Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Muhammad Ali Butt | -- | 3686 | 2023-08-29 08:27:39 | | | |

| 2 | Dean Liu | -6 word(s) | 3680 | 2023-08-30 02:33:51 | | | | |

| 3 | Dean Liu | Meta information modification | 3680 | 2023-09-06 03:45:20 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A. Optical Fibre-Based Sensors. Encyclopedia. Available online: https://encyclopedia.pub/entry/48570 (accessed on 04 March 2026).

Khonina SN, Kazanskiy NL, Butt MA. Optical Fibre-Based Sensors. Encyclopedia. Available at: https://encyclopedia.pub/entry/48570. Accessed March 04, 2026.

Khonina, Svetlana N., Nikolay L. Kazanskiy, Muhammad A. Butt. "Optical Fibre-Based Sensors" Encyclopedia, https://encyclopedia.pub/entry/48570 (accessed March 04, 2026).

Khonina, S.N., Kazanskiy, N.L., & Butt, M.A. (2023, August 29). Optical Fibre-Based Sensors. In Encyclopedia. https://encyclopedia.pub/entry/48570

Khonina, Svetlana N., et al. "Optical Fibre-Based Sensors." Encyclopedia. Web. 29 August, 2023.

Copy Citation

Optical fibre sensors are an essential subset of optical fibre technology, designed specifically for sensing and measuring several physical parameters. These sensors offer unique advantages over traditional sensors, making them gradually more valuable in a wide range of applications. They can detect extremely small variations in the physical parameters they are designed to measure, such as analytes in the case of biosensing.

optical fibre

biosensing

photonic sensor

plastic optical fibre

1. Introduction

Over the past 30 years, there has been a significant advancement in research on chemical and biological sensors [1]. For environmental, clinical, or security purposes, much of this research is now being conducted on the development of systems that can detect many analytes in a single sample [2][3][4]. The ability of optical sensors to probe surface coatings utilizing a variety of optical phenomena while attaining low noise and high sensitivity gives them considerable promise in this area [5]. They also allow for in situ sensing and real-time measurements and offer benefits in terms of speed. Miniaturization, remote sensing, and multi-analyte sensing are supplementary applications for optical sensors [5][6][7][8]. In comparison to electrical transduction systems, optical sensor systems have a reduced likelihood of producing an explosion in a hazardous environment and are thus freer from electromagnetic (EM) interference [9]. As a result, concerning other sensing systems, optical biosensors have a few benefits over laboratory-based systems [10][11][12].

Fibre optics makes use of the total internal reflection (TIR) concept, which allows for a correlation between the light intensity assessed at the detector and the initial target concentration [5]. For interaction with the target analyte, bio-receptors, for example, oligonucleotides, antibodies, and enzymes, can be immobilized on the core surface of the fibre [13]. Following the establishment of a reference standard curve, this interaction will affect the sensitive layer’s characteristics and be associated with the analyte concentration. Fibre optic biosensors have the advantages of high sensitivity, resistance, rapid detection, high sensitivity, and real-time monitoring and are unaffected by EM interference [5]. These qualities help fibre optic biosensors work well; because they can concurrently and discretely direct light of several wavelengths, they may be utilized for several analyte detections utilizing various DNA probes [14][15].

Optical fibre sensing techniques take advantage of the interaction between light and the fibre’s properties to enable accurate and reliable measurements. Some of the optical fibre sensors that work on different mechanisms, include fibre Bragg grating sensors (FBGs), Fabry–Perot sensors, interferometric fibre sensors, Raman scattering-based sensors, Brillouin scattering-based sensors, optical time-domain reflectometry (OTDR), polarimetric sensors, evanescent wave sensors, and optical frequency domain reflectometry (OFDR).

FBGs are periodic variations in the refractive index of an optical fibre’s core. When exposed to changes in strain or temperature, the Bragg wavelength (the wavelength of light that is reflected) shifts [16]. This shift is used to measure strain, temperature, pressure, and other parameters.

Fabry–Perot interferometers use a partially reflective surface (usually a thin film) to create an interference pattern between incoming and reflected light. Changes in the gap between the reflecting surfaces due to strain, pressure, or temperature variations lead to changes in the interference pattern, which can be measured to determine the parameter being sensed [17].

Interferometric fibre sensors use interference patterns in the light that travels through the optical fibre. This can include Mach–Zehnder interferometers and Michelson interferometers, where changes in the fibre’s properties cause phase shifts in the interfering light waves [18].

Raman scattering occurs when light interacts with molecules in the fibre, leading to a shift in wavelength proportional to temperature or strain. By analyzing this shift, temperature or strain can be measured along the fibre length. Brillouin scattering involves the interaction between light and acoustic waves in the fibre. The frequency shift of the scattered light provides information about temperature and strain changes along the fibre [19].

Optical time-domain reflectometry (OTDR) is a technique that uses backscattered light to measure the properties of an optical fibre. It is commonly used for distributed sensing of events like fibre breaks and bends [20].

Polarimetric sensors measure changes in the polarization state of light travelling through an optical fibre [21]. Changes in temperature, strain, or other parameters can alter the polarization, allowing these quantities to be determined.

Evanescent wave sensors exploit a small fraction of light that extends beyond the core of an optical fibre. By allowing this light to interact with the surrounding environment, changes in refractive index due to external factors can be measured [22].

Optical frequency domain reflectometry (OFDR) measures the frequency response of an optical fibre along its length. This technique provides high-resolution measurements of various parameters, including strain and temperature [23].

These techniques offer different levels of sensitivity, spatial resolution, and suitability for various applications. Fibre sensing technology continues to evolve, leading to innovations in sensor design and performance.

Optical fibre biosensors have undergone significant advances in recent years, offering numerous benefits for various applications [24][25]. Researchers have made substantial progress in improving the sensitivity and detection limits of optical fibre biosensors. This has been achieved through the development of novel sensing mechanisms, such as surface plasmon resonance (SPR) and localized surface plasmon resonance (LSPR), which enable extremely sensitive recognition of analytes at minimal concentrations [26][27]. Functionalization techniques have evolved to enhance the selectivity and specificity of optical fibre biosensors [28]. Various methods, such as immobilizing specific biomolecules on the fibre surface or incorporating functional nanomaterials, enable targeted detection of analytes, including proteins, DNA, and pathogens [10].

