Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | R. R. Rousse | -- | 3993 | 2023-07-13 21:15:03 | | | |

| 2 | Peter Tang | + 1 word(s) | 3994 | 2023-07-14 03:33:48 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Motamedi, S.; Rousse, D.R.; Promis, G. Crop-Based Materials in the Built Environment. Encyclopedia. Available online: https://encyclopedia.pub/entry/46788 (accessed on 07 February 2026).

Motamedi S, Rousse DR, Promis G. Crop-Based Materials in the Built Environment. Encyclopedia. Available at: https://encyclopedia.pub/entry/46788. Accessed February 07, 2026.

Motamedi, Sina, Daniel R. Rousse, Geoffrey Promis. "Crop-Based Materials in the Built Environment" Encyclopedia, https://encyclopedia.pub/entry/46788 (accessed February 07, 2026).

Motamedi, S., Rousse, D.R., & Promis, G. (2023, July 13). Crop-Based Materials in the Built Environment. In Encyclopedia. https://encyclopedia.pub/entry/46788

Motamedi, Sina, et al. "Crop-Based Materials in the Built Environment." Encyclopedia. Web. 13 July, 2023.

Copy Citation

The use of bio-based building materials as an alternative to replacing concrete or insulation materials is called to become a growing trend in the construction industry.

crop-based materials

building applications

life cycle assessment (LCA)

biogenic carbon

thermo-hygro-mechanical characteristics

1. Introduction

In the last two decades, global environmental issues have emerged at an alarming rate. Improving energy efficiency and reducing greenhouse gas emissions have become key concerns across all industries. The construction sector is particularly highlighted as it is one of the most energy-intensive industries [1]. The built environment alone accounts for 40% of energy consumption and 36% of carbon emissions in the EU [2]. Embodied energy, which represents a significant portion of a building’s carbon emissions (approximately 10–30%) [3][4][5], has only recently started to receive the attention it deserves.

Currently, there is a noticeable trend in construction practices towards bio-based building materials. In comparison to the common and traditional practices the commonly utilize materials such as concrete, steel, and plastics, these materials are reported to have a range of advantageous properties such as low toxicity, durability, low level of GHG and other pollutants emissions, high local recycling potential, local availability, minimal processing requirements, and low embodied energy [6]. Moreover, in the context of a desired shift from zero-energy buildings (ZEB) to life-cycle ZEBs (LCZEB), bio-based materials could be the key approach to address sustainability issues [7]. The resources used to produce these materials could comprise agricultural crops and residues, forest materials, animal wastes, and post-consumer biological wastes [8].

2. Life Cycle Assessment Stages

EN 15804 (CEN (2012b)) [9] describes the common core of product category rules (PCR) for Type III environmental declarations relating to any construction product and service. It provides a comprehensive definition of the material life cycle, which encompasses raw material cultivation and harvesting to manufacturing, construction, operation, demolition, and final disposal [2][10][11]. Each of these stages includes sub-stages that are associated with different procedures, boundaries, and functional units, which are listed in Table 1. EN 15804 involves four main stages (product, construction process, use, and end-of-life stages) which in turn cover supply, transport, manufacturing, construction installation, use, maintenance, repair, replacement, refurbishment, deconstruction, waste processing, and disposal. Moreover, it accounts for reuse, recovery, and recycling potentials.

Table 1. Boundaries of the study in building’s life cycle assessment [2].

|

Building Life Cycle Information |

|||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

A 1–3 |

A 4–5 |

B 1–7 |

C 1–4 |

||||||||||

|

Product stage |

Construction Process stage |

Use stage |

End of life stage |

||||||||||

|

A1 |

A2 |

A3 |

A4 |

A5 |

B1 |

B2 |

B3 |

B4 |

B5 |

C1 |

C2 |

C3 |

C4 |

|

Raw material supply |

Transpor |

Manufacturing |

Transport |

Construction Installation Process |

Use |

Maintanance (incl. transport) |

Repair (incl. transport) |

Replacement (incl. transport) |

Refurbishment (incl. transport) |

De-construction /Demolition |

Transport |

Waste processing |

Disposal |

|

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

Scenario |

|||

|

B6 |

Operational energy use |

||||||||||||

|

Scenario |

|||||||||||||

|

B7 |

Operational water use |

||||||||||||

|

Scenario |

|||||||||||||

2.1. Product Stage

In this category, although most of the literature focuses on biomass or other materials capable of producing ethanol throughout their life time, some studies have explored the cultivation of fiber crops, which are the main source of material in the bio-construction industry [12]. Cultivation of crop-based materials varies significantly with forest materials since most of the crops utilized in crop-based bricks or infills are perennial plants, so recurring cultivation could happen during annual periods. The quantification of LCA is conducted in cumulative A1 to A3 stages (Table 1), which is the combination of the entire process from cultivation to the end of the manufacturing process. Therefore, the quantified comparison is discussed in the manufacturing (A3) paragraph below.

