Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Juan Camilo Solarte-Toro | -- | 3480 | 2023-07-04 18:15:12 | | | |

| 2 | Sirius Huang | Meta information modification | 3480 | 2023-07-05 03:18:58 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Solarte-Toro, J.C.; Ortiz-Sanchez, M.; Inocencio-García, P.; Cardona Alzate, C.A. Sustainable Biorefineries Based on Catalytic Biomass Conversion. Encyclopedia. Available online: https://encyclopedia.pub/entry/46410 (accessed on 07 February 2026).

Solarte-Toro JC, Ortiz-Sanchez M, Inocencio-García P, Cardona Alzate CA. Sustainable Biorefineries Based on Catalytic Biomass Conversion. Encyclopedia. Available at: https://encyclopedia.pub/entry/46410. Accessed February 07, 2026.

Solarte-Toro, Juan Camilo, Mariana Ortiz-Sanchez, Pablo-José Inocencio-García, Carlos Ariel Cardona Alzate. "Sustainable Biorefineries Based on Catalytic Biomass Conversion" Encyclopedia, https://encyclopedia.pub/entry/46410 (accessed February 07, 2026).

Solarte-Toro, J.C., Ortiz-Sanchez, M., Inocencio-García, P., & Cardona Alzate, C.A. (2023, July 04). Sustainable Biorefineries Based on Catalytic Biomass Conversion. In Encyclopedia. https://encyclopedia.pub/entry/46410

Solarte-Toro, Juan Camilo, et al. "Sustainable Biorefineries Based on Catalytic Biomass Conversion." Encyclopedia. Web. 04 July, 2023.

Copy Citation

Biorefineries have been profiled as potential alternatives to increase biomass use at the industrial level. However, more efforts are required to improve the sustainability of these facilities through process improvement and product portfolio increase.

biocatalysis

catalysts recycling and re-use

sustainability

process design

biofuels

platform molecules

1. Introduction

Energy matrix diversification has been categorized as the most reliable approach to guarantee energy security in different world regions [1]. Currently, most countries depend highly on non-renewable energy sources (i.e., crude oil, natural gas, coal). Price fluctuations and geopolitical conflicts can affect the power, electricity, building, industry, agriculture, and transport sectors [2]. This dependence is not convenient because any change in the global context can affect the economic and environmental goals proposed and discussed by international organizations (e.g., the UN). For instance, the Russian Federation’s invasion of Ukraine has affected the energy transition goals and discourse of different European countries (e.g., Germany) [3]. Fossil fuel prices, especially coal, increased for heating and power generation in late 2021 [4]. This increased demand caused a domino effect in coal-exporting countries (e.g., Colombia), because the increase in coal prices reduced the profit margin of coal-dependent industries (e.g., brick-making industries). Therefore, energy matrix diversification is mandatory to guarantee a reliable, affordable, and efficient service for the world population.

Bioenergy has become one of the most important pillars in energy transition topics, as biomass can reduce greenhouse gas emissions (GHG) and environmental damages caused by the excessive use of fossil fuels [5]. Biomass is an alternative for energy production, as this renewable resource can contribute to accomplishing the requirements of the transport sector, especially in the aviation and marine sectors [4][6]. On the other hand, sustainable production and consumption patterns have awakened consumers’ interest in bio-based products instead of synthetic ones. Therefore, biomass has been studied as a potential feedstock for producing biomaterials (e.g., bioplastics, biocomposites), bulk chemicals (organic acids, alcohols), nutraceutical products (e.g., antioxidants), biosurfactants (e.g., rhamnolipids, surfactin), and food additives (e.g., sweeteners and preservatives) [7][8].

Second-generation biomass has been profiled as a potential raw material to replace crude oil, as different research efforts have demonstrated the possibility of obtaining the same products with a lower environmental impact (e.g., olefins, paraffin) while avoiding food security issues [9]. Most studies involve lignocellulosic biomass fractionation and upgrading by implementing biotechnological, thermochemical, physical, and chemical processes [10]. Several reactions with specific activation energies and reaction pathways can occur when disrupting biomass, providing a complex mixture of degradation products as described for the evolution pathways of herbal tea waste when implementing hydrothermal conversion [11]. Moreover, different process configurations have been proposed for the integral use of all lignocellulosic biomass fractions [12]. Nevertheless, the range of products derived from these processes is restricted, as more complex molecules require specific reaction conditions (i.e., temperature, pressure). Therefore, catalysis plays a key role in biomass conversion, as “new products” with a high yield, selectivity, and conversion are achieved at milder operating conditions [13].

Catalysis occurs in almost all biomass-processing stages (i.e., pretreatment and conversion) [2]. Recent trends have promoted heterogeneous catalysis, considering possible catalyst recovery and re-use. Instead, homogenous catalysis has also been studied for most lignocellulosic biomass-upgrading processes (e.g., acid hydrolysis) [14]. Biomass-to-biofuels conversion through catalytic processes has been one of the most studied issues due to the low global implementation of bioenergy in the industrial and transport sectors for heat and power requirements [15]. In addition, high-value-added compounds produced via heterogeneous catalysis have been studied for the cosmetic, pharmaceutical, and chemical sectors. Thus, the integral processing of lignocellulosic biomass by implementing catalytic processes can help reach the proposed decarbonization and climate change mitigation goals. Furthermore, lignocellulosic biomass upgrading through catalytic processes avoids a structural and technological shift in the industry and transport sectors [16]. Advantages related to the catalytic upgrading of biomass are (i) improvement of different processes’ sustainability by reducing energy requirements, (ii) production of platform molecules as a strong option to diversify the list of bio-based products derived from biomass, and (iii) reduction in waste streams [17]. Thus, lignocellulosic biomass conversion involving catalytic processes can contribute to reaching energy transition and fossil fuel independence goals faster.

2. Biorefineries and Catalytic Biomass Upgrading

Lignocellulosic biomass conversion in biorefineries has been analyzed based on the main biomass constituents. These facilities are complex systems where biomass is integrally processed or fractioned to obtain more than one product, including bioenergy, biofuels, chemicals, and high-value-added compounds [18]. Biorefineries are designed while considering a comprehensive study of the raw materials and promising technologies [19]. These facilities have been proposed as the starting point for developing and implementing a consolidated bioeconomy [20]. Thus, biorefineries can help to accomplish the Sustainable Development Goals (SDGs) proposed by the UN.

