption Calculation Tool (VECTO), while in the U.S., the EPA uses the Greenhouse Gas Emissions Model (GEM). Although details differ, both tools combine ICE performance and emissions maps with powertrain (transmission, etc.) and vehicle configuration (load/weight, rolling resistance, drag) data over a series of defined drive cycles. GHG restrictions can be based on vehicle configuration: VECTO includes over 15 different classes of LHTs, while the EPA regulates different standards based on weight and vehicle configuration (e.g., day cab vs. sleeper cab). In the U.S., GHG emissions include tailpipe CO2 as well as other GHGs (including CH4 and N2O). In the EU, the regulations are for tailpipe CO2 only; emissions of other GHGs are captured under air pollutant emissions limits.

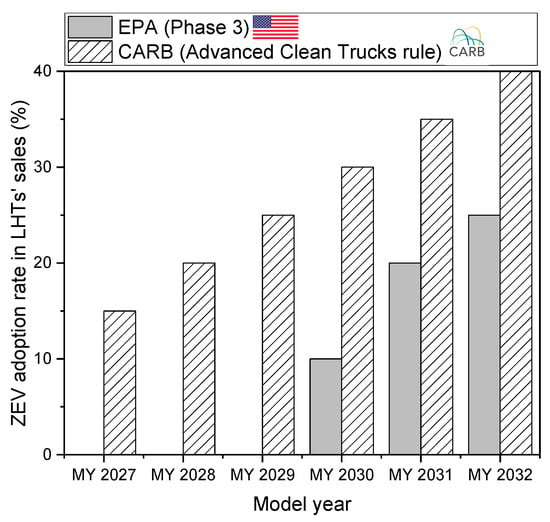

Along with fleet average GHG/CO2 reductions, regulators are also implementing requirements for a fraction of new HDV sales of zero-emission vehicles (ZEVs). In NA, CARB is implementing ZEV requirements, as shown in Figure 4, and the EPA estimated ZEV adoption rates as one potential technology pathway to meet the CO2 standards [24][25]. Similarly, in the European context, there is flexibility to comply with the CO2 regulations determined by the zero- and low-emission vehicle (ZLEV) factor to reduce the manufacturer’s target by 3% depending on the number of produced ZLEVs [26]. Moreover, the International Energy Agency (IEA) has projected that the share of battery electric trucks needs to be 25% by 2030 to comply with the Net Zero Emissions by 2050 Scenario (NZE) [27]. Similarly, the share of battery electric vehicles in the medium and HD sectors is envisioned to reach 40% by 2040, based on the BloombergNEF report [28]. It is significant to consider the required infrastructure and life-cycle implications of full powertrain electrification. Moreover, different factors, such as battery weight/size and their impact on cargo capacity and charging time, need to be better evaluated in ZEVs regarding long-haul trucking applications. According to the abovementioned optimistic ZEV adoption rates, the majority of new HDVs will still include an internal combustion engine as a key part of the propulsion system. Therefore, continuous work to improve efficiency and reduce GHG emissions from these vehicles is imperative in addressing climate change in the near term.

4. Technology Systems for Efficiency Improvement in LHTs

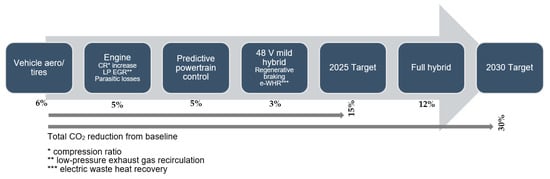

Commercial vehicles must meet stringent emission and CO2 regulations alongside FE improvements to lower operational costs. Fuel-saving technologies for HDVs can be generally classified as engine, powertrain, or vehicle efficiency improvements. There are significant interactions: downspeeding, for example, leads to lower friction losses and hence higher engine efficiency but is only achievable through a combination of engine design to improve torque at low rotational speeds, combined with advanced transmissions incorporating more reactive shift strategies and a reoptimized final-drive ratio. To meet emissions targets, incremental technology improvements across all aspects of the LHT will be required. A good example of combining different technology pathways is a study by Pischinger et al. [31] to reach the European 2030 CO2 target defined in 2019 (note that this does not address the current, more aggressive restrictions from 2023). Different engine, driveline, and vehicle technologies are incorporated in the analysis as shown in Figure 5; hybridization is recognized as a potential contributor, along with vehicle, engine, and powertrain control improvements.

