Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Honglin Liu | -- | 1870 | 2023-10-07 04:35:11 | | | |

| 2 | Camila Xu | Meta information modification | 1870 | 2023-10-07 04:52:49 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ju, J.; Liu, H.; Hu, H.; Hang, Y.; Shan, C.; Wang, H. Control Technology for a Geological Bedding Bias Tunnel. Encyclopedia. Available online: https://encyclopedia.pub/entry/49893 (accessed on 07 February 2026).

Ju J, Liu H, Hu H, Hang Y, Shan C, Wang H. Control Technology for a Geological Bedding Bias Tunnel. Encyclopedia. Available at: https://encyclopedia.pub/entry/49893. Accessed February 07, 2026.

Ju, Jinmao, Honglin Liu, Hongqian Hu, Yinjian Hang, Chengfang Shan, Hongzhi Wang. "Control Technology for a Geological Bedding Bias Tunnel" Encyclopedia, https://encyclopedia.pub/entry/49893 (accessed February 07, 2026).

Ju, J., Liu, H., Hu, H., Hang, Y., Shan, C., & Wang, H. (2023, October 07). Control Technology for a Geological Bedding Bias Tunnel. In Encyclopedia. https://encyclopedia.pub/entry/49893

Ju, Jinmao, et al. "Control Technology for a Geological Bedding Bias Tunnel." Encyclopedia. Web. 07 October, 2023.

Copy Citation

The Baishitou Tunnel of the Dali–Lincang railway project is a weakly cemented surrounding rock tunnel with geological bedding bias. The deformation of the surrounding rock on the side with the greatest stress is nearly 1 m, which seriously affects construction progress and significantly increases construction cost. In order to achieve the goal of safe, efficient, economic, and socially sustainable development in tunnel construction, it is necessary to study the large deformation of weakly cemented surrounding rock in the geological bedding bias tunnel.

weakly cemented surrounding rock

geological bedding bias

yielding anchor bolt

numerical simulation

1. Introduction

With the continuous advancement of China’s western development strategy, in order to meet the needs of China’s traffic growth and improve people’s travel conditions, road traffic construction continues to extend to some remote mountainous areas. The geological conditions for engineering are worsening, and the construction difficulty is increasing, requiring the construction of a large number of bridges and tunnels [1]. The mountainous area in southwest Yunnan is known as the Geological Museum of China. The geological conditions are complex, and construction is difficult. Various geological problems emerge, such as large deformations of weakly cemented surrounding rock, mud and water inrush, geological bedding bias, high ground stress, and other geological problems [2][3][4]. The joints and cracks develop in the weakly cemented surrounding rock, and the disturbance from engineering makes the joints and cracks of the surrounding rock more developed. The soft rock containing montmorillonite expands when it encounters water, resulting in greater expansion pressure on the supporting body. Due to its characteristics of water softening, rheology, and low rock strength, the deformation of the surrounding rock becomes particularly large after the engineering exposure, and it weathers easily and is difficult to support. Hazards such as initial support deformation, collapse, and secondary lining cracking occur [5][6][7][8][9], leading to a slow construction progress and increased construction costs, and threatening the safety of personnel and equipment. Sometimes, unoccupied airborne systems (UASs), also known as drones, must be used for construction management [10].

At present, the large deformation control of weakly cemented surrounding rock has become a hot research topic in the engineering field. Yu et al. [11] studied different lateral pressure coefficients (λ), namely the angle between the roadway and the maximum horizontal principal stress (α) and the impact of typical lithological combinations on the deformation of weakly cemented roadway surrounding rocks. Liu et al. [12] used the 11,303 return air road of the Hongqingliang coal mine as the engineering background to study the influence of tunnel structural morphology on stress distribution characteristics and stability of weakly cemented soft rock tunnels, the stress and deformation evolution law of weakly cemented soft rock tunnels, and the plastic zone of top and bottom coal seam support. Vrettos, C. et al. [13] applied the available numerical analysis method of lateral two-dimensional response to the case study of stations and inter station tunnels on subway lines in seismic regions. Two continuum methods were considered: (a) time-domain dynamic finite element analysis and (b) quasi-static analysis. The cross-sectional force is determined for typical seismic vibrations. They are compared with each other and compared with the results obtained from the static design of excavation support. According to different deformation mechanisms, the large deformation of weakly cemented surrounding rock can be divided into two types: plastic extrusion type and water expansion type. The large deformation of weakly cemented surrounding rock in Baishitou Tunnel of the Dali–Lincang railway project is the plastic extrusion type, that is, the extrusion deformation of surrounding rock due to the force exceeding its strength [14][15][16]. At present, the traditional methods used to solve large deformation of weakly cemented surrounding rock mainly include increasing the reserve amount, increasing the support strength, and changing the excavation method [17][18][19][20]. In the past, most of the supporting means were passive.