Miniaturization is a key area of advancement in optical fibre-based sensors. Researchers have been able to fabricate miniature optical fibres with diameters as small as a few micrometres, allowing for integration into microfluidic devices and other compact systems [29]. Miniaturization enhances portability, facilitates point-of-care testing, and enables in vivo sensing [30]. Progress in optical fibre biosensors has enabled the development of multiplexed sensing platforms [31][32]. By incorporating multiple sensing elements or using different sensing principles within a single fibre, it is now possible to detect multiple analytes simultaneously. This has applications in medical diagnostics, environmental monitoring, and food safety [33]. Improving the stability and biocompatibility of optical fibre biosensors is crucial for their integration into biological systems. Researchers have established coatings and surface modifications that boost sensor stability, reduce biofouling, and minimize interactions with biological samples, ensuring reliable and long-term operation [34][35][36].

Optical fibre biosensors now offer real-time monitoring and imaging competences. By integrating imaging fibres or utilizing optical coherence tomography (OCT) techniques, researchers can envisage and track biological processes and dynamic fluctuations in analyte concentrations in real time [37]. Optical fibre-based biosensors can be integrated with lab-on-a-chip systems, allowing for the creation of compact, portable, and highly efficient sensing platforms. This integration enables sample handling, processing, and analysis in a single device, simplifying the overall sensing process. These sensors find applications in various fields, including biomedicine and environmental monitoring. They are used for detecting biomarkers in bodily fluids, monitoring drug levels in patients, assessing water quality, and detecting pollutants in the environment [11].

These advances in optical fibre-based sensors hold great potential for enhancing diagnostic capabilities, enabling real-time monitoring, and improving the accuracy and efficiency of biological and environmental sensing applications. Two fundamental strategies can be taken into consideration depending on how the fibre waveguide’s structure is being optimized. The first involves varying the properties of the inner guiding wave using a particular kind of optical fibre as a probe. The second method involves applying additional handling and processing to the optical fibre’s structure to alter the guiding wave shape. Since optical fibre is so widely used, multi-mode fibre (MMF) [38] and single-mode fibre (SMF) [39] have been combined into a single fibre structure to significantly lower the cost of sensing devices. Conversely, numerous special fibre structures with fabricating properties, a controllable mode, and ease of integration, including polymer optical fibre (POF) [40], multi-core fibre (MCF) [41], photonic crystal fibre (PCF) [42], and hollow core fibre (HCF) [43][44][45], among others, have been suggested and manufactured for a variety of plasmon detection purposes.

It is challenging for evanescence waves to reach the cladding surface because incident light travels in the fibre’s core, which is enclosed inside the cladding. Due to this, it is commonly required to modify the fibre optic structure’s shape using a unique processing technique to disrupt the original optical transmission mode. In recent years, a growing number of fibre architectures, including the fibre grating structure [16][46], tapered optical fibre (TOF) [47], D-shaped fibre [48], and U-shaped fibre [49][50], have entered the scene. Appropriately specialized optical fibre processing machinery is required to realize these various optical fibre architectures.

Optical fibre-based plasmonic sensors offer several advantages over traditional fibre sensors, such as high sensitivity, miniaturization, remote sensing capabilities, and the ability to perform real-time monitoring [1]. They find applications in several fields, including environmental monitoring, biomedical diagnostics, food safety, and chemical analysis. It is important to note that the development and implementation of optical fibre-based plasmonic sensors involves complex engineering and fabrication methods. Additionally, the choice of plasmonic materials, sensing elements, and detection methods can vary depending on the specific application requirements. The sensitivity and specificity of plasmonic sensors for low-dose analyte detection must be better due to the growing demand for sensor applications, principally in life science, clinical diagnostics, medicine, and food safety. SPR/LSPR technology in the detection system has thus been focused on increasing sensitivity and detection range. A light source, fibre probe, and spectrometer are the typical components of an SPR/LSPR-based fibre analyte system. The evanescence waves generated by the light flow stimulate SPs at the interface between the metal layer and the sensor layer. The greatest coupling effectiveness between the evanescent field and surface plasmon waves depends significantly on the light wavelength, probe geometry, fibre parameters, and metal layer properties. Considering the aforementioned problems, optimizing the fibre waveguide’s shape and the immobilization effects of the coating materials are the two most effective ways to improve the sensing performance of SPR/LSPR sensors [51][52][53].

2. Optical Fibre-Based Sensor Market and Implications

Since the 1980s, the use of fibre-optic sensors has steadily expanded across a range of applications. The underlying sectors have seen considerable advancements in distributed fibre-optic sensors, which provide continuous and real-time measurements over the whole length of an optical fibre cable [54]. Distributed fibre-optic sensors have substantial value throughout a well’s life cycle and may monitor pipelines that carry hydrocarbons over long distances in the oil and gas industry [55]. Distributed fibre optic sensors have several advantages over traditional electromechanical-based sensors used in the environmental, mining, civil, and geo-energy fields, particularly for harsh and difficult-to-access conditions [54][56][57][58]. These advantages include light weight, small size, electromagnetic interference immunity, remote detection, resistance to high pressure and high temperature, multiplexing, and smart sensing. Due to these factors, distributed fibre optic sensors are an optimum solution for displaying temperature, micro-seismic, and minor deformation changes caused by geologic CO2 sequestration over vast distances.