Figure 5. Technology pathways to meet European 2025 and 2030 CO2 regulations on LHTs [31][32], adapted from Pischinger et al. [31] and Joshi [24]. CO2 reductions are relative to a 2019 baseline. Studies were conducted prior to 2023 EU standards, so they do not incorporate the most aggressive CO2 reductions.

Combining engine, driveline, and vehicle technologies is the key consideration in fuel economy improvement, as different papers showed a 20% to 40% FC reduction by combining these technologies. The long-term role of ICE and its centric role in hybrid systems are also highlighted in different studies due to progressive efficiency improvements [33][34]. Buysse et al. [33] underscored HD diesel engines’ crucial role in U.S. long-haul trucking using efficient technology systems. Their analysis showed a 24% CO2 emissions reduction beyond the 2027 standard using a 55% brake thermal efficiency (BTE) engine, advanced predictive cruise control, and low-rolling resistance (LRR) tires. Also, further utilizing engine downspeeding, downsizing, and mild hybrids can reduce CO2 emissions to 34% lower than the Phase II standard. Delgado and Lutsey [35], simulating an LHT, showed that FE could be doubled by utilizing aerodynamic improvement, higher tire efficiency, downspeeding, downsizing, WHR, and hybridization. In a similar study, Delgado et al. [36] evaluated the FE benefits of different technology packages in the 2020–2030 time frame by modeling an LHT. The results showed a potential 27% reduction in fuel consumption using commercialized technologies, such as low-rolling-resistance tires, aerodynamics, engine friction improvement, turbocompounding, and downspeeding. Also, implementing a 55% BTE engine model equipped with WHR and hybridization showed a further reduction in fuel consumption, i.e., 43% from the baseline.

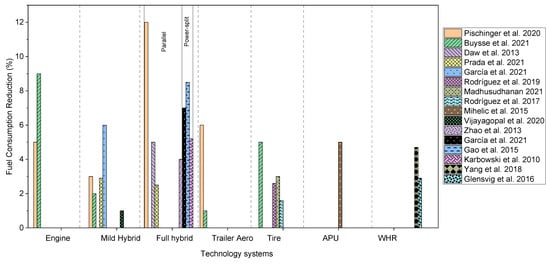

By reviewing the literature on LHTs, the general contribution of engine, powertrain, and vehicle technologies to FE improvement is comparable with the results of Pischinger et al. This alignment is shown in Figure 6, which illustrates an overview of the current FE improvements in LHTs. Figure 6 results are from research papers evaluating different technology features in LHTs in the U.S. and Europe; the papers relied on simulation to assess FE benefits and selected different baseline LHTs. The details of engine, vehicle, and powertrain technologies will be discussed in the next sections.

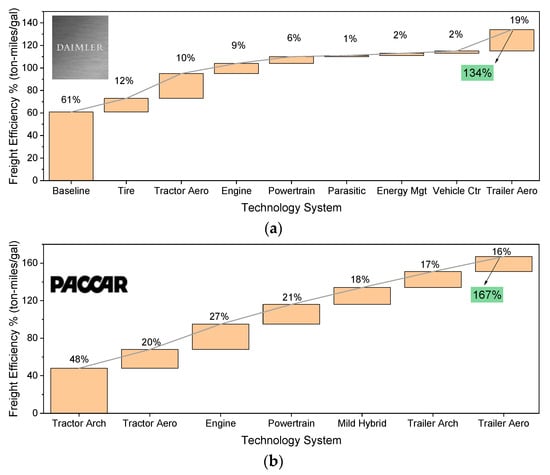

Similarly, in the SuperTruck II program, the participating OEMs have claimed freight efficiency (payload carried multiplied by distance covered divided by fuel consumed, i.e., ton-mil/gallon) improvements of more than 100%. These have been achieved by combining incremental improvements to multiple technology elements relating to the engine, powertrain, and vehicle, as shown in Figure 7.