Biorefineries’ implementation has been slowed, as current technologies upgrade non-renewable resources at the industrial level. Therefore, the transition from crude-oil refineries to biorefineries remains slow compared to the research on biomass upgrading at a lab scale [21]. A path towards easier industrial biomass use, leaving aside traditional uses (i.e., combustion), is to upgrade biomass-derived products through catalytic processes to obtain chemicals without requiring an in-depth technological transition. Therefore, catalysis is crucial for (i) shortening distances between academia and industry regarding biomass use, (ii) enhancing biorefinery designs, (iii) creating new biomass conversion pathways, and (iv) increasing processes’ sustainability. Biorefineries comprise thermochemical, biotechnological, chemical, and physical processes through which several compounds can be produced. Thus, catalytic upgrading can be present in all these processes. Indeed, several research efforts have demonstrated the importance of applying catalysis to improve technical indicators (i.e., yields, productivity, and product purity) [22].

3. Recent Trends Related to Catalytic Processes for Improving Biorefineries’ Designs

Catalytic upgrading of biomass has increased in recent years in order to obtain more bio-based products that can be used in any productive sector. Therefore, different research efforts have been focused on analyzing new ways to implement catalytic processes for biomass upgrading or waste-streams valorization [23][24][25][26]. This section refers to some trends related to the catalytic upgrading of bio-based compounds. However, there are more trends worthy of being studied and analyzed. The trends presented are as follows: biocatalysis, CO2-upgrading, catalysts’ recyclability and use, and biochar as catalysts’ source. The above-mentioned research lines in catalytic processes aim to improve biorefineries’ designs, as more products can be involved in a biorefinery. Moreover, the sustainability of these facilities is upgraded due to the emissions reduction and waste-streams minimization.

3.1. Biocatalysis as the Basis for Producing Specialty and Fine Chemicals

Biocatalysis is a new alternative that several industrial processes are implementing to assist or replace existing synthetic routes through which specialty and fine chemicals are produced [27]. Therefore, the use of cell systems or enzymes has mainly been studied specifically to cover the demands of pharmaceutical applications to obtain high-value compounds. The current technologies are based on the production of optical purity species for the required chiral center that represents a specific function in a medical patient [28]. Moreover, several authors have implemented green chemistry metrics to study the optimum operating conditions to allow the minimum waste generation and use of hazardous reagents or solvents [29].

The use of a biocatalyst involves economic factors that must be considered during the process. According to Pollard et al. [28], the obtained products must present considerably similar concentrations of those products generated when using chemical standard routes. Nevertheless, enzymes need to work in high-substrate concentrations without decreasing the activity. The second aspect that conditions the productive process is the biocatalyst cost, and this metric must be at a value around 1000 gproduct/genzyme activity for the enzymes and at around 15 gproduct/gbiocatalyst for the cell systems.

Ketone is the most common substrate and is used for the obtaining of pyrimidines and chiral intermediates. According to Chong et al. [30], the inhibitor ipatasertib can be efficiently synthetized by bicyclic pyrimidine as the starting material of the Ketoreductase enzyme (KRED) that acts on the ketone. This compound is produced with a yield of 86.00 wt%, and as reported, the operating conditions in terms of temperature and pH are neutral or not highly energy demanding for the biocatalytic asymmetric reduction that occurs. When comparing to chemical routes, the use of extreme conditions can cause isomerization, rearrangement of the compound, or racemization [31]. These phenomena reduce the productivity and make upstream processing necessary in order to reach purity and demanded standards.

Pollard et al. [28] note that biocatalytic processes are carried out in small scales when compared to most of the existing chemical processes. Up to 10,000 tons of pharmaceutical compounds are produced per year, and the scaling-up from laboratory scale is difficult. Factors such as batch operating mode can represent a negative effect for the enzyme or cell systems, as the substrate consumption has repercussions on the product quality standards [32]. Moreover, the large capacity of the devices at industrial level does not allow a perfect mixing, or if so, the energy consumption is higher than that at laboratory scale. Finally, the equipment materials are not the same when referring to one scale or another, which leads to low productivities [28].

Enzymes promote stability and selectivity for the desired compound [31]. For instance, when using Cyclohexanol as substrate and KRED as enzyme, St-Jean et al. [33] described that for a thermal requirement of 50 °C in an advanced racemic intermediate, the process reaches a yield of 95.00 wt% for diketone intermediate, an intermediate for the synthesis of Navoximod (II) as an IDO inhibitor.

Several mental health diseases such as anxiety and depression are treated with medicine that causes side-effect profiles. Nevertheless, (R)-sec-Butylamine 17 and (R)-1-cyclopropylethylamine constitute chiral intermediates from which Corticotropin-Releasing Factor-1 (CRF-1) can be synthetized as a receptor antagonist [28]. Another receptor antagonist can be synthetized from 3-Fluoro-4-aminopiperidine, produced by the asymmetric transaminase [34]. The reaction time indicates that the product is obtained after 24 h; however, the yield is 94.00 wt%, and the operation is under mild conditions.

The implementation of a biocatalytic route in a productive process might demand specificity related to the equipment and a considerable economic investment. Nevertheless, the operating conditions indicate that biocatalysis is a promising alternative for the synthesis of fine chemicals, especially those related to the pharmaceutical sector, where productivity and selectivity constitute key factors [35]. Additionally, there is a great variety of enzymes and cell systems available for each compound, which contributes to avoiding subsequent purification stages that are common in the existing chemical processes. Finally, biocatalysts promise to prevent stream wastes, and the implemented agents consist of renewable materials [34], which are important considerations for any process, especially those related to biorefineries.

3.2. Carbon Dioxide Conversion through Heterogeneous Catalysis

Greenhouse gas (GHG) emissions constitute a current issue that demands new alternatives be implemented in the industrial sector to mitigate environmental implications. Within the total GHG emissions, CO2 occupies the second position after methane [36], representing an increase in concentration in the atmosphere by up to 400 ppm in recent years [37]. There have been several studies where CO2 utilization (CDU) is carried out to promote the production of high-value-added products when using catalysis [38]. Nevertheless, a complete integration of CO2 capture and storage (CCS) systems to utilize technologies by which this gas could be transformed to different polymeric, organic, and inorganic products [39] should be analyzed.

A complete analysis of CO2 as a raw material in transformation routes according to the production scale contributes to mitigating environmental problems. Moreover, the production of different compounds that are currently of great interest could be favored [40]. To achieve this proposal, new transformation routes in processing plants with CO2 streams that can be used as raw material must be installed after having developed the respective sustainability assessment, where the techno-economic, environmental, and social dimensions are considered [41]. Some of the investigated methods for CO2 conversion to chemicals include electrocatalytic or photocatalytic reduction, bio-catalysis, dry methane reforming, and catalytic hydrogenation [42]. Advances in molecular catalysis for electrocatalytic capture of CO2 have indicated the process to be an appealing option for transformation of CO2 to chemicals such as carbon monoxide, formic acid, formaldehyde, and ethanol [43].

