Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Hyun Kyu Shin | -- | 1902 | 2023-07-27 02:04:41 | | | |

| 2 | Conner Chen | Meta information modification | 1902 | 2023-07-28 02:44:19 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Shin, H.K.; Ha, S.K. Application of Hydrogen Storage Tanks. Encyclopedia. Available online: https://encyclopedia.pub/entry/47333 (accessed on 08 February 2026).

Shin HK, Ha SK. Application of Hydrogen Storage Tanks. Encyclopedia. Available at: https://encyclopedia.pub/entry/47333. Accessed February 08, 2026.

Shin, Hyun Kyu, Sung Kyu Ha. "Application of Hydrogen Storage Tanks" Encyclopedia, https://encyclopedia.pub/entry/47333 (accessed February 08, 2026).

Shin, H.K., & Ha, S.K. (2023, July 27). Application of Hydrogen Storage Tanks. In Encyclopedia. https://encyclopedia.pub/entry/47333

Shin, Hyun Kyu and Sung Kyu Ha. "Application of Hydrogen Storage Tanks." Encyclopedia. Web. 27 July, 2023.

Copy Citation

The most practical way of storing hydrogen gas for fuel cell vehicles is to use a composite overwrapped pressure vessel. Depending on the driving distance range and power requirement of the vehicles, there can be various operational pressure and volume capacity of the tanks, ranging from passenger vehicles to heavy-duty trucks. The current commercial hydrogen storage method for vehicles involves storing compressed hydrogen gas in high-pressure tanks at pressures of 700 bar for passenger vehicles and 350 bar to 700 bar for heavy-duty trucks. In particular, hydrogen is stored in rapidly refillable onboard tanks, meeting the driving range needs of heavy-duty applications, such as regional and line-haul trucking.

hydrogen energy

hydrogen storage tank

carbon fiber

1. Hydrogen Storage Systems

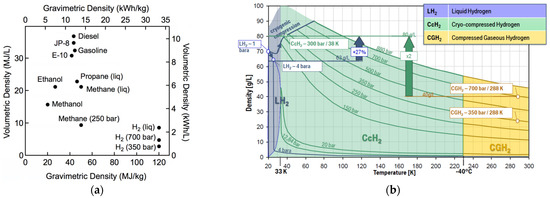

Hydrogen storage systems can be classified into physical storage (compressed gas, cryogenic) and storage in solid materials (physisorption, chemical storage [1][2][3]). The gravimetric and volumetric energy densities of hydrogen are used to assess the suitability of the storage media [4][5].

Figure 1 compares the volumetric and gravimetric H2 densities of the most common hydrogen storage methods. Although solid-state storage systems have a lower volumetric density and theoretical potential, additional system requirements must be met [6].

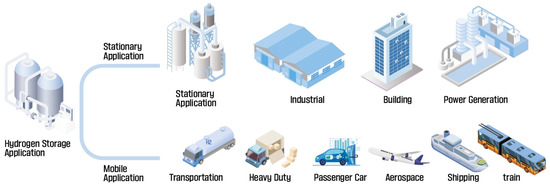

Hydrogen storage is a key component of hydrogen energy systems, particularly in scenarios involving large-scale hydrogen utilization. In the context of the hydrogen economy, hydrogen storage applications can be divided into two groups [9]: stationary and mobile applications, as summarized in Figure 2.

Figure 2. Types of hydrogen storage applications. Stationary includes on-site storage at the point of production or use and stationary power generation. Mobile applications include vehicle fuel and hydrogen transportation.

Various hydrogen storage methods have been compared based on density, pressure, temperature, and cost [4][10], as summarized in Table 1. Among the various methods, the onboard hydrogen storage method used in passenger cars such as the Mirai, NEXO, and Clarity is a compressed gas method, with hydrogen storage tanks of 350–700 bar. Whiston et al. [11] predicted that compressed hydrogen storage methods will be predominantly used by 2035 and will account for 67% of all hydrogen storage methods, and the proportion will rise to 56% by 2050. Cerri et al. [12] predicted the cost of storing 1 kg of hydrogen in a tank using the compressed gas method to be USD400–700, as shown in Table 1.

Table 1. Comparison of the main hydrogen storage media.

| Storage Technologies | Volumetric Density (kg H2/m3) | Gravimetric Density (Reversible) (wt.%) | Operating Pressure (bar) | Operating Temperature (K) | Cost * (USD/kg H2) |

|---|---|---|---|---|---|

| Compressed gas (H2) | 17–33 | 3–4.8 (system) | 350 and 700 | ambient | 400–700 * |

| Cryogenic (H2) | 35–40 | 6.5–14 (system) | 1 | 20 | 200–270 * |

| Cryo-compressed (H2) | 30–42 | 4.7–5.5 (system) | 350 | 20 | 400 |

| High pressure—solid | 40 | 2 (system) | 80 | 243–298 | |

| Sorbents (H2) | 20–30 | 5–7 (material) | 80 | 77 | |

| Metal hydrides (H) | <150 | 2–6.7 (material) | 1–30 | Ambient-553 | >500 |

| Complex hydrides (H) | <120 | 4.5–6.7 (material) | 1–50 | 423–573 | 300–450 * |

| Chemical hydrides (H) | 30 | 3–5 (system) | 1 | 353–473 | 160–270 ** |

* Cost estimates based on 500,000 units of production. ** Regeneration and processing costs not included.