The overview of the technological features of all the involved OEMs is summarized in Table 2 [53]. The developed technologies range from improved engine efficiency to reduced weight and drag, along with enhancing powertrain efficiency by recuperating dissipated heat via a WHR system and converting that to electricity to be stored in the battery pack. As shown in Figure 7, there is no single technology element that predominates the reported improvements in freight efficiency. Rather, incremental improvements are achieved across a wide range of system components. The details of the selected technologies vary between OEMs, but engine efficiency, powertrain optimization, and vehicle resistance reductions all make important contributions for all the project teams. The primary benefit is to reduce vehicle resistance and fuel consumption through efficiency improvements and system optimization. Weight reduction to increase payload within permitted gross vehicle weights has a secondary effect on the overall freight efficiency improvements. The details of the engine, powertrain, and vehicle side improvements will be discussed in the next sections.

| OEMs | Daimler | Volvo | Cummins/Peterbilt | PACCAR | Navistar |

|---|---|---|---|---|---|

| Engine, Combustion, and Air Management |

|

|

|

|

|

| Hybrid Architecture | 48 V mild hybrid- P2; better than belt starter generator (BSG) | Integrated starter/generator (ISG) mounted on the rear power take-off (PTO) connected via a two-speed gearbox |

|

|

|

| Battery | 7 kWh Li-ion | 14 kWh Li-ion | 10 kWh Li-ion | ||

| After-treatment |

|

|

|

|

|

| Waste Heat Recovery |

|

|

|

|

|

References

- Crippa, M.; Guizzardi, D.; Banja, M.; Solazzo, E.; Muntean, M.; Schaaf, E.; Pagani, F.; Monforti-Ferrario, F.; Olivier, J.; Quadrelli, R.; et al. CO2 Emissions of All World Countries. Available online: https://publications.jrc.ec.europa.eu/repository/handle/JRC130363 (accessed on 27 July 2023).

- Environment and Climate Change Canada. Greenhouse Gas Sources and Sinks in Canada: Executive Summary. 2022. Available online: https://www.canada.ca/en/environment-climate-change/services/climate-change/greenhouse-gas-emissions/sources-sinks-executive-summary-2022.html (accessed on 15 January 2023).

- ACEA. Fact Sheet: Trucks. Available online: https://www.acea.auto/fact/fact-sheet-trucks/ (accessed on 25 June 2023).

- Commercial Vehicle Market Size, Share|Global Report. 2022. Available online: https://www.fortunebusinessinsights.com/commercial-vehicle-market-104284 (accessed on 7 August 2023).

- Class 8 Truck Market in North America 2022–2027|July 2022 Updated. Available online: https://mobilityforesights.com/product/class-8-truck-market-in-north-america-2017-2022/ (accessed on 7 July 2023).

- Global Consulting. Available online: https://www.rolandberger.com/en/ (accessed on 7 June 2023).

- Statista—The Statistics Portal. Available online: https://www.statista.com/ (accessed on 8 July 2023).

- China Green Freight Assessment; China Automotive Technology and Research Center. 2018. Available online: https://theicct.org/publication/china-green-freight-assessment-enabling-a-cleaner-and-more-efficient-freight-system-in-china/ (accessed on 25 June 2023).

- Carbon Dioxide Emissions from Europe’s Heavy-Duty Vehicles—European Environment Agency. Available online: https://www.eea.europa.eu/themes/transport/heavy-duty-vehicles/carbon-dioxide-emissions-europe (accessed on 28 June 2023).

- US EPA. Fast Facts on Transportation Greenhouse Gas Emissions. Available online: https://www.epa.gov/greenvehicles/fast-facts-transportation-greenhouse-gas-emissions (accessed on 27 June 2023).

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2021; U.S. Environmental Protection Agency: Washington, DC, USA, 2023.

- CO2 Emission Standards for Heavy-Duty Vehicles. Available online: https://ec.europa.eu/commission/presscorner/detail/en/qanda_23_763 (accessed on 20 February 2023).

