You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Giulio Mangherini | -- | 3594 | 2023-10-09 09:51:13 | | | |

| 2 | Jason Zhu | -13 word(s) | 3581 | 2023-10-10 04:01:36 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Mangherini, G.; Diolaiti, V.; Bernardoni, P.; Andreoli, A.; Vincenzi, D. Different Building-Integrated Photovoltaic Typologies. Encyclopedia. Available online: https://encyclopedia.pub/entry/49954 (accessed on 15 December 2025).

Mangherini G, Diolaiti V, Bernardoni P, Andreoli A, Vincenzi D. Different Building-Integrated Photovoltaic Typologies. Encyclopedia. Available at: https://encyclopedia.pub/entry/49954. Accessed December 15, 2025.

Mangherini, Giulio, Valentina Diolaiti, Paolo Bernardoni, Alfredo Andreoli, Donato Vincenzi. "Different Building-Integrated Photovoltaic Typologies" Encyclopedia, https://encyclopedia.pub/entry/49954 (accessed December 15, 2025).

Mangherini, G., Diolaiti, V., Bernardoni, P., Andreoli, A., & Vincenzi, D. (2023, October 09). Different Building-Integrated Photovoltaic Typologies. In Encyclopedia. https://encyclopedia.pub/entry/49954

Mangherini, Giulio, et al. "Different Building-Integrated Photovoltaic Typologies." Encyclopedia. Web. 09 October, 2023.

Copy Citation

Building-integrated photovoltaic technologies have considerable potential for the generation of on-site renewable energy. Despite this, their market penetration is in a relatively embryonic phase with respect to grounded or building-attached solutions, and they have limited commercial application. Their integration into building façades may represent a key asset in meeting the net-zero emissions by 2050 scenario, in particular for high-rise buildings in which the roof-to-façade ratio is unfavorable for the fulfillment of the energy load using only roof photovoltaic technology.

BIPV

solar façades

semi-transparent photovoltaics

energy efficiency

zero-energy buildings

1. Introduction

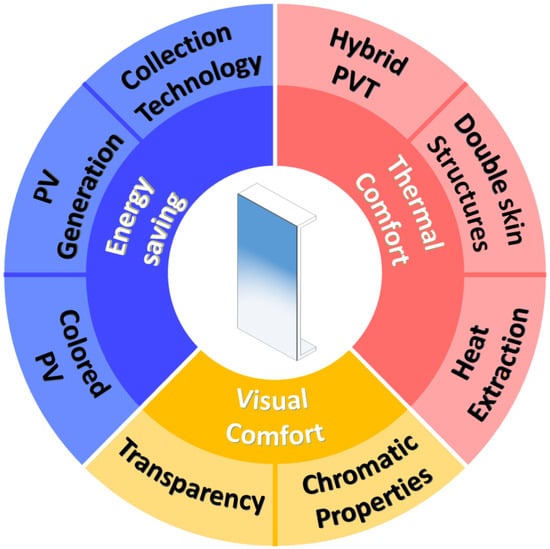

The need to tackle climate change is leading to an intensified global interest in energy generation based on renewable sources. Compared to other renewable resources, the harvesting of solar irradiance is one of the most widespread, practical, and economical ways to generate energy [1]. Because of the absence of mechanical motion components, the low maintenance costs, and the abundance of solar energy that reaches the Earth’s surface every year (1.8 × 1011 MW) [2], photovoltaics (PVs) represent one of the most promising solutions to fulfill the increasing world power consumption. In fact, the improvement in the cell conversion efficiency coupled with the decrease in manufacturing costs allowed for the installation of 1185 GW by the end of 2022 [3]. According to the International Energy Agency’s (IEA) “Renewable Energy Market Update” [4], the global solar PV capacity is envisioned to be able to produce almost 1 TW in 2024, which is sufficient to meet the yearly demand of 650 GW by 2030 and the net-zero emissions by 2050 scenario. The commitment to decreasing greenhouse gas (GHG) emissions related to building energy demands, which accounts for 40% of the global energy supply, is leading to the powering of several operations that extend beyond mere electricity production with solar energy, such as ventilation, air conditioning and refrigeration, water desalination, decontamination, and heating [5][6]. Figure 1 summarizes the possible applications for which a PV façade can be designed.

Figure 1. Possible applications and design concepts of PV technologies integrated into building façades.

In particular, buildings’ air conditioning and electricity needs consume more than 55% of the global electricity supply, with an estimated annual growth rate of 2.5% [7]. This, coupled with land acquisition constraints and the vast impact that PV plants have on biodiversity and the natural environment, has limited the growth of such plants in favor of smaller-scale distributed installations, especially in urban environments [8][9]. Article 2 of the amended Energy Performance of Buildings Directive (EPBD) (2018/844/EU) [10] aims to support the renovation of the national stock of buildings, residential and non-residential, into highly energy-efficient and decarbonized buildings by 2050, facilitating their transformation towards net-zero energy buildings (NZEBs). Building-integrated photovoltaic (BIPV) technologies constitute interesting and alternative solutions to the production of electricity, eliminating the necessity of areas exclusively dedicated to PV plants [11]. Since BIPV devices directly replace building elements, the surface area for PV installations is provided by the building envelope, and the building’s electrical system acts as an interface between the PV panels and the public utility grid [12][13][14]. Happle et al. [15] established that, if properly installed, BIPVs can limit GHG emissions by up to 50%. This represents a cost-effective method to considerably reduce the environmental impact of a sector that accounts for 39% of total GHG emissions [16].

In this regard, De Boeck et al. [17] identified the increase in a building envelope’s insulation efficiency as a key parameter for increasing its energy performance. Furthermore, BIPV technologies are designed to combine power production and insulation efficiency, improving a building’s architectural expression [18]. Indeed, according to IEA Task 15, to actually consider PV modules as building-integrated elements, they must provide additional functions other than energy production, such as mechanical rigidity or structural integrity for the building, impact protection against atmospheric agents (rain, snow, wind, and hail), shading, daylighting, or thermal insulation, as well as fire and noise protection.

A critical issue is represented by glazed surfaces since they highly impact a building’s lighting, heating, and ventilation [19]. The design of windows plays an important role in ensuring low cooling and lighting loads for NZEBs [20][21], leading to the implementation of smart windows or dynamic shading systems that increase the resilience of a glazed envelope in terms of energy savings [22][23]. The attention of the scientific community is therefore focused on the study of active glazed surfaces that could improve the building energy demand with respect to conventional static windows, especially for commercial buildings with large transparent façades [24]. De Masi et al. [25] analyzed the impact of windows on building performance in different European climates, showing that, depending on specific factors, such as window typology and orientation, climatic conditions, and window-to-wall ratio, the optimized design of a glazed building envelope may lead to an energy saving varying from 27% to 62%. Similarly, the U.S. Department of Energy reported that window-related energy losses account for up to 25% of a household’s energy consumption [26].

A possible solution to further decrease the cost of BIPV technologies is the manufacture of devices that have static or monoaxial concentrating components in the so-called building-integrated concentrating photovoltaic (BICPV) technology. Data from [27][28][29][30] estimated that systems with a low-concentration factor specifically designed for building integration can reduce the cost of the device by up to 40% with respect to similar non-concentrating devices. According to the most general definition, a solar concentrator is an object redirecting light rays from a larger area, namely the aperture area, to a smaller one, called the receiver of the absorber area [31]. The ratio between the aperture and the absorber area defines the concentration ratio, which is commonly used to classify optical concentrators. The concentrators enhance the luminous flux that reaches the active PV area by using relatively cheap optical concentrating elements. The goal is to maximize the power generated by the cells by a factor almost equal to the concentration ratio [32], while reducing the amount of PV cells per active area. However, optical concentration also leads to a higher nominal operating cell temperature; therefore, for a medium or high concentration factor, the presence of active cooling procedures is particularly important to avoid limitations in the system efficiency due to additional thermal losses within the PV cells [33][34].

