Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Rui Tan | -- | 3016 | 2023-08-02 10:26:59 | | | |

| 2 | Conner Chen | Meta information modification | 3016 | 2023-08-04 02:45:38 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zou, B.; Zhang, L.; Xue, X.; Tan, R.; Jiang, P.; Ma, B.; Song, Z.; Hua, W. Battery Fault Mechanism. Encyclopedia. Available online: https://encyclopedia.pub/entry/47539 (accessed on 16 January 2026).

Zou B, Zhang L, Xue X, Tan R, Jiang P, Ma B, et al. Battery Fault Mechanism. Encyclopedia. Available at: https://encyclopedia.pub/entry/47539. Accessed January 16, 2026.

Zou, Bosong, Lisheng Zhang, Xiaoqing Xue, Rui Tan, Pengchang Jiang, Bin Ma, Zehua Song, Wei Hua. "Battery Fault Mechanism" Encyclopedia, https://encyclopedia.pub/entry/47539 (accessed January 16, 2026).

Zou, B., Zhang, L., Xue, X., Tan, R., Jiang, P., Ma, B., Song, Z., & Hua, W. (2023, August 02). Battery Fault Mechanism. In Encyclopedia. https://encyclopedia.pub/entry/47539

Zou, Bosong, et al. "Battery Fault Mechanism." Encyclopedia. Web. 02 August, 2023.

Copy Citation

The battery system, as the core energy storage device of new energy vehicles, faces increasing safety issues and threats. An accurate and robust fault diagnosis technique is crucial to guarantee the safe, reliable, and robust operation of lithium-ion batteries. However, in battery systems, various faults are difficult to diagnose and isolate due to their similar features and internal coupling relationships.

electric vehicles

lithium-ion batteries

battery faults

1. Introduction

Lithium-ion batteries have attracted widespread attention from both academia and industry due to their high power and energy density, long cycle life, and low self-discharge rate, which have been applied in different scenarios such as consumer electronics, electric vehicles, distributed energy storage, and large-scale energy storage [1][2]. However, as a typical energy storage device, which involves complex electrochemical reaction mechanisms, lithium-ion batteries inherently have high safety risks, having potential safety issues that can threaten reliable vehicle operation [3][4][5]. Theories and techniques of system engineering are demanded to pay attention to battery material system development, battery management system (BMS) design, energy storage system structure optimization, and other levels to ensure its safety and stability in actual utilization in electric vehicles [6].

Limited by the current development level of electrical, thermal, and safety management system technologies, lithium-ion batteries will suffer from mechanical, electrical, and thermal abuse during actual operation, such as overcharge, overdischarge, and overheating [7][8]. These abuses can cause a rapid degradation in battery performances and even cause internal short circuits that can lead to severe safety problems [9]. In electric vehicles, distributed energy storage, and large-scale energy storage, a large number of individual lithium batteries tend to be connected in series and parallel to form battery modules and packs to meet the demand of current, voltage, power, and energy. The large number of connected components greatly increases the complexity of the system and will leads to an increased probability of various types of failures [10][11]. Consistent effort has been invested to prevent the thermal runaway of onboard batteries. To understand the battery faults mechanisms, Wu et al. reviewed the recent research on battery aging mechanisms. Besides, the state estimation accuracy influences the performance of the battery management system (BMS) [12]. Shrivastava et al. executed a review and analysis of the existing advanced state estimation methods [13]. They also proposed the comprehensive co-estimation method for battery states, which could effectively make use of the existing correlation between different battery states and reduce computational expense [14]. Gu et al. aimed to design an easy-to-implement diagnosis method that does not require accurate mathematical modeling, expert understanding, and complex computational process [15]. It is necessary to implement an effective and reliable fault diagnosis method of the battery system based on the recognition of the battery system fault initiation mechanism. Early warning of battery faults is required to improve the safety and reliability of the real application of the battery system [16].

