Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Marco Aurélio Suller Garcia | -- | 4936 | 2023-08-25 20:09:29 | | | |

| 2 | Dean Liu | -1 word(s) | 4935 | 2023-08-28 04:15:59 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Eduardo, S.D.S.; Mendonça, J.P.; Romano, P.N.; De Almeida, J.M.A.R.; Machado, G.; Garcia, M.A.S. Tailoring Ceria-Based Nanocatalysts in Steam Reforming Processes. Encyclopedia. Available online: https://encyclopedia.pub/entry/48496 (accessed on 07 February 2026).

Eduardo SDS, Mendonça JP, Romano PN, De Almeida JMAR, Machado G, Garcia MAS. Tailoring Ceria-Based Nanocatalysts in Steam Reforming Processes. Encyclopedia. Available at: https://encyclopedia.pub/entry/48496. Accessed February 07, 2026.

Eduardo, Samuel Da Silva, Jhonatam Pinheiro Mendonça, Pedro Nothaft Romano, João Monnerat Araújo Ribeiro De Almeida, Giovanna Machado, Marco Aurélio Suller Garcia. "Tailoring Ceria-Based Nanocatalysts in Steam Reforming Processes" Encyclopedia, https://encyclopedia.pub/entry/48496 (accessed February 07, 2026).

Eduardo, S.D.S., Mendonça, J.P., Romano, P.N., De Almeida, J.M.A.R., Machado, G., & Garcia, M.A.S. (2023, August 25). Tailoring Ceria-Based Nanocatalysts in Steam Reforming Processes. In Encyclopedia. https://encyclopedia.pub/entry/48496

Eduardo, Samuel Da Silva, et al. "Tailoring Ceria-Based Nanocatalysts in Steam Reforming Processes." Encyclopedia. Web. 25 August, 2023.

Copy Citation

Ceria-based nanostructures, employed as catalytic supports for noble and non-noble metals, are well-known for their remarkable activity in steam-reforming reactions, exceptional resistance to degradation, and thermal stability.

ceria

shape-control

nanoengineering

Ni

Co

Pt

1. Introduction

Energy is vital in driving economic growth as all production operations and activities rely on it as a fundamental input. Hence, with the expansion of economies, energy demand has a corresponding rise, with renewable energy resources emerging as promising options for sustainable energy production [1]. In this scenario, energy sources such as solar, wind, hydro, geothermal, and biomass play a significant role as they are naturally replenished within a human timescale [2]. However, it is crucial to recognize that these energy sources are not directly manageable as their primary energy cannot be stored.

Although some strategies are being studied to overcome potential offer shortages, hydrogen (H2) has emerged as part of the solution due to its chemical energy carrier properties [3], contributing significantly to decarbonizing dominant sectors and facilitating the achievement of net-zero CO2 emissions by 2050 [4]. However, H2 is predominantly found in compounds rather than in its free form, requiring the utilization of technologies that require substantial energy consumption for its obtaining [5]. In addition to the technical challenges associated with H2 production, other undeniable concerns must be addressed, which include storage, transportation, safety, the integration of H2 into the energy matrix, and the impact on greenhouse gas emissions [6]. Therefore, high costs, high energy consumption, and technical barriers present obstacles to the widespread adoption of H2 as an energy reservoir.

Considering the challenges mentioned and the present circumstances, H2 has not been widely regarded as a viable solution on a large scale due to persistent economic concerns and environmental impacts. However, its consumption is essential for fertilizer production in the ammonia industry, oil refining, methanol production, and iron and steel manufacturing [7][8][9]. Thus, attaining technological advancements and achieving economies of scale are crucial to making H2 economically feasible. Technologies such as photochemical water splitting, bio-photolysis, photo- and dark-fermentation, and thermochemical and biomass-to-energy processes have attracted attention toward producing green H2 that can help mitigate global temperature increases within the 2 °C limit [10][11][12]. Nevertheless, these technologies are still maturing for commercial viability.

Currently, the most prominent methods for H2 production are electrochemical water splitting (electrolysis) and steam-reforming reactions, with steam–methane reforming being the dominant process [13]. The primary factor behind the limited utilization of electrolysis is the high cost associated with electricity, a crucial requirement for its operation; reforming reactions do not require such input. The non-utilization of electricity is especially relevant for sectors such as the production of chemicals and certain segments of the transportation industry where alternative decarbonization methods may not be feasible. In the long run, attention will also be directed toward addressing portions of the heat market. However, a recent study stated that direct H2 technologies always increase the energy system’s cost and cannot be considered large-scale solutions for heating and transport, at least for now, and such sectors are critical for replacing the global carbon-based energy matrix [14]. Thus, it is crucial to continue reducing the cost of H2 production, and many efforts are being directed toward steam-reforming reactions due to its stage of development.

2. Shape-Controlled Cerium-Oxide-Based Nanocatalysts with Ni and Co

Low-cost and available non-noble catalysts, particularly Ni-based catalysts, are extensively used in steam-reforming reactions. However, there is a limited understanding in the literature regarding the mechanisms of their active sites and the significance of metal–support interactions in Ni and cerium oxide systems. Furthermore, when such discussions are present, they often refer to specific reaction conditions and substrates, making it challenging to generalize the findings. However, as a general assumption, the combination of highly dispersed metal nanoparticles on oxide surfaces exhibits high reactivity [15]. In this context, ceria is crucial in preventing metal sintering by establishing strong metal–support interactions, demonstrating high reducibility. As a result, ceria serves as a vital promoter for maintaining the stability and activity of metal catalysts [16]. In low-loaded Ni catalysts supported on CeO2, the presence of the ceria facilitates strong metal–support interactions, leading to the partial oxidation of Ni atoms in direct contact with the support [17][18][19], bringing significant changes in the chemical and catalytic properties of these systems, particularly in the cleavage of C–H and O–H bonds [20][21][22][23][24]. Moreover, the high reducibility of the ceria support allows it to act as an oxygen reservoir, enabling unique reaction pathways such as the reverse spillover of oxygen from ceria to metal sites, as discussed before. As a result, the remarkable decoking activity observed in ceria-supported Ni catalysts for methane steam reforming can be attributed to a mechanism involving the supply of oxygen from the support, facilitating the removal of carbon as CO, and water plays a crucial role as one of the reactants, reloading the oxygen vacancies generated during the reverse spillover step [25].

