| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Georgios Fotis | -- | 3102 | 2023-07-19 06:33:48 | | | |

| 2 | Lindsay Dong | Meta information modification | 3102 | 2023-07-20 03:21:54 | | |

Video Upload Options

Electrostatic discharge (ESD) is a physical phenomenon that may destroy electronic components due to its high discharge current that may reach a few amperes in just a few ns. However, another major aspect of ESD is the related high-frequency electromagnetic (E/M) fields radiated by the ESD event. The electronic equipment that is affected by the ESD phenomenon is additionally affected by the induced voltages caused by these E/M fields. This is the reason that the current version of the IEC 61000-4-2 on ESD has a special reference to these fields and the measurement setup.

1. Introduction

2. Effects before the Electrostatic Discharge

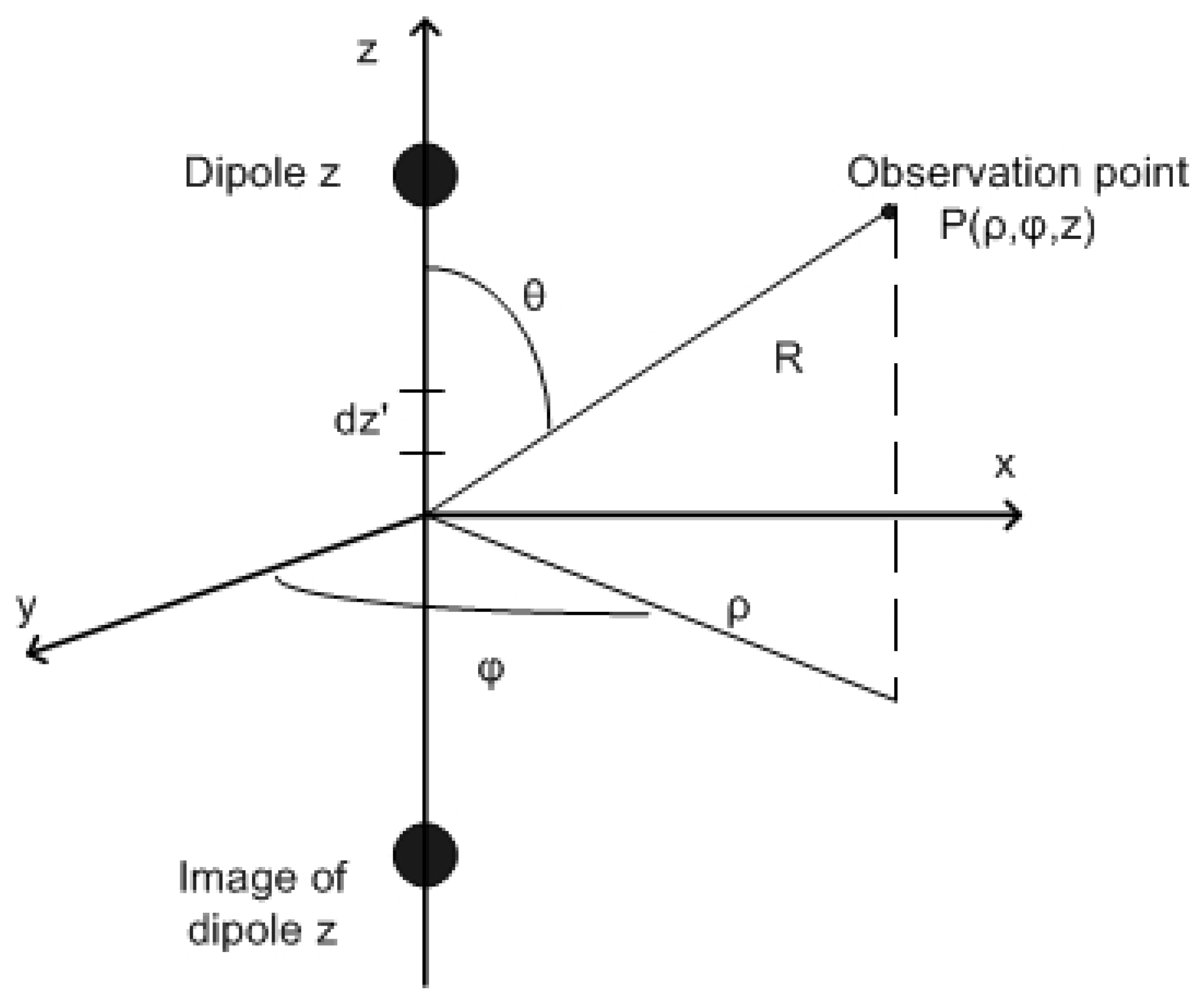

3. ESD Radiated Fields Approach Using the Dipole Model

4. Electromagnetic Field Measurement Radiated by ESD

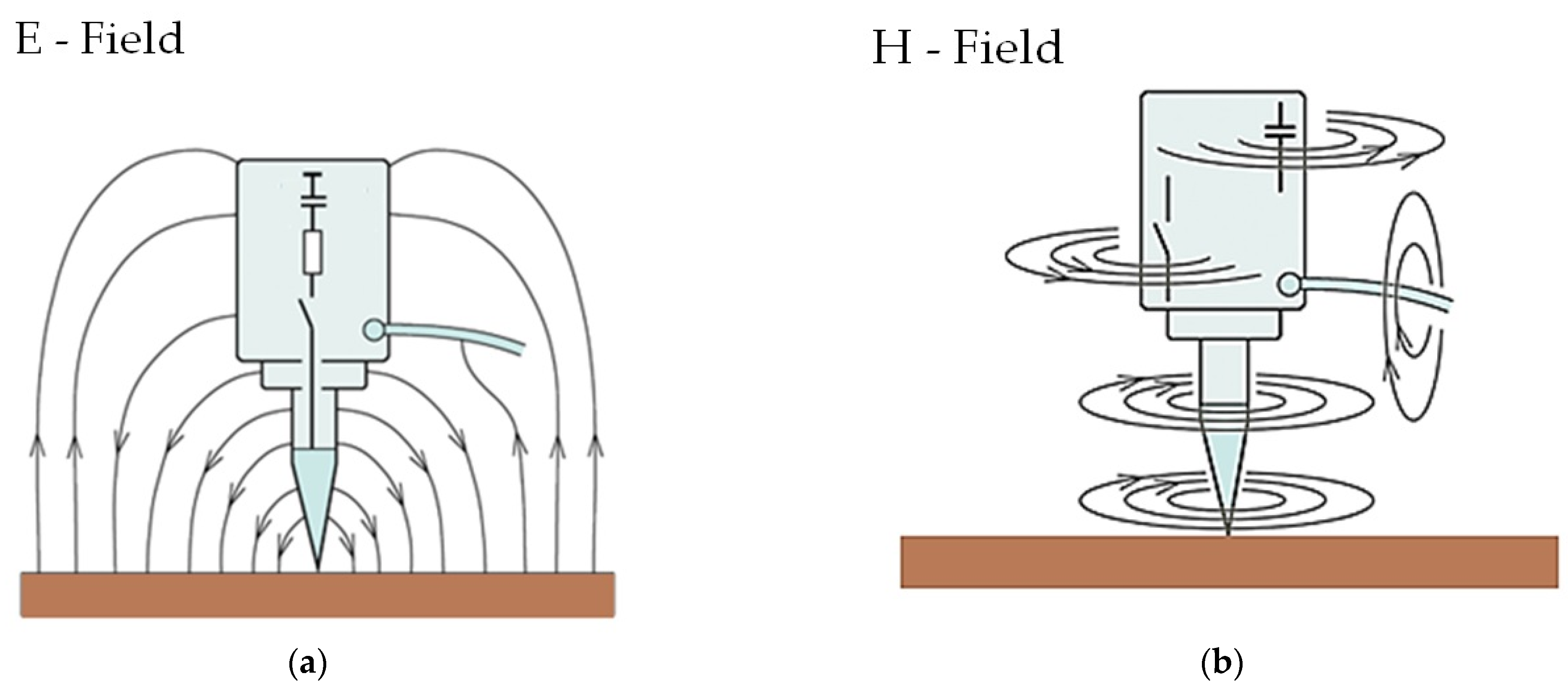

4.1. Electric and Magnetic Field Coupling of the ESD Generator

4.2. Measurement Setups and Instrumentation for the Measurement of the E/M Field Produced by ESD

| Ref. | Measured Magnitudes | Discharge Type | ||||

|---|---|---|---|---|---|---|

| Discharge Current | Electric Field | Magnetic Field | Optical Radiation | Induced Voltages | ||