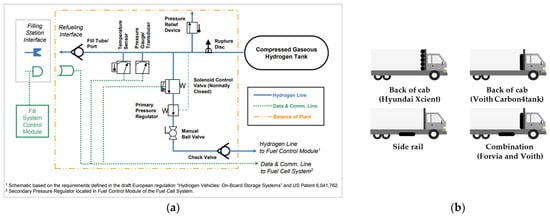

The onboard compressed gas hydrogen system for fuel cell electric vehicles (FCEVs) is depicted in Figure 3 and is categorized into the hydrogen storage tank and the BOP (balance of plant). Passenger car hydrogen storage tanks are designed with 1–3 tanks, considering packing based on 5–6 kg of hydrogen storage capacity depending on the vehicle’s layout. The BOP consists of a fill port, regulator, valves, and sensors. Heavy-duty truck hydrogen storage tanks have higher hydrogen storage capacity than passenger cars and use various mounting methods such as side rail, back of cab, combo, canopy, and top of the body [13].

In particular, development and demonstration of operations and initial commercialization are ongoing for heavy-duty trucks (classes seven and eight) [14], employing various hydrogen storage tank packing methods, as shown in Figure 3. While most passenger cars are designed with a hydrogen storage tank capacity of at least 5.6 kg per vehicle, heavy-duty trucks have a wide range of types and uses [15]. Kast et al. [13][16] calculated the required onboard hydrogen storage tank capacity for each class, as shown in Table 2.

Figure 3. (a) Compressed gas hydrogen storage system [17]; (b) compressed gas hydrogen storage onboard trucks, shown in various potential locations.

2. Types of Hydrogen Storage Tanks

Hydrogen storage tanks were previously one of four types [8][18][19]; recently, Type V [20][21][22][23][24], which is a linerless fully composite tank, was developed by Composite Technology Development Inc. [25][26]. The essential features of each type are as follows:

- Type I: All metal construction;

- Type II: Metal with hoop composite overwrap;

- Type III: Metal liner with full composite overwrap. Composite carries all load;

- Type IV: Polymer liner with a full composite overwrap;

- Type V: Linerless composite vessels.

Type I is an all-metal storage tank. Type II is a tank with a composite material overwrapped around the cylindrical part of the storage tank. In Type II, the internal pressure load is shared between the liner and composite layers. Type III consists of a metal liner fully overwrapped with carbon or glass fiber, whereas Type IV consists of a polymer liner fully overwrapped with carbon or glass fiber. Type V is a linerless structure, with the entire tank made of carbon or glass fiber. Carbon and glass fibers are commonly used as reinforcements in storage tanks, with epoxy or vinyl ester primarily used as the matrix system, as shown in Table 3.

| Type I | Type II | Type III | Type IV | Type V | |

|---|---|---|---|---|---|

| Schematic [32] |

|

|

|

|

|

| Composition | All Metal | Metal Liner with Composites Layer | Metal Liner with Full composites Overwrapped | Metal Liner with Full composites Overwrapped | Full Composites |

| Tank price (USD/kg) |

++ (83) |

+ (86) |

− (700) |

− (633) |

− |

| Gravimetric capacity | − | - | + | ++ | ++ |

| Composite layers load sharing | 45% load bearing | 80% load bearing | 100% load bearing | 100% load bearing |

Type I is currently the most widely used vessel, accounting for approximately 90% of the market. However, Type I is more than three times heavier than Type III and Type IV, whereas Type IV costs over 300% more than Type I [33]. Type II is over 50% more expensive and 30–40% lighter than Type I. Type III is 50% lighter but costs more than twice as much as Type II, shown in Figure 4. Additionally, Type III and Type VI offer the advantage of hydrogen storage at higher pressures for higher energy storage density.

3. On-Road Application

Current commercially available passenger cars with hydrogen pressure vessels are summarized in Table 4. Some initial models used 350 bar hydrogen pressure vessels, but owing to hydrogen storage limitations, most models currently use 700 bar hydrogen pressure vessels; 1–3 pressure vessels are used depending on the vehicle layout. The hydrogen storage capacity of vehicles equipped with hydrogen pressure vessels ranges from a minimum of 4.4 kg to a maximum of 6.33 kg. Hydrogen storage tanks adopt the Type IV manufacturing method that uses polymer liners (HDPE, PA6, etc.), and the wet winding process is widely used as an essential filament winding method during production.