In this stage of life cycle assessment for forest and agriculture products, life cycle measures are defined in terms of main products, additives-preservatives, and recycled products. Detrimental environmental effects in this phase include the burning of fossil fuels during exploitation, fertilizer application, and resulting eutrophication, pesticide use and related toxicity issues, and the impact of land and water use. Furthermore, for wood-based materials, forest’s beneficial CO2 removal and carbon sequestration are identified as the environmental advantages [11][13]. In addition to the environmental impacts, the cultivation of perennial plants for the production of crop-based materials is a critical issue due to its potential impact on increasing soil organic carbon (SOC) sequestration. This, in turn, will result in a significant decrease of carbon foot print in the life cycle of crop-based materials [14].

In this respect, the underlying issue is that there are some impact factors, which are not discussed extensively in the literature. For instance, acidification is often included in the LCAs, while other impact categories, such as eutrophication or land use change, may be overlooked [15]. Specifically in agriculture/animal products, a major environmental effect called Indirect Land Use Change (ILUC), has been introduced but has not been studied widely. ILUC accounts for the fact that production plants establishment on former agriculture lands result in spreading cultivation to areas such as grasslands, which in turn are crucial for mitigation of CO2 levels and even in some cases heat islands. Consequently, by diminishing vegetation, detrimental pollution effects will be rising up. Bioenergy projects can have complex impacts on land use, including both direct and indirect land use change. These changes can affect greenhouse gas balances in both positive and negative ways, making it difficult to assess bioenergy’s contribution to climate change mitigation [16][17]. Direct and indirect land use change, are examples of rebound effects in the progress of crop-based or waste-based technologies [18]. One obstacle to quantifying these impacts is the complex interplay between environmental factors and market dynamics in the specific case studies being evaluated. The use of consequential LCA (CLCA) in these studies can further complicate the assessment of multi-functional systems due to complex overlap between system boundaries, inputs, and outputs [19][20][21].