| [48] | X | X | Χ | Both air and contact discharges | ||

| [49] | X | X | Contact discharges | |||

| [50][51][52] | X | X | X | Air discharges | ||

| [53] | X | X | X | Both air and contact discharges | ||

| [54] | X | X | X | X | Contact discharges | |

| [55] | X | X | X | Contact discharges | ||

| [56] | X | X | X | X | Both air and contact discharges | |

| [22] | X | X | X | X | Contact discharges | |

| [37][38] | X | X | X | Contact discharges | ||

| [39] | X | X | X | Contact discharges | ||

| [15] | X | X | X | Contact discharges | ||

Bendjamin examined the magnetic field and optical radiation produced by electrostatic discharges [50][51][52]. The results presented showed that by reducing the conductivity of the material that the EUT is made from, one can reduce the peak current as well as the peak derivative of the magnetic field.

Even though ESD current curves for different generators are similar, regarding the Imax, tr, I30, and I60 parameters, tests show different outcomes (pass or fail) for the same EUT depending on the generator that has been used. This occurs because there is no specification for the generated transient field that differs for each ESD generator. The test’s repeatability must be improved by such a specification. Working in this direction, Pommerenke [55] investigates the requirements for the current derivative, fields, and induced voltages produc

4.3. E and H Field Sensors for the Measurement of the Electromagnetic Field from ESD

4.3.1. Ground-Based Field Sensors with Active Integration

4.3.2. Passive E- and H-Field Sensors

5. Comparison of Experimental Results from the International Literature

6. Conclusions

References

- Wang, A. Practical ESD Protection Design, 1st ed.; Wiley: Hoboken, NJ, USA; IEEE Press: Piscataway, NJ, USA, 2021.

- Bafleur, M.; Caignet, F.; Nolhier, N. ESD Protection Methodologies: From Component to System, 1st ed.; ISTE Press–Elsevier: Amsterdam, The Netherlands, 2017.

- Richman, P. ESD Simulation-Configuring a Full-Performance Facility. In Proceeding of the IEEE International Symposium on Electromagnetic Compatibility, Arlington, VA, USA, 23–25 August 1983; pp. 1–5.

- Duvvury, C.; Gossner, H. System Level ESD Co-Design; Wiley-IEEE Press: London, UK, 2015.

- Yousaf, J.; Shin, J.; Kim, K.; Youn, J.; Lee, D.; Hwang, C.; Nah, W. System level esd coupling analysis using coupling transfer impedance function. IEEE Trans. Electromagn. Compat. 2018, 60, 310–321.

- Muchaidze, G.; Koo, J.; Cai, Q.; Li, T.; Han, L.; Martwick, A.; Wang, K.; Min, J.; Drewniak, J.L.; Pommerenke, D. Susceptibility scanning as a failure analysis tool for system-level electrostatic discharge (ESD) problems. IEEE Trans. Electromagn. Compat. 2008, 50, 268–276.

- Intra, P.; Tippayawong, N. Design and evaluation of a high concentration, high penetration unipolar corona ionizer for electrostatic discharge and aerosol charging. J. Electr. Eng. Technol. 2013, 8, 1175–1181.

- Wang, K.; Pommerenke, D.; Zhang, J.M.; Chundru, R. The PCB level ESD immunity study by using 3-dimension ESD scan system. In Proceedings of the International Symposium on Electromagnetic Compatibility, Silicon Valley, CA, USA, 9–13 August 2004; pp. 343–348.

- Honda, M. Fundamental aspects of esd phenomena and its measurement techniques. IEICE Trans. Commun. 1996, 79, 457–4616.