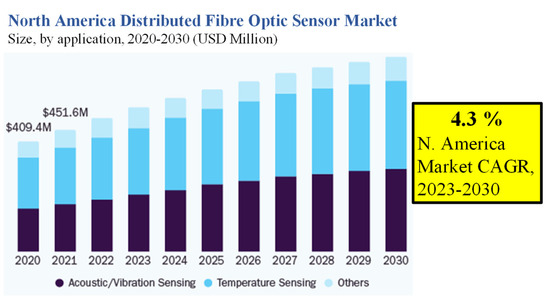

The market for distributed fibre optic sensors was estimated at USD 1.44 billion in 2022, and from 2023 to 2030, it is anticipated to rise at a CAGR of 6.8% [59]. The market is seeing development prospects due to the increasing demand from businesses and companies to perform efficient sensing operations on their machine systems, as shown in Figure 1. Fibre optic sensing is now extensively used in a variety of commercial fields, including the automobile, aircraft, civil, energy, and other industries [60][61][62]. Rayleigh’s effect-based and Raman effect-based sensing are two more types of sensing technologies that have unique operating properties.

Figure 1. North America Distributed Fibre Optic Sensor Market [59].

Distributed fibre optic sensors (DFOS) are very functional, which is driving more businesses to invest in technology and conduct R&D activities [63]. This leads to the creation of new items, giving businesses the chance to increase their industry share. Businesses want to improve productivity and control efficiency so that fibre optics technology will prevail over all alternatives. The high cost of DFOS product deployment and installation encourages businesses to create more dependable, competitively priced optic inspection devices.

By performing quality inspections of accuracy, range, and resolution, technologies like optical time domain reflectometry (OTDR) and optical frequency domain reflectometry (OFDR) now characterize fibre optics in the industry. Other notable changes include the use of cutting-edge technology like real-time thermal rating (RTTR) and intelligent distributed acoustic sensor (iDAS) technologies. The industry is seeing an increase in expenditures for R&D to produce revolutionary fibre cables and offer dependable connections at high speed and the most affordable pricing [64].

Optical fibre sensors are known for their high sensitivity. They can detect even small changes in physical variables such as temperature, pressure, strain, or refractive index [41]. This makes them valuable in various applications where precise measurements are required. Unlike traditional electronic sensors, optical fibre sensors are immune to EM interference. This property is particularly advantageous in environments with high electromagnetic noise, such as industrial settings or areas with strong radio frequencies. One of the key market drivers is the technology’s ability to provide top performance in difficult-end applications. Professionals can monitor and manage large-scale activities employed in pipeline construction, border security, and civil engineering thanks to optical fibres. Due to its high transmission capacity, the use of fibre optic cables provides businesses with better cost-saving potential than metal wires [65]. Companies are more likely to use the technology when it is deployed because of its high efficiency and fast transmission capabilities in remote and inaccessible locations.

In particular, the unique characteristics of optical fibre sensors make them indispensable in a wide range of industries, including telecommunications, aerospace, energy, manufacturing, environmental monitoring, and healthcare [66][67][68]. Their reliability, accuracy, and versatility continue to drive their importance in modern times [69].

Many companies are involved in the commercialization of optical fibre sensors. Some well-known players in this field include: (a) FISO Technologies, which offers fibre optic sensing solutions for medical, industrial, and energy applications [70]; (b) Luna Innovations, which provides fibre optic sensing solutions for aerospace, energy, and structural health monitoring [71]; (c) Micron Optics, which offers a range of fibre optic sensor products for various industries, including industrial monitoring and civil engineering [72]; (d) OSENSA Innovations, which specializes in fibre optic sensing solutions for the oil and gas, aerospace, and industrial sectors [73]; (e) Opsens, which provides fibre optic sensors for medical applications, including cardiovascular procedures [74]; (f) Neubrex, which focuses on distributed temperature and strain sensing technology [75]; and (g) Sensornet, which offers a variety of fibre optic sensors for industrial applications, particularly in the oil and gas industry [76].

3. Working Mechanism of Optical Fibre-Based Sensors

An optical fibre is a cylindrical waveguide mostly formed of silica (SiO2) that uses TIR to carry light down the fibre axis. A core (dielectric material) and cladding (another dielectric material with a lower refractive index) make up an optical fibre. The evanescent field, which penetrates the cladding when light is internally reflected, is a tiny component of light that may be created. The evanescent field at the fibre surface decays to a value that is almost negligible when the fibre cladding is significantly thicker than the fibre core. The EM field interacts with the surrounding medium when an optical fibre is tapered down to less than the core diameter, allowing light to pass through the cladding (rather than the core) and increasing the amplitude of the EM field in the tapered area [77][78][79].

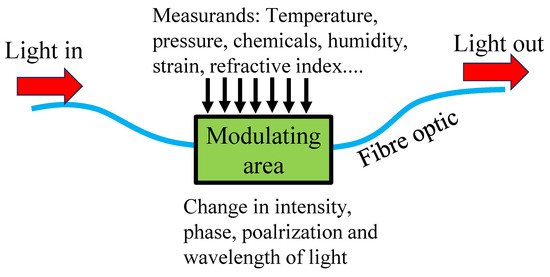

The sensing mechanism in fibre optics involves exploiting changes in light intensity, phase, wavelength, or polarization initiated by the external factors being measured, as illustrated in Figure 2. Here are a few commonly used optical fibre sensing mechanisms:

- (a)

-

Intensity-based sensing: In this mechanism, the deviation in the intensity of light transmitted through an optical fibre is utilized to measure variations in the surrounding environment. It can be achieved by utilizing the transformation in light absorption, scattering, or reflection due to the target variable. Intensity-based sensors are straightforward and often used for applications such as temperature sensing or the detection of strain or pressure.

- (b)

-

Phase-based sensing: In phase-based sensing, the phase shift of the light wave travelling through the optical fibre is utilized to measure the target variable. The phase shift can be induced by changes in length, refractive index, or birefringence of the fibre. Phase-based sensors are commonly used for applications like vibration sensing, displacement measurement, or acoustic sensing.

- (c)

-

Wavelength-based sensing: This mechanism utilizes the changes in the wavelength of light propagating through the optical fibre to measure the target variable. It can be achieved by using fibre Bragg gratings or interferometric techniques. Wavelength-based sensors are widely employed for applications like strain sensing, temperature monitoring, or chemical sensing.