A further strategy to maximize the utilization of solar radiation for building energy efficiency is its concurrent conversion into both thermal and electrical energy via hybrid photovoltaic–thermal (PVT) systems [35][36], also efficiently coupled with BICPVs. Building-integrated photovoltaic–thermal (BIPVT) devices are particularly indicated to support net-zero energy constructions. In addition to their insulation and electricity generation functions, they efficiently harvest a portion of the thermal energy related to solar irradiance [37]. The heat extracted by the thermal collectors of the PVT systems may be used in ventilation air pre-heating [38][39], underfloor heating systems [40], domestic hot water [41], passive and active cooling [42], and heat storage [43][44], thus increasing the overall building energy efficiency.

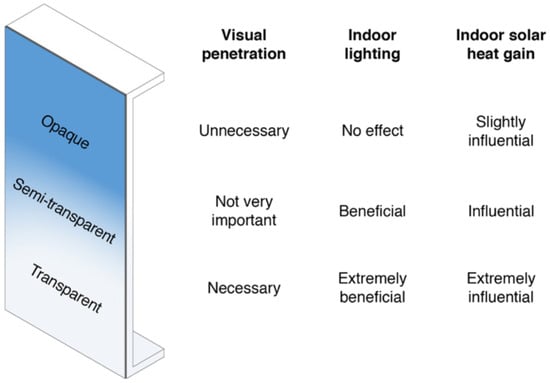

In terms of architectural and functional design, a façade’s optical properties depend on building energy and lighting needs. In Figure 2, an illustration that clarifies the effects of external skin transparency on indoor spaces is presented.

Figure 2. Graphical representation of the external skin transparency effect on the building indoor spaces.

In light of the current surge in interest surrounding BIPV systems, numerous researchers conducted comprehensive reviews that delve into distinct PV technologies. In particular, Sirin et al. [45] reviewed BIPVT systems for green buildings, presenting the operation of these systems, their classification, and potential contributions to building energy efficiency. Several in-depth works on building-integrated and -attached photovoltaic solutions have been performed by A. Ghosh in recent years [46]. In their review on fenestration photovoltaic devices [47], the authors presented different PV-based fenestration-integrated photovoltaic systems to estimate their impact on building energy consumption. Romani et al. [48] further examined this topic by presenting the most common optical, thermal, and electrical models, combined with the modeling capabilities of the most common building simulation tools. In 2022, Massod et al. [49][50] investigated the developments and applications of concentrating photovoltaic technologies. They concluded that the best concentrators for integration in building façades are asymmetric compound parabolic concentrators (ACPCs) and 3D crossed compound parabolic concentrators (CCPCs). Li et al. [51] discussed the recent advances in BIPVs with a particular emphasis on colored technologies, presenting design principles, theoretical analysis, technical routes, and the corresponding demonstration studies. All these works focused on specific PV categories regardless of the building component in which they are integrated. As a further example, Taser et al. [52] provided a comprehensive analysis of BIPV systems, ranging from façade-integrated solutions to roof-mounted solutions. However, due to the breadth of the review, the authors neglected some technical parameters, such as the U-value, the SHGF, or the WWR, which may represent crucial information in the comparison of different PV technologies.

3. Standard BIPV Systems

Cutting-edge BIPV solutions allow for the substitution of several envelope components, such as façades, windows, shading elements, or roofs [53]. However, for high-rise commercial or residential buildings, a rooftop PV alone is not sufficient to achieve the NZEB goal, as the building energy demand is greater than the energy produced by the roof PV installation. This forces a large part of the required PV installation to be placed on the façade, namely, a part of the building envelope having a significant architectural value and providing the building with a characteristic appearance and attractiveness. For this reason, innovative BIPV solutions present a tailored design in terms of transparency, color, or texture, thus increasing the building energy efficiency without compromising the façade aesthetics or functionality [54][55]. Moreover, a façade PV has the possibility of exploiting different orientations to guarantee a more uniform energy production during the entire day [56][57][58].

Biyik et al. [59] presented the advantages of the implementation of BIPV systems in comparison to utility-scale solutions that can be summarized as an increment in PV deployment areas as well as a reduction in building thermal losses and capital costs.

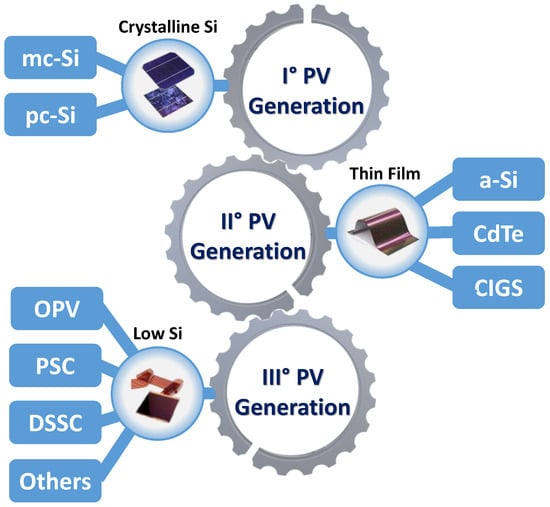

The efficiency of PV modules, currently in the range of 12–23% for commercial devices [2], depends strongly on the panel technology and its working conditions [41]. Depending on the technologies on which they are based, cutting-edge solar modules can have either single or multiple active layers. These layers may perform the proper conversion of solar energy into electrical energy, or improve the absorption of solar radiation in different ranges, thus enhancing the entire device efficiency [60]. A widespread methodology to classify solar cells and PV panels is based on the technology used for solar cell fabrication: each PV module can be subdivided into three main generations strictly related to the amount of contained crystal silicon [61]. The different generations are depicted in Figure 3. The first generation is characterized by the presence of crystalline silicon (c-Si) solar cells [62], which can be subdivided into monocrystalline (mc-Si) [63][64] or polycrystalline (pc-Si) silicon solar cells [65][66]. Standard second-generation PV panels are thin-film (TF) solar cells that present several advantages over first-generation c-Si devices, especially for building integration, having a lower thickness with respect to the first-generation ones. Indeed, the possibility of achieving TF solar cells with a thickness that ranges from a few nanometers to a few microns opens the possibility to tailor the flexibility, weight, and transparency of these devices according to their function in the building envelope. In addition, as the cell cost accounts for roughly 50% of the total module price [67], if the manufacturing cost of TF technologies competes with first-generation PV solutions, their implementation may lead to a potential cost reduction [68]. For this reason, research activities aiming to improve the efficiency of TF devices based on different technologies, such as copper–indium–gallium–selenide (CIGS) [69][70], cadmium telluride (CdTe) [71][72], or amorphous silicon (a-Si) [73][74], have significantly increased.

Figure 3. Graphical representation of the three generations of PV technologies.