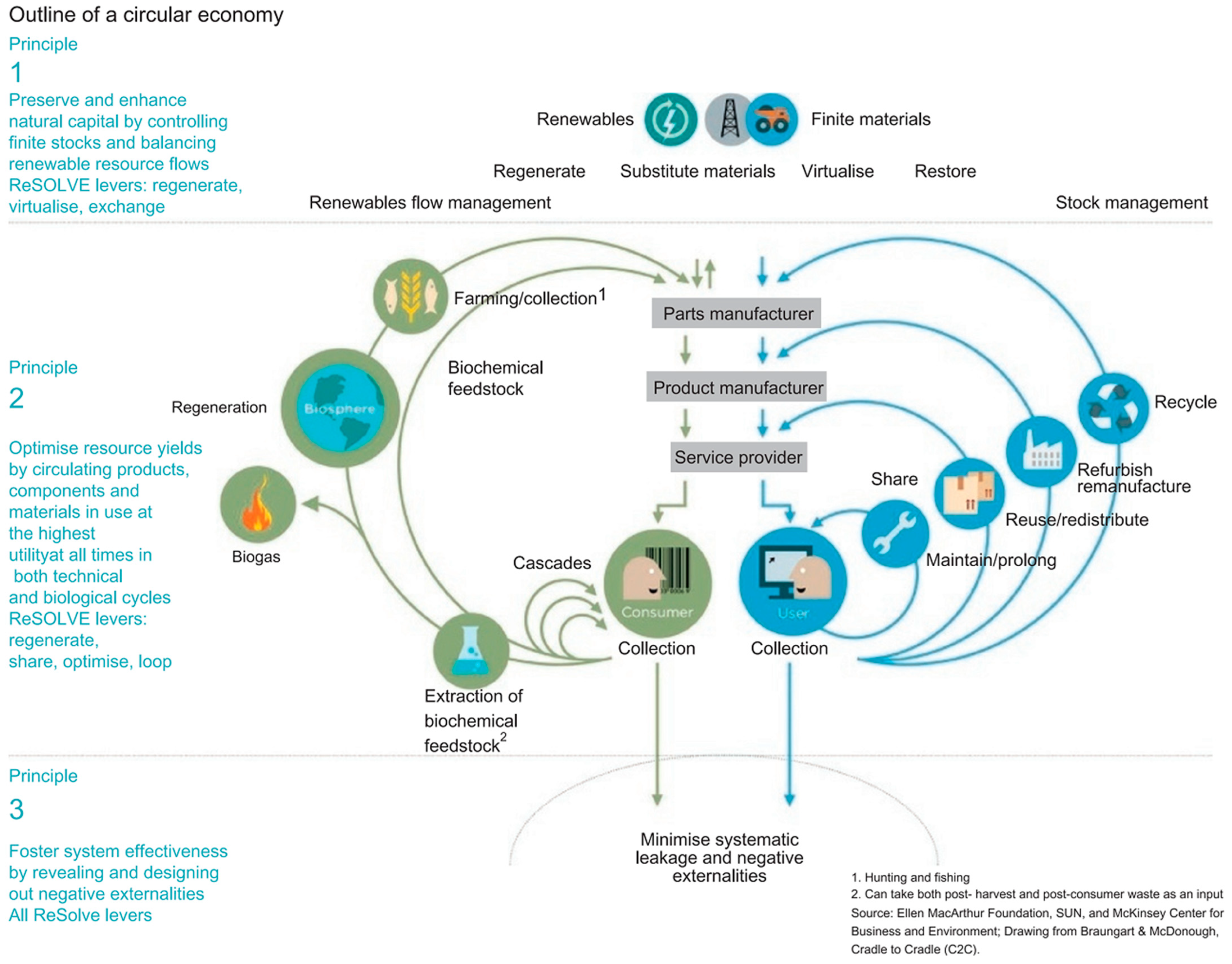

That being said, there are other phenomena such as water resource depletion, threats to biodiversity, ecosystem quality, etc. These are specific side effects of the development toward more utilization of crop-based resources [15][22]. Overexploitation of agricultural materials, resulting from the growth in the crop-based economy is another life cycle issue that falls within this category, leading to agricultural intensification and land use change [18][23][24][25]. Moreover, compared to forest products, higher levels of fertilizer, pesticides, and fuels are used, in agro-based products due to the higher annual cultivation cycle. The importance of recycled products in attenuating detrimental impacts has to be considered. For instance, there are products similar to wood beams and timbers that do not need any recycling process, which will be crucial in the life cycle process of crop-based building materials [2]. On the other hand, agro-sourced products (such as sugarcane) end up producing residues that can be used to manufacture wood-agro-based products [26][27]. In the waste-based economy which encompasses a significant percentage of this practice, LCA studies have to consider co-production since the main plan and its waste serve different purposes. Although co-production essentially leads the system to contribute to supporting circular economy (schematically depicted in Figure 1), defining a reference scenario can be challenging since the purposes and outputs are not the same and different defined systems are diverging in some sense [18]. To assess waste-based systems, the literature often employs input-based life cycle assessment [28][29][30].

Figure 1. Illustration of the circular economy [2].

The manufacturing (A3 in Table 1) life cycle is a critical part of the supply chain of crop-based resources. At this stage of the building materials’ life cycle, concrete has been a crucial source of debate in terms of its energy-intensive manufacturing cycles. It is vastly investigated, concerning its major effect on GHG emissions. Despite the use phase of building, in which the most share of energy consumption occurs, a major portion of the embodied energy of the building materials is discussed in the manufacturing stage. The vast scope of the literature focused on the embodied energy of buildings.

Asif et al. [31], conducted an LCA study of a detached house. The result demonstrates that concrete alone consumes most of the total embodied energy by 60%, along with having the highest environmental impacts among other constructing elements. Finally, geographical location’s related parameters of ‘climate’ and ‘upstream energy’ significantly influence the life cycle’s emissions. However, while this stage’s emission is quite sensitive to material/fuel choice and energy performance, its subsequent emission is also highly tied to available construction practices in the short term [32].

Peñaloza et al. [33] present a comparative traditional (common) and dynamic LCA on the effects of increasing the crop-based material content in the manufacturing process under scenarios with variations in four key assumptions: service life, end-of-life scenario, timing of forest carbon sequestration and time horizon of the impact assessment. The varying content of crop-based materials are assumed to be: a concrete design (0% crop-based in mass), a conventional cross-laminated timber (CLT) structure (50% crop-based in mass), and another CLT structure with higher crop-based material content (69% in mass). This study concludes that increasing the crop-based content of the material resulted in climate impact reductions in almost every studied scenario, but the differences between designs varied and were highly sensitive to the assumptions explored.

In the manufacturing phase, drying and gluing are critical processes due to the involvement of fossil fuel combustion; and its consequences on acidification, climate change, CO2 emissions and photo-oxidation, along with the consumption of abiotic resources [34]. Several studies claimed that by incorporation of a closed loop carbon cycle [35], i.e., consuming burning fuel from production waste (e.g., wood shavings and saw dust) and accumulated biogenic carbon, these materials become climate neutral [2][10][17]. Gluing activities, on the other hand, consume energy. Their impacts, therefore, depend on energy generation sources. The major emissions of traditional concrete occur in the production of clinker, which is the foundation of cement as the binder of concrete [36]. Cement is not a popular agent in crop-based concretes. Instead, lime has been used as the base binder for traditional crop-based concrete or insulation infills. The hemp-lime compound is the most common type of concrete in this category. Nonetheless, lime mixture usually yields low strength. Attempts are made to introduce new binders. In this regard, Bumanis et al. [37] analyzed gypsum, starch, and a type of geopolymer and compared the results with lime characteristics. The resulting material delivered lower density and thermal conductivity, as well as the same impact in LCA, though they did not examine the mechanical strength. There are also studies on wood-based products, which developed crop-based and eco-efficient adhesives for this sort of product [38][39][40]. This is a neglected area of research, which could lead to more enhanced thermo-physical characteristics of crop-based building materials.

As for other processing stages in building materials modifying forest products requires thermal treatment and impregnation infrastructures, as well as their associated chemical and energy consumption- related impacts [34]. The manufacturing process of crop-based boards including particle board, medium density fiberboard (MDF), light density fiber board (LDF), oriented strand board (OSB), and plywood are in similar processing categories, in which high-temperature pressing for wood layers demands combustion of fuels, and consumes electricity to veneer wood layers [2][41].