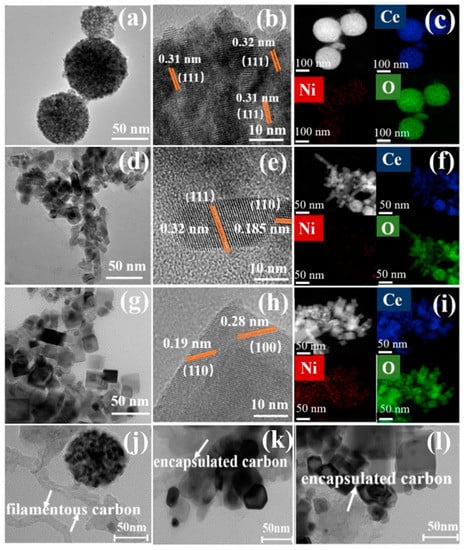

However, the scenario can be more complicated depending on the temperature at which the reaction is conducted and the substrate as Ni active species tend to sinter and suffer from carbon deposition, resulting in their deactivation [26]. In this context, shape-controlled CeO2 is one of many options and is highly used to avoid such drawbacks [27]. Luo and co-workers proposed a strategic approach to finely adjust the metal–support interaction by employing different shapes of CeO2—spheres, rods, and cubes—as supports for Ni nanoparticles (Figure 1a–i) [28]. This approach also influences the specific surface area exposed by the Ni nanoparticles, metal–support interactions, concentration of oxygen vacancies, and catalytic performance in glycerol steam reforming. The molar ratio of nC3H8O to nH2O was 1:9, with a gas hourly space velocity (GHSV) of 23,700 mL h−1 gcat−1, and the reaction was carried out at a pressure of 1 atm and a maximum temperature of 600 °C.

Figure 1. HRTEM images depict the reduced (a,b) sphere-shaped Ni/CeO2, (d,e) rod-shaped Ni/CeO2, and (g,h) cube-shaped Ni/CeO2 catalysts. In addition, scanning STEM images along with mappings illustrate the distribution of Ni, Ce, and O in the reduced (c) sphere-shaped Ni/CeO2, (f) rod-shaped Ni/CeO2, and (i) cube-shaped Ni/CeO2 samples. TEM images of spent catalysts: (j) sphere-shaped Ni/CeO2, (k) rod-shaped Ni/CeO2, and (l) cube-shaped Ni/CeO2 catalysts. Modified with permission from [28].

Interestingly, they observed that the sphere-shaped Ni/CeO2 catalyst did not change its morphology after the reaction (and promoted higher production of H2), unlike the rod- and cube-shaped Ni/CeO2 catalysts. Furthermore, the researchers noted distinct carbon deposition characteristics among the catalysts. The Ni/CeO2 catalyst supported on CeO2 spheres exhibited abundant filamentous carbon surrounding the catalyst, while encapsulated carbon was scarce, leaving the remaining facets still available for reactant adsorption (Figure 1j). On the other hand, the catalysts based on rod- and cube-shaped Ni/CeO2 structures displayed amorphous carbon on their surfaces (Figure 1k,l). This carbon layer covered the metal particles, leading to catalyst deactivation. These experimental findings corroborate the significance of the CeO2 shape in determining overall catalytic efficiency.

Although specific reaction conditions support morphology, and substrate utilization may highly account for the results, it should be noted that ceria enhances the catalytic activity of Ni through metal–support interactions and plays an essential role in the dissociation of water and prevention of coke formation, as discussed before for methane and glycerol steam reforming, also for ethanol steam reforming [25]. Thus, this seems to be the case for steam-reforming reactions.

The presence of oxygen vacancies on the catalyst surface is an important feature that can be tailored to enhance redox properties and oxygen mobility. Bearing that in mind, Ni et al. conducted a study to examine the correlation between Ni and CeO2 in Ni/CeO2 catalysts and its impact on the CO2 reforming of CH4. They employed various synthesis methods, including hydrothermal and precipitation techniques, and compared the results with a commercial counterpart. The CeO2 nanostructures obtained through these methods exhibited different shapes, although the control over the shape was not precise. Interestingly, the researchers observed variations in the oxygen vacancies between the different synthesis approaches after immobilizing Ni0 on the supports. They found that the material prepared through hydrothermal synthesis (the material with a higher shape control) exhibited higher efficiency, which they attributed to improved Ni0 dispersion and the presence of a more significant number of oxygen vacancies [29].

According to density functional theory (DFT) and experimental studies, it has been observed that the chemical activity of various planes in CeO2 follows the sequence (110) < (100) < (111), suggesting that the (110) planes of CeO2 are more prone to the formation of oxygen vacancies compared to (100) and (111) planes [30][31][32]. Thus, Wang et al. specifically controlled the shape of CeO2-based Ni catalysts and obtained nanorods, nanocubes, nanooctahedra, and nanoparticles of ceria, exposing mainly (110)/(100), (100), (111), and (111)/(100) facets, and used such materials for methane dry reforming. They found that CeO2-based nanorods used for Ni immobilization presented higher concentrations of oxygen vacancies than the other three ceria materials [33]. Once again, it is crucial to emphasize the need for further research on the data related to hydrogen production. In-depth studies in this area can enhance performance and enable the development of more tailored catalysts to meet specific requirements.

The Ce3+/Ce4+ redox cycle enables CeO2 to undergo a reversible transformation into a nonstoichiometric oxide, leading to its high OSC and enhanced oxygen mobility [34]. Tu et al. prepared paper-structured catalysts with dispersed CeO2–Ni flowers for dry reforming of methane and observed that the high oxygen storage capacity and oxygen mobility of their material contributed to the partial removal of coke formation on the catalyst particles during the reforming process, allowing for an improved catalytic activity compared to other Ni-based catalyst systems with higher Ni contents without the CeO2 flowers [35]. Based on their findings, it can be inferred that the shape of CeO2 has a significant impact on its overall OSC. It is commonly understood that rod- or cube-shaped CeO2 structures possess higher OSC than spherical particles in other CeO2-based catalytic systems than those discussed here [32][36][37], suggesting the shape effect. The same trend appears to hold for steam-reforming reactions as well. Further examples will support this observation.

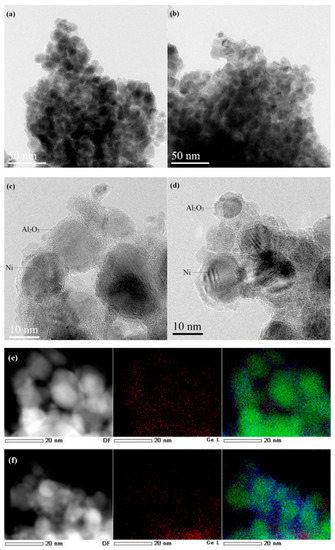

Qian and co-workers studied attractive core-shell catalysts (Ni in the core and alumina and ceria in the inner and outer shells, respectively) that provided a high hydrogen yield in the steam reforming of acetic acid. They prepared, with different Ni/Ce ratios, alumina over ceria catalysts (designated as Ni@AlxCe, x = 05, 10, 30), and the same was performed with ceria added to the alumina shell but with just one Ni/Ce ratio, designated as Ni@Al10Ce-a (Figure 2) [38]. They started the preparation by obtaining Ni nanoparticles using PVP as a stabilizer, NiCl2·6H2O as a metal precursor, and NaBH4 as a reductant that was added after the mixture was ultrasonicated for 15 min; then, Ce(NO3)3·6H2O (or Al2O3) was added to the suspension and underwent 1 h of ultrasonication and the Ni nanoparticles were coated with an alumina (or ceria) shell. The authors attributed the enhanced catalytic activity of the Ni@Al10Ce catalyst to the mobility of oxygen within the ceria lattice, allowing it to migrate to the surface of the Ni catalyst and react with the dissociated acetic acid, associated with optimized reaction conditions. Additionally, they attributed the minimal formation of coke to the oxygen storage property of ceria. The mobile oxygen released from ceria could migrate to the surface of Ni nanoparticles, where it reacted with the coke precursor or the already formed coke. The diffusion of acetic acid and water from the bulk solution to the surface of nickel nanoparticles, where dissociation took place, was attributed to the pathway provided by the alumina coating, having a better function at a specific ratio.