Table 4. Hydrogen vehicles and specification of hydrogen storage tanks.

| Hyundai NEXO (2018) [34][35][36][37] |

Hyundai ix35(2013) [36][38] |

Toyota MIRAI II (2021) [39][40][41][42][43] |

Honda Clarity (2016) [44][45][46] |

Mercedes Benz GLC (2017) [47][48][49] |

|

|---|---|---|---|---|---|

| Photos |  |

|

|

|

|

| Pressure (bar) | 700 | 700 | 700 | 700 | 700 |

| Tank volume (liter) | 156.6 (52/52/52) |

140 (36/104) |

142.2 (52/25.3/64.9) |

141.3 (24/117) |

117 (unknown) |

| Tank capacity (H2 kg) | 6.33 | 5.64 | 5.6 | 5.46 | 4.4 |

| Tank weight (kg) estimation |

111 kg (37/37/37) |

104 kg (36/104) |

unknown | unknown | unknown |

| Gravity capacity | 7.18 wt% | 6.43 wt% | 5.7 wt% | unknown | 5.64 wt% |

| Driving range(km) | 609 | 415 | 650 | 589 | 478 |

| Tank type | Type IV | Type IV | Type IV | Type III | Type IV |

| Liner materials | PA6 | HDPE | PA 6 | aluminum | unknown |

| Winding process | wet | wet | unknown | unknown | unknown |

The Tucson ix35, manufactured by Hyundai Motor Company in 2013, was the first commercialized FCEV passenger car, storing 5.64 kg of hydrogen in two hydrogen pressure vessels (36 L/104 L) with a total volume of 140 L. Toyota began developing fuel cell systems in 1992 and started sales on a limited lease basis in 2002 [50]. The mass-produced Mirai was launched in 2014, and the 2021 model has a total hydrogen storage capacity of 5.6 kg in three hydrogen pressure vessels (52 L/25.3 L/64.9 L) with a total volume of 142.2 L. In 2016, Honda launched the Clarity, which stores a total of 5.46 kg of hydrogen in two hydrogen tanks with a capacity of 141 L. In 2017, the Mercedes Benz GLC, capable of storing 4.4 kg of hydrogen in a 117 L tank, was launched. The 2018 Hyundai NEXO model stores 6.33 kg of hydrogen in three identical-capacity (52 L) tanks with a total capacity of 156.6 L. As shown in Table 4, original equipment manufacturers (OEMs) efficiently packed hydrogen pressure vessels of the same or different sizes according to the vehicle’s layout, securing adequate hydrogen storage capacity [51]. In the transportation sector, hydrogen energy is gaining importance for its application to heavy-duty trucks in Table 5, which have a driving range of more than 805 km, fast fuel supply, and shift operation [11][52]. According to an IEA report [53], as of 2022, 12 manufacturers have manufactured or plan to manufacture 16 types of fuel cell trucks by 2024. According to the Interreg North-West Europe H2-Share report [54], 15 types are currently in operation. Hydrogen storage tank suppliers, listed in Table 6, are developing or manufacturing Type III and Type IV hydrogen storage tanks for passenger cars, commercial vehicles, and transport tube trailers, with operating pressures ranging from 350 to 700 bar.

| Hyundai XCIENT (36 t) (2019) [58][59][60] |

Hyzon Hymax (24 t) [61] |

Daimler GenH2 [62] |

DAF-VDL H2 Share Project (27 t) (2020~) [54] |

MAN (35 t) [63] |

Scania (27 t) (2019~) [64] |

|

|---|---|---|---|---|---|---|

| Photos |  |

|

|

|

|

|

| Operator | COOP | - | Testing | - | COOP | Akso |

| Pressure (bar) | 350 | 350 | Liquid | 350 | 350 | 350 |

| Range (km) | 400 | 400 | 1000 | 400 | 400 | 500 |

| Tank Capacity (H2 kg) | 31 [60] | 30 | 80 | 30 | 31 | 33 |

| No. of Tanks/Type | 7/IV | 10/Unknown | 2/Liquid | Unknown | 7/III | Unknown/IV |

Table 6. The manufacturer of compressed gas hydrogen storage tanks.

| Manufacturer | Type [65] |

Pressure (bar) |

Water Volume (liter) |

Application |

|---|---|---|---|---|

| Advanced Structural Technologies, Inc. [66] | III | 350–517 | 290–540 | Off-road, mining, construction, marine, rail |

| Liaoning Alsafe Technology [67] | III | 350–700 | 3–180 | Hydrogen, medical, SCUBA, etc. |

| AMS composites cylinders [68] | III | 300 | 1–10 | Oxygen, UAV |

| Avanco (Hexagon) [69] | IV | 300–381 | 350 | Distribution, train |

| Cylinders Holding [70] | I | 300 | 166 | Trailer, container |

| CATEC [71] | IV | 275 | 30~53 ft trailer | trailer |

| EKC [72] | IV | 245 | 148–324 | Medical, industrial, truck |

| Faber Industries [73] | I, II, III, IV | 200–1100 | SCBA, hydrogen, CNG, food, etc. | |