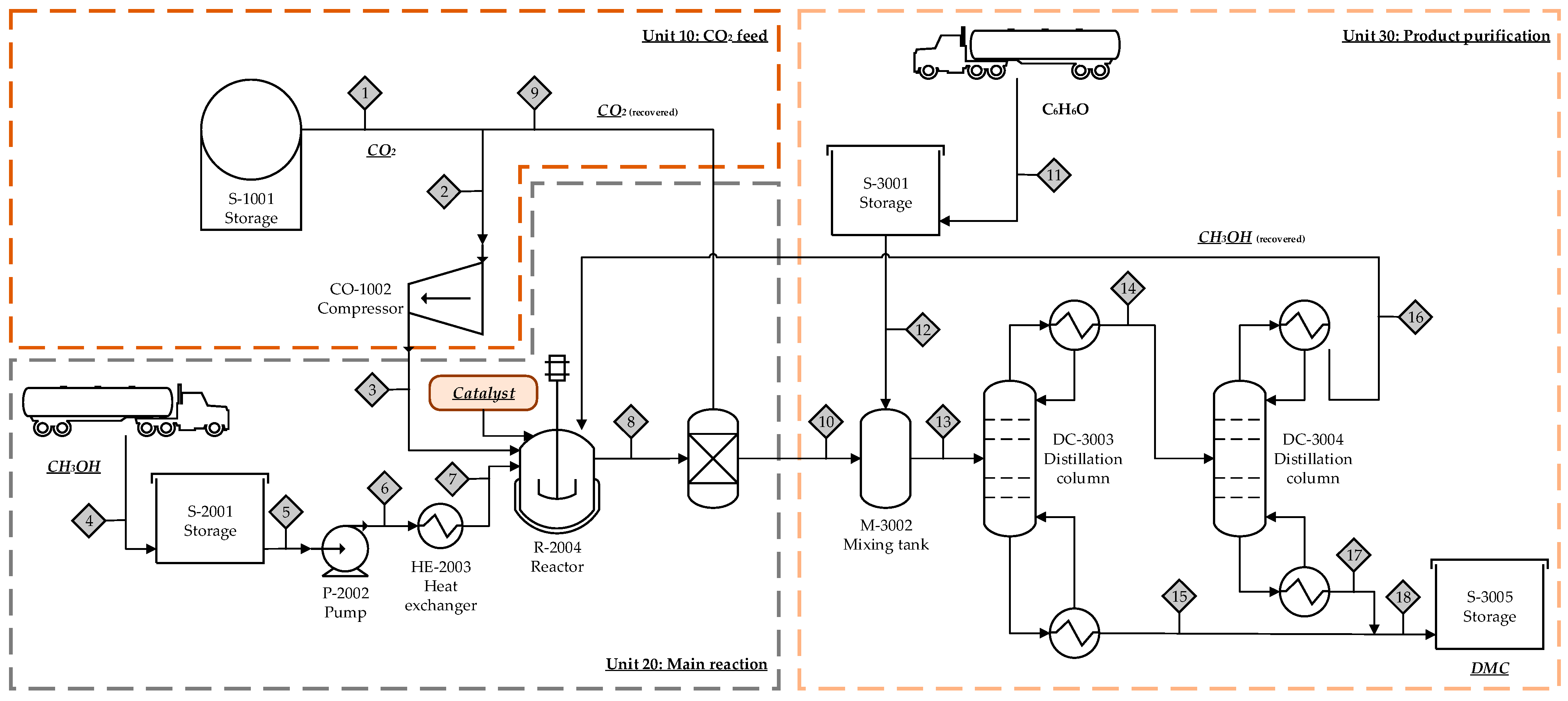

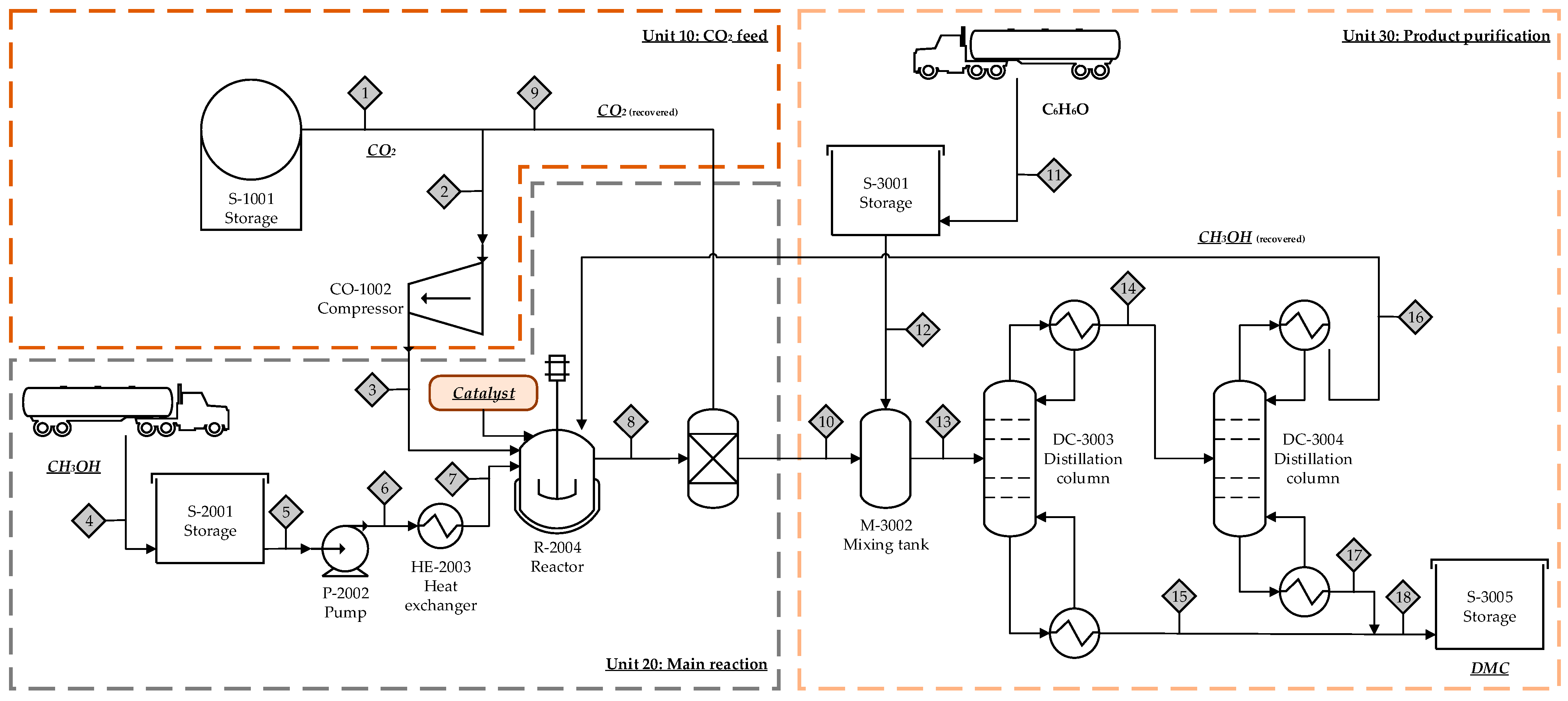

Von der Assen has focused on the evaluation of producing dimethyl carbonate (DMC) by several reaction routes through the CDU concept [44]. This product is an important carbonylating compound that can be utilized for different fields including electronics, chemicals, pesticides, and medicine [45]. Two main routes that use CO2 as raw material are the direct synthesis from CO2 and methanol, and the synthesis from propylene carbonate, which is also known as the PC-route. Furthermore, a high-level conversion (85.2%) can be reached with a zirconium (IV) acetylacetonate (Zr(acac)4) catalyst, leading to a carboxymethylation with a selectivity up to 99% [46]. Tamboli et al. [36] also studied the conversion of CO2 into DMC in a batch operating mode by using methanol as raw material to obtain a product yield of 26.17 wt% when the catalyst involved is Ce0.5Zr0.5O2 (see Figure 1). The reactions involved during the process enhance high efficiency and avoid the use of toxic chemicals such as phosgene, according to the kinetic study presented by Ohno et al. [46] and the work of Honda et al. [47].

Figure 1. Schematic of the production of dimethyl carbonate (DMC) using CO2 and methanol as raw material and Ce0.5Zr0.5O2 as catalyst.

Industrial sectors with high-residual-gas streams should consider the products to generate demanded and value-added compounds produced from CO2 through heterogeneous catalysis, considering the great variety of products that includes fuels, chemical precursors, and medicines such as Benzamide. This compound is produced from CO2 and low quantities of methanol when operating in high-pressure conditions to obtain a yield of 54.56 wt% [48]. Carbon monoxide (CO) can also be obtained by CO2 reduction using Ni/nSiO2 or Co-Fe/Al2O3, reaching yields up to 74 wt% with the use of the first catalyst operating at 800 °C and vacuum pressure [49].

3.3. Catalysis Recyclability and Re-Use

Once the catalytic operation has been completed by using either a homogenous or heterogenous catalyst, the recovery of these substances implementing different technologies must be guaranteed in order to reuse them once more in the process [50]. High catalytic performance is related to ease of separation and recycling of the catalyst. When carrying out the recovery, solid loss must be minimum to enhance a techno-economic process. According to the review paper presented by Miceli et al. [51], the separation methods that include extraction, filtration, and centrifugation required more time and, consequently, there is not a real industrial application because of the high economic requirements.

Homogenous catalysts enhance important advantages when compared to heterogenous catalyst regarding the selectivity and stability [52]. Nevertheless, in terms of separation facilities forming the reactive mixture, a heterogenous catalyst is cheaper and presents a low environmental impact, as non-sophisticated technologies must be implemented. Consequently, fewer limitations are presented for heterogenous substances when considering specialty and fine chemicals obtained in, for instance, the pharmaceutical industry [53]. Moreover, for reactive mixture in gas and solid phases, the catalyst can be separated and cleaned by using conventional techniques, and as for liquid and solid systems, the catalyst matrix can be recovered by filtration [51].