- (d)

-

Polarization-based sensing: Polarization-based sensing exploits changes in the polarization state of light travelling through the fibre to measure the target variable. These sensors often use fibre components such as polarizers, wave plates, or polarization-maintaining fibres. Polarization-based sensors are used in applications such as stress or strain sensing, current or magnetic field measurement, or biomedical sensing.

Figure 2. Working mechanism of fibre optic-based sensors.

These sensing mechanisms can be combined or adapted to various types of optical fibre sensors to measure a wide range of physical quantities such as temperature, strain, pressure, humidity, chemical composition, and more [80][81][82]. The choice of sensing mechanism depends on the specific application requirements and the target variable being measured [83].

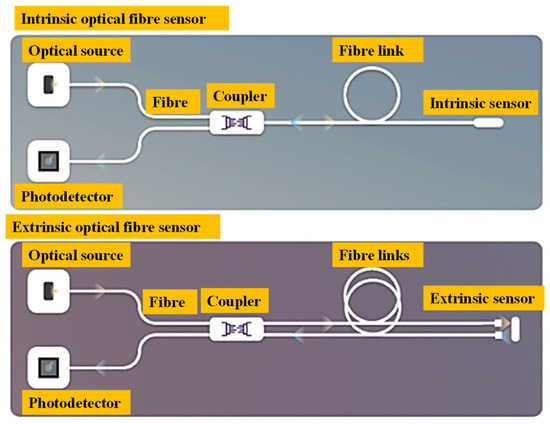

Optical fibre sensors are categorized in the literature considering many factors [84]. These sensors are usually categorized based on the operating theory or application as well as the position of the sensor within the fibre. When it comes to application, optical sensors can be divided into three categories based on the types of variables they are meant to measure: physical (such as strain and temperature), chemical (such as oil variables, pH, ammonia, detergents, and pesticides) [85], or bio-medical (such as oxygen, carbon dioxide, proteins, cells, and DNA) [84]. The optical sensor can be characterized as intrinsic or extrinsic depending on where it is located.

In an intrinsic sensor, the sensitive material (sensor head) and the channel for transmitting the optical signal containing the information measured are both directly made of an optical fibre, as shown in Figure 3 (top). They work by directly modulating the light that has been directed into the optical fibre; the light only exits the fibre at the detecting end. In this kind of sensor, physical disturbances alter the properties of the optical fibre, which alters the characteristics of the light it carries. As an alternative, the modulated light may be reflected or scattered back into the same fibre and then directed back to the detecting system. The simplest fibre sensors merely need a light source and a detector to alter the light’s intensity.

Figure 3. Types of optical fibre sensors based on the location of the sensor: intrinsic optical fibre sensor (top) and extrinsic optical fibre sensor (bottom) [86].

An extrinsic or hybrid optical fibre sensor directs light to and from the optical sensor head’s position (often based on a multimode fibre cable), as shown in Figure 3 (bottom). The sensor head, which is external to the optical fibre and is built from a tiny apparatus, is used to control the characteristics of light in response to alterations in the environment brought on by physical disturbances of interest. One end of the fibre transmits optical energy to the sensors’ heads, and the other end is modified and linked to the optical sensor.

The figure of merit (FOM) of an optical fibre sensor is a quantitative measure used to assess the sensor’s performance in terms of its sensitivity, precision, and overall effectiveness in measuring a specific parameter. Different types of optical fibre sensors may have different FOMs depending on the parameter being measured and the sensor’s design. The sensitivity of an optical fibre sensor refers to its ability to detect and measure small deviations in the quantity it is considered to sense. It is a measure of how responsive the sensor is to variations in the sensed variable. In other words, sensitivity quantifies the relationship between the change in the output signal of the sensor and the corresponding change in the sensed quantity. Sensitivity is typically articulated as a ratio or percentage, representing the change in the output signal per unit change in the sensed quantity [86].

The sensitivity of an optical fibre sensor can vary provisionally to various factors such as the design, construction, and operating principles of the sensor. Factors that can influence sensitivity include the type of sensing mechanism, the properties of the fibre (e.g., core size, numerical aperture), the detection method used, and environmental conditions. Higher sensitivity implies that the sensor can detect smaller changes in the sensed quantity [66]. It is an imperative variable to consider when selecting or designing an optical fibre sensor for a specific application. However, it is worth mentioning that sensitivity alone is not the sole determinant of a sensor’s performance. Other factors such as accuracy, resolution, dynamic range, response time, and stability also play crucial roles in evaluating the overall performance and suitability of an optical fibre sensor for a specific application [87][88]. Resolution is the smallest detectable change in the parameter that the sensor can reliably measure. It is related to the sensor’s noise level and determines the smallest incremental change in the parameter that can be distinguished from the sensor’s background noise [89].

The dynamic range of a sensor is the range of parameter values over which it can provide accurate measurements. A wide dynamic range allows the sensor to measure both small and large changes in the parameter without saturating or losing accuracy [90], whereas accuracy represents how close the sensor’s measurements are to the true value of the parameter being measured. It considers systematic errors and uncertainties introduced by the sensor’s design, calibration, and environment.

The response time of an optical fibre sensor is also important and refers to the time it takes for the sensor to detect and provide a meaningful output in response to a change in the parameter. Faster response times are often desirable, especially for dynamic or rapidly changing parameters [91].

Selectivity of the fibre sensor is vital, as it signifies the ability to specifically respond to a particular target analyte or parameter while minimizing or ignoring the effects of interfering substances or environmental factors [92].

Last but not least, the fibre sensor should be stable, which indicates the sensor’s ability to maintain its calibration and accuracy over time. Stable sensors retain their performance characteristics without significant drift.

References

- Butt, M.A.; Kazanskiy, N.L.; Khonina, S.N.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V. A Review on Photonic Sensing Technologies: Status and Outlook. Biosensors 2023, 13, 568.

- Haider, F.; Aoni, R.A.; Ahmed, R.; Mahdiraji, G.A.; Azman, M.F.; Adikan, F.R.M. Mode-multiplex plasmonic sensor for multi-analyte detection. Opt. Lett. 2020, 45, 3945–3948.

