Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sangseok Yu | -- | 1462 | 2023-07-04 10:13:58 | | | |

| 2 | Sirius Huang | Meta information modification | 1462 | 2023-07-05 02:33:15 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Nguyen, H.; Lee, S.; Yu, S. Proton Exchange Membrane Fuel Cell System. Encyclopedia. Available online: https://encyclopedia.pub/entry/46379 (accessed on 08 February 2026).

Nguyen H, Lee S, Yu S. Proton Exchange Membrane Fuel Cell System. Encyclopedia. Available at: https://encyclopedia.pub/entry/46379. Accessed February 08, 2026.

Nguyen, Huu-Linh, Sang-Min Lee, Sangseok Yu. "Proton Exchange Membrane Fuel Cell System" Encyclopedia, https://encyclopedia.pub/entry/46379 (accessed February 08, 2026).

Nguyen, H., Lee, S., & Yu, S. (2023, July 04). Proton Exchange Membrane Fuel Cell System. In Encyclopedia. https://encyclopedia.pub/entry/46379

Nguyen, Huu-Linh, et al. "Proton Exchange Membrane Fuel Cell System." Encyclopedia. Web. 04 July, 2023.

Copy Citation

Proton exchange membrane fuel cells (PEMFCs) are an alternative power source for automobiles that are capable of being cleaner and emission-free. As of yet, long-term durability is a core issue to be resolved for the mass production of hydrogen fuel cell vehicles that requires varied research in the range from sustainable materials to the optimal operating strategy. The capacity to accurately estimate performance degradation is critical for developing reliable and durable PEMFCs.

PEMFC

performance degradation

lifetime prediction

hydrogen fuel cell vehicle

1. Introduction

The rising demand for worldwide energy and the negative impact of using fossil fuels on the environment has prompted the development of renewable and environmentally friendly energy solutions. One potential solution is the hydrogen economy, which generates, stores, and converts hydrogen from renewable sources into electricity [1]. Fuel cell vehicles (FCVs) are crucial for achieving low-carbon transportation in the hydrogen economy, and utilizing renewable sources to produce hydrogen is expected to significantly reduce greenhouse gas emissions [2]. Proton exchange membrane fuel cells (PEMFCs), with their low emissions, high efficiency, and low operating temperature, have recently gained popularity as a potential power source for the automotive sector. Although FCVs have been running the road recently, the durability issue associated with performance degrading, which refers to a permanent drop in voltage or power during the long-term operation of PEMFCs, is still the main challenge. It must be solved to achieve worldwide commercialization [3].

PEMFCs integrated into vehicles, in contrast to stationary power plant sources, must meet more strict durability limitations, as fuel cells’ durability may worsen under extreme operating conditions such as sub-zero temperatures, dynamic load variations, and vibrations and shocks. Even though fuel cell deterioration is inevitable over prolonged use, the degradation gradient must be enhanced to make hydrogen fuel cell cars economically feasible [4].

As a system analysis tool, the performance degradation model is essential for health assessment and prognostics. Several tools have been introduced which may be grouped into three main groups: physics-based models, data-driven models, and hybrid models. Physics-based models primarily incorporate fundamental physical laws to explain the degradation process and gain insights into the main causes of failure. On the other hand, data-driven models employ historically collected data to create a model that can describe or predict the degradation process of the system under consideration. The hybrid model integrates both the physical-based and data-driven approaches, leveraging the strengths of both methodologies.

Until now, there have been numerous reviews conducted on the advancements of modeling PEMFC performance [5], degradation indexes [6], physics-based and data-driven models for real-time control [7], data-driven models for fault diagnosis [8], and degradation modeling and lifetime prediction [9][10]. Additionally, some reviews have explored the degradation of specific components such as gas diffusion layers [11], proton exchange membranes [12][13], catalyst layers [14], and membrane electrode assembly [15]. However, there have been relatively few reviews that have specifically addressed degradation modeling in automotive applications.