- Ragon, P.-L. Felipe Road Freight Decarbonization in Europe Readiness of The European Fleets for Zero-Emission Trucking; ICCT: Washington, DC, USA, 2022.

- Ragon, P.-L.; Buysse, C.; Sen, A.; Meyer, M.; Benoit, J.; Miller, J.; Rodríguez, F. Potential Benefits of the U.S. Phase 3 Greenhouse Gas Emissions Regulation for Heavy-Duty Vehicles; ICCT: Washington, DC, USA, 2023.

- Mao, S.; Basma, H.; Ragon, P.-L.; Zhou, Y.; Rodriguez, J.F. Total Cost of Ownership for Heavy Trucks in China: Battery-Electric, Fuel Cell Electric, and Diesel Trucks; International Council on Clean Transportation: Washington, DC, USA, 2021.

- Sharpe, B.; Rodríguez, F. Market Analysis of Heavy-Duty Commercial Trailers in Europe; International Council on Clean Transportation: Washington, DC, USA, 2018.

- Joshi, A. Characterizing the In-Use Heavy-Duty Vehicle Fleet; Mobility Notes: USA. 2022. Available online: https://mobilitynotes.com/characterizing-the-in-use-heavy-duty-vehicle-fleet/ (accessed on 25 June 2023).

- Truck CO2: Europe’s Chance to Lead. Available online: https://www.transportenvironment.org/discover/truck-co2-europes-chance-to-lead/ (accessed on 28 June 2023).

- Moving Goods in the United States. Available online: https://data.bts.gov/stories/s/Moving-Goods-in-the-United-States/bcyt-rqmu/ (accessed on 27 June 2023).

- Road Freight Transport by Vehicle Characteristics. Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Road_freight_transport_by_vehicle_characteristics (accessed on 28 June 2023).

- US EPA. Proposed Rule: Greenhouse Gas Emissions Standards for Heavy-Duty Vehicles—Phase 3. Available online: https://www.epa.gov/regulations-emissions-vehicles-and-engines/proposed-rule-greenhouse-gas-emissions-standards-heavy (accessed on 14 June 2023).

- Irles, S. Europe Proposes World-Leading Decarbonization Targets for Trucks and Buses; International Council on Clean Transportation: Washington, DC, USA, 2023.

- China: Heavy-Duty: Fuel Consumption|Transport Policy. Available online: https://www.transportpolicy.net/standard/china-heavy-duty-fuel-consumption/ (accessed on 14 June 2023).

- Joshi, A. Review of Vehicle Engine Efficiency and Emissions; SAE International: Warrendale, PA, USA, 2021; p. 2021-01-0575.

- Emission Standards. USA: California: Heavy-Duty ZEV Program. Available online: https://dieselnet.com/standards/us/ca_zev_hd.php (accessed on 9 May 2022).

- Irles, S. Europe’s New Heavy-Duty CO2 Standards, Explained; International Council on Clean Transportation: Washington, DC, USA, 2023.

- Global EV Outlook 2022—Analysis. Available online: https://www.iea.org/reports/global-ev-outlook-2022 (accessed on 1 August 2022).

- EVO Report 2022|BloombergNEF|Bloomberg Finance LP; BloombergNEF: London, UK, 2022; Available online: https://about.bnef.com/electric-vehicle-outlook/ (accessed on 28 June 2023).

- Zero-Emission On-Road Medium-and Heavy-Duty Strategies|California Air Resources Board. Available online: https://ww2.arb.ca.gov/resources/documents/zero-emission-road-medium-and-heavy-duty-strategies (accessed on 14 June 2023).

- US EPA. Final Rule and Related Materials for Control of Air Pollution from New Motor Vehicles: Heavy-Duty Engine and Vehicle Standards. Available online: https://www.epa.gov/regulations-emissions-vehicles-and-engines/final-rule-and-related-materials-control-air-pollution (accessed on 14 June 2023).

- Pischinger, S.; Aubeck, F.; Heuser, P.; van der Put, D.; Lindemann, B.; Müther, M.; Schönen, M.; Ehrly, M.; Schaub, J.; Walters, M.; et al. Efficient Commercial Powertrains—How to Achieve a 30% GHG Reduction in 2030; Geringer, B., Lenz, H.-P., Eds.; VDI Verlag: Düsseldorf, Germany, 2020; p. II-291.