2.2. Construction Stage

Within the construction stage, most of the LCA studies focus on the effect of equipment use (broken down by different tasks in construction project management) as well as the long-term environmental impacts of the utilized material in the use stage of the building [42]. A majority of the impacts of the construction phase are caused by the production of ancillary materials, and transportation. In the aforementioned processes, operations such as the on-site cut-to-fit, packaging, etc., generate wastes that affect the life cycle regarding their disposal process; however, their impact is less than the aforementioned operations [2][10][11].

A key feature of crop-based building materials during this phase is their ability to be produced from locally available materials, thereby eliminating significant emissions associated with long-distance transportation. The necessity of natural binders such as mycelium will be pivotal in agricultural communities, which in turn leads to the circular usage of materials and wastes and a substantial reduction of the emissions related to the usage of non-locally produced materials. In Canada and France as the preferred cases for this research, the researchers are seeing such arrangements. In France, a new environmental regulation (RE2020) is issued, which provides a regulatory basis for the use of crop-based alternative building materials for future sustainable construction. In an article in www.architectural-review.com (accessed on 29 April 2023) [43] there are interesting statistics reflected in the growth of crop-based construction in France. The main point is the abundance of straw as a bi-product of wheat cultivation in France, which produces up to 25 million tons per year, of which only 10 percent is reported to be enough for the insulation of 500,000 dwellings per year. In addition to that, France is also the leading producer of hemp in Europe, another substrate for crop-based materials [43].

2.3. Use Stage

Regarding the use phase, this stage of the lifecycle, in terms of environmental impacts, dominates all other stages throughout the cradle-to-grave boundaries. That is mainly rooted in the magnitude of energy consumption in this phase, which is consumed to satisfy the heating, air conditioning, electricity, and hot water needs of the residents. The role of crop-based materials in this phase is their considerable insulation capacity, which substantially decreases the building’s energy loss and consequent environmental impacts in some cases by 50% [44]. However, there are also drawbacks, which cause adverse impacts. Gérardin [45] mentions the potential leaching process caused by preservatives in this type of material, as well as the release of chemicals into terrestrial and aquatic environments. Furthermore, the emission of volatile organic compounds (VOCs) in both indoor and outdoor conditions, is another part of the studies given particular adhesives and coatings, used in these materials [2][11].

2.4. End-of-Life Stage

In this phase, since crop-based materials do not have a long history, end-of-life scenarios are not yet assessed in practice [46]. Therefore, studies are based on assumptions and consider different end-of-life scenarios. Two distinctive processes and scenarios are mainly covered in the literature, including recycling and disposal. One of the most examined disposal processes surveyed in the literature is incineration, which has a significant environmental impact. The reason lies in the fact that most crop-based materials are combustible, and incineration could provide efficient energy recovery solutions [47].

Beigbeder et al. [48] conducted an assessment of the biocomposites’ end-of-life scenarios. Their approach was based on examining four scenarios: landfilling, incineration, compositing, and recycling. Recycling scores best among other alternatives in terms of environmental impacts, except for crop-based plastic polymers wherein recycling is costly to be performed. In the case of incineration, resulting combustion gases may cause hazardous phenomena such as soil ecotoxicity and climate change if not properly carried out. Utilization of municipal incineration is suggested as an efficient approach. It results in saving fossil fuels for heat and electricity generation, especially when systematic exploitation of them happens within the framework of CHP systems in integrated neighborhoods [2].

Pittau et al. [49] investigated the effect of storing carbon in biogenic materials and lime-based products when they are used as construction materials, particularly in exterior walls. The novelty of this research is considering the time frame of emission and carbon sequestration. This in turn leads to different results compared to those assuming emitted and sequestered carbon as net zero. The results show that storing carbon in fast-growing biogenic materials is more efficient than in timber elements. The carbon accumulated in fast-growing biogenic materials is fully captured by crop regrowth only one year after construction; whereas a longer time is expected for forest products due to the long rotation period required for forest regrowth. The capacity for storing carbon increases when straw and hemp are used as thick insulation for exterior walls due to the rapid CO2 uptake in plantations. As for other compostable crop-based materials, the most commonly reported end-of-life scenario in the literature is landfilling. Its major consequences are categorized as land use pertaining issues, climate change, and eco-toxicity [50]. Furthermore, the anaerobic decay of this type of material (esp. wood, cork, and paper) is incomplete; and leads to long-term storage of carbon in landfills.

2.5. Partial Conclusion

The discussions presented in this section demonstrate that crop-based materials could have a positive impact at all stages of the life cycle of a building construction project.

In the production stage, the cultivation of perennial plants for the production of crop-based materials is found to be a critical issue due to its potential impact on increasing soil organic carbon (SOC) sequestration. The LCA review of this stage illuminates the critical issues related to crop-based materials such as acidification, eutrophication, land-use, etc. Water resource depletion, threats to biodiversity, and ecosystem quality are also factors to account for in this part of the complete analysis. Finally, the embodied energy difference between classical concrete-based structures and bio-based ones, are demonstrating that at the manufacturing phase, bio-based material manufacturing resulted in climate impact reductions in almost every studied scenario.