2. PEMFC System in Hydrogen Fuel Cell Vehicle

A hydrogen fuel cell vehicle is an electric vehicle that usually produces electricity from PEMFCs. In a pure fuel cell powertrain, the fuel cell is directly connected to an electric motor, which drives the vehicle’s wheels. The fuel cell system is paired with a battery or supercapacitor in a hybrid fuel cell powertrain. At high demand, such as acceleration or hill climbing, the energy storage system supplies extra power to the electric motor. While not in use, such as when cruising or braking, the fuel cell system recharges the energy storage system. Both pure and hybrid fuel cell powertrains offer benefits and drawbacks. Pure fuel cell powertrains are efficient and emit no pollutants, but they are costly and have a limited operating range. Hybrid fuel cell powertrains deliver greater power and range but are more complicated and may need more maintenance.

The PEMFC system, the heart of FCV, comprises a fuel cell stack and auxiliary systems, including fuel supply, air supply, and thermal management systems. The fuel supply system feeds the hydrogen to the anode. The air supply system provides compressed air to the cathode. A cooling system removes the produced heat and releases it into the environment to maintain the desired temperature.

A fuel cell stack consists of many individual fuel cells connected in series. The heart of each fuel cell is membrane electrode assembly (MEA). In the MEA, a polymer electrolyte membrane (PEM) separates the anode and cathode sides of the fuel cell. A catalyst and gas diffusion layers are attached on each membrane side. The catalyst layer comprises platinum nanoparticles, which aid the electrochemical processes which take place in the fuel cell. The GDL aids in uniform fuel and air distribution throughout the catalyst layer. Gaskets are utilized to establish a seal around the MEA and prevent gas leakage when assembling individual fuel cells into a fuel cell stack. Bipolar plates are also used to sandwich the individual fuel cells, enabling gaseous fuel and air to pass through the stack and transfer electrons between adjacent cells.

3. Performance Degradation of the PEMFC System

As mentioned earlier, fuel cell degradation during long-term operation is unavoidable. Researchers have identified several factors which contribute to fuel cell degradation, including platinum-particle dissolution and sintering, carbon-support corrosion, membrane thinning, and bipolar plate corrosion [16]. Understanding the causes of PEMFC system failures allows end users to evaluate the system performance and extend its useful life. The degradation phenomenon may be divided into three categories: mechanical degradation, thermal degradation, and chemical/electrochemical degradation.

-

Mechanical degradation: Fuel cells often fail, and this is attributable to material defects and poor structural design and manufacture. Material flaws may generate non-uniform mechanical stresses, fractures, and premature failure. Material flaws, improper structural design, and manufacturing errors produce non-uniform mechanical stresses and fractures. Operating conditions may affect fuel cell components’ physical qualities. Membranes, catalyst layers, etc., shrink or swell depending on the temperature. The non-uniform pressure distribution on components resulting from the cathode-anode pressure difference causes mechanical damage. High and non-uniform mechanical stresses may perforate or shred interfaces between components during cell or stack assembly [9][16].

-

Thermal degradation: The fuel cell operating outside the temperature range induces structural changes [17]. PEMFCs work well at 60–80 °C. The glass transition of PFSA polymers causes the severe destruction of conventional Nafion-type membranes around 80–120 °C [18]. One requirement for PEMFCs in automotive applications is the capacity to start at subfreezing temperatures. Notably, in automotive applications, the Department of Energy requires PEMFC stacks and systems to start up and operate at −20 °C to 50% rated power in 30 s using less than 5 MJ of energy [19]. However, the formation and melting of ice during long-term operation at subfreezing temperatures could delaminate the MEA and gas diffusion layers [16].

-

Chemical/electrochemical degradation: This is mainly caused by the material’s natural aging, including Pt dissolution and carbon support corrosion/oxidation in the catalyst layers (CLs) and gas diffusion layers (GDL), radial attack in the membrane, and bipolar plate (BBP) corrosion [9]. In addition, contaminants in the fuel and oxidation sources, such as CO, H2S, NH3, etc., may induce catalyst toxicity and affect the catalytic activity, diffusion, and hydrophobic properties [16].