As for battery system fault diagnosis, researchers have conducted a lot of exploration in terms of fault triggering mechanism, behavior characteristics, and reaction mechanism [17][18][19]. A further understanding of battery system faults has been obtained, and a preliminary fault diagnosis strategy has been developed based on the external characteristic behavior exhibited by the occurrence of faults.

2. Battery Fault Mechanism

During the practical use of new energy vehicles, battery performances are influenced by a variety of factors. In this section, different types of battery faults in new energy vehicles are introduced and the failure mechanisms of the battery system are elaborated in detail.

2.1. Battery Fault Types

Common lithium-ion battery systems mainly include cells, BMS, sensors, connection components, etc. Due to the complex internal operation mechanism and external user conditions, there are various types of faults in lithium-ion battery systems and complex fault evolution patterns. From the perspective of the control system, battery system fault modes can be divided into two main types, including cell fault and system fault, respectively. Cell fault is the dominant factor affecting the safety of battery systems, which can be further divided into progressive faults and sudden faults. System faults can be classified as management system faults, sensor faults, and connection component faults.

2.1.1. Cell Fault

Lithium-ion batteries can fail during actual operation due to changes in their internal structure or characteristics. According to the different development stages of cell fault, it can be mainly divided into two types: progressive fault and sudden fault.

Progressive fault is mainly caused by battery degradation, which is essentially a superposition of a series of internal battery side reactions and is affected by both internal and external battery environments. During the charge and discharge cycle, abnormalities such as loss of active material, electrolyte consumption, increase in internal resistance, lithium deposition, gas generation, SEI thickening, and current collector corrosion will occur inside the battery [20][21][22]. External stimulation and internal side reactions lead to continuous loss of cell active components and accumulation of insoluble by-products [23]. The consequent shift in electrochemical equilibrium can cause the battery degradation highly nonlinear and leads to high overpotential, low-rate capability, and especially limited lifespan, which hinders the battery’s commercial application. Therefore, timely detection of progressive faults and accurate assessment of battery health conditions can provide a strong guarantee for safe battery operation.

Sudden fault is a failure that causes sudden failure or significant degradation of the battery system without obvious signs or within a short period, including internal short circuits [24], thermal runaway, capacity diving, liquid leakage, etc. Sudden fault and progressive fault are equivalent to two successive processes in the reaction time sequence, and the final stage of progressive fault development is to trigger a sudden fault. For example, unreasonable charging and discharging strategies can lead to internal lithium plating, causing battery capacity to fade, which is still a progressive failure. With the further evolution of lithium deposition, lithium dendrites can penetrate the separator, triggering internal short circuits [25]. Massive heat is released and even triggers thermal runaway in a short period [26], which is a sudden failure. Therefore, progressive faults can develop into sudden faults through continuous evolution. However, the occurrence of sudden faults does not depend entirely on the evolution of progressive faults. In addition to battery degradation, other battery external factors can also directly lead to the sudden faults of batteries. For example, the battery in the use process, due to mechanical abuse resulting in an internal short circuit, can generate a lot of heat in a short period, which can lead to thermal runaway, smoke, fire, or even explosion [27].

2.1.2. System Fault

Battery system fault consists of the following three main types, management system fault, sensor fault, and connection component fault, respectively.

Management system fault: In the field of new energy vehicles, the function of power BMS mainly contains two aspects, which are monitoring and management. That is a real-time estimation of battery performance parameters and effective control of battery temperature according to the application environment [28]. BMS is the core control unit, its normal performance is significantly important to ensure the safe, stable, and reliable working condition of the battery [29]. The battery management system enables the safe monitoring of power cell characteristics by collecting external characteristics of the power cell system [30][31]. If the BMS fails, it will send an error command and interfere with the proper operation. The functions will be limited, and in severe cases, irreversible damage will be caused to the battery, which will lead to a series of chain failures [32]. For example, the failure of the equalization component of the BMS can lead to increased inconsistency in the battery system and affect the system’s performance. If the charging and discharging control components of the BMS fail, it will cause an increased risk of overcharge and overdischarge and reduce the battery life. If the temperature control component of the BMS fails, it will cause the battery system to operate at an abnormal temperature, which may lead to thermal abuse and even cause thermal runaway [33]. The development of BMS with a high level of functional safety is a hot issue for the industry, which needs to be solved from different aspects such as the design process, software, and hardware.