| Hexagon Purus [74] | IV | 250–950 | 193–1745 | Stationary, distribution, etc. |

| Hanhwa [75][76] | IV | 350–700 | 10.8–2078 | Passenger cars, buses, and trucks |

| IlJin Hysolus [77] | IV | 700 | 500 | Transport, mobility |

| Infinite composites [78] | V | 310 | 325 | Spacecraft applications |

| Luxfer [79] | I, II, III | 90–350 | 0.8–2250 | SCBA, specialty, medical. CO2, aerospace |

| Mahytec [80] | IV | 60–500 | 300–850 | Stationary storage |

| Nproxx [81] | III, IV | 100–700 | - | Stationary, railroad, passenger car |

| Plastic Omnium [82] | IV | 200–700 | - | Passenger car, truck |

| Quantum Fuel systems [83] | IV | 350–700 | 26–994 | Passenger car, truck, bus, transportable, aerospace |

| Steelhead composites [84] | III, IV | 200–700 | 90–270 | Storage and transport |

| Faurecia Ullit [85] | IV | 350–700 | 120–691 | Heavy truck |

| Toyoda Gosei [86] | IV | 700 | 25.3–64.9 (w/o truck) | Passenger vehicle, truck |

| Voith composites [87] | IV | 700 | 350 | Heavy-duty trucks |

| Wiretough [88] | II (wire) | 350–700 | 765–1750 | Ground storage |

| Jiangsu Guofu Hydrogen Energy Equipment Co., Ltd. [89][90] | III | 350 | 59–140 | Passenger car, bus, logistic vehicle |

| Sinoma Science and Technology Co., Ltd. [89][91][92] | III | 350–700 | 28–320 | Bus, UAM |

As shown in Table 4, passenger cars can store 5.4–6.33 kg of hydrogen in hydrogen storage tanks with volumes ranging from 25.3 to 117 L per vehicle and achieve a maximum driving range of 650 km. Class 8 heavy-duty trucks, as shown in Table 5, store 30–31 kg of hydrogen, with a driving range of 400–500 km.

The first heavy-duty FCEV vehicle, the Hyundai Xcient model, underwent test runs for 2 years and has covered 5 million km in Switzerland since October 2020. Full commercial sales of the hydrogen-powered fuel cell truck Xcient began in December 2022 [93]. At IAA Transportation 2022, FORVIA [94] exhibited a product that could store 80 kg of hydrogen by mounting five 700 bar XL Type IV hydrogen storage tanks in the cab module (diameter: 200–700 mm, length: up to 3300 mm) and two tanks in the module on the side (diameter: 700 mm, length: 2500 mm). Voith [95] developed a product with a 700 km driving range by storing 56–112 kg of hydrogen in 4–8 tanks; each hydrogen storage tank had 350 L and 14 kg of hydrogen capacity (7.4%) at 700 bar. Compared with passenger cars carrying 5.6 kg of hydrogen, heavy-duty trucks show an increasing trend of 5.5–20 times in the storage capacity, with a maximum storage of 112 kg, as shown in Table 7. Park, C. et al. [96] also reported that buses and trucks use 10–20 times more hydrogen than passenger cars.

Table 7. Compressed gas hydrogen storage tanks onboard trucks, shown by location.

References

- Eberle, U.; Felderhoff, M.; Schüth, F. Chemical and Physical Solutions for Hydrogen Storage. Angew. Chem. Int. Ed. 2009, 48, 6608–6630.

- Schlapbach, L.; Zuttel, A. Hydrogen-storage materials for mobile applications. Nature 2001, 414, 353–358.

- Ahluwalia, R.; Hua, T.; Peng, J.-K.; Lasher, S.; McKenney, K.; Sinha, J.; Gardiner, M. Technical assessment of cryo-compressed hydrogen storage tank systems for automotive applications. Int. J. Hydrogen Energy 2010, 35, 4171–4184.

- Ayakdas, O.; Aydin, L. Researches on Science and Art in 21st Century Turkey; Gece Kitapligi: Ankara, Türkiye, 2018; pp. 2890–2980.

- Lai, Q.W.; Paskevicius, M.; Sheppard, D.A.; Buckley, C.E.; Thornton, A.W.; Hill, M.R.; Gu, Q.F.; Mao, J.F.; Huang, Z.G.; Liu, H.K.; et al. Hydrogen Storage Materials for Mobile and Stationary Applications: Current State of the Art. Chemsuschem 2015, 8, 2789–2825.

- Züttel, A. Materials for hydrogen storage. Mater. Today 2003, 6, 24–33.

- Hydrogen Storage. Available online: https://www.energy.gov/eere/fuelcells/hydrogen-storage (accessed on 25 May 2023).