According to the theoretical Carnot limit, if efficiently converted, solar radiation can generate electricity close to 95% [75]. However, single-junction cells of the first and second generations can only convert 31% due to the Schockley–Queisser limit, whereas third-generation solar cells are free from this limit [76]. The percentage of solar energy not converted into electricity is dissipated as heat. Third-generation solar cells are characterized by devices in which silicon-based solutions play a secondary role and have not yet achieved large-scale manufacturing as opposed to first- and second-generation PVs. Examples of third-generation solar devices are dye-sensitized solar cells (DSSCs) [77][78], perovskite solar cells (PSCs) [79][80], and organic photovoltaics (OPVs) [81][82]. DSSCs include four main components: the photoanode, the counter electrode, the dye sensitizer, and the electrolyte. The first is a wide-bandgap semiconductor that, combined with the dye sensitizer, is needed to actively harvest light, while the electrolyte contains the redox couple for dye regeneration [83]. PSCs are distinguished by perovskite-structured compounds acting as a light-harvesting active layer; the most common ones are hybrid organic–inorganic lead or tin halide-based materials [84]. OPV devices are based on conductive organic polymers or small organic molecules for light absorption and charge transport rather than semiconductor p–n junctions [85]. Despite the technology on which they are based, PV panels are very sensitive to environmental conditions, such as irradiance, dust, humidity, and ambient temperature. Numerous investigations have focused on the influence of the inclination angle and the orientation of PV panels on their performance [86].

4. Concentrating BIPV Systems (BICPVs)

The building-integrated concentrating photovoltaic (BICPV) systems represent a niche that is still commercially under-exploited, mainly because of the esthetical constraints related to the concentrating components. Optical concentrators commonly used in PVT systems can be broadly classified into two main families, namely, conventional and holographic concentrators [87]. These two families can be further subdivided into different types, such as refractive, reflective, hybrid, and luminescent concentrators [88], which can be in turn subdivided into compound parabolic concentrators (CPCs), V-trough reflectors, Fresnel reflectors (FR), or luminescent solar concentrators (LSC) [89][90][91].

Due to their low transparency, CPCs and V-trough reflectors are preferably employed in low-concentration systems, integrated into opaque roofs or façades [92][93], whereas FR or LSC are usually integrated into transparent or semi-transparent installations [94]. A further advantage of BICPVs is the higher working temperature of the PV cells, since the excess of thermal energy generated on the modules can be used in residential spaces or for water heating, drying and agricultural processes, as well as for other domestic or industrial applications [95][96].

Devices with a concentration ratio greater than 100× are defined as high-concentration systems, and they require both the implementation of high-precision dual-axis tracking and, in some cases, active cooling systems [89]. Systems with a concentration ratio ranging from 10× to 100× are called medium concentration devices, and if their concentration ratio is near 100×, they can still feature active cooling but the tracking is limited to a monoaxial one [88]. Objects with a concentration ratio lower than 10× are identified as low-concentration systems that do not require to be coupled with active sun tracking. However, single-axial tracking can be implemented to extend light collection hours during the day [28][97]. The system implemented in BICPV applications are usually medium and low concentrating collectors, as they are stationary or single axial tracking systems [98][99], manufactured to maximize the radiation that reaches the PV cells considering daily and seasonal changes in the solar position [100]. To increase sunlight harvesting, the development of concentrators with a large light acceptance angle is generally preferred to the coupling with a tracking system, as this practice not only decreases the overall system cost but also allows for the concentration of a larger portion of the diffuse radiation.

The ability to focus diffuse radiation makes this type of collector particularly suitable for BICPV applications, as in urban environments diffused contributions can be dominant, especially in high-population-density areas [101][102].

Solar concentrators can be clustered according to the optics, as imaging or non-imaging, or according to their concentration method, since they can be categorized as reflective, refractive, hybrid, or luminescent concentrators [88]. Additionally, CPCs can be subdivided into either two-dimensional or three-dimensional concentrators, depending on whether the concentration is performed on one or two planes [88].

5. Photovoltaic–Thermal Systems (BIPVTs)

The electrical power supplied by PV panels depends also on their temperature. In fact, the rating plate of these devices is measured under specific Standard Test Conditions (STCs): irradiance of 1000 W/m2, ambient temperature of 25 °C, and wind speed of 1.5 m/s [103]. Typically, during standard test procedures, the modules are irradiated via flash lamps; thus, the ambient temperature corresponds to the cell temperature, even under STC irradiance. However, in on-field working conditions, if cells are exposed to 1000 W/m2, they reach a considerably higher temperature, thus diminishing the power produced by the modules [104][105]. The prolonged increase in the panel surface temperature contributes to an increment in the panel shunt resistance as well as to the creation of hot spots, which not only decrease their performance, but also have an impact on their lifetime.

A further advantage of these devices is that the thermal collector is embedded in the system frame and placed behind the PV components, thus employing the same collector area for the extraction of the additional thermal energy. Despite that typical PVT modules are realized for low and medium temperature processes, with a fluid delivery temperature ranging from 20 °C to 80 °C [106][107], the better efficiency for both thermal and electrical components can only be attained at relatively low temperatures. For ideal operating conditions, the reference temperatures are the ambient temperature and 25 °C for the thermal and electrical components, respectively [108][109]. Considering the impact that BIPVT systems may have on NZEBs, various thermal collectors have been developed to enhance the overall system efficiency, such as air [110], water [111], bi-fluidic [112], or thermoelectric [113][114] cooling. Concerning extraction methodology, some of the new developments are nanofluids [115][116], evaporative cooling [117][118], and phase-change material (PCM) [119][120]. As for standard BIPV technologies, BIPVT solutions can be integrated into façades, rooftops, and shading devices [121].

6. Semi-Transparent Photovoltaic Systems (STBIPVs)

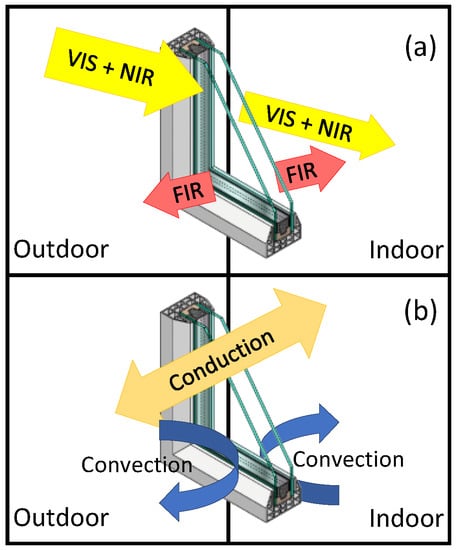

As for opaque BIPV solutions, the absence of mechanical motion components, the low maintenance costs, and the quantity of solar radiation filtering through traditional windows, make semi-transparent PV technologies the best candidates to turn traditional glazed surfaces into active building elements. In Figure 4, the heat and light transfer phenomena characterizing a standard window are presented. The optimization of fenestration-integrated PV performance is even more delicate with respect to opaque BIPV technologies since the primary purpose of PV windows is the visual and thermal comfort of the building occupants, whereas energy production represents an added value.

Figure 4. Schematic of a standard window showing (a) the radiative and (b) the conductive and the convective heat transfer mechanisms.

Indeed, as also testified by De Masi et al. [25], for a proper smart window design, additional parameters need to be taken into account, such as transparency, window-to-wall ratio, coverage, fresh air infiltration, and the solar-heat-gain coefficient (SHGC).