Sensor fault: The sensor measurements can be used to update the model parameters in the battery management system in real-time to achieve highly accurate monitoring and management of the battery. The battery management system is dependent on the suitable operation of temperature, voltage, current and other sensors to achieve battery state estimation, charging and discharging control, fault diagnosis, equalization control, temperature control, and other functions. There are three main types of battery sensor faults, including voltage sensor fault, current sensor fault, and temperature sensor fault, respectively [34]. During usage, there will be inevitable faults such as deviation, drift, decrease in accuracy level, or even stopping working. Once the sensor fault is not detected in time, it can lead to the current, voltage, temperature, and other data cannot be measured or can be measured inaccurately, affecting the accuracy of multi-state estimation of battery SOC, SOH, SOT, etc. It is difficult to make accurate and reasonable judgments on the current working state of the battery, inducing the BMS system to stop working or posting wrong commands. However, lithium-ion batteries must operate within safe voltage and temperature ranges, and exceeding these ranges can lead to reduced battery performance, equalization errors, and even thermal runaway accidents. Generally, compared with sensor-stopping faults, sensor faults such as deviation, drift, and accuracy level reduction are more hidden and more difficult to diagnose, which is the focus and challenge of the current sensor fault diagnosis technology research [35].

Connection component fault: The battery connection component fault tends to be induced by a bad connection between battery terminals. Connections between individual cells in a battery pack or between battery modules need to be made by nuts or welding processes. With the increase in vehicle running time and the uncertainty of operating conditions, the vibration, corrosion of components, and expansion of battery gas production can trigger the failure of internal connection components of the battery system, such as loose nuts or welding joints and poor contact [36][37]. If a false connection occurs between cells, it can affect the power performances of the battery system at high rates, resulting in insufficient battery output power. If such faults are not effectively detected and eliminated for a long time, they can cause the resistance to increase rapidly. Excessive internal resistance can lead to a continuous accumulation of local heat, which can result in an increase in the temperature of the battery and connections, causing accelerated degradation of the battery or even thermal runaway safety accidents [38].

2.2. Battery Fault Mechanism

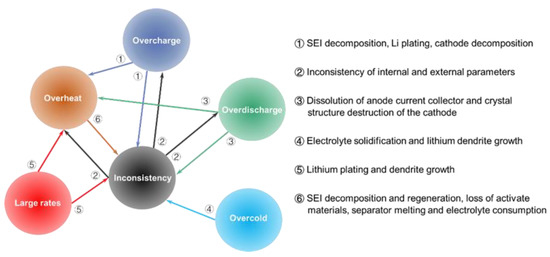

The study of the fault mechanism of battery can help us understand the occurrence and evolution of the fault pattern, so as to provide a scientific basis for the development of fault diagnosis methods. This subsection briefly introduces the causes and mechanisms of different faults. Currently, there are mainly overcharge, overdischarge, overcool, overheat, large rate charge and discharge, inconsistency, and other factors that may lead to battery failure, as shown in Figure 2.

Figure 2. Battery fault mechanisms and the internal coupling relationships. The six main battery failure mechanisms are coupled with each other and are not singularly induced.

Overcharge: In order to meet the voltage and capacity requirements of automotive power sources, the battery system consists of many individual cells connected in series or parallel. However, there are inconsistencies between individual cells due to manufacturing defects and differences in operating conditions [39]. During charging, overcharging of some individual batteries will inevitably occur due to problems such as battery charger failure or inaccurate detection or estimation of battery state (e.g., SOC) in the battery management system [40]. Even if the total voltage of the battery system remains relatively below its limit, some individual cells can still be overcharged [41]. Generally, when a battery is overcharged, lithium plating will occur on the surface of the anode. If there is a slight overcharge for a long period, it will lead to a progressive fault in the battery capacity fading too fast due to the loss of active lithium. At the same time, lithium plating may induce lithium dendrites, increasing the safety risk of micro or internal short circuits caused by separator penetration. In some extreme cases, such as when a BMS failure occurs, a long period of deep overcharge of the battery can occur. The battery temperature continues to rise, triggering a series of side reactions such as SEI film decomposition and cathode material decomposition [42], which eventually trigger sudden failures such as internal short circuits and thermal runaway of the battery [43][44].