- Leo, G.C.R.D.; Primiani, V.M. ESD in electronic equipment: Coupling mechanisms and compliance testing. In Proceedings of the Industrial Electronics ISIE 2002, L’Aquila, Italy, 8–11 July 2002; pp. 1382–1385.

- Caniggia, S.; Maradei, F. Circuit and numerical modeling of electrostatic discharge generators. IEEE Trans. Ind. Appl. 2006, 42, 1350–1357.

- Pommerenke, D.; Fan, J.; Drewniak, J. Simulation challenges in system level electrostatic discharge modeling. In Proceedings of the IEEE/ACES International Conference on Wireless Information Technology and Systems (ICWITS) and Applied Computational Electromagnetics (ACES), Honolulu, HI, USA, 13–18 March 2016; pp. 1–2.

- Smith, D.C. Techniques for investigating the effects of ESD on electronic equipment. J. Phys. Conf. Ser. 2015, 646, 012036.

- Berghe, S.V.; Zutter, D.D. Study of signal entry through coaxial cable shields. J. Electrost. 1998, 44, 135–148.

- IEC 61000-4-2; Electromagnetic Compatibility (EMC)-Part 4-2: Testing and Measurement Techniques Electrostatic Discharge (ESD) Immunity Test. IEC: London, UK, 2008.

- Fotis, G.; Gonos, I.F.; Assimakopoulou, F.E.; Stathopulos, I.A. Applying genetic algorithms for the determination of the parameters of the electrostatic discharge current equation. Inst. Phys. (IOP) Proc. Meas. Sci. Technol. 2006, 17, 2819–2827.

- Fotis, G.; Gonos, I.F.; Stathopulos, I.A. Determination of the Discharge Current Equation Parameters of ESD using Genetic Algorithms. IEE Electron. Lett. 2006, 42, 797–799.

- Katsivelis, P.; Fotis, G.; Gonos, I.F.; Koussiouris, T.G.; Stathopoulos, I.A. Electrostatic Discharge Current Linear Approach and Circuit Design Method. Energies 2010, 3, 1728–1740.

- Fotis, G.; Vita, V. Circuit Modeling and Simulation of the ESD Generator for Various Tested Equipment According to the IEC 61000-4-2. WSEAS Trans. Circuits Syst. 2022, 21, 193–201.

- Yousaf, J.; Shin, J.; Lee, H.; Youn, J.; Lee, D.; Hwang, C.; Nah, W. Esd triggered current analysis for floating eut with/without shielding of esd generator. In Proceedings of the 16th International Symposium on Microwave and Optical Technology, Seoul, Republic of Korea, 26–28 June 2017; p. 1.

- Yousaf, J.; Shin, J.; Leqian, R.; Nah, W.; Youn, J.; Lee, D.; Hwang, C. Effect of ESD generator ground strap configuration on esd waveform. In Proceedings of the Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Seoul, Republic of Korea, 20–23 June 2017; pp. 121–123.

- Caniggia, S.; Maradei, F. Numerical prediction and measurement of ESD radiated fields by free-space field sensors. IEEE Trans. Electromagn. Compat. 2007, 49, 494–503.

- Zhang, J.; Beetner, D.G.; Moseley, R.; Herrin, S.; Pommerenke, D. Modeling electromagnetic field coupling from an ESD generator to an IC. In Proceedings of the Electromagnetic Compatibility (EMC) IEEE International Symposium, Long Beach, California, USA, 14–19 August 2011; pp. 553–558.

- Park, M.; Park, J.; Kim, J.; Seung, M.; Choi, J.; Lee, C.; Lee, S. Measurement and modeling of system level ESD noise voltages in real mobile products. In Proceedings of the 2016 Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; pp. 632–634.

- Lee, J.; Lim, J.; Jo, C.; Seol, B.; Nandy, A.; Li, T.; Pommerenke, D. A study of a measurement and simulation method on ESD noise causing soft errors by disturbing signals. In Proceedings of the 33rd EOS/ESD Symposium Proceedings, Anaheim, CA, USA, 11–16 September 2011; pp. 1–5.