- Zhdanov, A.V.; Li, L.; Yang, P.; Shkirdova, A.O.; Tang, S.; Yashunsky, D.V.; Ponomarev, G.V.; Zamilatskov, I.A.; Papkovsky, D.B. Advanced multi-modal, multi-analyte optochemical sensing platform for cell analysis. Sens. Actuators B Chem. 2022, 355, 131116.

- Swiontek, S.E.; Pulsifer, D.P.; Lakhtakia, A. Optical sensing of analytes in aqueous solutions with a multiple surface-plasmon-polariton-wave platform. Sci. Rep. 2013, 3, 1409.

- Butt, M.A.; Voronkov, G.S.; Grakhova, E.P.; Kutluyarov, R.V.; Kazanskiy, N.L.; Khonina, S.N. Environmental Monitoring: A Comprehensive Review on Optical Waveguide and Fiber-Based Sensors. Biosensors 2022, 12, 1038.

- Butt, M.A. Numerical investigation of a small footprint plasmonic Bragg grating structure with a high extinction ratio. Photonics Lett. Pol. 2020, 12, 82–84.

- Butt, M.A.; Khonina, S.N.; Kazanskiy, N.L. Plasmonics: A Necessity in the Field of Sensing-A Review (Invited). Fiber Integr. Opt. 2021, 40, 14–47.

- Butt, M.A. Numerical Assessment of a Metal-Insulator-Metal Waveguide-Based Plasmonic Sensor System for the Recognition of Tuberculosis in Blood Plasma. Micromachines 2023, 14, 729. Available online: https://www.mdpi.com/2072-666X/14/4/729 (accessed on 10 July 2023).

- Kazanskiy, N.L.; Khonina, S.N.; Butt, M.A. Recent Development in Metasurfaces: A Focus on Sensing Applications. Nanomaterials 2023, 13, 118. Available online: https://www.mdpi.com/2079-4991/13/1/118 (accessed on 10 July 2023).

- Li, B.; Zhang, R.; Bi, R.; Olivo, M. Applications of Optical Fiber in Label-Free Biosensors and Bioimaging: A Review. Biosensors 2023, 13, 64. Available online: https://www.mdpi.com/2079-6374/13/1/64 (accessed on 10 July 2023).

- Cai, J.; Liu, Y.; Shu, X. Long-Period Fiber Grating Sensors for Chemical and Biomedical Applications. Sensors 2023, 23, 542. Available online: https://www.mdpi.com/1424-8220/23/1/542 (accessed on 10 July 2023).

- Zhu, C.; Gerald, R.E.; Huang, J. Micromachined Optical Fiber Sensors for Biomedical Applications. In Biomedical Engineering Technologies: Volume 1; Ossandon, M.R., Baker, H., Rasooly, A., Eds.; Methods in Molecular Biology; Springer: New York, NY, USA, 2022; pp. 367–414. ISBN 978-1-07-161803-5.

- Mulchandani, A.; Pan, S.; Chen, W. Fiber-Optic Enzyme Biosensor for Direct Determination of Organophosphate Nerve Agents. Biotechnol. Prog. 1999, 15, 130–134.

- Hengoju, S.; Shvydkiv, O.; Tovar, M.; Roth, M.; Rosenbaum, M.A. Advantages of optical fibers for facile and enhanced detection in droplet microfluidics. Biosens. Bioelectron. 2022, 200, 113910.

- Xie, Y.; Wang, M.; Zhong, Y.; Deng, L.; Zhang, J. Label-Free Anomaly Detection Using Distributed Optical Fiber Acoustic Sensing. Sensors 2023, 23, 4094. Available online: https://www.mdpi.com/1424-8220/23/8/4094 (accessed on 10 July 2023).

- Chen, M.; He, T.; Zhao, Y.; Yang, G. Ultra-short phase-shifted fiber Bragg grating in a microprobe for refractive index sensor with temperature compensation. Opt. Laser Technol. 2023, 157, 108672.

- Paixão, T.; Nunes, A.S.; Bierlich, J.; Kobelke, J.; Ferreira, M.S. Fabry-Perot Interferometer Based on Suspended Core Fiber for Detection of Gaseous Ethanol. Appl. Sci. 2022, 12, 726. Available online: https://www.mdpi.com/2076-3417/12/2/726 (accessed on 10 August 2023).

- Spammer, S.J.; Swart, P.L.; Booysen, A. Interferometric distributed optical-fiber sensor. Appl. Opt. 1996, 35, 4522–4525.

- Muanenda, Y.; Oton, C.J.; Di Pasquale, F. Application of Raman and Brillouin Scattering Phenomena in Distributed Optical Fiber Sensing. Front. Phys. 2019, 7, 155.

- Shatalin, S.V.; Treschikov, V.N.; Rogers, A.J. Interferometric optical time-domain reflectometry for distributed optical-fiber sensing. Appl. Opt. 1998, 37, 5600–5604.

- Mermelstein, M.D. All-fiber polarimetric sensor. Appl. Opt. 1986, 25, 1256–1258.

- Jiao, L.; Zhong, N.; Zhao, X.; Ma, S.; Fu, X.; Dong, D. Recent advances in fiber-optic evanescent wave sensors for monitoring organic and inorganic pollutants in water. TrAC Trends Anal. Chem. 2020, 127, 115892. Available online: https://www.sciencedirect.com/science/article/pii/S0165993620301217 (accessed on 10 August 2023).

- Liang, C.; Bai, Q.; Yan, M.; Wang, Y.; Zhang, H.; Jin, B. A Comprehensive Study of Optical Frequency Domain Reflectometry. IEEE Access 2021, 9, 41647–41668.

- Singh, S.; Chaudhary, B.; Upadhyay, A.; Sharma, D.; Ayyanar, N.; Taya, S.A. A review on various sensing prospects of SPR based photonic crystal fibers. Photonics Nanostructures—Fundam. Appl. 2023, 54, 101119.

- Singh, A.K.; Mittal, S.; Das, M.; Saharia, A.; Tiwari, M. Optical biosensors: A decade in review. Alex. Eng. J. 2023, 67, 673–691.