Overdischarge: Generally, the overdischarge is prevented by setting the discharge cut-off voltage. However, overdischarge is still a common trouble in electric vehicle applications due to high current inrush, unreasonable design of battery management system, long battery storage time, and unbalance between battery modules. As for the long-term slight overdischarge situation, the anode structure and the SEI film are easily damaged due to the complete deintercalation of lithium ions. It leads to irreversible loss of active material and triggers a progressive fault in which the battery capacity fades quickly. If a long period of deep overdischarge occurs, the lithium-ion stripping ability of the anode decreases. Battery polarization voltage rises, causing the negative current collector copper foil to be oxidized, dissolved, and deposited on the cathode surface. On the one hand, it affects the electron transport capacity of the negative current collector and hinders the deintercalation of lithium ions, resulting in the progressive fault of rapid fade of battery capacity and rapid increase of internal impedance [45]. On the other hand, copper deposited on the surface of the cathode may penetrate the separator, triggering sudden faults such as internal short circuits and thermal runaway of the battery [17]. In addition, deep overdischarge can cause excessive lithium embedding in the cathode, triggering irreversible damage to the crystal structure of the cathode material and leading to degradation of the battery performance [46].

Large rate charge and discharge: As the charge and discharge rate of the battery increases, the heat production rate increases consequently. It is easy to trigger exothermic side reactions inside the battery, increasing the risk of internal short circuits, and can cause sudden fault of the battery thermal runaway [47][48]. Especially for the large rate charging process, due to the solid phase diffusion rate limitation, the lithium plating tends to occur at the anode surface. It causes progressive fault of capacity fading, and induces lithium dendrite growth, causing internal short circuits as a safety hazard.

Overheat: Battery charging and discharging process will be accompanied by the violent movement of electrons, the result of this violent movement is the thermal effect. Many conditions can cause abnormal battery heating, such as side reactions during overcharge and overdischarge, external short circuits, internal short circuits, insufficient cooling system heat dissipation capability, etc. When the battery is at a relatively high operating temperature, it can increase the rate of internal side reactions, such as the rate of SEI decomposition and regeneration. It leads to an accelerated rate of irreversible loss of active material and triggers a progressive fault in which the battery capacity fades quickly [49][50]. In the charging and discharging process, if the battery working environment temperature is too high and the heat production rate is significantly higher than the heat dissipation rate, the lithium-ion battery may have different degrees of expansion. It can cause resistance increase and cycle life degradation, which triggers a series of exothermic side reactions such as electrolyte consumption and separator melting. The degradation of cathode material and the growth of solid electrolyte interfacial in the anode can be accelerated, which eventually leads to sudden faults such as internal short circuits and thermal runaway of the battery. If the decomposition of the materials inside the lithium-ion battery produces gas, the increased pressure will cause the battery to expand and possibly explode.

Overcool: When the battery is in a low-temperature operating environment, it may cause some of the solvents in the electrolyte to condense and solidify. Lithium-ion diffusion or migration rate becomes significantly smaller. Especially for the low-temperature charging case, there is a mismatch between the electrochemical reaction and the solid phase diffusion rate. The ionic conductivity of the SEI and electrolyte and the diffusion of lithium into the graphite can be decreased significantly, resulting in the battery capacity fading rapidly [51][52]. The lithium plating on the surface of the anode tends to occur, and the uncontrollable dendrites can cause a series of sudden faults such as separator penetration, internal short circuit, etc., [53][54].