As mentioned before, implementing catalyst recovery techniques guarantees economic and environmental improvements. Nevertheless, Sádaba et al. [54] explained that deactivation of the catalyst might occur by different phenomena such as poisoning, thermal degradation, or metals leaching into liquid phase. Therefore, when the recovery process has been completed several times and the catalyst activity has decreased, several authors recommend using the spent catalyst in an alternative process to mitigate environmental issues before disposition in landfills [55]. Chiranjeevi et al. [55] analyzed the minimization of spent catalyst as waste from refineries’ applications and concluded that the main reasons for the recent deactivation of catalyst in oil processing include the rapid demand for product that makes the flowrates increase, the reduction in time for the operating cycles, and particular characteristics of the feedstock that cause poisoning of the catalytic substances.

Among the most used methods for catalyst recovery, filtration and centrifugation constitute the most used technologies for heterogenous substances, considering the difference in both chemical and physical properties in the reactive mixture [51]. Filtration is carried out using a filter or membrane to remove the solid part of the liquid and gas mixture. The fluid phase that is separated from the solid fraction is called permeated, and the phenomenon is influenced by a pressure gradient. Santoro et al. [53] studied the hot filtration for the removal or solid catalyst to stop the reaction by using metal-catalyzed C-H functionalization. As for centrifugation, the driving force is the difference in density that is utilized to separate the liquid and solid mixtures. After the operation, the solid part remaining in the bottom of the flask is denominated as pellet, while the supernate refers to the fluid phase [51]. Liu et al. [56] analyzed the recovery of a silver nanoparticle catalyst by centrifugation to carry out capture and conversion of CO2 as a low-energy-consumption alternative.

Another recycling alternative for heterogenous catalyst recovery is magnetic separation. This technique offers promising options for recycling catalyst-based metals in terms of techno-economic feasibility, as the operation takes little time and the implementation cost is low [57]. When considering a biorefinery scenario, sustainable processes must consider green chemistry principles alongside the production stages. Therefore, there might exist technologies that promote metal recovery from spent catalyst before final disposition. Miceli et al. [51] present two traditional techniques whose aim involves both economic and environmental dimensions for the production process. The first technique, denominated as hydrometallurgy, refers to metal dissolution in acid or base solution for a subsequent recovery of the specific metal by solvent extraction. Hu et al. [58] studied the removal of vanadium by ion exchange from a molybdate solution using a loaded resin that allowed a vanadium desorption ratio of 98.5% when regenerating the column. The second alternative corresponds to a pyrometallurgical process in which metal separation is carried out by using chemical treatments. Pyrolysis and incineration are involved in these treatments, which makes this process much more complex and expensive due to the high energy demand. Additionally, Peng et al. [59] mentioned that for platinum group metals recovery, vaporization techniques can be applied, but there could be corrosion as well as environmental and health impacts.

3.4. Biochar Use as Catalyst Source

Biochar is a carbonaceous compound derived from thermochemical processing of lignocellulosic biomass, as reviewed in previous sections. Biochar can be used to enhance soil properties, pollutant adsorption (e.g., dyes, inorganic metals, and ions), and CO2 capture and storage. However, this material has a high potential to be used as catalyst, as physical properties such as porosity and surface area make this thermochemical product attractive [60]. In this way, biochar is a promising material to replace solid carbon-based catalysts. The most important advantages related to the use of biochar as catalysts are the low cost and easy production. Physicochemical properties of biochar can be modified using acid/base processes (e.g., impregnation).