Figure 2. HRTEM images of (a) Ni@Al10Ce and (b) Ni@Al10Ce-a with low magnification. (c) Ni@Al10Ce and (d) Ni@Al10Ce-a with high magnification. STEM images with cerium EDS mappings and overlaid mappings of the (e) Ni@Al10Ce and (f) Ni@Al10Ce-a catalysts reduced at 600 °C. The green and blue spots represent Ni and Al elements, respectively. Modified with permission from [38].

Also, using the synergy between CeO2 and Al2O3, Lai et al. prepared Ni−CeO2−Al2O3 hybrid nanoparticle clusters as catalysts for hydrogen production via low-temperature steam-methane reforming [39]. The authors obtained a significant metal–support interface generation in the hybrid nanostructure using aerosol-based evaporation-induced self-assembly, in which the addition of Al2O3 was responsible for the surficial area increase, suppression of Ni sintering, and lowering of coke formation. Tu et al. developed a novel two-step hydrothermal process to produce flower-like nanostructures comprised of ceria–zirconia with an OSC of 536 µmol O2 g−1, which was twice the OSC of pure flower-like CeO2 (284 µmol O2 g−1) [40]. By forming a solid solution with zirconia, the function of ceria as a support material for Ni catalysts in the dry reforming of methane was enhanced at 750 °C, with an initial methane conversion of 88.4%. The authors concluded that the flower-like catalyst’s petal-shaped structure improved the Ni metal’s sintering resistance and enhanced coking resistance. It is important to highlight that the manipulation of oxygen vacancies (and OSC) has been achieved through doping methods [41][42]. However, to the best of researchers' knowledge, no studies have been conducted on the control or rational effect of the different morphology or shape of CeO2-based catalysts in this regard. Moreover, researchers feel that such studies can provide interesting insights if they include experimental data and DFT calculations to support their findings.

Extensive research has been conducted on using Co as a catalyst (or co-catalyst) for steam-reforming reactions [43][44][45][46], Its combination with CeO2 structures has shown a synergistic effect, enhancing the active surface area, inhibiting sintering, and facilitating oxygen storage. The catalytic properties have long been studied as CeO2-morphology-dependent for Co-based catalysts [47]. However, the search indicated a recent trend of focusing on ethanol steam reforming and more profound knowledge regarding this substrate; thus, researchers will focus on the recent aspects of the interaction of Co and ceria, beyond simply speaking of a specific morphology and including the effect of ceria facets. Interestingly, the catalysts’ activity and selectivity are influenced by the acid-base properties of the oxide support, as discussed in Noronha’s excellent publication [48]. Thus, choosing the support correctly is of high priority, and ceria properties are remarkable. For example, Ferencz et al. reported a notable influence of the support on product selectivity during ethanol reforming for Co-based catalysts. Due to ceria’s basic nature, hydrogen production was accompanied by the generation of aldehyde and crotonaldehyde as byproducts. Therefore, the acidity/basicity properties of the support play a crucial role in determining the products’ formation [49]. In the same way, the oxidation state of the active species also can play a pivotal role in the activity and selectivity of the process [50].

The literature has already shown that the Co content influences the interaction between metal and cerium, favoring the catalytic properties in ethanol steam reforming, and the highest Co content proved to be when the catalyst was prepared by a co-precipitation method under optimized conditions (500 °C, H2O/EtOH = 12/1) [51]. However, metal dispersion plays a crucial role in the catalytic process, as expected in heterogeneous catalysis, and it is generally recognized as an essential factor. For that matter, the preparation method choice and adding additives can be beneficial. Greluk et al. prepared Co/CeO2 and Ni/CeO2 catalysts by employing various techniques—the impregnation method, different active phase precursors, impregnation solvents, and the presence of organic additives—in an attempt to enhance the dispersion of the metals (Co or Ni) and promote strong metal–support interactions [52]. Adding citric acid to the precursor metal salt solution has proven effective in achieving improved dispersion and smaller metal particle sizes for both catalysts.

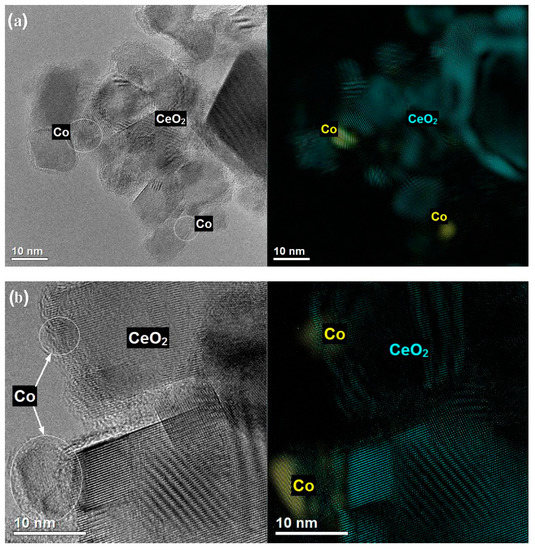

Conversely, catalysts prepared using an ammonia solution resulted in larger metal particle sizes. Interestingly, although the authors did not precisely control the shape of the CeO2 (they obtained rectangular-like shape ceria; Figure 3), the crucial step in the steam reforming of ethanol at 420 °C was using both catalysts is the dehydrogenation of ethanol, which predominantly takes place on the terrace sites of cobalt/nickel. However, the cleavage of the C–C bond is more favorable at the edge/step sites, leading to higher efficiency in the overall process. In the case of Co-based catalysts, apart from size effects, they found that their performance was based on the oxidation state of the Co nanoparticles.

Figure 3. HRTEM images and corresponding FFT patterns of (a) Co/CeO2 (obtained in the presence of citric acid) and (b) Co/CeO2 (obtained from ammonia solution). Modified with permission from [52].