Inconsistency: In the various stages of battery manufacturing, screening into groups and usage, there is a certain degree of inconsistency in internal and external parameters such as available capacity, internal resistance, open-circuit voltage, self-discharge rate, and charge state among the individual cells in the battery system, which can affect the system efficiency, safety, and service life [55][56]. Generally, with the charging and discharging cycles, the inconsistency among the individual cells tends to gradually increase due to the different degradation histories, which affects the overall capacity of the system. For example, in the screening stage, the low available capacity cell can be fully charged and discharged during actual operation, or even overcharged and overdischarged. It will accelerate the degradation process, which will eventually lead to premature battery failure, and the whole battery system will also show the progressive fault of capacity fade. Therefore, it is an important part of battery fault diagnosis to identify and locate the faulty single unit in advance and implement targeted operation and maintenance through real-time and accurate assessment of battery system inconsistency.

The trigger mechanism of battery cell fault is complex and requires optimal design and regulation at all stages of battery manufacturing, screening into groups, and use to improve battery system safety. During the actual operation, the electric and thermal management strategies are optimally designed to avoid abnormal operations such as overcharge, overdischarge, overcooling, overheating, and large rate charging and discharging as much as possible. It can delay the rate of capacity fade and internal resistance increase, reducing the risk of lithium plating, micro or internal short circuit, thermal runaway, etc. By designing a reasonable battery cell fault diagnosis technology to achieve accurate early identification of faulty cells, it can provide support for targeted operation and maintenance of the safety and reliability of the battery system.

References

- Levy, S.C. Safety and Reliability Considerations for Lithium Batteries. J. Power Sources 1997, 68, 75–77.

- Su, S.; Ma, J.; Zhao, L.; Lin, K.; Li, Q.; Lv, S.; Kang, F.; He, Y.B. Progress and Perspective of the Cathode/Electrolyte Interface Construction in All-Solid-State Lithium Batteries. Carbon Energy 2021, 3, 866–894.

- Mou, J.; Duan, P.; Gao, L.; Liu, X.; Li, J. An Effective Hybrid Collaborative Algorithm for Energy-Efficient Distributed Permutation Flow-Shop Inverse Scheduling. Futur. Gener. Comput. Syst. 2022, 128, 521–537.

- Zhang, L.S.; Gao, X.L.; Liu, X.H.; Zhang, Z.J.; Cao, R.; Cheng, H.C.; Wang, M.Y.; Yan, X.Y.; Yang, S.C. CHAIN: Unlocking Informatics-Aided Design of Li Metal Anode from Materials to Applications. Rare Met. 2022, 41, 1477–1489.

- Zhu, X.; Wang, H.; Wang, X.; Gao, Y.; Allu, S.; Cakmak, E.; Wang, Z. Internal Short Circuit and Failure Mechanisms of Lithium-Ion Pouch Cells under Mechanical Indentation Abuse Conditions: An Experimental Study. J. Power Sources 2020, 455, 227939.

- Liu, H.; Wei, Z.; He, W.; Zhao, J. Thermal Issues about Li-Ion Batteries and Recent Progress in Battery Thermal Management Systems: A Review. Energy Convers. Manag. 2017, 150, 304–330.

- Lin, J.; Liu, X.; Li, S.; Zhang, C.; Yang, S. A Review on Recent Progress, Challenges and Perspective of Battery Thermal Management System. Int. J. Heat Mass Transf. 2021, 167, 120834.

- Hua, Y.; Liu, X.; Zhou, S.; Huang, Y.; Ling, H.; Yang, S. Toward Sustainable Reuse of Retired Lithium-Ion Batteries from Electric Vehicles. Resour. Conserv. Recycl. 2021, 168, 105249.

- Chen, Y.; Kang, Y.; Zhao, Y.; Wang, L.; Liu, J.; Li, Y.; Liang, Z.; He, X.; Li, X.; Tavajohi, N.; et al. A Review of Lithium-Ion Battery Safety Concerns: The Issues, Strategies, and Testing Standards. J. Energy Chem. 2021, 59, 83–99.