At the same time, in the construction process of Baishitou Tunnel of the Dali–Lincang railway project, the problem of geological bedding bias generally occurs, which leads to strong pressure on one side of the tunnel and increased displacement. The initial support penetration limit and shotcrete falling block often occur in the positions where geological bedding bias is serious, thus increasing the difficulty of tunnel support [21][22]. The influence of geological bedding bias pressure is more pronounced in weakly cemented surrounding rock tunnels. Geological bedding bias has also been a hot issue in the field of engineering construction, and it needs to be solved urgently. Ge et al. [23] took the Qijiazhuang Tunnel as the research object, and they used the discrete element method to analyze the results of the stress, vertical displacement, and surface deformation of the surrounding rock of the geological bedding bias tunnel under different working conditions as well as the mechanism of system anchor support from a microscopic perspective. YanLi et al. [24] proposed a comprehensive method that combines monitoring technology with discrete element analysis (3DEC) numerical simulation to analyze the deformation characteristics of layered-rock tunnel-surrounding rock and the deformation laws of bias tunnels. Wu et al. [25] took the Wuduxi Tunnel as an engineering example to study the failure behavior and surrounding rock deformation mechanism of the support structure of a deeply buried geological bedding bias tunnel. Hu et al. [26] investigated the mechanical properties of surrounding rock and supporting structure of a shallow-buried bias tunnel crossing the soil–rock interface using a combination of model tests and numerical simulations. Guo et al. [27] analyzed the overall stability and instability failure mechanism of the shallow tunnel under unsymmetrical pressure during the operation period by using the strength reduction method in light of the operational safety of the tunnel, proposed a reasonable monitoring strategy, and also constructed a monitoring index system. Ma et al. [28] conducted a numerical study of the influence of karst caves on tunnel stability using the Discrete Lattice Spring Model (DLSM).

2. Engineering Background

The Baishitou Tunnel of the Dali–Lincang railway project, located in the mountainous area of southwest Yunnan Province, has complex geological conditions, with many geological folds, and the unfavorable geology mainly includes geological bedding pressure, radioactivity, harmful gases, etc. The strata in the section DK161 + 960~DK167 + 60 are mainly schist with carbonaceous schist and chlorite schist, belonging to the class Ⅳ weakly cemented surrounding rock. The total length of the tunnel is 9375 m, and the maximum buried depth is about 300 m. The angle between the rock strike and the line is 2~28° < 30°, with an apparent inclination angle of 25~52°. The rock dip angle is in the range of 20~70°, and there is geological bedding bias on the right side of the tunnel.

The Baishitou Tunnel is designed according to Grade V surrounding rock, and the construction method of three bench reserved core soil is adopted. The support parameters during construction are steel frame with a full-ring I20b steel frame, and the distance is 0.6 m. The arch part is φ25 combined hollow bolt, the length is 5 m, the side wall is φ22 mortar bolt, the length is 5 m, and the longitudinal and circumferential spacing is 1.0 m.