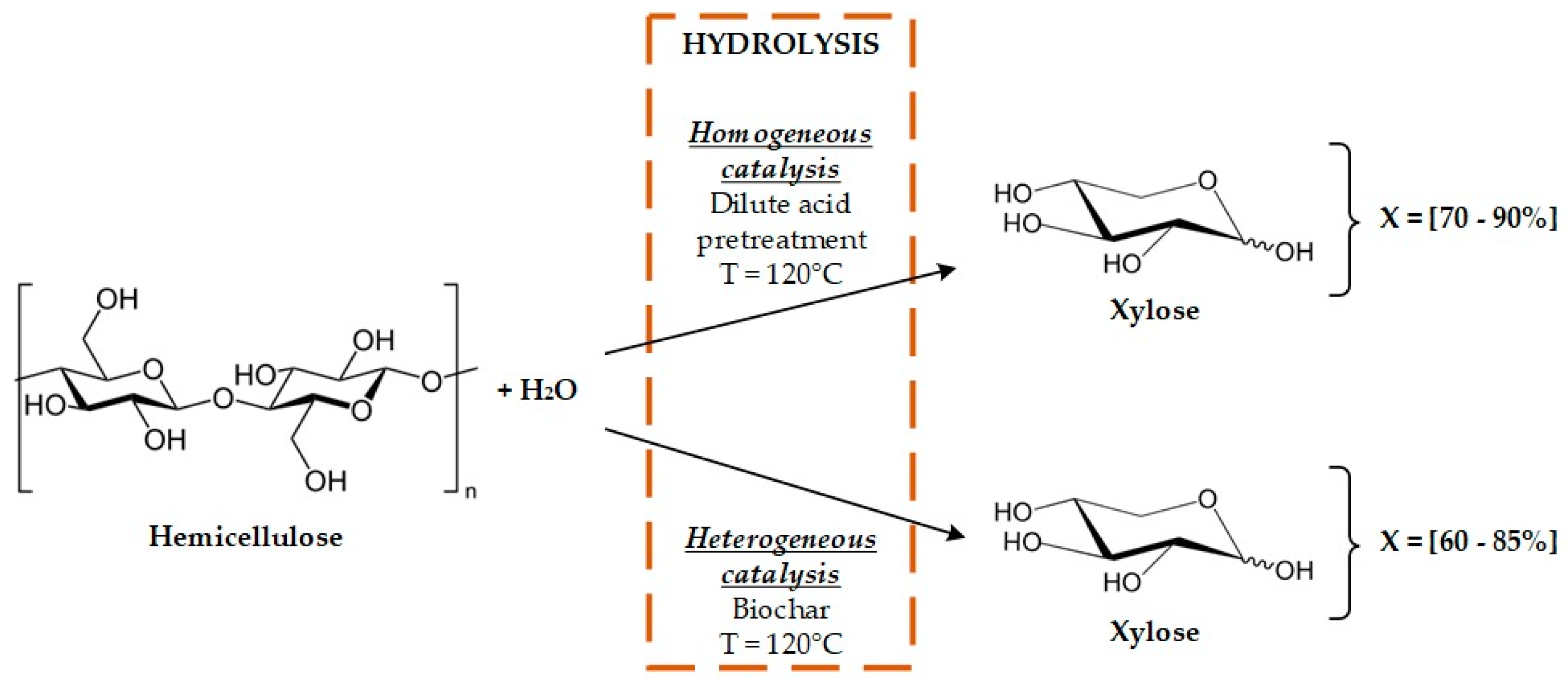

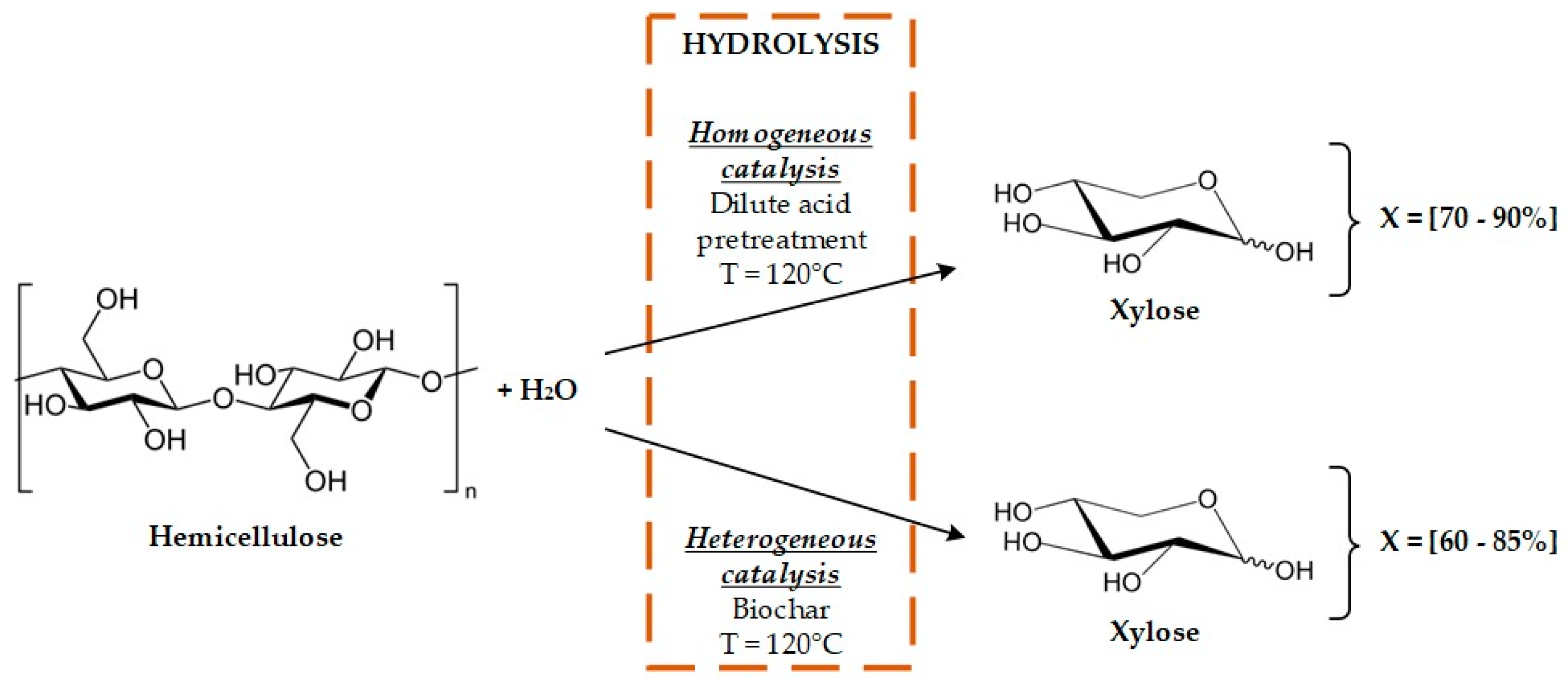

Biochar needs to be activated to improve catalytic efficiency. Indeed, biochar properties such as surface area, porosity, pore volume, pore size, and acidity are also improved. These properties can help to increase yield, productivity, and selectivity. A way to increase biochar porosity is via hydrothermal treatment or oxygenation [61]. Examples of different reactions catalyzed by biochar are transesterification and hydrolysis. Several authors have reported biochar sulfonation using sulfuric acid and calcination. This process increases the hydrolytic capacity. Lee et al. [60] analyzed the implementation of sulfonated pine-chip biochar as catalyst for hemicellulose hydrolysis to xylose and compared the conversion obtained (85%) when applying a commercial activated carbon at similar operating conditions (see Figure 2). Another application of biochar as catalysts addresses tar cracking. Indeed, biochar can be used to increase H2 concentration in syngas, as this compound promotes different reactions in the gasification process. Moreover, the Fisher–Tropsch reaction has been catalyzed using activated biochar. The yields obtained after the process are similar to those obtained using iron-based catalyst [62]. Finally, activated biochar can be used as acid catalyst for the lignocellulosic matrix disruption and to remove hemicellulose. Ormsby et al. [63] performed hemicellulose hydrolysis, reaching an 85% conversion to xylose. Thus, biochar can be used for producing sugar-derived compounds and chemical platforms [64].

Figure 2. Implementation of biochar as catalyst for the hydrolysis of hemicellulose.

Despite the high potential of biochar to be used as catalyst, issues related to the standardized production of this material need to be researched and improved. Moreover, research on proper raw materials for biochar production is required, as the raw material chemical composition and physical properties affect the biochar quality. Another important aspect to improve biochar’s use as catalyst is related to the operating conditions for producing biochar. Slow or fast pyrolysis processes should be optimized for improving the above-mentioned properties. Similar points were highlighted by Lee et al. [60]. Indeed, these authors concluded that further investigations into developing the catalytic properties of biochar are important to produce stable catalysts. If these hotspots are improved, biochar can be used as catalyst by improving the sustainability of the thermochemical production processes, as more income can be obtained from the production of biochar and other products (i.e., bio-oil). Furthermore, the use of biochar as catalysts also offers benefits to other processes, as biochar can be a cheaper catalyst than homogeneous (e.g., inorganic acids) or heterogeneous catalysts (e.g., zeolites).