- Yao, L.; Wang, Z.; Ma, J. Fault Detection of the Connection of Lithium-Ion Power Batteries Based on Entropy for Electric Vehicles. J. Power Sources 2015, 293, 548–561.

- Hou, Q.; Liu, J.; Zhang, J.; Xu, Z.; Chen, X.; Chen, P. A Vehicle Alarm Network for High-Temperature Fault Diagnosis of Electric Vehicles. Appl. Intell. 2023, 53, 6230–6247.

- Wu, C.; Zhu, C.; Ge, Y.; Zhao, Y. A Review on Fault Mechanism and Diagnosis Approach for Li-Ion Batteries. J. Nanomater. 2015, 2015, 8.

- Shrivastava, P.; Naidu, P.A.; Sharma, S.; Panigrahi, B.K.; Garg, A. Review on Technological Advancement of Lithium-Ion Battery States Estimation Methods for Electric Vehicle Applications. J. Energy Storage 2023, 64, 107159.

- Shrivastava, P.; Soon, T.K.; Bin Idris, M.Y.I.; Mekhilef, S.; Adnan, S.B.R.S. Comprehensive Co-Estimation of Lithium-Ion Battery State of Charge, State of Energy, State of Power, Maximum Available Capacity, and Maximum Available Energy. J. Energy Storage 2022, 56, 106049.

- Gu, X.; Shang, Y.; Kang, Y.; Li, J.; Mao, Z.; Zhang, C. An Early Minor-Fault Diagnosis Method for Lithium-Ion Battery Packs Based on Unsupervised Learning. IEEE/CAA J. Autom. Sin. 2023, 10, 810–812.

- Meng, J.; Boukhnifer, M.; Diallo, D. On-Line Model-Based Short Circuit Diagnosis of Lithium-Ion Batteries for Electric Vehicle Application. In Proceedings of the IECON 2019-45th Annual Conference of the IEEE Industrial Electronics Society, Lisbon, Potrugal, 14–17 October 2019; Volume 1, pp. 6022–6027.

- Chao, W.; Chunbo, Z.; Jinlei, S.; Jianhu, J. Fault Mechanism Study on Li-Ion Battery at over-Discharge and Its Diagnosis Approach. IET Electr. Syst. Transp. 2017, 7, 48–54.

- Abaza, A.; Ferrari, S.; Wong, H.K.; Lyness, C.; Moore, A.; Weaving, J.; Blanco-Martin, M.; Dashwood, R.; Bhagat, R. Experimental Study of Internal and External Short Circuits of Commercial Automotive Pouch Lithium-Ion Cells. J. Energy Storage 2018, 16, 211–217.

- Yang, R.; Xiong, R.; Ma, S.; Lin, X. Characterization of External Short Circuit Faults in Electric Vehicle Li-Ion Battery Packs and Prediction Using Artificial Neural Networks. Appl. Energy 2020, 260, 114253.

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A Review on the Key Issues of the Lithium Ion Battery Degradation among the Whole Life Cycle. eTransportation 2019, 1, 100005.

- Verma, P.; Maire, P.; Novák, P. A Review of the Features and Analyses of the Solid Electrolyte Interphase in Li-Ion Batteries. Electrochim. Acta 2010, 55, 6332–6341.

- Koltypin, M.; Cohen, Y.S.; Markovsky, B.; Cohen, Y.; Aurbach, D. The Study of Lithium Insertion-Deinsertion Processes into Composite Graphite Electrodes by in Situ Atomic Force Microscopy (AFM). Electrochem. Commun. 2002, 4, 17–23.

- Amine, K.; Liu, J.; Belharouak, I.; Kang, S.H.; Bloom, I.; Vissers, D.; Henriksen, G. Advanced Cathode Materials for High-Power Applications. J. Power Sources 2005, 146, 111–115.

- Wang, H.; Simunovic, S.; Maleki, H.; Howard, J.N.; Hallmark, J.A. Internal Configuration of Prismatic Lithium-Ion Cells at the Onset of Mechanically Induced Short Circuit. J. Power Sources 2016, 306, 424–430.