- Zhang, H.; Zhou, X.; Li, X.; Gong, P.; Zhang, Y.; Zhao, Y. Recent Advancements of LSPR Fiber-Optic Biosensing: Combination Methods, Structure, and Prospects. Biosensors 2023, 13, 405.

- Wang, Z.; Zhang, W.; Liu, X.; Li, M.; Lang, X.; Singh, R.; Marques, C.; Zhang, B.; Kumar, S. Novel Optical Fiber-Based Structures for Plasmonics Sensors. Biosensors 2022, 12, 1016. Available online: https://www.mdpi.com/2079-6374/12/11/1016 (accessed on 10 July 2023).

- Du, C.; Wang, Q.; Zhao, S.; Deng, X. Biological sensors based on long period fiber grating. Opt. Laser Technol. 2023, 158, 108936.

- Shi, F.; Zhang, H.; Ye, Z.; Tang, X.; Qin, F.; Yan, J.; Amano, H. Miniature optical fiber curvature sensor via integration with GaN optoelectronics. Commun. Eng. 2022, 1, 47. Available online: https://www.nature.com/articles/s44172-022-00049-w (accessed on 10 July 2023).

- Liang, Y.; Wei, X.; Chu, S.; Zhang, X.; Fang, Y.; Peng, W. Tamm-surface plasmon resonances from nanograting-coupled plasmonic-photonic multilayer structure for an integrated fiber-optic sensing application. J. Phys. Appl. Phys. 2023, 56, 385101.

- Yin, Z.; Jing, X.; Bai, G.; Wu, B.; Gao, Z.; Liu, C.; Wang, C.; Li, Y. Experimental Study of Dual-Parameter SPR Sensor With Integrated Sensing Channel. IEEE Sens. J. 2023, 23, 8385–8390.

- Khonina, S.N.; Kazanskiy, N.L.; Butt, M.A.; Karpeev, S.V. Optical multiplexing techniques and their marriage for on-chip and optical fiber communication: A review. Opto-Electron. Adv. 2022, 5, 210127-1. Available online: https://www.oejournal.org//article/doi/10.29026/oea.2022.210127 (accessed on 18 July 2023).

- Lyu, S.; Wu, Z.; Shi, X.; Wu, Q. Optical Fiber Biosensors for Protein Detection: A Review. Photonics 2022, 9, 987. Available online: https://www.mdpi.com/2304-6732/9/12/987 (accessed on 10 July 2023).

- Cruz, J.; Fangueiro, R. Surface Modification of Natural Fibers: A Review. Procedia Eng. 2016, 155, 285–288.

- Meunier, D.; Schruyers, J.; Gonzales Palla, R.; Mendoza, C.; Calberg, C.; Heinrichs, B.; Pirard, S.; Mahy, J.G. Controlled-chemical etching of the cladding in optical fibers for the design of analytical sensors. Opt. Fiber Technol. 2023, 78, 103328.

- Li, H.; Ni, J.; Zhao, Q.; Jiang, L. Surface Modified Optical Fiber Fabry–Perot Cavity Pressure Sensor With Carbon Film. IEEE Sens. J. 2023, 23, 9353–9358.

- Lee, B.H.; Min, E.J.; Kim, Y.H. Fiber-based optical coherence tomography for biomedical imaging, sensing, and precision measurements. Opt. Fiber Technol. 2013, 19, 729–740.

- Rahmani, B.; Oguz, I.; Tegin, U.; Hsieh, J.L.; Psaltis, D.; Moser, C. Learning to Image and Compute with MULTIMODE optical Fibers. Nanophotonics 2022, 11, 1071–1082. Available online: https://www.degruyter.com/document/doi/10.1515/nanoph-2021-0601/html (accessed on 12 July 2023).

- Smith, A.M. Polarization and magnetooptic properties of single-mode optical fiber. Appl. Opt. 1978, 17, 52–56.

- Savović, S.; Simović, A.; Drljača, B.; Kovačević, M.S.; Kuzmanović, L.; Djordjevich, A.; Aidinis, K.; Min, R. Power Flow in Multimode Graded-Index Microstructured Polymer Optical Fibers. Polymers 2023, 15, 1474. Available online: https://www.mdpi.com/2073-4360/15/6/1474 (accessed on 12 July 2023).

- Highly Sensitive Multi-Core Flat Fiber Surface Plasmon Resonance Refractive Index Sensor. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-24-3-2485&id=335915 (accessed on 12 July 2023).

- Kiroriwal, M.; Singal, P. Applications of photonic crystal fibers in optical communication. J. Opt. Commun. 2022.

- Divya, J.; Selvendran, S. Surface Plasmon Resonance-Based Gold-Coated Hollow-Core Negative Curvature Optical Fiber Sensor. Biosensors 2023, 13, 148.

- Shih, M.; Nelson-Quillin, H.D.; Garrett, K.E.; Coyle, E.J.; Secondo, R.; Keyser, C.K.; Mills, M.S.; Harper, E.S. Maximizing supercontinuum bandwidths in gas-filled hollow-core fibers using artificial neural networks. J. Appl. Phys. 2023, 133, 233101.

- Arroyo, E.; Tentori, D.; Garcia, A.; Valdez, R.; Armenta, M.A.; Nava, O.J.; Machorro, R.; Olivas, A. Carbon Quantum Dot Optical Properties for potential infiltration into Hollow Core Photonic Crystal Fibers. Part. Part. Syst. Charact. 2023, 40, 2200200.

- Gupta, B.D.; Kant, R. Recent advances in surface plasmon resonance based fiber optic chemical and biosensors utilizing bulk and nanostructures. Opt. Laser Technol. 2018, 101, 144–161.

- Tapered Optical Fiber Sensor Based on Localized Surface Plasmon Resonance. Available online: https://opg.optica.org/oe/fulltext.cfm?uri=oe-20-19-21693&id=241250 (accessed on 12 July 2023).