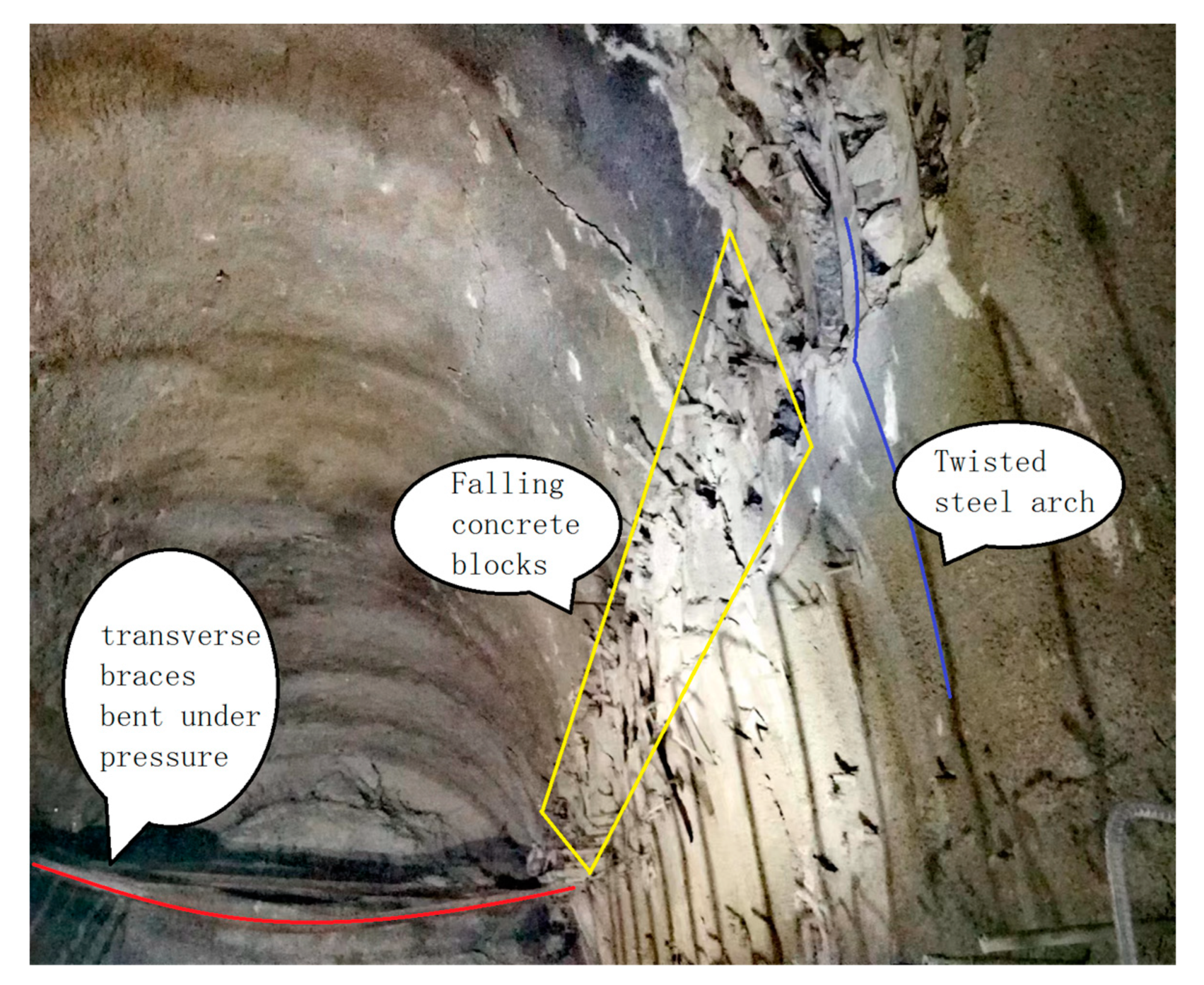

After the construction of the main tunnel began, the deformation of the surrounding rock was significant, and the added transverse braces were severely bent. The right steel arch frame of the line was seriously twisted, and concrete blocks from the initial support fell off, as shown in Figure 1. The maximum convergence point could reach 1 m, and the convergence could reach about 8 cm per day.

Figure 1. Deformation of initial support.