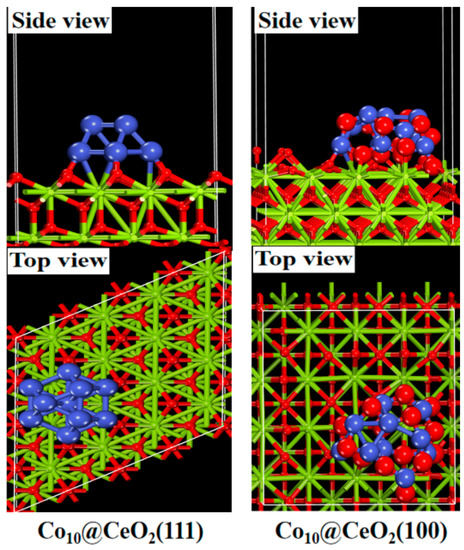

Following a similar trajectory of exploration, Li et al. recently studied Co/CeO2 catalysts with an exposure preference of (111) and (100) facets of CeO2, aiming to understand how to regulate the Co chemical state [53]. They discovered that the Co supported on ceria with (111) facets presented a lower oxidation state and displayed an enhanced capability for cleaving C–C bonds, resulting in superior catalytic performance for the ethanol steam-reforming reaction compared to the Co supported on ceria with (100) facets. Using in situ synchrotron radiation photoionization mass spectrometry and DFT calculations, it has been revealed that Co sites in a low oxidation state exhibit a strong preference for carbon chain shortening through C–C cleavage rather than carbon chain lengthening via condensation reactions. This unique property enhances the efficiency of hydrogen production in the ethanol steam-reforming reaction. Additional information regarding DFT calculations provided the knowledge that the O-terminated (111) facet allowed for the stable support of metallic Co, while the O-terminated (100) facet led to the formation of cobalt oxide, controlling the chemical states of the Co sites, indicating that the oxidation state of Co could be regulated by the CeO2 support with a specific facet exposure (Figure 4).

Figure 4. Side and top views of optimized geometries of Co10 clusters over CeO2 with the exposure of (111) and (100) facets. Reproduced with permission from [53].

One may notice that the Co species may undergo differences during the reaction. Interestingly, Huck-Iriart et al. studied the chemical state of Co in Co-based catalysts during the ethanol steam-reforming reaction by near-ambient pressure XPS (NAP-XPS), extended X-ray absorption fine structure (EXAFS), and X-ray absorption near-edge structure (XANES) [54]. They realized that differences in synthesis methods and precursors affected the Co species during the reaction, which is fascinating. Although their studies did not focus on CeO2-based catalysts, they provided valuable insights that could be applied to investigate supported cobalt on CeO2, particularly with different morphologies, opening possibilities for future research in this area. Although with another aim, Sohn et al. employed AP-XPS and XANES techniques to observe the effect of Co on the reduction characteristics of ceria under ethanol steam-reforming conditions. The authors found that the reducibility of ceria particles is influenced by their particle size, with smaller particles exhibiting a greater degree of surface reduction. Moreover, the presence of fully oxidized Co nanoparticles on the ceria support hinders the surface reducibility of ceria as the reduction of cobalt oxide phases (Co3O4 and CoO) takes priority over the reduction of ceria [55].

Researchers used La2O3 as a promoter for Co/CeO2 and Ni/CeO2 catalysts for the conversion of hydrogen at a temperature of 500 °C, obtaining a complete conversion of ethanol in 21 h [56]. However, the Co/CeO2 catalyst prepared with a La/Co molar ratio equal to 0.1 by co-impregnation proved selective during ethanol steam reforming, showing hydrogen and carbon dioxide selectivity of 94% and 88%, respectively. Although this showed good conversion, methane and carbon monoxide were produced in low amounts, and trace level acetaldehyde was detected among the reaction products. Incorporating La in the structure resulted in forming smaller particle sizes of Co and good dispersion, improving the catalytic activity; however, there was no control of ceria. Thus, it is crucial to understand the effect of promoters, like La and other lanthanides as Zr [57], but there is a lack of studies associating the doping process with shape controlling. The doping of Co into the lattice of CeO2 was studied for the auto-thermal reforming of acetic acid. Although it was unrelated to ethanol reforming, the authors’ findings may be interesting for other substrates and open up further possibilities.

As a final example considering Co-based catalysts and showing the importance of the shape control of ceria, Hu et al. prepared Co-Ce-O by different hydrothermal methods; however, the material that offered the best response was based on ceria nanorods [58], which exhibited a stable hydrogen yield of 2.69 mol-H2/mol acetic acid and a H2 production rate of 332.3 mmol-H2/(gcat·h), even at 600 °C. The acetic acid conversion was initially close to 98.6% and remained stable. In addition, the authors obtained CO2 and CO selectivity of 69.2% and 29.9%, respectively, with no records of by-products. Its greater reactivity concerning the other structures was related to controlling the material’s morphology, exhibiting a greater surface area than the others. It is important to emphasize that a comprehensive understanding of the catalysts’ surface processes requires further research. Therefore, a combination of theoretical and experimental studies becomes essential. For example, Varga et al. observed a strong dissolution of Co into ceria and a certain extent of Co encapsulation by ceria through XRD, XPS, and LEIS (low energy ion scattering) [59]. These observations can significantly influence the material’s performance, indicating the need for further investigations in this area.

3. Shape-Controlled Cerium-Oxide-Based Nanocatalysts with Pt

Despite their high value, noble metals are commonly used as catalysts for steam-reforming reactions due to their high catalytic activity, resistance to catalyst poisoning, thermal stability, and ability to control selectivity [60]. Research is ongoing to explore alternative non-noble metal catalysts, as discussed before; however, the fine-tuning of ceria as a support for noble metals can be used to improve metal–support interactions, avoiding high concentrations of the metal on the support, improving efficiency and resistance to deactivation. Thus, the influence of the noble metal used is important, and deeper knowledge regarding its effect is still the focus of much research [60]. In this context, Vayssilov et al. observed that the electron transfer is favorable on ceria supports regardless of their morphology, while oxygen transfer requires nanostructured ceria in close proximity to Pt. These findings provide valuable insights into the formation mechanism of Pt–O species on ceria and the structure-activity dependence of ceria-based catalysts [61].

Thus, through the reduction of nanoparticle size, catalytic activities can be enhanced while reducing costs. However, smaller noble nanostructures tend to aggregate during catalytic processes, and significant efforts have been made to develop sinter-resistant, single-site catalysts. Jones et al. conducted research using various CeO2 nanostructures to identify the most effective facet for trapping Pt, forming highly thermally stable, single-atom Pt on CeO2 nanostructures [62]. Atomically dispersed Pt was observed on CeO2 nanocubes and polyhedra, and, after various catalytic cycles at temperatures of up to 300 °C, the Pt on CeO2 nanorods remained atomically dispersed, showing CeO2’s role in suppressing catalyst sintering and offering insights for the design of single-atom nanocatalysts. A recent study by Wang et al. showed that steam treatment had a significant impact on catalytic properties by accelerating the formation of active surface lattice oxygen near Pt single atoms [63]. This treatment led to a substantial enhancement in catalytic performance. Unfortunately, researchers could not find similar studies for steam-reforming reactions, but they prove to be promising to the field.

However, other studies show that the shape-control of ceria is important in Pt-based catalysts. For example, CeO2 nanorods have been studied as a support for Pt nanoparticles for the steam reforming of various substrates. Claudio-Piedras et al. conducted a study on Pt/CeO2 nanorod (hydrothermal method) catalysts for methanol steam reforming [64]. They discovered that the choice of Pt precursor (Pt(NH3)4(NO3)2), (CH3-COCHCO-CH3)2Pt, and H2PtCl6.6H2O) immobilized onto the ceria by the incipient impregnation method and that synthesis solvent influenced the catalyst’s performance, indicating that further research is required to establish a common trend. Additionally, the impact of ceria shape on catalytic properties suggests that there is still much to explore in this area.