- Azkarate, I.T.; Barthélémy, H.A.L.; Hooker, P.H.; Jordan, T.K.; Keller, J.; Markert, F.D.; Steen, M.; Tchouvelev, A.A. Research Priority Workshop on Hydrogen Safety; Publications Office of the European Union: Luxembourg, 2018.

- Moradi, R.; Groth, K.M. Hydrogen storage and delivery: Review of the state of the art technologies and risk and reliability analysis. Int. J. Hydrogen Energy 2019, 44, 12254–12269.

- Adolfo Iulianelli, A.B. Advances in Hydrogen Production, Storage and Distribution; Elsevier: Cambridge, UK, 2014.

- Whiston, M.M.; Lima Azevedo, I.M.; Litster, S.; Samaras, C.; Whitefoot, K.S.; Whitacre, J.F. Hydrogen Storage for Fuel Cell Electric Vehicles: Expert Elicitation and a Levelized Cost of Driving Model. Environ. Sci. Technol. 2021, 55, 553–562.

- Cerri, I.; Lefebvre-Joud, F.; Holtappels, P.; Honegger, K.; Stubos, T.; Millet, P.; Coordination, J.; Pfrang, A.; Bielewski, M.; Tzimas, E. Strategic Energy Technology Plan; European Commission: Brussels, Belgium, 2012.

- Kast, J.; Vijayagopal, R.; Gangloff, J.J.; Marcinkoski, J. Clean commercial transportation: Medium and heavy duty fuel cell electric trucks. Int. J. Hydrogen Energy 2017, 42, 4508–4517.

- Cunanan, C.; Tran, M.-K.; Lee, Y.; Kwok, S.; Leung, V.; Fowler, M. A Review of Heavy-Duty Vehicle Powertrain Technologies: Diesel Engine Vehicles, Battery Electric Vehicles, and Hydrogen Fuel Cell Electric Vehicles. Clean Technol. 2021, 3, 474–489.

- Gangloff, J.J.; Kast, J.; Morrison, G.; Marcinkoski, J. Design Space Assessment of Hydrogen Storage Onboard Medium and Heavy Duty Fuel Cell Electric Trucks. J. Electrochem. Energy Convers. Storage 2017, 14, 8.

- Kast, J.; Morrison, G.; Gangloff, J.J.; Vijayagopal, R.; Marcinkoski, J. Designing hydrogen fuel cell electric trucks in a diverse medium and heavy duty market. Res. Transp. Econ. 2018, 70, 139–147.

- Law, K.; Rosenfeld, J.; Han, V.; Chan, M.; Chiang, H.; Leonard, J. US Department of Energy Hydrogen Storage Cost Analysis; TIAX LLC: Lexington, MA, USA, 2013.

- David, E. An overview of advanced materials for hydrogen storage. J. Mater. Process. Technol. 2005, 162, 169–177.

- Barral, K.; Barthélémy, H. Hydrogen high pressure tanks storages: Overview and new trends due to H2 Energy specifications and constraints. In Proceedings of the 16th World Hydrogen Energy Conference (WHEC-16), Lyon, France, 13–16 June 2006.

- Jones, B.H.; Li, M.-C. Liner-less tanks for space application-design and manufacturing considerations. In Proceedings of the 5th Conference on Aerospace Materials, Processes, and Environmental Technology, Huntsville, AL, USA, 1 November 2003.

- Air, A.; Shamsuddoha, M.; Gangadhara Prusty, B. A review of Type V composite pressure vessels and automated fibre placement based manufacturing. Compos. Part B Eng. 2023, 253, 110573.

- Gardiner, G. Infinite Composites: Type V Tanks for Space, Hydrogen, Automotive and More. Composites World, 27 June 2023.

- Demonstrating the Future of Composite Space Tank Technology. Available online: https://www.nccuk.com/media/0i5b10jw/space-tank.pdf (accessed on 27 June 2023).

- Gardiner, G. Viritech and Haydale Pursue New Functionalized Materials for Type V Composite Vessels for Hydrogen Storage. Composites World. 28 April 2023. Available online: https://www.compositesworld.com/news/viritech-and-haydale-pursue-new-functionalized-materials-for-type-v-composite-vessels-for-hydrogen-storage (accessed on 6 May 2023).

- Legault, M. The First Commercial Type V Composite Pressure Vessel; Composites world: Cincinnati, OH, USA, 2012.

- Ebermann, M.; Bogenfeld, R.; Kreikemeier, J.; Glüge, R. Analytical and numerical approach to determine effective diffusion coefficients for composite pressure vessels. Compos. Struct. 2022, 291, 115616.

- Rivard, E.; Trudeau, M.; Zaghib, K. Hydrogen storage for mobility: A review. Materials 2019, 12, 1973.

- Hassan, I.; Ramadan, H.S.; Saleh, M.A.; Hissel, D. Hydrogen storage technologies for stationary and mobile applications: Review, analysis and perspectives. Renew. Sustain. Energy Rev. 2021, 149, 111311.