In the construction stage, the ability of crop-based building materials to be produced from locally available materials is found to eliminate significant GHG and other pollutant emissions associated with long-distance transportation.

In the most impacting use stage, the excellent insulation properties of crop-based materials at low cost are found to be a significant factor for their use. Despite these performances, care should be taken when comes to additives and related emissions of volatile organic compounds, for instance.

In the end-of-life stage, efficient energy recovery solutions are suggested as suitable ways to treat crop-based materials. In this case, ecotoxicity should be evaluated. For several compostable crop-based materials, the most commonly reported end-of-life scenario in the literature is landfilling.

3. Applications and Performance

Some of the most recurring investigated properties in the literature include hygric and thermal conductivity coefficients, moisture uptake capacity and moisture buffer, moisture retention curves, and hysteresis effect on recurring wetting and drying cycles. Analysis of their hygrothermal capacity leads to other attributes such as occupant comfort, indoor air quality, hygienic conditions, etc. As a whole, the hygrothermal performance of the building envelope can be evaluated via thermal and hygroscopic characteristics, namely conductivity, heat capacity, and thermal diffusivity as thermal properties, alongside moisture buffer, moisture diffusion efficiency, porosity, and water permeability as hygric behaviors.

Jones and Brischke [2] reviewed many of the key properties of crop-based materials and how these materials are chosen within modern construction methods and during their service life. The authors divided crop-based materials into non-wood (plant-based) and wooden substances. Wooden crop-based materials are enumerated as solid wood, cross-laminated timber, panels, wood plastic composites, cellulose, pulp and paper, and finally bark and cork. Non-wood crop-based materials, on the other hand, involve flax, hemp, straw, bamboo, rattan reed, wool, peat, grass, and vegetal pith. Hence based on the mentioned study’s benchmarks, the following research will be conducted for each of these categories distinctly.

Plant-based materials have a wider variety of species, compared to wood-based materials, especially for insulation applications. These materials are implemented either as insulation infills or as crop-based blocks used in the building walls and floors. Based on the utilized plant type in the crop-based materials, their subsequent properties can vary widely, which are reviewed as follows.

One of the most popular crop-based materials in both academic studies and the construction market is the combination of lime and hemp, known as Lime Hemp Concrete (LHC) or hempcrete. Evrard and De Herde [51] reviewed the hygrothermal properties of Lime Hemp (LH) wall assemblies and compared their transient performance, as per five traditional assemblies using WUFI Pro 4.1 simulation. The results depicted the ability of LH for fast liquid transfer combined with high vapor permeability and high moisture retention level. These properties play a key role in the hygrothermal dynamic both inside the material and in the indoor environment. This capacity is enabled by lime hemp, especially when used in the inner layer of insulation and capillary active materials. Hence, it avoids condensation-related issues that lead to increasing comfort levels, enhanced hygienic indoor environments, etc. In addition, this study also considers parameters to analyze components’ responses under sudden changes in exterior temperature (cold nights, intense solar radiation, and scorching days). Authors concluded that LH walls provide better results to dampen the effect of fast weather changes, more than other assemblies. Along with its hygroscopic capacity, its strength is examined by de Bruijn et al. [52], in which both fibers and shives of this plant are agglomerated using a lime-binding agent. Although its results showed that the mechanical strength did not differ in comparison with merely using fibers, it asserted that LHC could be used in load-bearing structures. Haik et al. [53] expanded this material’s thermal characteristics by replacing lime agents with other materials and identified its thermal and hygric performance as to temperature fluctuation, relative humidity balance, and moisture buffer. Although alternative binders demonstrated the same thermal performance as the lime-based binder, they are shown to perform better, in terms of embodied carbon and energy in this study.

Rahim et al. [54] discuss the moisture properties of two crop-based materials, flax lime concrete (FLC), and hemp lime concrete (HLC). Hygric properties (sorption isotherm, water vapor permeability, moisture diffusivity, and moisture buffer capacity) are quantified by the Moisture Buffer Value (MBV). Materials’ responses are analyzed under different equilibrium and dynamic conditions. Both crop-based materials exhibited an “excellent” moisture buffer capacity according to the classification proposed by the Nordtest project [55]. The sorption process is very slow, particularly under high relative humidity levels. The sorption isotherms of the two materials display a similar pattern, which is justifiable since they have similar microstructures. HLC absorbs lower moisture content than FLC since the width of flax’s pores is smaller than that of hemp, and thus promotes more capillary condensation which results in more moisture adsorption [54].

In addition to more common crop-based materials including flax, hemp and straw based concretes, there are other non-wood materials (e.g., reed, wool, vegetal pith, grass, peat, etc.), all of which are capable of being developed into viable building materials, that are partly reflected in the literature.

Despite the lack of studies on the reed, Brischke and Hanske [56] investigated the viability of its usage as a thatching material. They recognized decay in the material as a result of its use in roofing applications. They also studied the moisture absorption and durability of this material. Hofmann et al. [57] studied the adverse effects of a specific fungus on the mentioned decay in the roof thatching. Wöhler-Geske et al. [58] measured the water absorption of this material and analyzed the subsequent quality changes in the material.