- Antong, R.; Low, D.; Pommerenke, D.; Abdullah, M.Z. Prediction of electrostatic discharge (ESD) soft error on two-way radio using ESD simulation in CST and ESD immunity scanning technique. In Proceedings of the 36th International Electronics Manufacturing Technology Conference, Johor Bahru, Malaysia, 11–13 November 2014; pp. 1–10.

- Centola, F.; Pommerenke, D.; Kai, W.; Doren, T.V.; Caniggia, S. ESD excitation model for susceptibility study. In Proceedings of the IEEE Symposium on Electromagnetic Compatibility. Symposium Record (Cat. No. 03CH37446), Boston, MA, USA, 18–22 August 2003; pp. 58–63.

- Fujiwara, O.; Zhang, X.; Yamanaka, Y. FDTD simulation of electrostatic discharge current by ESD testing. IEICE Trans. Commun. 2003, 86, 2390–2396.

- Lee, J.S.; Pommerenke, D.; Lim, J.D.; Seol, B.S. ESD field coupling study in relation with PCB GND and metal chassis Pommerenke, D. In Proceedings of the 20th International Zurich Symposium on Electromagnetic Compatibility, Zurich, Switzerland, 12–16 January 2009; pp. 153–156.

- Kim, K.H.; Kim, Y. Systematic analysis methodology for mobile phone’s electrostatic discharge soft failures. IEEE Trans. Electromagn. Compat. 2011, 53, 611–618.

- Park, J.; Lee, J.; Seol, B.; Kim, J. Efficient calculation of inductive and capacitive coupling due to electrostatic discharge (ESD) using PEEC method. IEEE Trans. Electromagn. Compat. 2015, 57, 743–753.

- Nieden, F.; Scheier, S.; Frei, S. Circuit models for ESD-generator-cable field coupling configurations based on measurement data. In Proceedings of the Electromagnetic Compatibility (EMC EUROPE), Rome, Italy, 17–21 September 2012; pp. 1–6.

- Yoshida, T.; Masui, N. A study on system-level ESD stress simulation using circuit simulator. In Proceedings of the 2013 Asia-Pacific Symposium on Electromagnetic Compatibility (APEMC), Melbourne, VIC, Australia, 20–23 May 2013; pp. 1–4.

- Yoshida, T. A study on transmission line modeling method for system-level ESD stress simulation. In Proceedings of the 2015 Asia-Pacific Symposium on Electromagnetic Compatibility (APEMC), Taipei, Taiwan, 26–29 May 2015; pp. 577–580.

- Xiu, Y.; Thomson, N.; Mertens, R.; Rosenbaum, E. S-parameter based modeling of system-level ESD test bed. In Proceedings of the 37th Electrical Overstress/Electrostatic Discharge Symposium (EOS/ESD), Reno, NV, USA, 27 September–2 October 2015; pp. 1–10.

- Zhao, S.; Zhou, C.; Liang, Z.; Qian, Z.; Wang, Z. Modeling electromagnetic immunity of ldo under ESD electromagnetic field coupling. In Proceedings of the Asia-Pacific International Symposium on Electromagnetic Compatibility (APEMC), Shenzhen, China, 17–21 May 2016; pp. 355–358.

- Fotis, G.; Gonos, I.F.; Stathopulos, I.A. Measurement of the electric field radiated by electrostatic discharges. Inst. Phys. (IOP) Proc. Meas. Sci. Technol. 2006, 17, 1292–1298.

- Fotis, G.; Rapanakis, A.G.; Gonos, I.F.; Stathopulos, I.A. Measurement of the magnetic field radiating by electrostatic discharges during the verification of the ESD generators. J. Int. Meas. Confed. 2007, 40, 428–436.

- Fotis, G.; Christodoulou, C.A.; Pippis, C.D.; Ekonomou, L.; Zafeiropoulos, I.; Maris, T.I.; Karamousantas, D.C.; Chatzarakis, G.E.; Gonos, I.F.; Stathopulos, I.A. Measurement of the electromagnetic field radiating by commercial ESD generators with the Pellegrini target on insulating material. J. Int. Meas. Confed. 2009, 42, 1073–1081.