- Azeem, M.; Ya, H.H.; Alam, M.A.; Kumar, M.; Stabla, P.; Smolnicki, M.; Gemi, L.; Khan, R.; Ahmed, T.; Ma, Q.; et al. Application of filament winding technology in composite pressure vessels and challenges: A review. J. Energy Storage 2022, 49, 103468.

- Barthélémy, H.; Weber, M.; Barbier, F. Hydrogen storage: Recent improvements and industrial perspectives. Int. J. Hydrogen Energy 2017, 42, 7254–7262.

- Amirthan, T.; Perera, M.S.A. The role of storage systems in hydrogen economy: A review. J. Nat. Gas Sci. Eng. 2022, 108, 104843.

- Gardiner, G. Hydrogen Is Poised to Fuel Composites Growth, Part 1. Composites World, 24 September 2021.

- Meyer, K.; Pignagnoli, F.; Potts, D.; Hunter, G. Lightweighting matters in energy storage. Reinf. Plast. 2014, 58, 20–23.

- NEXO Specifications. Available online: https://www.hyundai.com/kr/en/eco/nexo/highlights (accessed on 1 April 2023).

- Aminudin, M.; Kamarudin, S.; Lim, B.; Majilan, E.; Masdar, M.; Shaari, N. An overview: Current progress on hydrogen fuel cell vehicles. Int. J. Hydrogen Energy 2022, 48, 4371–4388.

- Hong, B.K.; Kim, S.H. Recent advances in fuel cell electric vehicle technologies of Hyundai. ECS Trans. 2018, 86, 3.

- Sery, J.; Leduc, P. Fuel cell behavior and energy balance on board a Hyundai Nexo. Int. J. Engine Res. 2022, 23, 709–720.

- Hong, B.K.; Kim, S.H.; Kim, C.M. Powering the Future through Hydrogen and Polymer Electrolyte Membrane Fuel Cells: Current commercialisation and key challenges with focus on work at Hyundai. Johns. Matthey Technol. Rev. 2020, 64, 236–251.

- 2022 Mirai Full Specs. Available online: https://toyota-cms-media.s3.amazonaws.com/wp-content/uploads/2021/11/2022-Toyota-Mirai_Product-Info-Guide.pdf (accessed on 1 April 2023).

- Yamashita, A.; Kondo, M.; Goto, S.; Ogami, N. Development of High-Pressure Hydrogen Storage System for the Toyota “Mirai”; SAE Technical Paper 2015-01-1169; SAE International: Warrendale, PA, USA, 2015.

- Ube Industries Supplying Nylon 6 Resin for High-Pressure Hydrogen Tanks in Latest Toyota MIRAI Fuel Cell Vehicle. Available online: https://www.ube.co.jp/ube/en/news/2020/20210303_01.html (accessed on 1 April 2023).

- De Almeida, S.C.A.; Kruczan, R. Effects of drivetrain hybridization on fuel economy, performance and costs of a fuel cell hybrid electric vehicle. Int. J. Hydrogen Energy 2021, 46, 39404–39414.

- Tanaka, S.; Nagumo, K.; Yamamoto, M.; Chiba, H.; Yoshida, K.; Okano, R. Fuel cell system for Honda CLARITY fuel cell. ETransportation 2020, 3, 100046.

- 2021 Clarity Fuel Cell Specifications & Features. Available online: https://hondanews.com/en-US/honda-automobiles/releases/release-4f88c507e72a4e7630685979cb04f2cb-2021-clarity-fuel-cell-specifications-features (accessed on 1 April 2023).

- Brachmann, T. Honda Clarity Fuel Cell. Available online: https://www.hfc-hungary.org/hylaw/HyLaw_presentation_HONDA_2018_sept.pdf (accessed on 1 April 2023).

- Kimura, K.; Kawasaki, T.; Ohmura, T.; Atsumi, Y.; Shimizu, K. Development of new fuel cell vehicle Clarity Fuel Cell. Honda RD Tech. Rev. 2016, 28, 1–7.

- GLC F-CELL Goes Into Preproduction: World’s First Electric Vehicle with Fuel-Cell/Battery Powertrai. Available online: https://mercedes-benz-media.co.uk/en-gb/releases/41 (accessed on 3 April 2023).

- Charolais, A.; Ammouri, F.; Vyazmina, E.; Werlen, E.; Harris, A. Safety Watchdog for universally safe gaseous high pressure hydrogen fillings. Int. J. Hydrogen Energy 2021, 46, 16019–16029.

- BMW Group Reaffirms Commitment to Hydrogen Fuel Cell Technology. Available online: https://www.bmwblog.com/2020/03/30/bmw-group-reaffirms-commitment-to-hydrogen-fuel-cell-technology/ (accessed on 28 April 2023).

- Yumiya, H.; Kizaki, M.; Asai, H. Toyota fuel cell system (TFCS). World Electr. Veh. J. 2015, 7, 85–92.