- Liu, C.; Wang, J.; Wang, F.; Su, W.; Yang, L.; Lv, J.; Fu, G.; Li, X.; Liu, Q.; Sun, T.; et al. Surface plasmon resonance (SPR) infrared sensor based on D-shape photonic crystal fibers with ITO coatings. Opt. Commun. 2020, 464, 125496.

- Sensitivity Optimization of U-Shaped Fiber Optics Based on the Taguchi Method. Available online: https://opg.optica.org/osac/fulltext.cfm?uri=osac-4-7-2024&id=452914 (accessed on 12 July 2023).

- Johari, S.H.; Cheak, T.Z.; Rahim HR, A.; Jali, M.H.; Yusof HH, M.; Johari MA, M.; Harun, S.W. Formaldehyde Sensing Using Tapered U-Shape Plastic Optical Fiber Coated With Zinc Oxide Nanorods. IEEE Access 2022, 10, 91445–91451. Available online: https://ieeexplore.ieee.org/document/9868774 (accessed on 15 July 2023).

- Ren, Z.-H.; Wang, Q.; Zhao, W.-M.; Wang, L.; Jiang, C.-Q.; Cong, X.-W.; Yan, X.; Zhu, A.-S.; Qiu, F.-M.; Chen, B.-H.; et al. A High-FOM surface plasmon resonance sensor based on MMF-TUMMF-MMF structure of optical fiber. Opt. Fiber Technol. 2022, 72, 102970.

- Li, L.; Zhang, Y.; Zheng, W.; Li, X.; Zhao, Y. Optical fiber SPR biosensor based on gold nanoparticle amplification for DNA hybridization detection. Talanta 2022, 247, 123599.

- Zhang, J.; Mai, X.; Hong, X.; Chen, Y.; Li, X. Optical fiber SPR biosensor with a solid-phase enzymatic reaction device for glucose detection. Sens. Actuators B Chem. 2022, 366, 131984.

- Kishida, K.; Imai, M.; Kawabata, J.; Guzik, A. Distributed Optical Fiber Sensors for Monitoring of Civil Engineering Structures. Sensors 2022, 22, 4368.

- Ashry, I.; Mao, Y.; Wang, B.; Hveding, F.; Bukhamsin, A.Y.; Ng, T.K.; Ooi, B.S. A Review of Distributed Fiber–Optic Sensing in the Oil and Gas Industry. J. Light. Technol. 2022, 40, 1407–1431.

- Liu, T.; Wei, Y.; Song, G.; Hu, B.; Li, L.; Jin, G.; Wang, J. Fibre Optic Sensors for Coal Mine Hazard Detection. Measurement 2018, 124, 211–223. Available online: https://www.sciencedirect.com/science/article/pii/S0263224118302239 (accessed on 9 August 2023).

- Schenato, L. A Review of Distributed Fibre Optic Sensors for Geo-Hydrological Applications. Appl. Sci. 2017, 7, 896. Available online: https://www.mdpi.com/2076-3417/7/9/896 (accessed on 9 August 2023).

- Bado, M.F.; Casas, J.R. A Review of Recent Distributed Optical Fiber Sensors Applications for Civil Engineering Structural Health Monitoring. Sensors 2021, 21, 1818. Available online: https://www.mdpi.com/1424-8220/21/5/1818 (accessed on 9 August 2023).

- Distributed Fiber Optic Sensor Market Share Report, 2030. Available online: https://www.grandviewresearch.com/industry-analysis/distributed-fiber-optic-sensor-sensing-dfos-market (accessed on 13 July 2023).

- Nedoma, J.; Fajkus, M.; Martinek, R.; Vanus, J.; Kepak, S.; Kahankova, R.; Jaros, R.; Cvejn, D.; Prauzek, M. Analysis of the use of fiber-optic sensors in the road traffic. IFAC-Pap. 2018, 51, 420–425.

- García, I.; Zubia, J.; Durana, G.; Aldabaldetreku, G.; Illarramendi, M.A.; Villatoro, J. Optical Fiber Sensors for Aircraft Structural Health Monitoring. Sensors 2015, 15, 15494–15519. Available online: https://www.mdpi.com/1424-8220/15/7/15494 (accessed on 13 July 2023).

- Lorincz, J.; Klarin, Z.; Begusic, D. Advances in Improving Energy Efficiency of Fiber–Wireless Access Networks: A Comprehensive Overview. Sensors 2023, 23, 2239. Available online: https://www.mdpi.com/1424-8220/23/4/2239 (accessed on 13 July 2023).

- Bednarz, B.; Popielski, P.; Sieńko, R.; Howiacki, T.; Bednarski, Ł. Distributed Fibre Optic Sensing (DFOS) for Deformation Assessment of Composite Collectors and Pipelines. Sensors 2021, 21, 5904. Available online: https://www.mdpi.com/1424-8220/21/17/5904 (accessed on 13 July 2023).

- Liu, Z.; Wang, L.; Meng, Y.; He, T.; He, S.; Yang, Y.; Xiao, Q. All-Fiber High-Speed Image Detection Enabled by Deep Learning. Nat. Commun. 2022, 13, 1433. Available online: https://www.nature.com/articles/s41467-022-29178-8 (accessed on 13 July 2023).

- Mittal, N.; Shah, M.; John, J. A Low Cost Short Haul Plastic Optical Fiber Link for Home Networking Applications. In Proceedings of the 2016 IEEE International Conference on Recent Trends in Electronics, Information & Communication Technology, Bangalore, India, 20–21 May 2016; IEEE: New York, NY, USA, 2016; Available online: https://ieeexplore.ieee.org/document/7808212 (accessed on 16 July 2023).

- Xu, J.; Li, T.; Li, Y.; Zhang, C.; Cheng, L.; Liu, L.; Miao, C. Fabrication and application of a grooved optical fiber respiratory sensor based on geometric parameter optimization by optical simulation. Opt. Laser Technol. 2023, 167, 109747.

- Huang, L.; Liu, S.; Zheng, B.; Zhao, Y.; Dang, L.; Gao, L.; Huang, W.; Yin, G.; Zhu, T. Narrowband all-fiber acousto-optic tunable add-drop filter based on dispersion-compensating fiber. Opt. Laser Technol. 2023, 167, 109759.