The estimation of indoor visual comfort is usually defined by the external daylight penetration [122][123], the correlated color temperature (CCT), and the color rendering index (CRI) [124]. The last two parameters are typically used to define the colorimetric properties of a light source. In this case, the PV glass is assimilated to a light source enlightened by solar radiation and having an emission spectrum equal to its transmission one. To ensure the occupants’ visual comfort, the CRI value should be higher than 80 out of 100 and the CCT should range between 3000 K and 7500 K [55]. In the literature, the external daylight that penetrates through fenestration BIPV devices is estimated by using the daylight glare probability (DGP) and the daylight glare index (DGI) [125][126] or by evaluating the illuminance of the building interior, which should be between 100 lx and 2000 lx to avoid discomfort due to glare [127].

All aspects related to thermal comfort are not of secondary importance, namely, the thermal energy transmission coefficient, U-value (W/(m2K)), SHGC, and solar factor (SF). The U-value quantifies the window heat-insulating properties, whereas the SHGC and SF are dimensionless coefficients, respectively, measuring the solar radiation and the energy transmitted to the window. Both the SHGC and SF range from 0 to 1, with 0 indicating a glaze with no transmittance of radiation or energy while 1 represents the full transmittance of the related quantities [128]. Despite having minor differences, the SHGC and SF are used as alternative parameters to evaluate solar penetration through transparent or semi-transparent surfaces.

Typical single-glazed windows have U-values of 3–5 W/(m2K), which decrease to 2–2.99 W/(m2K) if double-glazed air-filled windows are considered. This value can be further reduced by manufacturing multiple-layered windows or by increasing the glass thickness [129]. The adoption of multiple-glazed windows also allows the substitution of the air inside the cavity with inert gas, aerogel [130], or vacuum [131]. Due to the manufacturing process involving innovative techniques or materials, and the common utilization of a multilayer structure, which facilitates the PV component integration, smart windows typically have lower U-values when compared to traditional windows. Since a portion of the incoming radiation is absorbed by the integrated solar technology for energy production, the SHGC is usually lower, which is beneficial for hot climates as it decreases the building cooling load, but it negatively impacts the buildings in cold climatic areas. Smart windows can be subdivided into first, second, and third generation, according to the integrated PV technology.

As c-Si absorbs 90.5% of the incident radiation [132], it behaves as an opaque surface and the transparency of first-generation PV fenestration is obtained by spacing two adjacent cells. Semitransparent PV glazing is therefore realized by encapsulating crystalline PV cells between two glasses using standard encapsulant materials like EVA, PVB, or TPO. The transparency of these smart windows may be varied by modifying the glass transmittance or the cell interspacing. Thin-film PV technologies are particularly indicated for the integration in semi-transparent surfaces as they combine the reliability of first-generation PV cells with the possibility of creating devices that have uniform and continuous transparency. DSSCs, PSCs, and OPVs are becoming increasingly popular semi-transparent PV applications compared to those of previous generations due to their tunable transparency and their simpler fabrication processes [133]. Moreover, DSSCs and OPVs are characterized, respectively, by eco-friendly and low-toxicity properties [134].

References

- Dutta, R.; Chanda, K.; Maity, R. Future of Solar Energy Potential in a Changing Climate across the World: A CMIP6 Multi-Model Ensemble Analysis. Renew. Energy 2022, 188, 819–829.

- Maghrabie, H.M.; Abdelkareem, M.A.; Al-Alami, A.H.; Ramadan, M.; Mushtaha, E.; Wilberforce, T.; Olabi, A.G. State-of-the-Art Technologies for Building-Integrated Photovoltaic Systems. Buildings 2021, 11, 383.

- Masson, G.; Bosch, E.; Van Rechem, A.; de l’Epine, M. Snapshot of Global PV Markets 2023 Task 1 Strategic PV Analysis and Outreach PVPS; Report IEA-PVPS T1-44:2023; IEA PVPS: Paris, France, 2023; ISBN 978-3-907281-43-7.

- International Energy Agency (IEA). Renewable Energy Market Update Outlook for 2023 and 2024. 2023. Available online: https://iea.blob.core.windows.net/assets/63c14514-6833-4cd8-ac53-f9918c2e4cd9/RenewableEnergyMarketUpdate_June2023.pdf (accessed on 28 July 2023).

- Selimefendigil, F.; Şirin, C. Experimental Investigation of a Parabolic Greenhouse Dryer Improved with Copper Oxide Nano-Enhanced Latent Heat Thermal Energy Storage Unit. Int. J. Energy Res. 2021, 46, 3647–3662.

- Boschetti, M.; Vincenzi, D.; Mangherini, G.; Bernardoni, P.; Andreoli, A.; Gjestila, M.; Camattari, R.; Fugattini, S.; Caramori, S.; Cristino, V.; et al. Modular Stand-Alone Photoelectrocatalytic Reactor for Emergent Contaminant Degradation via Solar Radiation. Sol. Energy 2021, 228, 120–127.

- Maghrabie, H.M.; Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Olabi, A.G. Building-Integrated Photovoltaic/Thermal (BIPVT) Systems: Applications and Challenges. Sustain. Energy Technol. Assess. 2021, 45, 101151.

- Barron-Gafford, G.A.; Minor, R.L.; Allen, N.A.; Cronin, A.D.; Brooks, A.E.; Pavao-Zuckerman, M.A. The Photovoltaic Heat Island Effect: Larger Solar Power Plants Increase Local Temperatures. Sci. Rep. 2016, 6, 35070.

- Gorman, C.E.; Torsney, A.; Gaughran, A.; McKeon, C.M.; Farrell, C.A.; White, C.; Donohue, I.; Stout, J.C.; Buckley, Y.M. Reconciling Climate Action with the Need for Biodiversity Protection, Restoration and Rehabilitation. Sci. Total Environ. 2023, 857, 159316.

- EUR-Lex Directive (EU) 2018/844 of the European Parliament and of the Council. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=uriserv%3AOJ.L_.2018.156.01.0075.01.ENG (accessed on 11 July 2023).

- Zhang, H.; Chen, H.; Liu, H.; Huang, J.; Guo, X.; Li, M. Design and Performance Study of a Low Concentration Photovoltaic-Thermal Module. Int. J. Energy Res. 2018, 42, 2199–2212.

- Dos Santos, Í.P.; Rüther, R. The Potential of Building-Integrated (BIPV) and Building-Applied Photovoltaics (BAPV) in Single-Family, Urban Residences at Low Latitudes in Brazil. Energy Build. 2012, 50, 290–297.

- Parida, B.; Iniyan, S.; Goic, R. A Review of Solar Photovoltaic Technologies. Renew. Sustain. Energy Rev. 2011, 15, 1625–1636.

- Eiffert, P.; Kiss, G.J. Building-Integrated Photovoltaic Designs for Commercial and Institutional Structures: A Sourcebook for Architects; DIANE Publishing: Darby, PA, USA, 2000.

- Happle, G.; Shi, Z.; Hsieh, S.; Ong, B.; Fonseca, J.A.; Schlueter, A. Identifying Carbon Emission Reduction Potentials of BIPV in High-Density Cities in Southeast Asia. J. Phys. Conf. Ser. 2019, 1343, 012077.

- Shabunko, V.; Badrinarayanan, S.; Pillai, D.S. Evaluation of In-Situ Thermal Transmittance of Innovative Building Integrated Photovoltaic Modules: Application to Thermal Performance Assessment for Green Mark Certification in the Tropics. Energy 2021, 235, 121316.

- De Boeck, L.; Verbeke, S.; Audenaert, A.; De Mesmaeker, L. Improving the Energy Performance of Residential Buildings: A Literature Review. Renew. Sustain. Energy Rev. 2015, 52, 960–975.