- Concawe. Low Carbon Pathways Until 2050—Deep Dive on Heavy Duty Transportation (FEV Report); Concawe: Brussels, Belgium, 2022.

- Buysse, C.; Sharpe, B.; Delgado, O. Efficiency Technology Potential for Heavy-Duty Diesel Vehicles in the United States through 2035; International Council on Clean Transportation: Washington, DC, USA, 2021.

- Liang, X.; Wang, Y.; Chen, Y.; Deng, S. Advances in Emission Regulations and Emission Control Technologies for Internal Combustion Engines. SAE J. STEEP 2021, 2, 101–119.

- Delgado, O.; Lutsey, N. Advanced Tractor-Trailer Efficiency Technology Potential in the 2020–2030 Timeframe; International Council on Clean Transportation: Washington, DC, USA, 2015.

- Delgado, O.; Rodríguez, F.; Muncrief, R. Fuel Efficiency Technology in European Heavy-Duty Vehicles: Baseline and Potential for the 2020–2030 Time Frame; International Council on Clean Transportation: Washington, DC, USA, 2017.

- Daw, C.S.; Gao, Z.; Smith, D.E.; Laclair, T.J.; Pihl, J.A.; Edwards, K.D. Simulated Fuel Economy and Emissions Performance during City and Interstate Driving for a Heavy-Duty Hybrid Truck. SAE Int. J. Commer. Veh. 2013, 6, 161–182.

- Nieto Prada, D.; Vijayagopal, R.; Costanzo, V. Opportunities for Medium and Heavy Duty Vehicle Fuel Economy Improvements through Hybridization; SAE International: Warrendale, PA, USA, 2021; p. 2021-01-0717.

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Gaillard, P. Emissions Reduction by Using E-Components in 48 V Mild Hybrid Trucks under Dual-Mode Dual-Fuel Combustion. Appl. Energy 2021, 299, 117305.

- Rodríguez, F.; Delgado, O. The Future of VECTO: CO2 Certification of Advanced Heavy-Duty Vehicles in the European Union; International Council on Clean Transportation: Washington, DC, USA, 2019.

- Madhusudhanan, A.K.; Ainalis, D.; Na, X.; Garcia, I.V.; Sutcliffe, M.; Cebon, D. Effects of Semi-Trailer Modifications on HGV Fuel Consumption. Transp. Res. Part Transp. Environ. 2021, 92, 102717.

- Rodríguez, F.; Muncrief, R.; Delgado, O.; Baldino, C. Market Penetration of Fuel Efficiency Technologies for Heavy-Duty Vehicles in the European Union, the United States, and China; International Council on Clean Transportation: Washington, DC, USA, 2017.

- Mihelic, R.; Smith, J.; Ellis, M. Aerodynamic Comparison of Tractor-Trailer Platooning and a-Train Configuration. SAE Int. J. Commer. Veh. 2015, 8, 740–746.

- Vijayagopal, R.; Rousseau, A. Benefits of Electrified Powertrains in Medium-and Heavy-Duty Vehicles. World Electr. Veh. J. 2020, 11, 12.

- Zhao, H.; Burke, A.; Zhu, L. Analysis of Class 8 Hybrid-Electric Truck Technologies Using Diesel, LNG, Electricity, and Hydrogen, as the Fuel for Various Applications. In Proceedings of the 2013 World Electric Vehicle Symposium and Exhibition (EVS27), Barcelona, Spain, 17–20 November 2013; pp. 1–16.

- García, A.; Monsalve-Serrano, J.; Martinez-Boggio, S.; Gaillard, P. Impact of the Hybrid Electric Architecture on the Performance and Emissions of a Delivery Truck with a Dual-Fuel RCCI Engine. Appl. Energy 2021, 301, 117494.

- Gao, Z.; LaClair, T.J.; Smith, D.E.; Daw, C.S. Exploring Fuel-Saving Potential of Long-Haul Truck Hybridization. Transp. Res. Rec. 2015, 2502, 99–107.