- Orendorff, C.J.; Lambert, T.N.; Chavez, C.A.; Bencomo, M.; Fenton, K.R. Polyester Separators for Lithium-Ion Cells: Improving Thermal Stability and Abuse Tolerance. Adv. Energy Mater. 2013, 3, 314–320.

- Wang, Q.; Mao, B.; Stoliarov, S.I.; Sun, J. A Review of Lithium Ion Battery Failure Mechanisms and Fire Prevention Strategies. Prog. Energy Combust. Sci. 2019, 73, 95–131.

- Huang, P.; Wang, Q.; Li, K.; Ping, P.; Sun, J. The Combustion Behavior of Large Scale Lithium Titanate Battery. Sci. Rep. 2015, 5, 7788.

- Pal, P.; Devabalaji, K.R.; Priyadarshini, S. Design of Battery Management System for Residential Applications. Int. J. Eng. Trends Technol. 2020, 68, 12–17.

- Trov, A. Battery Management System for Industrial-Scale Vanadium Redox Flow Batteries: Features and Operation. J. Power Sources 2020, 465, 228229.

- Hu, X.; Feng, F.; Liu, K.; Zhang, L.; Xie, J.; Liu, B. State Estimation for Advanced Battery Management: Key Challenges and Future Trends. Renew. Sustain. Energy Rev. 2019, 114, 109334.

- Wei, J. Remaining Useful Life Prediction and State of Health Diagnosis for Lithium-Ion Batteries Using Particle Filter and Support Vector Regression. IEEE Trans. Ind. Electron. 2018, 65, 5634–5643.

- Bruen, T.; Widanage, W.D.; Gama-valdez, M.A.; Marco, J.; Pastor-fern, C. A Study of Cell-to-Cell Interactions and Degradation in Parallel Strings: Implications for the Battery Management System. J. Power Sources 2016, 329, 574–585.

- Raihan, A.; Siddique, M.; Mahmud, S.; Heyst, B. Van Review Article A Comprehensive Review on a Passive (Phase Change Materials) and an Active (Thermoelectric Cooler) Battery Thermal Management System and Their Limitations. J. Power Sources 2018, 401, 224–237.

- Dey, S.; Mohon, S.; Pisu, P.; Ayalew, B. Sensor Fault Detection, Isolation, and Estimation in Lithium-Ion Batteries. IEEE Trans. Control Syst. Technol. 2016, 24, 2141–2149.

- Chen, W.; Chen, W.T.; Saif, M.; Li, M.F.; Wu, H. Simultaneous Fault Isolation and Estimation of Lithium-Ion Batteries via Synthesized Design of Luenberger and Learning Observers. IEEE Trans. Control Syst. Technol. 2014, 22, 290–298.

- Offer, G.J.; Yufit, V.; Howey, D.A.; Wu, B.; Brandon, N.P. Module Design and Fault Diagnosis in Electric Vehicle Batteries. J. Power Sources 2012, 206, 383–392.

- Xia, B.; Mi, C. A Fault-Tolerant Voltage Measurement Method for Series Connected Battery Packs. J. Power Sources 2016, 308, 83–96.

- Liu, G.; Ouyang, M. Analysis of the Heat Generation of Lithium-Ion Battery during Charging and Discharging Considering Different Influencing Factors. J. Therm. Anal. Calorim. 2014, 116, 1001–1010.

- Baronti, F.; Roncella, R.; Saletti, R. Performance Comparison of Active Balancing Techniques for Lithium-Ion Batteries. J. Power Sources 2014, 267, 603–609.

- Yuan, Q.F.; Zhao, F.; Wang, W.; Zhao, Y.; Liang, Z.; Yan, D. Overcharge Failure Investigation of Lithium-Ion Batteries. Electrochim. Acta 2015, 178, 682–688.

- Ren, D.; Feng, X.; Lu, L.; He, X.; Ouyang, M. Overcharge Behaviors and Failure Mechanism of Lithium-Ion Batteries under Different Test Conditions. Appl. Energy 2019, 250, 323–332.