- Polo López, C.S.; Troia, F.; Nocera, F. Photovoltaic Bipv Systems and Architectural Heritage: New Balance between Conservation and Transformation. an Assessment Method for Heritage Values Compatibility and Energy Benefits of Interventions. Sustainability 2021, 13, 5107.

- Tavares, P.; Bernardo, H.; Gaspar, A.; Martins, A. Control Criteria of Electrochromic Glasses for Energy Savings in Mediterranean Buildings Refurbishment. Sol. Energy 2016, 134, 236–250.

- Gratia, E.; De Herde, A. Design of Low Energy Office Buildings. Energy Build. 2003, 35, 473–491.

- Xing, Y.; Hewitt, N.; Griffiths, P. Zero Carbon Buildings Refurbishment—A Hierarchical Pathway. Renew. Sustain. Energy Rev. 2011, 15, 3229–3236.

- Carlucci, F.; Negendahl, K.; Fiorito, F. Energy Flexibility of Building Systems in Future Scenarios: Optimization of the Control Strategy of a Dynamic Shading System and Definition of a New Energy Flexibility Metric. Energy Build. 2023, 289, 113056.

- Hawila, A.A.W.; Merabtine, A.; Troussier, N.; Bennacer, R. Combined Use of Dynamic Building Simulation and Metamodeling to Optimize Glass Facades for Thermal Comfort. Build. Environ. 2019, 157, 47–63.

- Nageib, A.; Elzafarany, A.M.; Elhefnawy, M.H.; Mohamed, F.O. Using Smart Glazing for Reducing Energy Consumption on Existing Office Building in Hot Dry Climate. HBRC J. 2020, 16, 157–177.

- De Masi, R.F.; Festa, V.; Gigante, A.; Ruggiero, S.; Peter Vanoli, G. The Role of Windows on Building Performance under Current and Future Weather Conditions of European Climates. Energy Build. 2023, 292, 113177.

- Feng, Y.; Duan, Q.; Wang, J.; Baur, S. Approximation of Building Window Properties Using in Situ Measurements. Build. Environ. 2020, 169, 106590.

- Bowden, S.; Wenham, S.R.; Green, M.A. Application of Static Concentrators to Photovoltaic Roof Tiles. Prog. Photovolt. 1995, 3, 413–423.

- Aldegheri, F.; Baricordi, S.; Bernardoni, P.; Brocato, M.; Calabrese, G.; Guidi, V.; Mondardini, L.; Pozzetti, L.; Tonezzer, M.; Vincenzi, D. Building Integrated Low Concentration Solar System for a Self-Sustainable Mediterranean Villa: The Astonyshine House. Energy Build. 2014, 77, 355–363.

- Vincenzi, D.; Aldegheri, F.; Baricordi, S.; Bernardoni, P.; Calabrese, G.; Guidi, V.; Pozzetti, L. Low Concentration Solar Louvres for Building Integration. Proc. AIP Conf. Proc. 2013, 1556, 110–113.

- Mallick, T.K.; Eames, P.C. Design and Fabrication of Low Concentrating Second Generation PRIDE Concentrator. Sol. Energy Mater. Sol. Cells 2007, 91, 597–608.

- Muhammad-Sukki, F.; Abu-Bakar, S.H.; Ramirez-Iniguez, R.; McMeekin, S.G.; Stewart, B.G.; Sarmah, N.; Mallick, T.K.; Munir, A.B.; Mohd Yasin, S.H.; Abdul Rahim, R. Mirror Symmetrical Dielectric Totally Internally Reflecting Concentrator for Building Integrated Photovoltaic Systems. Appl. Energy 2014, 113, 32–40.

- Shanks, K.; Senthilarasu, S.; Mallick, T.K. Optics for Concentrating Photovoltaics: Trends, Limits and Opportunities for Materials and Design. Renew. Sustain. Energy Rev. 2016, 60, 394–407.

- Royne, A.; Dey, C.J.; Mills, D.R. Cooling of Photovoltaic Cells under Concentrated Illumination: A Critical Review. Sol. Energy Mater. Sol. Cells 2005, 86, 451–483.

- Alharbi, F.H.; Kais, S. Theoretical Limits of Photovoltaics Efficiency and Possible Improvements by Intuitive Approaches Learned from Photosynthesis and Quantum Coherence. Renew. Sustain. Energy Rev. 2015, 43, 1073–1089.

- Salem Ahmed, M.; Mohamed, A.S.A.; Maghrabie, H.M. Performance Evaluation of Combined Photovoltaic Thermal Water Cooling System for Hot Climate Regions. J. Sol. Energy Eng. Trans. ASME 2019, 141, 041010.

- Sarhaddi, F.; Farahat, S.; Ajam, H.; Behzadmehr, A.; Mahdavi Adeli, M. An Improved Thermal and Electrical Model for a Solar Photovoltaic Thermal (PV/T) Air Collector. Appl. Energy 2010, 87, 2328–2339.

- Yu, G.; Yang, H.; Yan, Z.; Kyeredey Ansah, M. A Review of Designs and Performance of Façade-Based Building Integrated Photovoltaic-Thermal (BIPVT) Systems. Appl. Therm. Eng. 2021, 182, 116081.

- Nagano, K.; Mochida, T.; Shimakura, K.; Murashita, K.; Takeda, S. Development of Thermal-Photovoltaic Hybrid Exterior Wallboards Incorporating PV Cells in and Their Winter Performances. Sol. Energy Mater. Sol. Cells 2003, 77, 265–282.

- Candanedo, L.M.; Athienitis, A.; Park, K.W. Convective Heat Transfer Coefficients in a Building-Integrated Photovoltaic/Thermal System. J. Sol. Energy Eng. Trans. ASME 2011, 133, 021002.

- Fraisse, G.; Ménézo, C.; Johannes, K. Energy Performance of Water Hybrid PV/T Collectors Applied to Combisystems of Direct Solar Floor Type. Sol. Energy 2007, 81, 1426–1438.

- Chow, T.T.; Ji, J.; He, W. Photovoltaic-Thermal Collector System for Domestic Application. J. Sol. Energy Eng. Trans. ASME 2007, 129, 205–209.

- Oropeza-Perez, I.; Østergaard, P.A. Active and Passive Cooling Methods for Dwellings: A Review. Renew. Sustain. Energy Rev. 2018, 82, 531–544.

- Reji Kumar, R.; Samykano, M.; Pandey, A.K.; Kadirgama, K.; Tyagi, V.V. Phase Change Materials and Nano-Enhanced Phase Change Materials for Thermal Energy Storage in Photovoltaic Thermal Systems: A Futuristic Approach and Its Technical Challenges. Renew. Sustain. Energy Rev. 2020, 133, 110341.

- Chow, T.T. A Review on Photovoltaic/Thermal Hybrid Solar Technology. Appl. Energy 2010, 87, 365–379.

- Şirin, C.; Goggins, J.; Hajdukiewicz, M. A Review on Building-Integrated Photovoltaic/Thermal Systems for Green Buildings. Appl. Therm. Eng. 2023, 229, 120607.

- Ghosh, A. Potential of Building Integrated and Attached/Applied Photovoltaic (BIPV/BAPV) for Adaptive Less Energy-Hungry Building’s Skin: A Comprehensive Review. J. Clean. Prod. 2020, 276, 123343.

- Ghosh, A. Fenestration Integrated BIPV (FIPV): A Review. Sol. Energy 2022, 237, 213–230.