3. Surrounding Rock Monitoring

3.1. Results of Initial Support Stress Monitoring

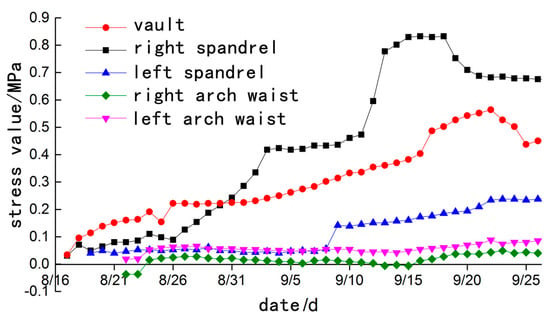

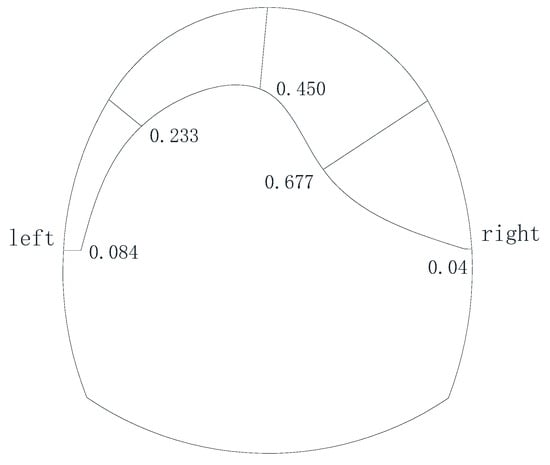

At the DK163 + 720 mileage of the tunnel, using a YH-45 pressure box for initial support stress monitoring, an initial support stress monitoring section was arranged. When each step of the tunnel was excavated to this section, technicians installed five pressure boxes between the arch and surrounding rock of this section, respectively located at the vault, left and right spandrels, and left and right arch waists of this section. The pressure box data were recorded daily, and the statistical results of the stress between the surrounding rock and the initial support of the monitoring section are shown in Figure 2. As can be seen from Figure 2, when the upper step was excavated on August 16, the pressure boxes located at the arch and at the left and right spandrels were buried. After that, the surrounding rock pressure gradually increased, especially the arch pressure, with a faster growth rate. On 22 August, when the middle step was excavated, the pressure box of the left and right arch waists was buried. The surrounding rock pressure continued to increase, but the pressure on the right side increased significantly faster, showing a bias characteristic. From the excavation of the lower step on 9 September to the excavation of the invert on 14 September, the pressure on the right spandrel increased in steps to a maximum of 0.832 MPa, resulting in a sharp bias, which led to a large deformation of the steel arch, and the initial support began to violate the limit. After 54 days of tunnel excavation, the pressure reached a stable value. By 26 September, the stress was distributed between the surrounding rock of the tunnel section and the initial branch, as shown in Figure 3. The surrounding rock pressure on the vault and left and right spandrels of the tunnel was relatively high. At the same time, the surrounding rock pressure was severely affected by the tunnel bedding bias. The pressure on the right spandrel reached 0.677 MPa, which is significantly greater than the pressure on the left spandrel of 0.233 MPa, and the pressure value on the vault was 0.450 MPa.

Figure 2. Variation of stress change between surrounding rock and initial support of DK163 + 720 section.

Figure 3. Distribution of stress between surrounding rock and initial support of DK163 + 720 section as of 26 September (unit/MPa).