References

- Udemba, E.N.; Tosun, M. Energy Transition and Diversification: A Pathway to Achieve Sustainable Development Goals (SDGs) in Brazil. Energy 2022, 239, 122199.

- Cardona Alzate, C.A.; Solarte Toro, J.C.; Peña, Á.G. Fermentation, Thermochemical and Catalytic Processes in the Transformation of Biomass through Efficient Biorefineries. Catal. Today 2018, 302, 61–72.

- Wiertz, T.; Kuhn, L.; Mattissek, A. A Turn to Geopolitics: Shifts in the German Energy Transition Discourse in Light of Russia’s War against Ukraine. Energy Res. Soc. Sci. 2023, 98, 103036.

- REN21 Renewables 2022 Global Status Report 2022. Available online: https://www.ren21.net/gsr-2022/ (accessed on 30 April 2023).

- International Energy Agency Sustainable International Bioenergy Trade: Securing Supply and Demand. Available online: http://www.fao.org/uploads/media/0611_IEA_Task_40_-_Technology_report.pdf (accessed on 1 May 2023).

- Wang, H.; Yang, B.; Zhang, Q.; Zhu, W. Catalytic Routes for the Conversion of Lignocellulosic Biomass to Aviation Fuel Range Hydrocarbons. Renew. Sustain. Energy Rev. 2020, 120, 109612.

- Wang, J.; Liu, S.; Huang, J.; Qu, Z. A Review on Polyhydroxyalkanoate Production from Agricultural Waste Biomass: Development, Advances, Circular Approach, and Challenges. Bioresour. Technol. 2021, 342, 126008.

- Mujtaba, M.; Fraceto, L.; Fazeli, M.; Mukherjee, S.; Savassa, S.M.; de Medeiros, G.A.; do Espírito Santo Pereira, A.; Mancini, S.D.; Lipponen, J.; Vilaplana, F. Lignocellulosic Biomass from Agricultural Waste to the Circular Economy: A Review with Focus on Biofuels, Biocomposites and Bioplastics. J. Clean. Prod. 2023, 402, 136815.

- Wang, W.; Gu, Y.; Zhou, C.; Hu, C. Current Challenges and Perspectives for the Catalytic Pyrolysis of Lignocellulosic Biomass to High-Value Products. Catalysts 2022, 12, 1524.

- Aristizábal-Marulanda, V.; Solarte-Toro, J.C.; Cardona Alzate, C.A. Study of Biorefineries Based on Experimental Data: Production of Bioethanol, Biogas, Syngas, and Electricity Using Coffee-Cut Stems as Raw Material. Environ. Sci. Pollut. Res. 2021, 28, 24590–24604.

- Shen, Y. A Review on Hydrothermal Carbonization of Biomass and Plastic Wastes to Energy Products. Biomass Bioenergy 2020, 134, 105479.

- Morakile, T.; Mandegari, M.; Farzad, S.; Görgens, J.F. Comparative Techno-Economic Assessment of Sugarcane Biorefineries Producing Glutamic Acid, Levulinic Acid and Xylitol from Sugarcane. Ind. Crops Prod. 2022, 184, 115053.

- Ahorsu, R.; Constanti, M.; Medina, F. Recent Impacts of Heterogeneous Catalysis in Biorefineries. Ind. Eng. Chem. Res. 2021, 60, 18612–18626.

- Karuppasamy, K.; Theerthagiri, J.; Selvaraj, A.; Vikraman, D.; Parangusan, H.; Mythili, R.; Choi, M.Y.; Kim, H.S. Current Trends and Prospects in Catalytic Upgrading of Lignocellulosic Biomass Feedstock into Ultrapure Biofuels. Environ. Res. 2023, 226, 115660.