Wool is studied as to its hygric and thermal performance as a construction material. Joshi et al. [59] compared this substance’s environmental aspects with reinforced glass fiber composites. It concludes that due to lower environmental impact, a diminished amount of pollutant polymers facilitated transportation due to their light weight, and lower embodied energy and carbon footprint caused by their capacity of being incinerated at their end-of-life scenario, this category of insulation material plays a pivotal role in the construction of green buildings. Abdou and Budaiwi [60] examined wool’s hygric performance at different moisture content levels. They concluded that increasing moisture content at a specific temperature would result in higher changes in conductivity, according to the relationship between k-value and thermal resistance. Patnaik et al. [61] studied the acoustic and thermal insulation properties of this material. They asserted that the thermal conductivity of the waste wool fibers is considerably low compared to chemical counterparts, although the conductivity increases with the rise of temperature. In addition, the samples tested in this report demonstrated a good acoustic absorption over the whole sound frequency test range (50–5700 Hz).

Vegetal pith, as the innermost layer of many plants, has been studied by a few researchers in recent years, as the construction materials. There are many crop-based sources to extract this material. Korjenic et al. [62] offered a hygroscopicity analysis of this material throughout their study on natural insulation materials. Given its porous inner structure, this material is highly capable of absorbing and releasing moisture, thereby maintaining a hygric balance in the environment. Georgiev et al. [63] performed an analysis of the relationship between aggregate density and the product’s conductivity and derived a linear connection between these two parameters. Palumbo et al. [64] studied the pith extracted from corn aggregates. It compared the material’s thermal conductivity to straw fibers and concluded that it is 10% more resistant to heat flow than straw fibers.

References

- Moussa, T.; Maalouf, C.; Ingrao, C.; Scrucca, F.; Costantine, G.; Asdrubali, F. Bio-based and recycled-waste materials in buildings: A study of energy performance of hemp-lime concrete and recycled-polyethylene terephthalate façades for office facilities in France and Italy. Sci. Technol. Built Environ. 2018, 24, 492–501.

- Jones, D.; Brischke, C. Performance of BIO-Based Building Materials; Woodhead Publishing: Delhi, India, 2017.

- Beccali, M.; Cellura, M.; Fontana, M.; Longo, S.; Mistretta, M. Energy retrofit of a single-family house: Life cycle net energy saving and environmental benefits. Renew. Sustain. Energy Rev. 2013, 27, 283–293.

- Lawrence, M. Reducing the environmental impact of construction by using renewable materials. J. Renew. Mater. 2015, 3, 163–174.

- Cuéllar-Franca, R.M.; Azapagic, A. Environmental Impacts of the UK Residential Sector: Life Cycle Assessment of Houses. Build. Environ. 2012, 54, 86–99.

- Joseph, P.; Tretsiakova-McNally, S. Sustainable non-metallic building materials. Sustainability 2010, 2, 400–427.

- Dutil, Y.; Rousse, D.; Quesada, G. Sustainable buildings: An ever evolving target. Sustainability 2011, 3, 443–464.

- Calkins, M. Materials for Sustainable Sites: A Complete Guide to the Evaluation, Selection, and Use of Sustainable Construction Materials; John Wiley & Sons: Hoboken, NJ, USA, 2008.

- Menet, J.-L.; Gruescu, I.-C. A comparative life cycle assessment of exterior walls constructed using natural insulation materials. Short Hyper Artic. En Ligne 2012, 1, 14.

- Gorse, C.; Thomas, F.; Glew, D.; Shenton, D.M. Achieving Sustainability in New Build and Retrofit: Building Performance and Life Cycle Analysis. In Building Sustainable Futures; Springer: Berlin, Germany, 2016; pp. 183–207.

- EN 15804:2012; European Committee for Standardization. Sustainability of Construction Works—Environmental Product Declarations—Core Rules for the Product Category of Construction Products. CEN-CENELEC Management Centre: Brussels, Belgium, 2012.

- Van Dam, J.E.G.; Bos, H.L. The Environmental Impact of Fibre Crops in Industrial Applications; Food and Agriculture Organization: Rome, Italy, 2004.

- Cherubini, F.; Guest, G.; Strømman, A.H. Bioenergy from forestry and changes in atmospheric CO2: Reconciling single stand and landscape level approaches. J. Environ. Manag. 2013, 129, 292–301.

- Schulte, M.; Lewandowski, I.; Pude, R.; Wagner, M. Comparative life cycle assessment of bio-based insulation materials: Environmental and economic performances. GCB Bioenergy 2021, 13, 979–998.

- Martin, M.; Røyne, F.; Ekvall, T.; Moberg, Å. Life cycle sustainability evaluations of bio-based value chains: Reviewing the indicators from a Swedish perspective. Sustainability 2018, 10, 547.

- Berndes, G.; Ahlgren, S.; Börjesson, P.; Cowie, A.L. Bioenergy and land use change—State of the art. Wiley Interdiscip. Rev. Energy Environ. 2013, 2, 282–303.