Studying the catalytic properties of Pt/CeO2 nanorods (hydrothermally prepared) for the steam reforming of methanol, Papavasiliou et al. used the H2PtCl6.6H2O as the metal precursor for the immobilization of Pt by wet impregnation and deposition–precipitation methods. The latter technique provided highly dispersed Pt (mean particle size of less than 1 nm) over the support, which was correlated by the authors due to oxygen vacancies (although no characterizations were provided to prove such a relationship). Interestingly, the catalyst with just 0.3 wt.% Pt strongly interacted with the support surface, in agreement with the STEM, HR-TEM, XRD, and Raman analyses, resulting in an efficient material for the steam reforming of methanol reactions [65].

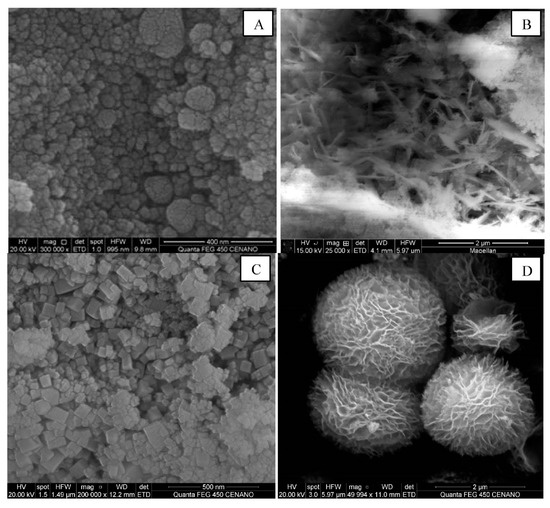

Verykios and co-workers gave researchers an overview of the catalyst performance of differently shaped CeO2 supports as carriers of Pt nanoparticles for low-temperature steam reforming of methanol [66]. Comparing CeO2 bulk (PPT), nanocubes (NC), nanorods (NR), and flower-like (FL) structures (Figure 5), the Pt/CeO2–PPT catalyst demonstrated the highest activity for the dehydrogenation of ethanol to acetaldehyde. On the other hand, the Pt/CeO2–FL and Pt/CeO2–NC catalysts exhibited a higher rate of decomposition of acetaldehyde into CH4 and CO. The ethanol dehydrogenation activity followed the order PPT > NR > NC > FL, while Pt/CeO2–NR presented the best stability and Pt/CeO2–PPT deactivated quickly. XPS analysis showed the presence of Ce3+ and Pt0 on the Pt/CeO2–NR catalyst after a reaction at 300 °C. However, the Pt/CeO2–PPT catalyst exhibited a lower degree of reduction related to the accumulation of acetate species, which can be attributed to the imbalance between the decomposition rate of acetate species to CHx species on Ptδ+ and their desorption as CH4. The authors believe that this was caused by the lower metal–support interface of the Pt/CeO2–PPT catalyst, which had a lower Pt dispersion. The blockage of the Pt–support interface by these CHx species leads to catalyst deactivation. Curiously, nanorods are the focus of great interest, probably due to their best performances.

Figure 5. SEM images for the (A) CeO2–PPT, (B) CeO2–NR, (C) CeO2–NC, and (D) CeO2–FL catalysts. Reproduced with permission from [66].

Raúl Pérez-Hernández researched Pt/Ni catalysts supported on CeO2 nanorods for methanol steam reforming. The study revealed that the enhanced catalytic activity was not solely attributed to the synergy between the metals; CO-DRIFTS (CO diffuse reflectance infrared Fourier transform spectroscopy) experiments indicated that the bimetallic PtNi nanoparticles were predominantly Pt-terminated, which contributed to the improved performance. TPD-DRIFTS (temperature-programmed desorption associated with diffuse reflectance infrared Fourier transform spectroscopy) experiments conducted in the presence of methanol demonstrated that methoxy species and C-H groups strongly interacted with the support’s surface oxygen near Pt. This interaction, facilitated by Pt, resulted in the formation of formate species and suggested Pt’s important role as an intermediary in the reaction [67].

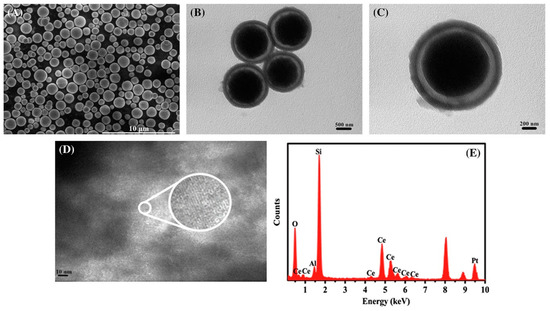

Based on a sophisticated synthesis approach, Dai et al. created a CeO2@Pt-Beta yolk-shell (“Beta”—the name of the material refers to the zeolite Beta) catalyst for low-temperature ethanol steam reforming (Figure 6) [68].

Figure 6. SEM image of (A) CeO2; TEM images of (B–D) CeO2@Pt-Beta catalyst view at different magnifications. (E) The EDX spectrums of the catalyst. Reproduced with permission from [68].

To guarantee the superior performance of the prepared catalyst, the authors compared it with the Pt-Beta and CeO2-Pt-Beta counterparts. They attributed the better performance of the synthesized material to the synergistic effect between the movable CeO2 core and the Pt nanoparticles and the high dispersion of the metal, which achieved 100% conversion with 67% hydrogen selectivity. They also believe that the interstitial hollow space within the catalyst allows for the high loading of reactant molecules, particularly promoting the reaction of larger molecules such as ethanol and acetaldehyde with the CeO2 core and metal Pt active sites. Throughout the 20 h test at 350 °C, the catalyst remained stable, without any significant decrease in activity. Once more, it is crucial to emphasize that the synthesis of shape-controlled nanostructures is an actively developing field. Ongoing research and advancements are necessary to gain a comprehensive understanding of the intrinsic processes occurring during reactions, including the significance of doping techniques. This is also pertinent when considering Pt-based catalysts [42].

Although extensive research has focused on Pt as a catalyst for steam reforming, leading to a comprehensive understanding of its performance and behavior in this application, the established catalytic response of Pt makes it the preferred choice for researchers and industry professionals. However, other noble metals also are promising candidates for steam-reforming reactions, although there is a relatively limited volume of studies exploring their utilization with shape-controlled CeO2 nanostructures. For instance, Kolb et al. conducted a study on the impact of ceria oxide supports’ morphology and crystalline facets on the performance of Rh/CeO2 and Rh/CeO2/Al2O3 catalysts in the oxidative steam reforming of propylene glycol (630 °C, with a steam-to-carbon ratio of 3.5 and an oxygen-to-carbon ratio of 0.15) [69]. A hydrothermal method was employed to synthesize well-defined ceria nanorods and nanocubes, which were then deposited onto α-Al2O3. TEM images revealed that the ceria nanorods exhibited exposed (110) and (100) planes, while the nanocubes possessed only (100) planes; such structures were used as supports for Rh nanoparticles, providing a large surface area and efficient heat and mass transfer. The superior performance of the Rh catalyst supported on ceria nanorods could be attributed to the improved dispersion of Rh species and the presence of higher surface oxygen vacancies associated with the exposed (100) and (110) crystal planes. Also, the catalyst design allowed Rh nanoparticles to stabilize, prevented sintering, and minimized carbon deposition. Unfortunately, little is known about the shape-controlling of ceria for other noble metals, which is the reason for the emphasis on Pt nanoparticles herein presented.