- Karbowski, D.; Delorme, A.; Rousseau, A. Modeling the Hybridization of a Class 8 Line-Haul Truck; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2010; p. 2010-01-1931.

- Yang, K.; Bargende, M.; Grill, M. Evaluation of Engine-Related Restrictions for the Global Efficiency by Using a Rankine Cycle-Based Waste Heat Recovery System on Heavy Duty Truck by Means of 1D-Simulation; SAE International: Warrendale, PA, USA, 2018; p. 2018-01-1451.

- Glensvig, M.; Schreier, H.; Tizianel, M.; Theissl, H.; Krähenbühl, P.; Cococcetta, F.; Calaon, I. Testing of a Long Haul Demonstrator Vehicle with a Waste Heat Recovery System on Public Road; SAE International: Warrendale, PA, USA, 2016; p. 2016-01-8057.

- Villeneuve, D.; Girbach, J.; Musselman, S. Improving Transportation Efficiency Through Integrated Vehicle, Engine, and Powertrain Research—SuperTruck 2. Presented at the 2021 DOE Vehicle Technology Office Annual Merit Review. 2021. Available online: https://www.energy.gov/eere/vehicles/articles/2021-annual-merit-review-report#:~:text=The%202021%20U.S.%20Department%20of,(COVID%2D19)%20pandemic (accessed on 2 August 2023).

- Meijer, M. Development and Demonstration of Advanced Engine and Vehicle Technologies for Class 8 Heavy-Duty Vehicle (SuperTruck II). Presented at the 2022 DOE Vehicle Technology Office Annual Merit Review. 2022. Available online: https://www.energy.gov/eere/vehicles/articles/2022-annual-merit-review-report (accessed on 2 August 2023).

- DOE. Progress on Fuel Efficiency and Market Adoption; Department of Energy (DOE): Washington, DC, USA, 2016.

- Delgado, O.; Lutsey, N. The U.S. SuperTruck Program Expediting the Development of Advanced Heavy-Duty Vehicle Efficiency Technologies; International Council on Clean Transportation: Washington, DC, USA, 2014.

- McLaughlin, S.; Bond, E.; Li, J. Pathway to Cost-Effective Commercialized Freight Efficiency. Presented at the 2021 DOE Vehicle Technology Office Annual Merit Review. 2021. Available online: https://www.energy.gov/eere/vehicles/articles/2021-annual-merit-review-report#:~:text=The%202021%20U.S.%20Department%20of,(COVID%2D19)%20pandemic (accessed on 2 August 2023).

- Dickson, J.; Damon, K. Cummins/Peterbilt SuperTruck II. Presented at the 2021 DOE Vehicle Technology Office Annual Merit Review. 2021. Available online: https://www.energy.gov/eere/vehicles/articles/2021-annual-merit-review-report#:~:text=The%202021%20U.S.%20Department%20of,(COVID%2D19)%20pandemic (accessed on 2 August 2023).

- Girbach, J.; Bashir, M. Daimler, Improving Transportation Efficiency through Integrated Vehicle, Engine, and Powertrain Research—SuperTruck 2. Presented at the 2022 DOE Vehicle Technology Office Annual Merit Review. 2022. Available online: https://www.energy.gov/eere/vehicles/articles/2022-annual-merit-review-report (accessed on 2 August 2023).

- Bond, E.; Li, J. Volvo SuperTruck 2 Pathway to Cost-Effective Commercialized Freight Efficiency. Presented at the 2022 DOE Vehicle Technology Office Annual Merit Review. 2022. Available online: https://www.energy.gov/eere/vehicles/articles/2022-annual-merit-review-report (accessed on 2 August 2023).

- Zukouski, R.; Cigler, J.; Oppermann, D. Navistar SuperTruck II Development and Demonstration of a Fuel-Efficient Class 8 Tractor & Trailer. Presented at the 2022 DOE Vehicle Technology Office Annual Merit Review. 2022. Available online: https://www.energy.gov/eere/vehicles/articles/2022-annual-merit-review-report (accessed on 2 August 2023).

More

Information

Subjects:

Transportation Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

589

Revisions:

2 times

(View History)

Update Date:

16 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No