- Potrč, T.; Rebec, K.M.; Knez, F.; Kunič, R.; Legat, A. Environmental footprint of external thermal insulation composite systems with different insulation types. Energy Procedia 2016, 96, 312–322.

- Escobar, N.; Laibach, N. Sustainability check for bio-based technologies: A review of process-based and life cycle approaches. Renew. Sustain. Energy Rev. 2021, 135, 110213.

- Zamagni, A.; Guinée, J.; Heijungs, R.; Masoni, P.; Raggi, A. Lights and shadows in consequential LCA. Int. J. Life Cycle Assess. 2012, 17, 904–918.

- Schmidt, J.H. System delimitation in agricultural consequential LCA. Int. J. Life Cycle Assess. 2008, 13, 350–364.

- Escobar, N.; Ribal, J.; Clemente, G.; Sanjuán, N. Consequential LCA of two alternative systems for biodiesel consumption in Spain, considering uncertainty. J. Clean. Prod. 2014, 79, 61–73.

- Lewandowski, I. Securing a sustainable biomass supply in a growing bioeconomy. Glob. Food Secur. 2015, 6, 34–42.

- Rosegrant, M.W.; Ringler, C.; Zhu, T.; Tokgoz, S.; Bhandary, P. Water and food in the bioeconomy: Challenges and opportunities for development. Agric. Econ. 2013, 44, 139–150.

- Escobar, N.; Haddad, S.; Boerner, J.; Britz, W. Land use mediated GHG emissions and spillovers from increased bioplastic consumption. Environ. Res. Lett. 2018, 13, 125005.

- Nong, D.; Escobar, N.; Britz, W.; Börner, J. Long-term impacts of bio-based innovation in the chemical sector: A dynamic global perspective. J. Clean. Prod. 2020, 272, 122738.

- Florentino, B.; Chanton, J.P.; Barlaz, M.A. Measurement of carbon storage in landfills from the biogenic carbon content of excavated waste samples. Waste Manag. 2013, 33, 2001–2005.

- Silva, D.A.L.; Lahr, F.A.R.; Pavan, A.L.R.; Saavedra, Y.M.B.; Crespo-Mendes, N.; Sousa, S.R.; Sanches, R.; Ometto, A.R. Do wood-based panels made with agro-industrial residues provide environmentally benign alternatives? An LCA case study of sugarcane bagasse addition to particle board manufacturing. Int. J. Life Cycle Assess. 2014, 19, 1767–1778.

- Fieschi, M.; Pretato, U. Role of compostable tableware in food service and waste management. A life cycle assessment study. Waste Manag. 2018, 73, 14–25.

- Garfí, M.; Flores, L.; Ferrer, I. Life cycle assessment of wastewater treatment systems for small communities: Activated sludge, constructed wetlands and high rate algal ponds. J. Clean. Prod. 2017, 161, 211–219.

- Seghetta, M.; Tørring, D.; Bruhn, A.; Thomsen, M. Bioextraction potential of seaweed in Denmark—An instrument for circular nutrient management. Sci. Total Environ. 2016, 563, 513–529.

- Asif, M.; Muneer, T.; Kelley, R. Life cycle assessment: A case study of a dwelling home in Scotland. Build. Environ. 2007, 42, 1391–1394.

- Bowick, M.F. A Life Cycle Assessment Model of Canadian Residential Dwellings and Building Stocks. Ph.D. Dissertation, Ryerson University, Toronto, ON, Canada, 2011.

- Peñaloza, D.; Erlandsson, M.; Falk, A. Exploring the climate impact effects of increased use of bio-based materials in buildings. Constr. Build. Mater. 2016, 125, 219–226.

- Hill, C.A. Wood Modification: Chemical, Thermal and Other Processes; John Wiley & Sons: Hoboken, NJ, USA, 2007; Volume 5.

- Ding, T.; Xiao, J.; Tam, V.W. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375.

- Giergiczny, Z.; Król, A.; Tałaj, M.; Wandoch, K. Performance of concrete with low CO2 emission. Energies 2020, 13, 4328.

- Bumanis, G.; Vitola, L.; Pundiene, I.; Sinka, M.; Bajare, D. Gypsum, Geopolymers, and starch—Alternative binders for bio-based building materials: A review and life-cycle assessment. Sustainability 2020, 12, 5666.

- Heinrich, L.A. Future opportunities for bio-based adhesives–advantages beyond renewability. Green Chem. 2019, 21, 1866–1888.

- Pizzi, A. Recent developments in eco-efficient bio-based adhesives for wood bonding: Opportunities and issues. J. Adhes. Sci. Technol. 2006, 20, 829–846.

- Segovia, F.; Blanchet, P.; Auclair, N.; Essoua, G.G.E. Thermo-mechanical properties of a wood fiber insulation board using a bio-based adhesive as a binder. Buildings 2020, 10, 152.

- Ferreira, J.V.; Esteves, B.; Nunes, L.; Domingos, I. Life Cycle Assessment of Thermally Treated and Untreated Maritime Pine Boards: A Portuguese Case Study. In Proceedings of the European Conference on Wood Modification, Lisbon, Portugal, 10–12 March 2014.