- Romaní, J.; Ramos, A.; Salom, J. Review of Transparent and Semi-Transparent Building-Integrated Photovoltaics for Fenestration Application Modeling in Building Simulations. Energies 2022, 15, 3286.

- Masood, F.; Nor, N.B.M.; Nallagownden, P.; Elamvazuthi, I.; Saidur, R.; Alam, M.A.; Akhter, J.; Yusuf, M.; Mehmood, M.; Ali, M. A Review of Recent Developments and Applications of Compound Parabolic Concentrator-Based Hybrid Solar Photovoltaic/Thermal Collectors. Sustainability 2022, 14, 5529.

- Masood, F.; Nor, N.B.M.; Elamvazuthi, I.; Saidur, R.; Alam, M.A.; Akhter, J.; Yusuf, M.; Ali, S.M.; Sattar, M.; Baba, M. The Compound Parabolic Concentrators for Solar Photovoltaic Applications: Opportunities and Challenges. Energy Rep. 2022, 8, 13558–13584.

- Li, Z.; Ma, T.; Yang, H.; Lu, L.; Wang, R. Transparent and Colored Solar Photovoltaics for Building Integration. Sol. RRL 2021, 5, 2000614.

- Taşer, A.; Koyunbaba, B.K.; Kazanasmaz, T. Thermal, Daylight, and Energy Potential of Building-Integrated Photovoltaic (BIPV) Systems: A Comprehensive Review of Effects and Developments. Sol. Energy 2023, 251, 171–196.

- Khencha, K.; Wided, B.R.; Hocine, B. Techno-Economic Study of BIPV in Typical Sahara Region in Algeria. J. Econ. Dev. Environ. People 2020, 9, 27–59.

- Choi, W.J.; Joo, H.J.; Park, J.W.; Kim, S.K.; Lee, J.B. Power Generation Performance of Building-Integrated Photovoltaic Systems in a Zero Energy Building. Energies 2019, 12, 2471.

- Eder, G.; Peharz, G.; Trattnig, R.; Bonomo, P.; Saretta, E.; Frontini, F.; Polo Lopez, C.S.; Rose Wilson, H.; Eisenlohr, J.; Martín Chivelet, N.; et al. COLOURED BIPV Market, Research and Development IEA PVPS Task 15, Report IEA-PVPS T15-07: 2019. 2019. Available online: https://iea-pvps.org/wp-content/uploads/2020/01/IEA-PVPS_15_R07_Coloured_BIPV_report.pdf (accessed on 27 July 2023).

- Shabunko, V.; Bieri, M.; Reindl, T. Building Integrated Photovoltaic Facades in Singapore: Online BIPV LCC Calculator. In Proceedings of the 2018 IEEE 7th World Conference on Photovoltaic Energy Conversion (WCPEC) (A Joint Conference of 45th IEEE PVSC, 28th PVSEC & 34th EU PVSEC), Waikoloa, HI, USA, 10–15 June 2018; pp. 1231–1233.

- Corti, P.; Capannolo, L.; Bonomo, P.; De Berardinis, P.; Frontini, F. Comparative Analysis of BIPV Solutions to Define Energy and Cost-Effectiveness in a Case Study. Energies 2020, 13, 3827.

- Saretta, E.; Caputo, P.; Frontini, F. A Review Study about Energy Renovation of Building Facades with BIPV in Urban Environment. Sustain. Cities Soc. 2019, 44, 343–355.

- Biyik, E.; Araz, M.; Hepbasli, A.; Shahrestani, M.; Yao, R.; Shao, L.; Essah, E.; Oliveira, A.C.; del Caño, T.; Rico, E.; et al. A Key Review of Building Integrated Photovoltaic (BIPV) Systems. Eng. Sci. Technol. Int. J. 2017, 20, 833–858.

- Rabaia, M.K.H.; Abdelkareem, M.A.; Sayed, E.T.; Elsaid, K.; Chae, K.J.; Wilberforce, T.; Olabi, A.G. Environmental Impacts of Solar Energy Systems: A Review. Sci. Total Environ. 2021, 754, 141989.

- Mohammad Bagher, A. Types of Solar Cells and Application. Am. J. Opt. Photonics 2015, 3, 94.

- Radziemska, E. The Effect of Temperature on the Power Drop in Crystalline Silicon Solar Cells. Renew. Energy 2003, 28, 1–12.

- Lämmle, M.; Kroyer, T.; Fortuin, S.; Wiese, M.; Hermann, M. Development and Modelling of Highly-Efficient PVT Collectors with Low-Emissivity Coatings. Sol. Energy 2016, 130, 161–173.

- Sandnes, B.; Rekstad, J. A Photovoltaic/Thermal (PV/T) Collector with a Polymer Absorber Plate. Experimental Study and Analytical Model. Sol. Energy 2002, 72, 63–73.

- Battisti, R.; Corrado, A. Evaluation of Technical Improvements of Photovoltaic Systems through Life Cycle Assessment Methodology. Energy 2005, 30, 952–967.

- Seng, L.Y.; Lalchand, G.; Sow Lin, G.M. Economical, Environmental and Technical Analysis of Building Integrated Photovoltaic Systems in Malaysia. Energy Policy 2008, 36, 2130–2142.

- Madhusudanan, S.P.; Caroline, C.S.; Batabyal, S.K. Sustainable Energy Harvesting Technologies. In Sulfide and Selenide Based Materials for Emerging Applications; Dalapati, G., Wong, T.S., Subrata, K., Amit, C., Zhuk, S., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 15–33. ISBN 9780323998604.

- Lee, T.D.; Ebong, A.U. A Review of Thin Film Solar Cell Technologies and Challenges. Renew. Sustain. Energy Rev. 2017, 70, 1286–1297.

- Mufti, N.; Amrillah, T.; Taufiq, A.; Sunaryono; Aripriharta; Diantoro, M.; Zulhadjri; Nur, H. Review of CIGS-Based Solar Cells Manufacturing by Structural Engineering. Sol. Energy 2020, 207, 1146–1157.

- Rawat, S.; Gupta, R.; Gohri, S. Performance Assessment of CIGS Solar Cell with Different CIGS Grading Profile. Mater. Today Proc. 2023, 3–6.

- Kumar, N.M. Performance of Single-Sloped Pitched Roof Cadmium Telluride (CdTe) Building-Integrated Photovoltaic System in Tropical Weather Conditions. Beni-Suef Univ. J. Basic Appl. Sci. 2019, 8, 2.

- Alrashidi, H.; Ghosh, A.; Issa, W.; Sellami, N.; Mallick, T.K.; Sundaram, S. Thermal Performance of Semitransparent CdTe BIPV Window at Temperate Climate. Sol. Energy 2020, 195, 536–543.

- Maurus, H.; Schmid, M.; Blersch, B.; Lechner, P.; Schade, H. PV for BUILDINGS—Benefits and Experiences with Amorphous Silicon in BIPV Applications. Refocus 2004, 5, 22–27.

- Yoon, J.H.; Song, J.; Lee, S.J. Practical Application of Building Integrated Photovoltaic (BIPV) System Using Transparent Amorphous Silicon Thin-Film PV Module. Sol. Energy 2011, 85, 723–733.

- Landsberg, P.T.; Badescu, V. Carnot Factor in Solar Cell Efficiencies. J. Phys. D Appl. Phys. 2000, 33, 3004–3008.

- Dupré, O.; Vaillon, R.; Green, M.A. Physics of the Temperature Coefficients of Solar Cells. Sol. Energy Mater. Sol. Cells 2015, 140, 92–100.