- Liu, Y.; Liu, Q.; Li, Z.; Ren, Y.; Xie, J.; He, H.; Xu, F. Failure Study of Commercial LiFePO4 Cells in Over-Discharge Conditions Using Electrochemical Impedance Spectroscopy. J. Electrochem. Soc. 2014, 161, A620–A632.

- Huang, L.; Zhang, Z.; Wang, Z.; Zhang, L.; Zhu, X.; Dorrell, D.D. Thermal Runaway Behavior during Overcharge for Large-Format Lithium-Ion Batteries with Different Packaging Patterns. J. Energy Storage 2019, 25, 100811.

- Larsson, F.; Andersson, P.; Blomqvist, P.; Mellander, B.E. Toxic Fluoride Gas Emissions from Lithium-Ion Battery Fires. Sci. Rep. 2017, 7, 10018.

- Zheng, Y.; Qian, K.; Luo, D.; Li, Y.; Lu, Q.; Li, B.; He, Y.B.; Wang, X.; Li, J.; Kang, F. Influence of Over-Discharge on the Lifetime and Performance of LiFePO4/Graphite Batteries. RSC Adv. 2016, 6, 30474–30483.

- Shu, J.; Shui, M.; Xu, D.; Wang, D.; Ren, Y.; Gao, S. A Comparative Study of Overdischarge Behaviors of Cathode Materials for Lithium-Ion Batteries. J. Solid State Electrochem. 2012, 16, 819–824.

- Gao, Y.; Jiang, J.; Zhang, C.; Zhang, W.; Ma, Z.; Jiang, Y. Lithium-Ion Battery Aging Mechanisms and Life Model under Different Charging Stresses. J. Power Sources 2017, 356, 103–114.

- Barcellona, S.; Piegari, L. Effect of Current on Cycle Aging of Lithium Ion Batteries. J. Energy Storage 2020, 29, 101310.

- Lindgren, J.; Lund, P.D. Effect of Extreme Temperatures on Battery Charging and Performance of Electric Vehicles. J. Power Sources 2016, 328, 37–45.

- Wu, M.S.; Chiang, P.C.J. High-Rate Capability of Lithium-Ion Batteries after Storing at Elevated Temperature. Electrochim. Acta 2007, 52, 3719–3725.

- Bandhauer, T.M.; Garimella, S.; Fuller, T.F. A Critical Review of Thermal Issues in Lithium-Ion Batteries. J. Electrochem. Soc. 2011, 158, R1.

- Wang, Q.; Ping, P.; Zhao, X.; Chu, G.; Sun, J.; Chen, C. Thermal Runaway Caused Fire and Explosion of Lithium Ion Battery. J. Power Sources 2012, 208, 210–224.

- Ma, S.; Jiang, M.; Tao, P.; Song, C.; Wu, J.; Wang, J.; Deng, T.; Shang, W. Temperature Effect and Thermal Impact in Lithium-Ion Batteries: A Review. Prog. Nat. Sci. Mater. Int. 2018, 28, 653–666.

- Burow, D.; Sergeeva, K.; Calles, S.; Schorb, K.; Börger, A.; Roth, C.; Heitjans, P. Inhomogeneous Degradation of Graphite Anodes in Automotive Lithium Ion Batteries under Low-Temperature Pulse Cycling Conditions. J. Power Sources 2016, 307, 806–814.

- Zheng, Y.; Ouyang, M.; Lu, L.; Li, J.; Han, X.; Xu, L. On-Line Equalization for Lithium-Ion Battery Packs Based on Charging Cell Voltages: Part 2. Fuzzy Logic Equalization. J. Power Sources 2014, 247, 460–466.

- Xie, L.; Ren, D.; Wang, L.; Chen, Z.; Tian, G.; Amine, K.; He, X. OPEN A Facile Approach to High Precision Detection of Cell-to-Cell Variation for Li-Ion Batteries. Sci. Rep. 2020, 10, 7182.

More

Information

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

982

Revisions:

2 times

(View History)

Update Date:

04 Aug 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No