4. End-of-Life Definition/Criterion

The end-of-life (EoL) criteria for fuel cells are not consistently used in the literature. There are no EoL criteria that are widely followed, particularly for automobile applications. The most used definition for EoL was created by the US Department of Energy (DOE), which targets 10% voltage degradation [9][20]. This criterion works well for static conditions of current but not load changes [20]. Fuel cells in automobiles provide drive cycle power. In such cases, using the power to define the EoL appears to be better. EoL occurs when the fuel cell cannot provide the power that is required [21]. An EoL threshold could be set. However, it would rely strongly on the system designer [20]. The Fuel Cell Testing and Standards Network established another EoL criterion (FCTESTNEST), a pre-defined minimum value of the fuel cell voltage. If the voltage drops below the threshold value of 0.3 V, the durability test stops [16].

5. Classification of Degradation Modeling Methods

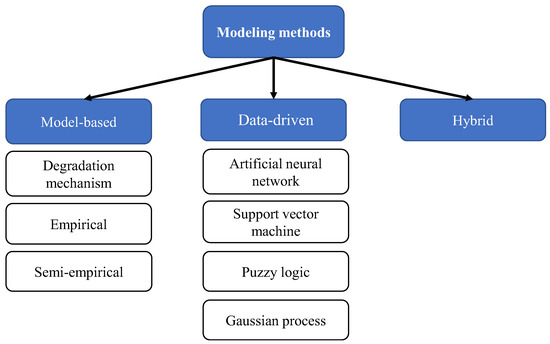

A performance degradation model forecasts the PEMFC performance deterioration during operation. Modeling the performance degradation of PEMFCs is necessary to predict their state of health (SOH) and remaining useful life (RUL). Degradation modeling methods can be classified into two main approaches: model-based and data-driven methods, as seen in Figure 1. In addition, the hybrid approach combines the model-based and data-driven methods based on their advanced features.

Figure 1. Degradation modeling methods.

-

The model-based method predicts the aging process using mathematical equations. This method does not need a large amount of data. However, it may be computationally expensive, and model construction may be tricky.

-

The data-driven method uses collected data to understand the system’s behavior. It detects non-linearities without a degradation model. However, it demands a large amount of data to perform prognostics.

-

The hybrid method enhances model learning and improves model uncertainties. However, it may be challenging to design and computationally costly.

References

- Jiao, K.; Xuan, J.; Du, Q.; Bao, Z.; Xie, B.; Wang, B.; Zhao, Y.; Fan, L.; Wang, H.; Hou, Z.; et al. Designing the next Generation of Proton-Exchange Membrane Fuel Cells. Nature 2021, 595, 361–369.

- Itaoka, K.; Saito, A.; Sasaki, K. Public Perception on Hydrogen Infrastructure in Japan: Influence of Rollout of Commercial Fuel Cell Vehicles. Int. J. Hydrogen Energy 2017, 42, 7290–7296.

- Borup, R.L.; Kusoglu, A.; Neyerlin, K.C.; Mukundan, R.; Ahluwalia, R.K.; Cullen, D.A.; More, K.L.; Weber, A.Z.; Myers, D.J. Recent Developments in Catalyst-Related PEM Fuel Cell Durability. Curr. Opin. Electrochem. 2020, 21, 192–200.

- Nguyen, H.L.; Han, J.; Vu, H.N.; Yu, S. Investigation of Multiple Degradation Mechanisms of a Proton Exchange Membrane Fuel Cell under Dynamic Operation. Energies 2022, 15, 9574.

- Wu, H.W. A Review of Recent Development: Transport and Performance Modeling of PEM Fuel Cells. Appl. Energy 2016, 165, 81–106.

- Liu, H.; Chen, J.; Hissel, D.; Lu, J.; Hou, M.; Shao, Z. Prognostics Methods and Degradation Indexes of Proton Exchange Membrane Fuel Cells: A Review. Renew. Sustain. Energy Rev. 2020, 123, 109721.