- Fotis, G.; Ekonomou, L.; Maris, T.I.; Liatsis, P. Development of an artificial neural network software tool for the assessment of the electromagnetic field radiating by electrostatic discharges. IEE Proc. Sci. Meas. Technol. 2007, 1, 261–269.

- Ekonomou, L.; Fotis, G.; Maris, T.I.; Liatsis, P. Estimation of the electromagnetic field radiating by electrostatic discharges using artificial neural networks. Simul. Model. Pract. Theory 2007, 15, 1089–1102.

- Fotis, G.; Vita, V.; Ekonomou, L. Machine Learning Techniques for the Prediction of the Magnetic and Electric Field of Electrostatic Discharges. Electronics 2022, 11, 1858.

- Miao, M.; Zhou, Y.; Salcedo, J.A.; Hajjar, J.-J.; Liou, J.J. A New Method to Estimate Failure Temperatures of Semiconductor Devices Under Electrostatic Discharge Stresses. IEEE Electron Device Lett. 2016, 37, 1477–1480.

- Byrne, W.W. The meaning of electrostatic discharge (ESD) in relation to the human body characteristics and electronic equipment. In Proceedings of the IEEE International Symposium on Electromagnetic Compatibility, Arlington, VA, USA, 23–25 August 1983; pp. 1–12.

- Gaskill, S.G.; Davuluri, P. Equivalent Circuit for I/O Electrical Fast Transient Testing. In Proceeding of the IEEE International Symposium on Electromagnetic Compatibility & Signal/Power Integrity (EMCSI), Spokane, WA, USA, 1–5 August 2022; pp. 141–145.

- Woods, M.H.; Gear, G. A new electrostatic discharge failure mode. IEEE Trans. Electron Devices 1979, 26, 16–21.

- Wilson, P.F.; Ma, M.T. Fields radiated by electrostatic discharges. IEEE Trans. Electromagn. Compat. 1991, 33, 10–18.

- Takai, T.; Kaneko, M.; Honda, M. One of the methods of observing ESD around electronic equipment. J. Electrost. 1998, 42, 305–320.

- Frei, S.; Pommerenke, D. A transient field measurement system to analyze the severity and occurrence rate of electrostatic discharge (ESD). J. Electrost. 1998, 44, 191–203.

- Bendjamin, J.; Gomes, C.; Cooray, V. Remote sensing of ESD through optical and magnetic radiation fields. IEEE Trans. Dielectr. Electr. Insul. 1999, 6, 896–899.

- Bendjamin, J.; Thottappillil, R.; Scuka, V. Time varying electromagnetic fields generated by electrostatic discharges. In Proceedings of the 1st IEEE International Symposium on Polymeric Electronics Packaging, PEP ‘97 (Cat. No.97TH8268), Norrkoping, Sweden, 30 October 1997; pp. 197–202.

- Bendjamin, J.; Thottappillil, R.; Scuka, V. Time varying magnetic fields generated by human metal (ESD) electrostatic discharges. J. Electrost. 1999, 46, 259–269.

- Pommerenke, D.; Aidam, M. ESD: Waveform calculation, field and current of human and simulator ESD. J. Electrost. 1996, 38, 33–51.

- Frei, S.; Pommerenke, D. Fields on the horizontal coupling plane excited by direct ESD and discharges to the vertical coupling plane. J. Electrost. 1998, 44, 177–190.

- Wang, K.; Pommerenke, D.; Chundru, R.; Van Doren, T.; Drewniak, J.L.; Shashindranath, A. Numerical modeling of electrostatic discharge generators. IEEE Trans. Electromagn. Compat. 2003, 45, 258–271.

- Chundru, R.; Pommerenke, D.; Wang, K.; Doren, T.V.; Centola, F.P.; Huang, J.S. Characterization of human Metal ESD reference discharge event and correlation of generator parameters to failure levels-part I: Reference event. IEEE Trans. Electromagn. Compat. 2004, 46, 498–504.