- Teng, T.; Zhang, X.; Dong, H.; Xue, Q. A comprehensive review of energy management optimization strategies for fuel cell passenger vehicle. Int. J. Hydrogen Energy 2020, 45, 20293–20303.

- DOE National Clean Hydrogen Strategy and Roadmap (Draft). Available online: https://www.hydrogen.energy.gov/clean-hydrogen-strategy-roadmap.html (accessed on 7 April 2023).

- Global Hydrogen Review. 2022. Available online: https://iea.blob.core.windows.net/assets/c5bc75b1-9e4d-460d-9056-6e8e626a11c4/GlobalHydrogenReview2022.pdf (accessed on 20 April 2023).

- The Worldwide Overview of Heavy-Duty Trucks Running on Hydrogen. Available online: https://fuelcelltrucks.eu/ (accessed on 20 April 2023).

- Sharpe, B.; Basma, H. A Meta-Study of Purchase Costs for Zero-Emission Trucks; International Council on Clean Energy Transportation: Washington, DC, USA, 2022.

- Basma, H.; Rodríguez, F. Fuel cell electric tractor-trailers: Technology overview and fuel economy. Int. Counc. Clean Transp. Work. Pap. 2022, 23, 2022.

- Danebergs, J. Techno-Economic Study of Hydrogen as a Heavy-Duty Truck Fuel. A Case Study on the Transport Corridor Oslo–Trondheim. Master’s Thesis, Universitat Politècnica de Catalunya, Barcelona, Spain, 2020.

- XCIENT Fuel Cell. Available online: https://trucknbus.hyundai.com/hydrogen/ko/download/catalog-xcient-fuel-cell-en.pdf (accessed on 1 May 2023).

- Hyundai Motor’s XCIENT Fuel Cell Heavy-Duty Trucks to Hit German Roads. Available online: https://www.hyundaimotorgroup.com/news/CONT0000000000046014 (accessed on 30 April 2023).

- Hyundai Motor’s Delivery of XCIENT Fuel Cell Trucks in Europe Heralds Its Commercial Truck Expansion to Global Markets. Available online: https://hyundai-hm.com/en/2020/10/07/hyundai-motors-delivery-of-xcient-fuel-cell-trucks-in-europe-heralds-its-commercial-truck-expansion-to-global-markets/ (accessed on 2 May 2023).

- Hyzon Hymax Series Built for Your Operations, without the Emissions. Available online: https://www.hyzonmotors.com/vehicles/hyzon-hymax-series (accessed on 25 April 2023).

- Nehls, G. Daimler Truck Tests Fuel-Cell Truck with Liquid Hydrogen. Available online: https://www.compositesworld.com/news/daimler-truck-tests-fuel-cell-truck-with-liquid-hydrogen (accessed on 20 April 2023).

- Swiss Fuel Cell Truck. 2016. Available online: https://esoro.ch/en/portfolio-item/swiss-fuel-cell-truck-2016/ (accessed on 21 April 2023).

- Products and Services. Available online: https://www.scania.com/group/en/home.html (accessed on 20 April 2023).

- Hydrogen Tank. Available online: https://hyfindr.com/hydrogen-tank/ (accessed on 10 April 2023).

- Advanced Structural Technologies, Inc. H2 MAX Brochures. Available online: https://astforgetech.com/wp-content/uploads/2022/04/H2Max-Brochure.pdf (accessed on 25 April 2023).

- Liaoning Alsafe Technology. Hydrogen Storage Tank. Available online: http://www.alsafegascylinders.com/?products_5/26.html (accessed on 25 April 2023).

- AMS Composite Cylinders. Hydrogen Fuel Cells. Available online: https://ams-composites.com/hydrogen-fuel-cells/ (accessed on 25 April 2023).

- XPERION—XPERION Delivers X-STORE Type 4 Hydrogen Cylinders for Regional Trains Developed by Alstom. Available online: https://www.avanco.de/en/news/xperion-xperion-delivers-x-store-type-4-hydrogen-cylinders-for-regional-trains-developed-by-alstom/ (accessed on 21 April 2023).

- Cylinder Holdings. Hydrogen Products. Available online: https://www.cylinders.cz/en/vodik/vodikove-produkty/a-159/ (accessed on 26 April 2023).

- Highway to Hydrogen. Available online: https://www.catecgases.com/hydrogen (accessed on 26 April 2023).

- EKC. Type IV Cylinders. Available online: https://ekcuae.com/3d-flip-book/type-4-composite-cylinder/ (accessed on 25 April 2023).

- Faber Cylinders. Available online: https://drawings.faber-italy.com/eng-product-hydrogen.asp (accessed on 25 April 2023).

- Hexagon Purus. Datasheets. Available online: https://hexagonpurus.com/brochures (accessed on 22 April 2023).

- Hanwha Cimarron. Gas Transport and Storage. Available online: https://hanwhacimarron.com/ (accessed on 25 April 2023).