References

- Al-Shetwi, A.Q. Sustainable development of renewable energy integrated power sector: Trends, environmental impacts, and recent challenges. Sci. Total Environ. 2022, 822, 153645.

- Dincer, I.; Bicer, Y. Integration of renewable energy systems for multigeneration. In Integrated Energy Systems for Multigeneration; Elsevier: Amsterdam, The Netherlands, 2020; pp. 287–402.

- Egeland-Eriksen, T.; Hajizadeh, A.; Sartori, S. Hydrogen-based systems for integration of renewable energy in power systems: Achievements and perspectives. Int. J. Hydrog. Energy 2021, 46, 31963–31983.

- Deutch, J. Is Net Zero Carbon 2050 Possible? Joule 2020, 4, 2237–2240.

- McCay, M.H.; Shafiee, S. Hydrogen. In Future Energy; Elsevier: Amsterdam, The Netherlands, 2020; pp. 475–493.

- Sgarbossa, F.; Arena, S.; Tang, O.; Peron, M. Renewable hydrogen supply chains: A planning matrix and an agenda for future research. Int. J. Prod. Econ. 2023, 255, 108674.

- Schmidt, O.; Gambhir, A.; Staffell, I.; Hawkes, A.; Nelson, J.; Few, S. Future cost and performance of water electrolysis: An expert elicitation study. Int. J. Hydrog. Energy 2017, 42, 30470–30492.

- AbouSeada, N.; Hatem, T.M. Climate action: Prospects of green hydrogen in Africa. Energy Rep. 2022, 8, 3873–3890.

- Nazir, H.; Muthuswamy, N.; Louis, C.; Jose, S.; Prakash, J.; Buan, M.E.; Flox, C.; Chavan, S.; Shi, X.; Kauranen, P.; et al. Is the H2 economy realizable in the foreseeable future? Part II: H2 storage, transportation, and distribution. Int. J. Hydrog. Energy 2020, 45, 20693–20708.

- Megía, P.J.; Vizcaíno, A.J.; Calles, J.A.; Carrero, A. Hydrogen Production Technologies: From Fossil Fuels toward Renewable Sources. A Mini Review. Energy Fuels 2021, 35, 16403–16415.

- Akhlaghi, N.; Najafpour-Darzi, G. A comprehensive review on biological hydrogen production. Int. J. Hydrog. Energy 2020, 45, 22492–22512.

- Fiorio, J.L.; Gothe, M.L.; Kohlrausch, E.C.; Zardo, M.L.; Tanaka, A.A.; de Lima, R.B.; Silva, A.A.M.; Garcia, M.A.S.; Vidinha, P.; Machado, G. Nanoengineering of Catalysts for Enhanced Hydrogen Production. Hydrogen 2022, 3, 218–254.

- Reeve, J.; Grasham, O.; Mahmud, T.; Dupont, V. Advanced Steam Reforming of Bio-Oil with Carbon Capture: A Techno-Economic and CO2 Emissions Analysis. Clean Technol. 2022, 4, 309–328.

- Korberg, A.D.; Thellufsen, J.Z.; Skov, I.R.; Chang, M.; Paardekooper, S.; Lund, H.; Mathiesen, B.V. On the feasibility of direct hydrogen utilisation in a fossil-free Europe. Int. J. Hydrog. Energy 2023, 48, 2877–2891.

- Freund, H.-J.; Pacchioni, G. Oxide ultra-thin films on metals: New materials for the design of supported metal catalysts. Chem. Soc. Rev. 2008, 37, 2224.

- Farmer, J.A.; Campbell, C.T. Ceria Maintains Smaller Metal Catalyst Particles by Strong Metal-Support Bonding. Science 2010, 329, 933–936.

- Mao, Z.; Lustemberg, P.G.; Rumptz, J.R.; Ganduglia-Pirovano, M.V.; Campbell, C.T. Ni Nanoparticles on CeO2 (111): Energetics, Electron Transfer, and Structure by Ni Adsorption Calorimetry, Spectroscopies, and Density Functional Theory. ACS Catal. 2020, 10, 5101–5114.

- Carrasco, J.; Barrio, L.; Liu, P.; Rodriguez, J.A.; Ganduglia-Pirovano, M.V. Theoretical Studies of the Adsorption of CO and C on Ni(111) and Ni/CeO2 (111): Evidence of a Strong Metal–Support Interaction. J. Phys. Chem. C 2013, 117, 8241–8250.

- Lustemberg, P.G.; Ramírez, P.J.; Liu, Z.; Gutiérrez, R.A.; Grinter, D.G.; Carrasco, J.; Senanayake, D.S.; Rodriguez, J.A.; Ganduglia-Pirovano, M.V. Room-Temperature Activation of Methane and Dry Re-forming with CO2 on Ni-CeO2 (111) Surfaces: Effect of Ce3+ Sites and Metal–Support Interactions on C–H Bond Cleavage. ACS Catal. 2016, 6, 8184–8191.

- Carrasco, J.; López-Durán, D.; Liu, Z.; Duchoň, T.; Evans, J.; Senanayake, S.D.; Crumlin, E.J.; Matolín, V.; Rodríguez, J.A.; Ganduglia-Pirovano, M.V. In Situ and Theoretical Studies for the Dissociation of Water on an Active Ni/CeO2 Catalyst: Importance of Strong Metal-Support Interactions for the Cleavage of O-H Bonds. Angew. Chem. Int. Ed. 2015, 54, 3917–3921.

- Ganduglia-Pirovano, M.V. The non-innocent role of cerium oxide in heterogeneous catalysis: A theoretical perspective. Catal. Today 2015, 253, 20–32.

- Lustemberg, P.G.; Zhang, F.; Gutiérrez, R.A.; Ramírez, P.J.; Senanayake, S.D.; Rodriguez, J.A.; Ganduglia-Pirovano, V. Breaking Simple Scaling Relations through Metal–Oxide Interactions: Understanding Room-Temperature Activation of Methane on M/CeO2 (M = Pt, Ni, or Co) Interfaces. J. Phys. Chem. Lett. 2020, 11, 9131–9137.

- Liu, Z.; Grinter, D.C.; Lustemberg, P.G.; Nguyen-Phan, T.; Zhou, Y.; Luo, S.; Waluyo, I.; Crumlin, E.J.; Stacchiola, D.J. Dry Reforming of Methane on a Highly-Active Ni-CeO2 Catalyst: Effects of Metal-Support Interactions on C−H Bond Breaking. Angew. Chem. Int. Ed. 2016, 55, 7455–7459.