- Khemthong, P.; Yimsukanan, C.; Narkkun, T.; Srifa, A.; Witoon, T.; Pongchaiphol, S.; Kiatphuengporn, S.; Faungnawakij, K. Advances in Catalytic Production of Value-Added Biochemicals and Biofuels via Furfural Platform Derived Lignocellulosic Biomass. Biomass Bioenergy 2021, 148, 106033.

- Deng, F.; Amarasekara, A.S. Catalytic Upgrading of Biomass Derived Furans. Ind. Crops Prod. 2021, 159, 113055.

- Yan, P.; Wang, H.; Liao, Y.; Wang, C. Zeolite Catalysts for the Valorization of Biomass into Platform Compounds and Biochemicals/Biofuels: A Review. Renew. Sustain. Energy Rev. 2023, 178, 113219.

- Moncada, B.J.; Aristizábal, M.V.; Cardona, A.C.A. Design Strategies for Sustainable Biorefineries. Biochem. Eng. J. 2016, 116, 122–134.

- Palmeros Parada, M.; Osseweijer, P.; Posada Duque, J.A. Sustainable Biorefineries, an Analysis of Practices for Incorporating Sustainability in Biorefinery Design. Ind. Crops Prod. 2017, 106, 105–123.

- Solarte-Toro, J.C.; Cardona Alzate, C.A. Biorefineries as the Base for Accomplishing the Sustainable Development Goals (SDGs) and the Transition to Bioeconomy: Technical Aspects, Challenges and Perspectives. Bioresour. Technol. 2021, 340, 125626.

- Solarte-Toro, J.C.; Laghezza, M.; Fiore, S.; Berruti, F.; Moustakas, K.; Cardona Alzate, C.A. Review of the Impact of Socio-Economic Conditions on the Development and Implementation of Biorefineries. Fuel 2022, 328, 125169.

- Shah, A.A.; Sharma, K.; Haider, M.S.; Toor, S.S.; Rosendahl, L.A.; Pedersen, T.H.; Castello, D. The Role of Catalysts in Biomass Hydrothermal Liquefaction and Biocrude Upgrading. Processes 2022, 10, 207.

- Tuck, C.O.; Pérez, E.; Horváth, I.T.; Sheldon, R.A.; Poliakoff, M. Valorization of Biomass: Deriving More Value from Waste. Science 2012, 337, 695–699.

- Wicker, R.J.; Kumar, G.; Khan, E.; Bhatnagar, A. Emergent Green Technologies for Cost-Effective Valorization of Microalgal Biomass to Renewable Fuel Products under a Biorefinery Scheme. Chem. Eng. J. 2021, 415, 128932.

- Zoppi, G.; Pipitone, G.; Pirone, R.; Bensaid, S. Aqueous Phase Reforming Process for the Valorization of Wastewater Streams: Application to Different Industrial Scenarios. Catal. Today 2022, 387, 224–236.

- Manara, P.; Zabaniotou, A. Co-Valorization of Crude Glycerol Waste Streams with Conventional and/or Renewable Fuels for Power Generation and Industrial Symbiosis Perspectives. Waste Biomass Valorization 2016, 7, 135–150.

- Rossino, G.; Robescu, M.S.; Licastro, E.; Tedesco, C.; Martello, I.; Maffei, L.; Vincenti, G.; Bavaro, T.; Collina, S. Biocatalysis: A Smart and Green Tool for the Preparation of Chiral Drugs. Chirality 2022, 34, 1403–1418.

- Pollard, D.J.; Woodley, J.M. Biocatalysis for Pharmaceutical Intermediates: The Future Is Now. Trends Biotechnol. 2007, 25, 66–73.

- Sheldon, R.A. Biocatalysis, Solvents, and Green Metrics in Sustainable Chemistry. In Biocatalysis in Green Solvents; Academic Press: Cambridge, MA, USA, 2022.

- Han, C.; Savage, S.; Al-Sayah, M.; Yajima, H.; Remarchuk, T.; Reents, R.; Wirz, B.; Iding, H.; Bachmann, S.; Fantasia, S.M.; et al. Asymmetric Synthesis of Akt Kinase Inhibitor Ipatasertib. Org. Lett. 2017, 19, 4806–4809.

- Patel, R.N. Biocatalysis: Synthesis of Key Intermediates for Development of Pharmaceuticals. ACS Catal. 2011, 1, 1056–1074.

- Wu, S.; Snajdrova, R.; Moore, J.C.; Baldenius, K.; Bornscheuer, U.T. Biocatalysis: Enzymatic Synthesis for Industrial Applications. Angew. Chem.-Int. Ed. 2021, 60, 88–119.

- St-Jean, F.; Angelaud, R.; Bachmann, S.; Carrera, D.E.; Remarchuk, T.; Piechowicz, K.A.; Niedermann, K.; Iding, H.; Meier, R.; Hou, H.; et al. Stereoselective Synthesis of the IDO Inhibitor Navoximod. J. Org. Chem. 2022, 87, 4955–4960.

- Molinaro, C.; Phillips, E.M.; Xiang, B.; Milczek, E.; Shevlin, M.; Balsells, J.; Ceglia, S.; Chen, J.; Chen, L.; Chen, Q.; et al. Synthesis of a CGRP Receptor Antagonist via an Asymmetric Synthesis of 3-Fluoro-4-Aminopiperidine. J. Org. Chem. 2019, 84, 8006–8018.

- Wohlgemuth, R. The Power of Biocatalysts for Highly Selective and Efficient Phosphorylation Reactions. Catalysts 2022, 12, 1436.

- Tamboli, A.H.; Chaugule, A.A.; Gosavi, S.W.; Kim, H. CexZr1−xO2 Solid Solutions for Catalytic Synthesis of Dimethyl Carbonate from CO2: Reaction Mechanism and the Effect of Catalyst Morphology on Catalytic Activity. Fuel 2018, 216, 245–254.

- Luis, P. Use of Monoethanolamine (MEA) for CO2 Capture in a Global Scenario: Consequences and Alternatives. Desalination 2016, 380, 93–99.

- Chen, Y.; Mu, T. Conversion of CO2 to Value-Added Products Mediated by Ionic Liquids. Green Chem. 2019, 21, 2544–2574.

- Zhao, Y.; Liu, Z. Transformation of CO2 into Valuable Chemicals. In Encyclopedia of Sustainability Science and Technology; Springer: Berlin/Heidelberg, Germany, 2018.

- Ateka, A.; Rodriguez-Vega, P.; Ereña, J.; Aguayo, A.T.; Bilbao, J. A Review on the Valorization of CO2. Focusing on the Thermodynamics and Catalyst Design Studies of the Direct Synthesis of Dimethyl Ether. Fuel Process. Technol. 2022, 233, 107310.