- Hanwha Solutions Advanced Materials Division. Hydrogen Tank. Available online: https://pict.space/hanwhasolutions/en/scene_12_en.html (accessed on 25 April 2023).

- Kim, D.-H. Hydrogen Fuel Tank Maker Iljin Hysolus Eyes August IPO. Available online: https://www.kedglobal.com/hydrogen-conomy/newsView/ked202107120006 (accessed on 2 May 2023).

- Infinite Composites. IC Products & Services. Available online: https://www.infinitecomposites.com/infinite-composite-pressure-vessels (accessed on 25 April 2023).

- Luxfer. Spec Tables. Available online: https://www.luxfercylinders.com/products/ (accessed on 24 April 2023).

- Mahytec. Compressed Hydrogen Storage. Available online: https://www.mahytec.com/en/compressed-hydrogen-storage/ (accessed on 25 April 2023).

- NPROXX. Type 4 Pressure Vessels. Available online: https://www.nproxx.com/capabilities/type-4-pressure-vessels/ (accessed on 23 April 2023).

- Plastic Omnium. A Reference Player in Hydrogen Mobility. Available online: https://www.plasticomnium.com/wp-content/uploads/2021/01/plastic-omnium-hydrogen-conference-september-2020-en.pdf (accessed on 24 April 2023).

- Quantum Fuel Systems. Hydrogen Cylinder General Specifications. Available online: https://www.qtww.com/wp-content/uploads/2019/01/H2-Tank-Specifications-Sept-2021-All-Tanks.pdf (accessed on 20 April 2023).

- Steelhead Composites. Available online: https://steelheadcomposites.com/hydrogen-storage/ (accessed on 24 April 2023).

- H2 Mobility Faurecia Hydrogen Strategy. Available online: https://www.faurecia.com/sites/groupe/files/investisseurs/2019%2006%2014%20-%20Kepler%20Cheuvreux%20Event%20-%20Hydrogen%20-%20pour%20envoi.pdf (accessed on 1 April 2023).

- Toyoda Gosei Launches Large High Pressure Hydrogen Tank for Commercial Vehicles. Available online: https://www.toyoda-gosei.com/news/details.php?id=338 (accessed on 26 April 2023).

- Carbon4Tank 700 Bar Hydrogen Vessels for Heavy Duty Trucks. Available online: https://voith.com/corp-en/drives-transmissions/drive-h2.html (accessed on 24 April 2023).

- Wiretough. Hydrogen Storage Solutions. Available online: https://wiretough.com/wp-content/uploads/2023/03/Hydrogen-Storage-2023.pdf (accessed on 28 April 2023).

- Li, J.; Lv, R.; Gu, C.; Liu, Y.; Li, J.; Li, X. An Ageing Test Standards Analysis on Thermoplastic Liners of Type IV Composite Hydrogen Storage Tanks. Energies 2023, 16, 2818.

- Jiangsu Guofu Hydrogen Energy Equipment Co., Ltd. Vehicle Hydrogen Supply System. Available online: https://www.en.guofuhee.com/Product/detil/id/11.html (accessed on 23 April 2023).

- On-Board Fuel Cell Hydrogen Supply System. Available online: http://suzhou.sinomatech.com/yw/products_and_services/CompressedHydrogenProductsandHydrogenSupplySystem/1222.html (accessed on 28 April 2023).

- Zhao, F.; Mu, Z.; Hao, H.; Liu, Z.; He, X.; Victor Przesmitzki, S.; Ahmad Amer, A. Hydrogen Fuel Cell Vehicle Development in China: An Industry Chain Perspective. Energy Technol. 2020, 8, 2000179.

- Hyundai Motor Sells Hydrogen-Powered Truck Xcient in South Korea. Available online: https://www.kedglobal.com/automobiles/newsView/ked202212080013 (accessed on 2 May 2023).

- Forvia. PressKit IAA Transportation. 2022. Available online: https://www.faurecia.com/sites/groupe/files/documents/IAA%20TRANSPORTATION%20PRESS%20KIT.pdf (accessed on 2 May 2023).

- Plug & Drive H2 Storage System. Available online: https://voith.com/corp-en/products-services/composites-solutions/carbon4tank.html (accessed on 1 March 2023).

- Park, C.; Lim, S.; Shin, J.; Lee, C.-Y. How much hydrogen should be supplied in the transportation market? Focusing on hydrogen fuel cell vehicle demand in South Korea: Hydrogen demand and fuel cell vehicles in South Korea. Technol. Forecast. Soc. Chang. 2022, 181, 121750.

- XCIENT Fuel Cell Tractor. Available online: https://trucknbus.hyundai.com/hydrogen/ko/download/catalog-Xcient-fuel-cell-tractor.pdf (accessed on 1 May 2023).

More

Information

Subjects:

Energy & Fuels

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

4.5K

Revisions:

2 times

(View History)

Update Date:

28 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No