- Zhao, J.; Li, X.; Shum, C.; McPhee, J. A Review of Physics-Based and Data-Driven Models for Real-Time Control of Polymer Electrolyte Membrane Fuel Cells. Energy AI 2021, 6, 100114.

- Zheng, Z.; Petrone, R.; Péra, M.C.; Hissel, D.; Becherif, M.; Pianese, C.; Yousfi Steiner, N.; Sorrentino, M. A Review on Non-Model Based Diagnosis Methodologies for PEM Fuel Cell Stacks and Systems. Int. J. Hydrogen Energy 2013, 38, 8914–8926.

- Hua, Z.; Zheng, Z.; Pahon, E.; Péra, M.C.; Gao, F. A Review on Lifetime Prediction of Proton Exchange Membrane Fuel Cells System. J. Power Sources 2022, 529, 231256.

- Vichard, L.; Steiner, N.Y.; Zerhouni, N.; Hissel, D. Hybrid Fuel Cell System Degradation Modeling Methods: A Comprehensive Review. J. Power Sources 2021, 506, 230071.

- Pan, Y.; Wang, H.; Brandon, N.P. Gas Diffusion Layer Degradation in Proton Exchange Membrane Fuel Cells: Mechanisms, Characterization Techniques and Modelling Approaches. J. Power Sources 2021, 513, 230560.

- Pan, M.; Pan, C.; Li, C.; Zhao, J. A Review of Membranes in Proton Exchange Membrane Fuel Cells: Transport Phenomena, Performance and Durability. Renew. Sustain. Energy Rev. 2021, 141, 110771.

- Okonkwo, P.C.; Ben Belgacem, I.; Emori, W.; Uzoma, P.C. Nafion Degradation Mechanisms in Proton Exchange Membrane Fuel Cell (PEMFC) System: A Review. Int. J. Hydrogen Energy 2021, 46, 27956–27973.

- Tzelepis, S.; Kavadias, K.A.; Marnellos, G.E.; Xydis, G. A Review Study on Proton Exchange Membrane Fuel Cell Electrochemical Performance Focusing on Anode and Cathode Catalyst Layer Modelling at Macroscopic Level. Renew. Sustain. Energy Rev. 2021, 151, 111543.

- Dafalla, A.M.; Wei, L.; Habte, B.T.; Guo, J.; Jiang, F. Membrane Electrode Assembly Degradation Modeling of Proton Exchange Membrane Fuel Cells: A Review. Energies 2022, 15, 9247.

- Nguyen, H.L.; Han, J.; Nguyen, X.L.; Yu, S.; Goo, Y.M.; Le, D.D. Review of the Durability of Polymer Electrolyte Membrane Fuel Cell in Long-Term Operation: Main Influencing Parameters and Testing Protocols. Energies 2021, 14, 4048.

- Hissel, D.; Pera, M.C. Diagnostic & Health Management of Fuel Cell Systems: Issues and Solutions. Annu. Rev. Control 2016, 42, 201–211.

- Yu, S.; Jung, D. Thermal Management Strategy for a Proton Exchange Membrane Fuel Cell System with a Large Active Cell Area. Renew. Energy 2008, 33, 2540–2548.

- Büchi, F.N.; Inaba, M.; Schmidt, T.J. Polymer Electrolyte Fuel Cell Durability; Springer: New York, NY, USA, 2009; ISBN 9780128114599.

- Jouin, M.; Bressel, M.; Morando, S.; Gouriveau, R.; Hissel, D.; Péra, M.C.; Zerhouni, N.; Jemei, S.; Hilairet, M.; Ould Bouamama, B. Estimating the End-of-Life of PEM Fuel Cells: Guidelines and Metrics. Appl. Energy 2016, 177, 87–97.

- Mayur, M.; Gerard, M.; Schott, P.; Bessler, W.G. Lifetime Prediction of a Polymer Electrolyte Membrane Fuel Cell under Automotive Load Cycling Using a Physically-Based Catalyst Degradation Model. Energies 2018, 11, 2054.

More

Information

Subjects:

Engineering, Mechanical

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

719

Revisions:

2 times

(View History)

Update Date:

05 Jul 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No