- Gokul, G.; Pradhan, S.C.; Soman, S. Dye-Sensitized Solar Cells as Potential Candidate for Indoor/Diffused Light Harvesting Applications: From BIPV to Self-Powered IoTs; Springer: Singapore, 2019; ISBN 9789811333026.

- Yuan, H.; Wang, W.; Xu, D.; Xu, Q.; Xie, J.; Chen, X.; Zhang, T.; Xiong, C.; He, Y.; Zhang, Y.; et al. Outdoor Testing and Ageing of Dye-Sensitized Solar Cells for Building Integrated Photovoltaics. Sol. Energy 2018, 165, 233–239.

- Lim, S.H.; Seok, H.J.; Kwak, M.J.; Choi, D.H.; Kim, S.K.; Kim, D.H.; Kim, H.K. Semi-Transparent Perovskite Solar Cells with Bidirectional Transparent Electrodes. Nano Energy 2021, 82, 105703.

- Wahad, F.; Abid, Z.; Gulzar, S.; Aslam, M.S.; Rafique, S.; Shahid, M.; Altaf, M.; Ashraf, R.S. Semitransparent Perovskite Solar Cells. In Fundamentals of Solar Cell Design; Scrivener Publishing LLC: Beverly, MA, USA, 2023; Chapter 15; pp. 461–503.

- Muteri, V.; Cellura, M.; Curto, D.; Franzitta, V.; Longo, S.; Mistretta, M.; Parisi, M.L. Review on Life Cycle Assessment of Solar Photovoltaic Panels. Energies 2020, 13, 252.

- Jiang, T.; Zhang, G.; Xia, R.; Huang, J.; Li, X.; Wang, M.; Yip, H.L.; Cao, Y. Semitransparent Organic Solar Cells Based on All-Low-Bandgap Donor and Acceptor Materials and Their Performance Potential. Mater. Today Energy 2021, 21, 100807.

- Çakar, S.; Özacar, M.; Fındık, F. MOFs-Based Dye-Sensitized Photovoltaics. In Metal-Organic Framework-Based Nanomaterials for Energy Conversion and Storage; Gupta, R.K., Nguyen, T.A., Yasin, G., Eds.; Elsevier: Amsterdam, The Netherlands, 2022; pp. 487–506. ISBN 9780323911795.

- Manser, J.S.; Christians, J.A.; Kamat, P.V. Intriguing Optoelectronic Properties of Metal Halide Perovskites. Chem. Rev. 2016, 116, 12956–13008.

- Ameri, T.; Dennler, G.; Lungenschmied, C.; Brabec, C.J. Organic Tandem Solar Cells: A Review. Energy Environ. Sci. 2009, 2, 347–363.

- Wu, S.; Xiong, C. Passive Cooling Technology for Photovoltaic Panels for Domestic Houses. Int. J. Low-Carbon Technol. 2014, 9, 118–126.

- Ferrara, M.A.; Striano, V.; Coppola, G. Volume Holographic Optical Elements as Solar Concentrators: An Overview. Appl. Sci. 2019, 9, 193.

- Freier, D.; Ramirez-Iniguez, R.; Jafry, T.; Muhammad-Sukki, F.; Gamio, C. A Review of Optical Concentrators for Portable Solar Photovoltaic Systems for Developing Countries. Renew. Sustain. Energy Rev. 2018, 90, 957–968.

- Chemisana, D. Building Integrated Concentrating Photovoltaics: A Review. Renew. Sustain. Energy Rev. 2011, 15, 603–611.

- Gite, S.S.; Walke, P.V. Photovoltaic Cell With Concentrating Collector—A Review. Int. J. Eng. Res. Technol. 2013, 2, 1–8.

- Mangherini, G.; Bernardoni, P.; Baccega, E.; Andreoli, A.; Diolaiti, V.; Vincenzi, D. Design of a Ventilated Façade Integrating a Luminescent Solar Concentrator Photovoltaic Panel. Sustainability 2023, 15, 9146.

- Paul, D.I. Experimental Characterisation of Photovoltaic Modules with Cells Connected in Different Configurations to Address Nonuniform Illumination Effect. J. Renew. Energy 2019, 2019, 5168259.

- Michael, J.J.; Iqbal, S.M.; Iniyan, S.; Goic, R. Enhanced Electrical Performance in a Solar Photovoltaic Module Using V-Trough Concentrators. Energy 2018, 148, 605–613.

- Aste, N.; Del Pero, C.; Tagliabue, L.C.; Leonforte, F.; Testa, D.; Fusco, R. Performance Monitoring and Building Integration Assessment of Innovative LSC Components. In Proceedings of the 2015 International Conference on Clean Electrical Power (ICCEP), Taormina, Italy, 16–18 June 2015; pp. 129–133.

- Elsaid, K.; Taha Sayed, E.; Yousef, B.A.A.; Kamal Hussien Rabaia, M.; Ali Abdelkareem, M.; Olabi, A.G. Recent Progress on the Utilization of Waste Heat for Desalination: A Review. Energy Convers. Manag. 2020, 221, 113105.

- Iqbal, A.; Mahmoud, M.S.; Sayed, E.T.; Elsaid, K.; Abdelkareem, M.A.; Alawadhi, H.; Olabi, A.G. Evaluation of the Nanofluid-Assisted Desalination through Solar Stills in the Last Decade. J. Environ. Manag. 2021, 277, 111415.

- Tadeu, S.; Rodrigues, C.; Tadeu, A.; Freire, F.; Simões, N. Energy Retrofit of Historic Buildings: Environmental Assessment of Cost-Optimal Solutions. J. Build. Eng. 2015, 4, 167–176.

- Micheli, L.; Sarmah, N.; Luo, X.; Reddy, K.S.; Mallick, T.K. Opportunities and Challenges in Micro- and Nano-Technologies for Concentrating Photovoltaic Cooling: A Review. Renew. Sustain. Energy Rev. 2013, 20, 595–610.

- Li, G.; Xuan, Q.; Akram, M.W.; Golizadeh Akhlaghi, Y.; Liu, H.; Shittu, S. Building Integrated Solar Concentrating Systems: A Review. Appl. Energy 2020, 260, 114288.

- Sarmah, N.; Mallick, T.K. Design, Fabrication and Outdoor Performance Analysis of a Low Concentrating Photovoltaic System. Sol. Energy 2015, 112, 361–372.

- Pagliaro, M.; Ciriminna, R.; Palmisano, G. BIPV: Merging the Photovoltaic with the Construction Industry. Prog. Photovolt. Res. Appl. 2010, 18, 61–72.

- Debije, M.G.; Verbunt, P.P.C. Thirty Years of Luminescent Solar Concentrator Research: Solar Energy for the Built Environment. Adv. Energy Mater. 2012, 2, 12–35.

- Makki, A.; Omer, S.; Sabir, H. Advancements in Hybrid Photovoltaic Systems for Enhanced Solar Cells Performance. Renew. Sustain. Energy Rev. 2015, 41, 658–684.

- Li, M.; Ji, X.; Li, G.; Wei, S.; Li, Y.F.; Shi, F. Performance Study of Solar Cell Arrays Based on a Trough Concentrating Photovoltaic/Thermal System. Appl. Energy 2011, 88, 3218–3227.

- Cuce, E.; Cuce, P.M. Improving Thermodynamic Performance Parameters of Silicon Photovoltaic Cells via Air Cooling. Int. J. Ambient Energy 2014, 35, 193–199.