- Elmasoudi, I.; Ibrahim, M.G.; Tokimatsu, K.; Elbeltagi, E. Environmental impact assessment model for buildings’ construction activities. Int. J. Constr. Manag. 2022, 22, 849–860.

- The Architectural Review. Available online: www.architectural-review.com (accessed on 29 April 2023).

- Livne, A.; Wösten, H.A.B.; Pearlmutter, D.; Gal, E. Fungal Mycelium Bio-Composite Acts as a CO2-Sink Building Material with Low Embodied Energy. ACS Sustain. Chem. Eng. 2022, 10, 12099–12106.

- Gérardin, P. New alternatives for wood preservation based on thermal and chemical modification of wood—A review. Ann. For. Sci. 2016, 73, 559–570.

- Lecompte, T.; Levasseur, A.; Maxime, D. Lime and hemp concrete LCA: A dynamic approach of GHG emissions and capture. Acad. J. Civ. Eng. 2017, 35, 513–521.

- Wojnowska-Baryła, I.; Kulikowska, D.; Bernat, K. Effect of bio-based products on waste management. Sustainability 2020, 12, 2088.

- Beigbeder, J.; Soccalingame, L.; Perrin, D.; Bénézet, J.-C.; Bergeret, A. How to manage biocomposites wastes end of life? A life cycle assessment approach (LCA) focused on polypropylene (PP)/wood flour and polylactic acid (PLA)/flax fibres biocomposites. Waste Manag. 2019, 83, 184–193.

- Pittau, F.; Krause, F.; Lumia, G.; Habert, G. Fast-growing bio-based materials as an opportunity for storing carbon in exterior walls. Build. Environ. 2018, 129, 117–129.

- Fouquet, M.; Levasseur, A.; Margni, M.; Lebert, A.; Lasvaux, S.; Souyri, B.; Buhé, C.; Woloszyn, M. Methodological challenges and developments in LCA of low energy buildings: Application to biogenic carbon and global warming assessment. Build. Environ. 2015, 90, 51–59.

- Evrard, A.; De Herde, A. Hygrothermal performance of lime-hemp wall assemblies. J. Build. Phys. 2010, 34, 5–25.

- de Bruijn, P.B.; Jeppsson, K.-H.; Sandin, K.; Nilsson, C. Mechanical properties of lime–hemp concrete containing shives and fibres. Biosyst. Eng. 2009, 103, 474–479.

- Haik, R.; Peled, A.; Meir, I. The thermal performance of lime hemp concrete (LHC) with alternative binders. Energy Build. 2020, 210, 109740.

- Rahim, M.; Douzane, O.; Tran Le, A.; Promis, G.; Laidoudi, B.; Crigny, A.; Dupre, B.; Langlet, T. Characterization of flax lime and hemp lime concretes: Hygric properties and moisture buffer capacity. Energy Build. 2015, 88, 91–99.

- Rode, C.; Peuhkuri, R.; Time, B.; Svennberg, K.; Ojanen, T.; Mukhopadhyaya, P.; Kumaran, M.; Dean, S.W. Moisture Buffer Value of Building Materials. J. ASTM Int. 2007, 4.

- Brischke, C.; Hanske, M. Durability of untreated and thermally modified reed (Phragmites australis) against brown, white and soft rot causing fungi. Ind. Crops Prod. 2016, 91, 49–55.

- Hofmann, K.; Kreisel, H.; Kordon, K.; Preuss, F.; Kües, U.; Schauer, F. The key role of lignin decomposing fungi in the decay of roofs thatched with water reed. Mycol. Prog. 2016, 15, 35.

- Wöhler-Geske, A.; Moschner, C.R.; Gellerich, A. Provenances and properties of thatching reed (Phragmites australis). Landbauforsch. Ger. 2016, 66, 1–10.

- Joshi, S.V.; Drzal, L.T.; Mohanty, A.K. Are natural fiber composites environmentally superior to glass fiber reinforced composites? Compos. Part A Appl. Sci. Manuf. 2004, 35, 371–376.

- Abdou, A.; Budaiwi, I. The variation of thermal conductivity of fibrous insulation materials under different levels of moisture content. Constr. Build. Mater. 2013, 43, 533–544.

- Patnaik, A.; Mvubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwala, R. Thermal and sound insulation materials from waste wool and recycled polyester fibers and their biodegradation studies. Energy Build. 2015, 92, 161–169.

- Korjenic, A.; Petránek, V.; Zach, J.; Hroudová, J. Development and performance evaluation of natural thermal-insulation materials composed of renewable resources. Energy Build. 2011, 43, 2518–2523.

- Georgiev, G.P.; Theuerkorn, W.; Krus, M.; Kilian, R.; Grosskinsky, T. The potential role of cattail-reinforced clay plaster in sustainable building. Mires Peat 2014, 13, 1–13.

- Palumbo, M.; Formosa, J.; Lacasta, A. Thermal degradation and fire behaviour of thermal insulation materials based on food crop by-products. Constr. Build. Mater. 2015, 79, 34–39.

More

Information

Subjects:

Construction & Building Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

614

Revisions:

2 times

(View History)

Update Date:

14 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No