3.2. Monitoring Measurement Results

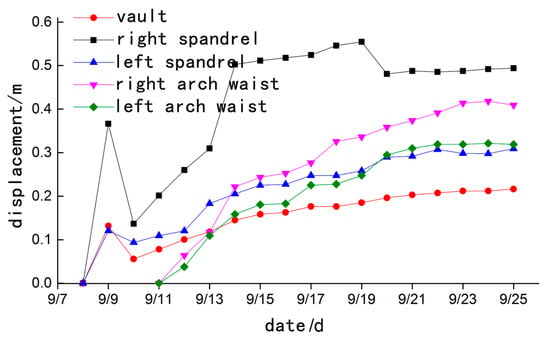

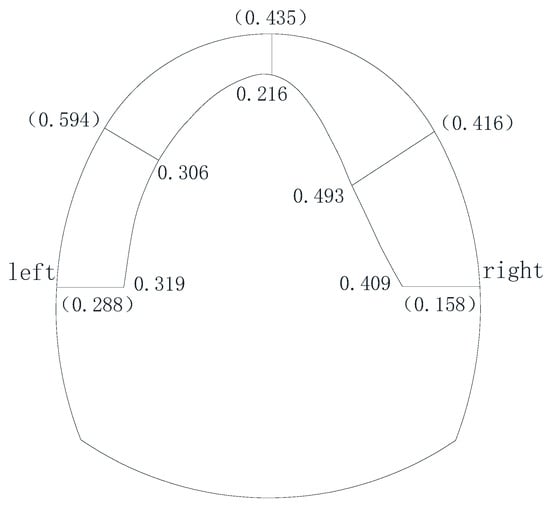

Surveyors used the GM-101/102 total station to monitor and measure the DK163 + 720 section of the tunnel every day, and they obtained the displacement values of the five measuring points of the vault, left and right spandrels, and left and right arch waists of this section as they changed over time, as shown in Figure 4. From Figure 4, one can see the displacements of the vault and left and right spandrels began to be detected on 8 September, and abnormal fluctuations occurred on 9 September when the lower step was excavated, and the data were stable on 10 September. However, the deformation of the right spandrel was larger than that of the left, and then the deformation increased steadily. On 11 September, monitoring of the displacement of the left and right arch waist measurement points began. On 14 September, the invert excavation showed that the deformation of the tunnel-surrounding rock increased sharply, and the deformation of the right spandrel reached a maximum of 0.53 m. The deformation distribution of the initial branch of the DK163 + 720 section as of 25 September is shown in Figure 5. Affected by its low strength, the weakly cemented surrounding rock had the characteristics of fast deformation speed and large deformation amount. At the same time, the surrounding rock was severely affected by geological bedding bias, with the deformation of the right spandrel reaching 0.493 m, which is significantly greater than the deformation of the left spandrel of 0.306 m, while the subsidence of the vault was relatively small, reaching 0.216 m.

Figure 4. Variation of displacement of measuring points on the DK163 + 720 section over time.

Figure 5. Distribution of initial support deformation of DK163 + 720 section as of 25 September (unit/m).

References

- Gijzel, D.; Bosch-Rekveldt, M.; Schraven, D.; Hertogh, M. Integrating Sustainability into Major Infrastructure Projects: Four Perspectives on Sustainable Tunnel Development. Sustainability 2019, 12, 6.

- Huang, K.; Opdyke, N.D. Paleomagnetic Results from Cretaceous and Jurassic Rocks of South and Southwest Yunnan: Evidence for Large Clockwise Rotations in the Indochina and Shan-Thai-Malay Terranes. Earth Planet. Sci. Lett. 1993, 117, 507–524.

- Shubing, W.; Yuzhen, W.; Fuchu, J.; Guoqiang, T. Time of the Tengchong-Lianghe Movement in Southwest Yunnan. Acta Geol. Sin. Engl. Ed. 2015, 89, 674–675.

- Huang, L.; Ma, J.; Lei, M.; Liu, L.; Lin, Y.; Zhang, Z. Soil-Water Inrush Induced Shield Tunnel Lining Damage and Its Stabilization: A Case Study. Tunn. Undergr. Space Technol. 2020, 97, 103290.

- Yeh, P.-T.; Lee, K.Z.-Z.; Chang, K.-T. 3D Effects of Permeability and Strength Anisotropy on the Stability of Weakly Cemented Rock Slopes Subjected to Rainfall Infiltration. Eng. Geol. 2020, 266, 105459.

- Yu, W.; Wang, B.; Zi, X.; Guo, X.; Wang, Z. Effect of Prestressed Anchorage System on Mechanical Behavior of Squeezed Soft Rock in Large-Deformation Tunnel. Tunn. Undergr. Space Technol. 2023, 131, 104782.

- Zhang, H.; Li, Z.; Liu, L.; Liang, Z. Geometry-Based Mass Grading of Betelnut Using Image Processing. In Proceedings of the 2018 13th World Congress on Intelligent Control and Automation (WCICA), Changsha, China, 4–8 July 2018; pp. 1014–1019.

- Han, L.; Zuo, Y.; Guo, Z.; Zhang, L.; Chen, X.; Mao, J. Mechanical Properties and Deformation and Failure Characteristics of Surrounding Rocks of Tunnels Excavated in Soft Rocks. Geotech. Geol. Eng 2017, 35, 2789–2801.

- Zhang, H.; Chen, L.; Zhu, Y.; Zhou, Z.; Chen, S. Stress Field Distribution and Deformation Law of Large Deformation Tunnel Excavation in Soft Rock Mass. Appl. Sci. 2019, 9, 865.

- Zhang, S.; Bogus, S.M.; Lippitt, C.D.; Kamat, V.; Lee, S. Implementing Remote-Sensing Methodologies for Construction Research: An Unoccupied Airborne System Perspective. J. Constr. Eng. Manag. 2022, 148, 03122005.

- Yu, H.; Liu, H.; Xia, Y.; Zhang, M.; Hang, Y.; Luo, W. A Study on the Deformation Mechanism of the Rock Surrounding a Weakly Cemented Cross-Layer Roadway, under Tectonic Stress. Energies 2023, 16, 2546.

- Liu, Y.; Li, J.; Duan, Y.; Qin, T.; Liu, Z. Study on the Influence of Roadway Structural Morphology on the Mechanical Properties of Weakly Cemented Soft Rock Roadways. Sustainability 2023, 15, 821.