- Damyanova, S.; Pawelec, B.; Palcheva, R.; Karakirova, Y.; Sanchez, M.C.C.; Tyuliev, G.; Gaigneaux, E.; Fierro, J.L.G. Structure and surface properties of ceria-modified Ni-based catalysts for hydrogen production. Appl. Catal. B 2018, 225, 340–353.

- Liu, Z.; Senanayake, S.D.; Rodriguez, J.A. Elucidating the interaction between Ni and CeOx in ethanol steam reforming catalysts: A perspective of recent studies over model and powder systems. Appl. Catal. B 2016, 197, 184–197.

- Meloni, E.; Martino, M.; Palma, V. A Short Review on Ni Based Catalysts and Related Engineering Issues for Methane Steam Reforming. Catalysts 2020, 10, 352.

- Sepehri, S.; Rezaei, M.; Wang, Y.; Younesi, A.; Arandiyan, H. The evaluation of autothermal methane reforming for hydrogen production over Ni/CeO2 catalysts. Int. J. Hydrog. Energy 2018, 43, 22340–22346.

- Wang, Y.; Zhao, Y.; Zhu, S.; Lu, J.; He, S.; Lu, H.; Song, D.; Luo, Y. Insight into the effect of CeO2 morphology on catalytic performance for steam reforming of glycerol. Fuel 2023, 334, 126587.

- Ni, Z.; Djitcheu, X.; Gao, X.; Wang, J.; Liu, H.; Zhang, Q. Effect of preparation methods of CeO2 on the properties and performance of Ni/CeO2 in CO2 reforming of CH4. Sci. Rep. 2022, 12, 5344.

- Sayle, D.C.; Maicaneanu, S.A.; Watson, G.W. Atomistic Models for CeO2 (111), (110), and (100) Nanoparticles, Supported on Yttrium-Stabilized Zirconia. J. Am. Chem. Soc. 2002, 124, 11429–11439.

- Esch, F.; Fabris, S.; Zhou, L.; Montini, T.; Africh, C.; Fornasiero, P.; Comelli, G.; Rosei, R. Electron Localization Determines Defect Formation on Ceria Substrates. Science 2005, 309, 752–755.

- Zhou, K.; Wang, X.; Sun, X.; Peng, Q.; Li, Y. Enhanced catalytic activity of ceria nanorods from well-defined reactive crystal planes. J. Catal. 2005, 229, 206–212.

- Wang, N.; Qian, W.; Chu, W.; Wei, F. Crystal-plane effect of nanoscale CeO2 on the catalytic performance of Ni/CeO2 catalysts for methane dry reforming. Catal. Sci. Technol. 2016, 6, 3594–3605.

- Migani, A.; Vayssilov, G.N.; Bromley, S.T.; Illas, F.; Neyman, K.M. Greatly facilitated oxygen vacancy formation in ceria nanocrystallites. Chem. Commun. 2010, 46, 5936.

- Tu, P.H.; Le, D.N.; Dao, T.D.; Tran, Q.-T.; Doan, T.C.D.; Shiratori, Y.; Dang, C.M. Paper-structured catalyst containing CeO2–Ni flowers for dry reforming of methane. Int. J. Hydrog. Energy 2020, 45, 18363–18375.

- Mai, H.-X.; Sun, L.-D.; Zhang, Y.-W.; Si, R.; Feng, W.; Zhang, H.-P.; Liu, H.-C.; Yan, C.-H. Shape-Selective Synthesis and Oxygen Storage Behavior of Ceria Nanopolyhedra, Nanorods, and Nanocubes. J. Phys. Chem. B 2005, 109, 24380–24385.

- Sreeremya, T.S.; Krishnan, A.; Remani, K.C.; Patil, K.R.; Brougham, D.F.; Ghosh, S. Shape-Selective Oriented Cerium Oxide Nanocrystals Permit Assessment of the Effect of the Exposed Facets on Catalytic Activity and Oxygen Storage Capacity. ACS Appl. Mater. Interfaces 2015, 7, 8545–8555.

- Pu, J.; Luo, Y.; Wang, N.; Bao, H.; Wang, X.; Qian, E.W. Ceria-promoted Ni@Al2O3 core-shell catalyst for steam reforming of acetic acid with enhanced activity and coke resistance. Int. J. Hydrog. Energy 2018, 43, 3142–3153.

- Lai, G.-H.; Lak, J.H.; Tsai, D.-H. Hydrogen Production via Low-Temperature Steam–Methane Reforming Using Ni–CeO2–Al2O3 Hybrid Nanoparticle Clusters as Catalysts. ACS Appl. Energy Mater. 2019, 2, 7963–7971.

- Tu, P.H.; Sakamoto, M.; Sasaki, K.; Shiratori, Y. Synthesis of flowerlike ceria–zirconia solid solution for promoting dry reforming of methane. Int. J. Hydrog. Energy 2022, 47, 42171–42184.

- Xiao, Z.; Li, Y.; Hou, F.; Wu, C.; Pan, L.; Zou, J.; Wang, L.; Zhang, X.; Liu, G.; Li, G. Engineering oxygen vacancies and nickel dispersion on CeO2 by Pr doping for highly stable ethanol steam reforming. Appl. Catal. B 2019, 258, 117940.

- Vecchietti, J.; Lustemberg, P.; Fornero, E.L.; Calatayud, M.; Collins, S.E.; Mohr, S. Controlled selectivity for ethanol steam reforming reaction over doped CeO2 surfaces: The role of gallium. Appl. Catal. B 2020, 277, 119103.

- Sohn, H.; Ozkan, U.S. Cobalt-Based Catalysts for Ethanol Steam Reforming: An Overview. Energy Fuels 2016, 30, 5309–5322.

- Wolf, M. Thermodynamic assessment of the stability of bulk and nanoparticulate cobalt and nickel during dry and steam reforming of methane. RSC Adv. 2021, 11, 18187–18197.

- Wong, Y.; Halim, H.H.; Khairudin, N.F.; Pham, T.N.; Putra, S.E.M.; Hamamoto, Y.; Inagaki, K.; Hamada, I.; Mohamed, A.R.; Morikawa, Y. Dry Reforming of Methane on Cobalt Catalysts: DFT-Based Insights into Carbon Deposition Versus Removal. J. Phys. Chem. C 2021, 125, 21902–21913.

- Ayodele, B.V.; Mustapa, S.I.; Bin Mohd Yassin, M.Y.; Abdullah, S. Experimental and optimization studies of hydrogen production by steam methane reforming over lanthanum strontium cobalt ferrite supported Ni catalyst. Int. J. Energy Res. 2019, 43, 8118–8135.

- Wang, H.; Zhang, L.; Li, M.; Liu, Y.; Bai, X. Co/CeO2 for ethanol steam reforming: Effect of ceria morphology. J. Rare Earths 2013, 31, 565–571.

- Mattos, L.V.; Jacobs, G.; Davis, B.H.; Noronha, F.B. Production of Hydrogen from Ethanol: Review of Reaction Mechanism and Catalyst Deactivation. Chem. Rev. 2012, 112, 4094–4123.