- Wieduwilt, T.; Förster, R.; Nissen, M.; Kobelke, J.; Schmidt, M.A. Characterization of diffusing sub-10 nm nano-objects using single anti-resonant element optical fibers. Nat. Commun. 2023, 14, 3247.

- Shao, M.; Cao, Z.; Gao, H.; Yu, D.; Qiao, X. Optical Fiber Ultrasonic Sensor Based on Partial Filling PDMS in Hollow-Core Fiber. Opt. Laser Technol. 2023, 167, 109648. Available online: https://www.sciencedirect.com/science/article/pii/S0030399223005418?via%3Dihub (accessed on 16 July 2023).

- Home. Available online: https://fiso.com/en/ (accessed on 9 August 2023).

- Luna Innovations|Fiber Optic Sensing and Measurement Systems. Available online: https://lunainc.com/ (accessed on 9 August 2023).

- Micron Optics, Inc. SENSORS. Available online: http://micronoptics.ru/sensors_products.html (accessed on 9 August 2023).

- OSENSA Innovations Corp. OSENSA Innovations. Available online: https://www.osensa.com/ (accessed on 9 August 2023).

- Opsens Fiber Optic Sensor Company for FFR and Oil & Gas. Available online: https://opsens.com/ (accessed on 9 August 2023).

- Neubrex Co., Ltd. Home. Available online: https://www.neubrex.com/ (accessed on 9 August 2023).

- Advanced Fiber Optic DTS & Monitoring Systems—Sensornet. Available online: https://www.sensornet.co.uk/ (accessed on 9 August 2023).

- Uniyal, A.; Srivastava, G.; Pal, A.; Taya, S.; Muduli, A. Recent Advances in Optical Biosensors for Sensing Applications: A Review. Plasmonics 2023, 18, 735–750.

- De, A.; Kalita, D. Bio-Fabricated Gold and Silver Nanoparticle Based Plasmonic Sensors for Detection of Environmental Pollutants: An Overview. Crit. Rev. Anal. Chem. 2023, 53, 672–688.

- Chen, Y.; Li, H.; Li, B.; Wan, L.; Wang, L. Fault diagnosis of fiber optic current sensor induced by light source based on support vector machines. In Proceedings of the International Conference on Electronic Information Technology (EIT 2022), Chengdu, China, 18–20 March 2022; SPIE: Bellingham, WA, USA, 2022; Volume 12254, p. 1225402.

- Vahdati, N.; Shiryayev, O.; Parapurath, S.M.; Yap, F.F.; Butt, H. Cost-Effective Corrosion Detection Sensor for Above-Ground Oil and Gas Flowlines. Sensors 2022, 22, 8489.

- Liu, W.; Liu, Z.; Zhang, Y.; Li, S.; Zhang, Y.; Yang, X.; Zhang, J.; Yuan, L. Specialty optical fibers and 2D materials for sensitivity enhancement of fiber optic SPR sensors: A review. Opt. Laser Technol. 2022, 152, 108167.

- Zhu, C.; Zhuang, Y.; Liu, B.; Huang, J. Review of Fiber Optic Displacement Sensors. IEEE Trans. Instrum. Meas. 2022, 71, 1–12.

- Losch, M.S.; Kardux, F.; Dankelman, J.; Hendriks, B.H.W. Steering light in fiber-optic medical devices: A patent review. Expert Rev. Med. Devices 2022, 19, 259–271.

- Applications of Fiber-Optic Biochemical Sensor in Microfluidic Chips: A Review—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/pii/S0956566320304413?via%3Dihub (accessed on 16 July 2023).

- Mittal, S.; Sharma, T.; Tiwari, M. Surface plasmon resonance based photonic crystal fiber biosensors: A review. Mater. Today Proc. 2021, 43, 3071–3074.

- Dejdar, P.; Mokry, O.; Cizek, M.; Rajmic, P.; Munster, P.; Schimmel, J.; Pravdova, L.; Horvath, T.; Cip, O. Characterization of sensitivity of optical fiber cables to acoustic vibrations. Sci. Rep. 2023, 13, 7068.

- Huang, Q.; Shi, H.; Huang, C.; Sun, J. Improvement of response speed and precision of distributed Brillouin optical fiber sensors using neural networks. Opt. Laser Technol. 2023, 167, 109705.

- Tian, Y.; Dang, H.; Liu, W.; Cui, J.; Li, Y.; Tan, J. Structure shape measurement method based on an optical fiber shape sensor. Meas. Sci. Technol. 2023, 34, 085102.

- Singh, M.; Raghuwanshi, S.K.; Prakash, O.; Saini, P.K. High-Resolution Fiber Optic Sensor based on Coated Linearly Chirped Bragg Grating. Optik 2020, 212, 164698.

- Zheng, Y.; Shum, P.P.; Luo, Y.; Zhang, Y.; Ni, W.; Wang, G.; Wu, Z.; Dinh, X.Q.; Auguste, J.-L.; Humbert, G. High-resolution, large-dynamic-range multimode interferometer sensor based on a suspended-core microstructured optical fiber. Opt. Lett. 2020, 45, 1017–1020.

- Alabbas, S.H.; Ashworth, D.C.; Bezzaa, B.; Momin, S.A.; Narayanaswamy, R. Factors affectig the response time of an optical-fibre reflectance pH sensor. Sens. Actuators Phys. 1995, 51, 129–134.

- Dooly, G.; Manap, H.; O’Keeffe, S.; Lewis, E. Highly Selective Optical Fibre Ammonia Sensor for use in Agriculture. Procedia Eng. 2011, 25, 1113–1116.

- Dooly, G.; Manap, H.; O’Keeffe, S.; Lewis, E. Highly Selective Optical Fibre Ammonia Sensor for use in Agriculture. Procedia Eng. 2011, 25, 1113–1116.

More

Information

Subjects:

Optics

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

878

Revisions:

3 times

(View History)

Update Date:

06 Sep 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No