- Vrettos, C.; Chen, D.; Rizos, D. Fallstudie zur seismischen Auslegung der Stationen und der Tunnel einer U-Bahnlinie in weichem Boden. Bautechnik 2013, 90, 333–340.

- Nilsen, B. Cases of Instability Caused by Weakness Zones in Norwegian Tunnels. Bull. Eng. Geol. Env. 2011, 70, 7–13.

- Li, Y.; Ma, C.; Zhang, L.; Li, B. Influence Research for Softening and Swelling of Weakly Cemented Soft Rock on the Stability of Surrounding Rock in Roadway. Geofluids 2022, 2022, 6439277.

- Zhao, J.; Tan, Z.; Wang, W.; Yu, R.; Wang, J.; Li, Z. Study on the Large Deformation Control Technology of a Single-Hole Double-Track Railway Tunnel. Bull. Eng. Geol. Env. 2023, 82, 343.

- Li, Q.; Shi, W.; Yang, R. Deformation Mechanisms in a Coal Mine Roadway in Extremely Swelling Soft Rock. SpringerPlus 2016, 5, 1310.

- Hashemnejad, A.; Aghda, S.M.F.; Talkhablou, M. Introducing a New Classification of Soft Rocks Based on the Main Geological and Engineering Aspects. Bull. Eng. Geol. Env. 2021, 80, 4235–4254.

- Kang, H.P.; Lin, J.; Fan, M.J. Investigation on Support Pattern of a Coal Mine Roadway within Soft Rocks—A Case Study. Int. J. Coal Geol. 2015, 140, 31–40.

- Djizanne, H.; Zghondi, J.; Armand, G.; Conil, N.; De La Vaissière, R. Some Aspects of the Hydro-Mechanical Behaviour of Callovo-Oxfordian (COx) Claystone around a Gallery Parallel to the Principal Horizontal Minor Stress. Geomech. Energy Environ. 2019, 17, 3–15.

- Ma, J.; Chen, J.; Guan, J.; Lin, Y.; Chen, W.; Huang, L. Implementation of Johnson-Holmquist-Beissel Model in Four-Dimensional Lattice Spring Model and Its Application in Projectile Penetration. Int. J. Impact. Eng. 2022, 170, 104340.

- Ma, J.; Zhao, J.; Lin, Y.; Liang, J.; Chen, J.; Chen, W.; Huang, L. Study on Tamped Spherical Detonation-Induced Dynamic Responses of Rock and PMMA Through Mini-Chemical Explosion Tests and a Four-Dimensional Lattice Spring Model. Rock. Mech. Rock. Eng. 2023, 5, 1–19.

- Ge, C.; Su, L.; Wang, L.; Xu, S.; Yu, P. Discrete Element Simulation and Monitoring Analysis of Different Construction Methods of the Shallow Buried Bias Tunnel. Adv. Civ. Eng. 2022, 2022, 6759797.

- Yanli, Q.; Shaoquan, W.; Mingzhou, B.; Hai, S.; Pengxiang, L.; Hao, Z.; Bohu, H. Evaluation and Deformation Control Study on the Bias Pressure of Layered Rock Tunnels. Math. Probl. Eng. 2021, 2021, 9937678.

- Wu, H.; Fan, F.; Yang, X.; Wang, Z.; Lai, J.; Xie, Y. Large Deformation Characteristics and Treatment Effect for Deep Bias Tunnel in Broken Phyllite: A Case Study. Eng. Fail. Anal. 2022, 135, 106045.

- Hu, Z.; Zhang, J.; Wang, Y.; Wang, Y. Mechanical Behaviors of Surrounding Rock and Supporting Structure of Shallow-Buried Unsymmetrical Pressure Tunnel Crossing Soil–Rock Interface. Front. Earth Sci. 2023, 10, 1113430.

- Guo, H.; Liu, X.; Li, K.; Zhong, Z. Overall Instability Failure Mechanism and Monitoring Strategy Research of the Shallow Tunnel under Unsymmetrical Pressure during Operation Period. Adv. Mater. Sci. Eng. 2022, 2022, 3105787.

- Ma, J.; Guan, J.; Duan, J.; Huang, L.; Liang, Y. Stability Analysis on Tunnels with Karst Caves Using the Distinct Lattice Spring Model. Undergr. Space 2021, 6, 469–481.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

506

Revisions:

2 times

(View History)

Update Date:

07 Oct 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No