- Mellor, A.; Alonso Alvarez, D.; Guarracino, I.; Ramos, A.; Riverola Lacasta, A.; Ferre Llin, L.; Murrell, A.J.; Paul, D.J.; Chemisana, D.; Markides, C.N.; et al. Roadmap for the Next-Generation of Hybrid Photovoltaic-Thermal Solar Energy Collectors. Sol. Energy 2018, 174, 386–398.

- Cabral, D. Development and Performance Comparison of a Modified Glazed CPC Hybrid Solar Collector Coupled with a Bifacial PVT Receiver. Appl. Energy 2022, 325, 119653.

- Bazilian, M.D.; Leenders, F.; Van Der Ree, B.G.C.; Prasad, D. Photovoltaic Cogeneration in the Built Environment. Sol. Energy 2001, 71, 57–69.

- Bakker, M.; Zondag, H.A.; Elswijk, M.J.; Strootman, K.J.; Jong, M.J.M. Performance and Costs of a Roof-Sized PV/Thermal Array Combined with a Ground Coupled Heat Pump. Sol. Energy 2005, 78, 331–339.

- Yang, T.; Athienitis, A.K. A Study of Design Options for a Building Integrated Photovoltaic/Thermal (BIPV/T) System with Glazed Air Collector and Multiple Inlets. Sol. Energy 2014, 104, 82–92.

- Jalalizadeh, M.; Fayaz, R.; Delfani, S.; Mosleh, H.J.; Karami, M. Dynamic Simulation of a Trigeneration System Using an Absorption Cooling System and Building Integrated Photovoltaic Thermal Solar Collectors. J. Build. Eng. 2021, 43, 102482.

- Ge, M.; Zhao, Y.; Xuan, Z.; Zhao, Y.; Wang, S. Experimental Research on the Performance of BIPV/T System with Water-Cooled Wall. Energy Rep. 2022, 8, 454–459.

- Kane, A.; Verma, V.; Singh, B. Optimization of Thermoelectric Cooling Technology for an Active Cooling of Photovoltaic Panel. Renew. Sustain. Energy Rev. 2017, 75, 1295–1305.

- Kossyvakis, D.N.; Voutsinas, G.D.; Hristoforou, E.V. Experimental Analysis and Performance Evaluation of a Tandem Photovoltaic-Thermoelectric Hybrid System. Energy Convers. Manag. 2016, 117, 490–500.

- Elsaid, K.; Abdelkareem, M.A.; Maghrabie, H.M.; Sayed, E.T.; Wilberforce, T.; Baroutaji, A.; Olabi, A.G. Thermophysical Properties of Graphene-Based Nanofluids. Int. J. Thermofluids 2021, 10, 100073.

- Maghrabie, H.M.; Elsaid, K.; Sayed, E.T.; Abdelkareem, M.A.; Wilberforce, T.; Ramadan, M.; Olabi, A.G. Intensification of Heat Exchanger Performance Utilizing Nanofluids. Int. J. Thermofluids 2021, 10, 100071.

- Alami, A.H. Effects of Evaporative Cooling on Efficiency of Photovoltaic Modules. Energy Convers. Manag. 2014, 77, 668–679.

- Chandrasekar, M.; Senthilkumar, T. Passive Thermal Regulation of Flat PV Modules by Coupling the Mechanisms of Evaporative and Fin Cooling. Heat Mass Transf. 2016, 52, 1381–1391.

- Pandey, A.K.; Hossain, M.S.; Tyagi, V.V.; Abd Rahim, N.; Selvaraj, J.A.L.; Sari, A. Novel Approaches and Recent Developments on Potential Applications of Phase Change Materials in Solar Energy. Renew. Sustain. Energy Rev. 2018, 82, 281–323.

- Stropnik, R.; Stritih, U. Increasing the Efficiency of PV Panel with the Use of PCM. Renew. Energy 2016, 97, 671–679.

- Rezk, H.; AL-Oran, M.; Gomaa, M.R.; Tolba, M.A.; Fathy, A.; Abdelkareem, M.A.; Olabi, A.G.; El-Sayed, A.H.M. A Novel Statistical Performance Evaluation of Most Modern Optimization-Based Global MPPT Techniques for Partially Shaded PV System. Renew. Sustain. Energy Rev. 2019, 115, 109372.

- Knoop, M.; Stefani, O.; Bueno, B.; Matusiak, B.; Hobday, R.; Wirz-Justice, A.; Martiny, K.; Kantermann, T.; Aarts, M.P.J.; Zemmouri, N.; et al. Daylight: What Makes the Difference? Light. Res. Technol. 2020, 52, 423–442.

- Quek, G.; Wienold, J.; Khanie, M.S.; Erell, E.; Kaftan, E.; Tzempelikos, A.; Konstantzos, I.; Christoffersen, J.; Kuhn, T.; Andersen, M. Comparing Performance of Discomfort Glare Metrics in High and Low Adaptation Levels. Build. Environ. 2021, 206, 108335.

- Ghosh, A.; Norton, B. Interior Colour Rendering of Daylight Transmitted through a Suspended Particle Device Switchable Glazing. Sol. Energy Mater. Sol. Cells 2017, 163, 218–223.

- Wienold, J.; Christoffersen, J. Evaluation Methods and Development of a New Glare Prediction Model for Daylight Environments with the Use of CCD Cameras. Energy Build. 2006, 38, 743–757.

- Wienold, J.; Iwata, T.; Sarey Khanie, M.; Erell, E.; Kaftan, E.; Rodriguez, R.G.; Yamin Garreton, J.A.; Tzempelikos, T.; Konstantzos, I.; Christoffersen, J.; et al. Cross-Validation and Robustness of Daylight Glare Metrics. Light. Res. Technol. 2019, 51, 983–1013.

- Nabil, A.; Mardaljevic, J. Useful Daylight Illuminances: A Replacement for Daylight Factors. Energy Build. 2006, 38, 905–913.

- Tait, D.B. Solar Heat Gain Coefficients for High-Mass Glazing Blocks. ASHRAE Trans. 2006, 112, 9.

- Kralj, A.; Drev, M.; Žnidaršič, M.; Černe, B.; Hafner, J.; Jelle, B.P. Investigations of 6-Pane Glazing: Properties and Possibilities. Energy Build. 2019, 190, 61–68.

- Buratti, C.; Belloni, E.; Merli, F.; Zinzi, M. Aerogel Glazing Systems for Building Applications: A Review. Energy Build. 2021, 231, 110587.

- Ghosh, A.; Norton, B.; Duffy, A. Effect of Sky Clearness Index on Transmission of Evacuated (Vacuum) Glazing. Renew. Energy 2017, 105, 160–166.

- Santbergen, R.Ã.; Zolingen, R.J.C. Van The Absorption Factor of Crystalline Silicon PV Cells: A Numerical and Experimental Study. Sol. Energy Mater. Sol. Cells 2008, 92, 432–444.

- Bati, A.S.R.; Zhong, Y.L.; Burn, P.L.; Nazeeruddin, M.K.; Shaw, P.E.; Batmunkh, M. Next-Generation Applications for Integrated Perovskite Solar Cells. Commun. Mater. 2023, 4, 2.

- Wang, Y.; Chen, Q.; Liu, Z.; Yu, F.; Su, W.; Cai, Z.; Guan, W.; Li, Y.; Sheng, L.; Qi, Z.; et al. Acidochromic Organic Photovoltaic Integrated Device. Chem. Eng. J. 2023, 452, 139479.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

956

Revisions:

2 times

(View History)

Update Date:

11 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No