- Lee, J.H.; Lee, J.H.; Park, I.K.; Lee, C.H. Techno-Economic and Environmental Evaluation of CO2 Mineralization Technology Based on Bench-Scale Experiments. J. CO2 Util. 2018, 26, 522–536.

- Gao, D.; Li, W.; Wang, H.; Wang, G.; Cai, R. Heterogeneous Catalysis for CO2 Conversion into Chemicals and Fuels. Trans. Tianjin Univ. 2022, 28, 245–264.

- Fegade, U.; Jethave, G. Conversion of Carbon Dioxide into Formic Acid. In Conversion of Carbon Dioxide into Hydrocarbons Vol. 2 Technology; Springer: Cham, Switzerland, 2020; pp. 91–110.

- Chen, Y.; Wang, H.; Qin, Z.; Tian, S.; Ye, Z.; Ye, L.; Abroshan, H.; Li, G. TiXCe1−XO2 Nanocomposites: A Monolithic Catalyst for the Direct Conversion of Carbon Dioxide and Methanol to Dimethyl Carbonate. Green Chem. 2019, 21, 4642–4649.

- Kongpanna, P.; Pavarajarn, V.; Gani, R.; Assabumrungrat, S. Techno-Economic Evaluation of Different CO2-Based Processes for Dimethyl Carbonate Production. Chem. Eng. Res. Des. 2015, 93, 496–510.

- Ohno, H.; Ikhlayel, M.; Tamura, M.; Nakao, K.; Suzuki, K.; Morita, K.; Kato, Y.; Tomishige, K.; Fukushima, Y. Direct Dimethyl Carbonate Synthesis from CO2 and Methanol Catalyzed by CeO2 and Assisted by 2-Cyanopyridine: A Cradle-to-Gate Greenhouse Gas Emission Study. Green Chem. 2021, 23, 457–469.

- Honda, M.; Tamura, M.; Nakagawa, Y.; Nakao, K.; Suzuki, K.; Tomishige, K. Organic Carbonate Synthesis from CO2 and Alcohol over CeO2 with 2-Cyanopyridine: Scope and Mechanistic Studies. J. Catal. 2014, 318, 95–107.

- Tomishige, K.; Tamura, M.; Nakagawa, Y. CO2 Conversion with Alcohols and Amines into Carbonates, Ureas, and Carbamates over CeO2 Catalyst in the Presence and Absence of 2-Cyanopyridine. Chem. Rec. 2019, 19, 1354–1379.

- Gonçalves, R.V.; Vono, L.L.R.; Wojcieszak, R.; Dias, C.S.B.; Wender, H.; Teixeira-Neto, E.; Rossi, L.M. Selective Hydrogenation of CO2 into CO on a Highly Dispersed Nickel Catalyst Obtained by Magnetron Sputtering Deposition: A Step towards Liquid Fuels. Appl. Catal. B 2017, 209, 240–246.

- Vural Gürsel, I.; Noël, T.; Wang, Q.; Hessel, V. Separation/Recycling Methods for Homogeneous Transition Metal Catalysts in Continuous Flow. Green Chem. 2015, 17, 2012–2026.

- Miceli, M.; Frontera, P.; Macario, A.; Malara, A. Recovery/Reuse of Heterogeneous Supported Spent Catalysts. Catalysts 2021, 11, 591.

- Shende, V.S.; Saptal, V.B.; Bhanage, B.M. Recent Advances Utilized in the Recycling of Homogeneous Catalysis. Chem. Rec. 2019, 19, 2022–2043.

- Santoro, S.; Kozhushkov, S.I.; Ackermann, L.; Vaccaro, L. Heterogeneous Catalytic Approaches in C-H Activation Reactions. Green Chem. 2016, 18, 3471–3493.

- Sádaba, I.; López Granados, M.; Riisager, A.; Taarning, E. Deactivation of Solid Catalysts in Liquid Media: The Case of Leaching of Active Sites in Biomass Conversion Reactions. Green Chem. 2015, 17, 4133–4145.

- Chiranjeevi, T.; Pragya, R.; Gupta, S.; Gokak, D.T.; Bhargava, S. Minimization of Waste Spent Catalyst in Refineries. Procedia Environ. Sci. 2016, 35, 610–617.

- Liu, X.-H.; Ma, J.-G.; Niu, Z.; Yang, G.-M.; Cheng, P. An Efficient Nanoscale Heterogeneous Catalyst for the Capture and Conversion of Carbon Dioxide at Ambient Pressure. Angew. Chem. 2015, 127, 1002–1005.

- Martinson, K.D.; Kondrashkova, I.S.; Omarov, S.O.; Sladkovskiy, D.A.; Kiselev, A.S.; Kiseleva, T.Y.; Popkov, V.I. Magnetically Recoverable Catalyst Based on Porous Nanocrystalline HoFeO3 for Processes of N-Hexane Conversion. Adv. Powder Technol. 2020, 31, 402–408.

- Hu, J.; Wang, X.; Xiao, L.; Song, S.; Zhang, B. Removal of Vanadium from Molybdate Solution by Ion Exchange. Hydrometallurgy 2009, 95, 203–206.

- Peng, Z.; Li, Z.; Lin, X.; Tang, H.; Ye, L.; Ma, Y.; Rao, M.; Zhang, Y.; Li, G.; Jiang, T. Pyrometallurgical Recovery of Platinum Group Metals from Spent Catalysts. JOM 2017, 69, 1553–1562.

- Lee, J.; Kim, K.H.; Kwon, E.E. Biochar as a Catalyst. Renew. Sustain. Energy Rev. 2017, 77, 70–79.

- Tong, S.; Zhang, S.; Yin, H.; Wang, J.; Chen, M. Study on Co-Hydrothermal Treatment Combined with Pyrolysis of Rice Straw/Sewage Sludge: Biochar Properties and Heavy Metals Behavior. J. Anal. Appl. Pyrolysis 2021, 155, 105074.

- Cheng, F.; Li, X. Preparation and Application of Biochar-Based Catalysts for Biofuel Production. Catalysts 2018, 8, 346.

- Ormsby, R.; Kastner, J.R.; Miller, J. Hemicellulose Hydrolysis Using Solid Acid Catalysts Generated from Biochar. Catal. Today 2012, 190, 89–97.

- Xiong, X.; Yu, I.K.M.; Chen, S.S.; Tsang, D.C.W.; Cao, L.; Song, H.; Kwon, E.E.; Ok, Y.S.; Zhang, S.; Poon, C.S. Sulfonated Biochar as Acid Catalyst for Sugar Hydrolysis and Dehydration. Catal. Today 2018, 314, 52–61.

More

Information

Subjects:

Engineering, Chemical

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

483

Revisions:

2 times

(View History)

Update Date:

05 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No