- Ferencz, Z.s.; Erdőhelyi, A.; Baán, K.; Oszkó, A.; Óvári, L.; Kónya, Z.; Papp, C.; Steinrück, H.-P.; Kiss, J. Effects of Support and Rh Additive on Co-Based Catalysts in the Ethanol Steam Reforming Reaction. ACS Catal. 2014, 4, 1205–1218.

- Varga, E.; Ferencz, Z.; Oszkó, A.; Erdőhelyi, A.; Kiss, J. Oxidation states of active catalytic centers in ethanol steam reforming reaction on ceria based Rh promoted Co catalysts: An XPS study. J. Mol. Catal. A Chem. 2015, 397, 127–133.

- Greluk, M.; Rotko, M.; Słowik, G.; Turczyniak-Surdacka, S. Hydrogen production by steam reforming of ethanol over Co/CeO2 catalysts: Effect of cobalt content. J. Energy Inst. 2019, 92, 222–238.

- Greluk, M.; Gac, W.; Rotko, M.; Słowik, G.; Turczyniak-Surdacka, S. Co/CeO2 and Ni/CeO2 catalysts for ethanol steam reforming: Effect of the cobalt/nickel dispersion on catalysts properties. J. Catal. 2021, 393, 159–178.

- Li, R.; Liu, C.; Li, L.; Xu, J.; Ma, J.; Ni, J.; Yan, J.; Han, J.; Pan, Y.; Lui, Y.; et al. Regulating cobalt chemical state by CeO2 facets preferred exposure for improved ethanol steam reforming. Fuel 2023, 336, 126758.

- Huck-Iriart, C.; Soler, L.; Casanovas, A.; Marini, C.; Prat, J.; Llorca, J.; Escudero, C. Unraveling the Chemical State of Cobalt in Co-Based Catalysts during Ethanol Steam Reforming: An in Situ Study by Near Ambient Pressure XPS and XANES. ACS Catal. 2018, 8, 9625–9636.

- Sohn, H.; Soykal, I.I.; Zhang, S.; Shan, J.; Tao, F.; Miller, J.T.; Ozkan, U.S. Effect of Cobalt on Reduction Characteristics of Ceria under Ethanol Steam Reforming Conditions: AP-XPS and XANES Studies. J. Phys. Chem. C 2016, 120, 14631–14642.

- Greluk, M.; Rotko, M.; Turczyniak-Surdacka, S. Enhanced catalytic performance of La2O3 promoted Co/CeO2 and Ni/CeO2 catalysts for effective hydrogen production by ethanol steam reforming. Renew Energy 2020, 155, 378–395.

- Ishihara, A.; Tsujino, H.; Hashimoto, T. Effects of the addition of CeO2 on the steam reforming of ethanol using novel carbon-Al2O3 and carbon-ZrO2 composite-supported Co catalysts. RSC Adv. 2021, 11, 8530–8539.

- Hu, X.; Ding, C.; Wang, Q.; Chen, H.; Jia, X.; Huang, L. Preparation of Co-Ce-O catalysts and its application in auto-thermal reforming of acetic acid. Inorg. Chem. Commun. 2022, 141, 109537.

- Varga, E.; Pusztai, P.; Óvári, L.; Oszkó, A.; Erdőhelyi, A.; Papp, C.; Steinrück, H.-P.; Kónyabc, Z.; Kiss, J. Probing the interaction of Rh, Co and bimetallic Rh–Co nanoparticles with the CeO2 support: Catalytic materials for alternative energy generation. Phys. Chem. Chem. Phys. 2015, 17, 27154–27166.

- Charisiou, N.D.; Siakavelas, G.I.; Papageridis, K.N.; Motta, D.; Dimitratos, N.; Sebastian, V. The Effect of Noble Metal (M: Ir, Pt, Pd) on M/Ce2O3-γ-Al2O3 Catalysts for Hydrogen Production via the Steam Reforming of Glycerol. Catalysts 2020, 10, 790.

- Vayssilov, G.N.; Lykhach, Y.; Migani, A.; Staudt, T.; Petrova, G.P.; Tsud, N.; Skála, T.; Bruix, A.; Illas, F.; Prince, K.C.; et al. Support nanostructure boosts oxygen transfer to catalytically active platinum nanoparticles. Nat. Mater. 2011, 10, 310–315.

- Jones, J.; Xiong, H.; DeLaRiva, A.T.; Peterson, E.J.; Pham, H.; Challa, S.R.; Qi, G.; Oh, S.; Wiebanga, M.H.; Wang, Y.L.; et al. Thermally stable single-atom platinum-on-ceria catalysts via atom trapping. Science 2016, 353, 150–154.

- Nie, L.; Mei, D.; Xiong, H.; Peng, B.; Ren, Z.; Hernandez, X.I.P.; DeLaRiva, A.; Wang, M.; Engelhard, M.H.; Kovarik, L.; et al. Activation of surface lattice oxygen in single-atom Pt/CeO2 for low-temperature CO oxidation. Science 2017, 358, 1419–1423.

- Claudio-Piedras, A.; Ramírez-Zamora, R.M.; Alcántar-Vázquez, B.C.; Gutiérrez-Martínez, A.; Mondragón-Galicia, G.; Morales-Anzures, F.; Pérez-Hérnandez, R. One dimensional Pt/CeO2-NR catalysts for hydrogen production by steam reforming of methanol: Effect of Pt precursor. Catal. Today 2021, 360, 55–62.

- Papavasiliou, J.; Paxinou, A.; Słowik, G.; Neophytides, S.; Avgouropoulos, G. Steam Reforming of Methanol over Nanostructured Pt/TiO2 and Pt/CeO2 Catalysts for Fuel Cell Applications. Catalysts 2018, 8, 544.

- Kourtelesis, M.; Moraes, T.S.; Mattos, L.V.; Niakolas, D.K.; Noronha, F.B.; Verykios, X. The effects of support morphology on the performance of Pt/CeO2 catalysts for the low temperature steam reforming of ethanol. Appl. Catal. B 2021, 284, 119757.

- Pérez-Hernández, R. Reactivity of Pt/Ni supported on CeO2-nanorods on methanol steam reforming for H2 production: Steady state and DRIFTS studies. Int. J. Hydrog. Energy 2021, 46, 25954–25964.

- Dai, R.; Zheng, Z.; Lian, C.; Li, X.; Wu, X.; An, X.; Xie, X. A high-performance CeO2@Pt-Beta yolk-shell catalyst used in low-temperature ethanol steam reforming for high-purity hydrogen production. Int. J. Energy Res. 2019, 43, 2075–2085.

- Shanmugam, V.; Zapf, R.; Hessel, V.; Pennemann, H.; Kolb, G. Nano-architectured CeO2 supported Rh with remarkably enhanced catalytic activity for propylene glycol reforming reaction in microreactors. Appl. Catal. B 2018, 226, 403–411.

More

Information

Subjects:

Nanoscience & Nanotechnology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

551

Revisions:

2 times

(View History)

Update Date:

28 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No