Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Nataliya Arutyunyan | -- | 5084 | 2023-06-23 22:33:29 | | | |

| 2 | Dean Liu | Meta information modification | 5084 | 2023-06-25 04:39:54 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Zaitsev, A.; Arutyunyan, N.; Koldaev, A. Effect of Precipitates on Hot Ductility of Steels. Encyclopedia. Available online: https://encyclopedia.pub/entry/45995 (accessed on 07 February 2026).

Zaitsev A, Arutyunyan N, Koldaev A. Effect of Precipitates on Hot Ductility of Steels. Encyclopedia. Available at: https://encyclopedia.pub/entry/45995. Accessed February 07, 2026.

Zaitsev, Alexander, Nataliya Arutyunyan, Anton Koldaev. "Effect of Precipitates on Hot Ductility of Steels" Encyclopedia, https://encyclopedia.pub/entry/45995 (accessed February 07, 2026).

Zaitsev, A., Arutyunyan, N., & Koldaev, A. (2023, June 23). Effect of Precipitates on Hot Ductility of Steels. In Encyclopedia. https://encyclopedia.pub/entry/45995

Zaitsev, Alexander, et al. "Effect of Precipitates on Hot Ductility of Steels." Encyclopedia. Web. 23 June, 2023.

Copy Citation

Hot ductility of high-strength microalloyed steel is of great importance since it affects cracking during metal production. This characteristic is controlled by the presence of phase precipitates of microalloying elements depending on the chemical composition and parameters of temperature-deformation treatment of steel.

low-carbon microalloyed steels

hot ductility

phase precipitates

1. Main Mechanisms of Ductility Decrease at a High Temperature

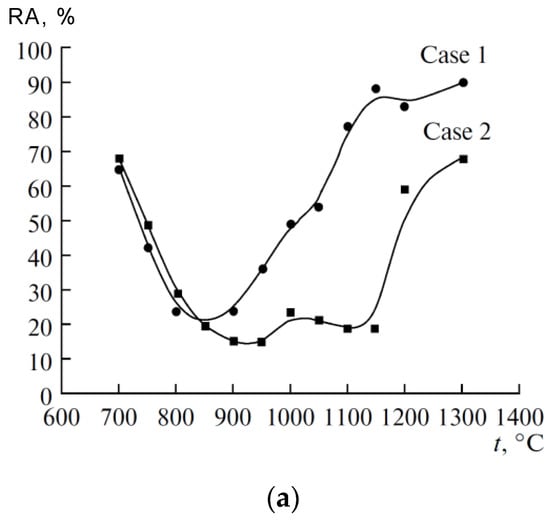

One of the most common methods for studying the ductility of steels at high temperatures is the measurement of the reduction in area (RA, %) of samples by tensile tests in the required temperature range, followed by the performance of the so-called hot ductility curves. The typical temperature dependence of ductility (RA) has a trough that starts at about 700 °C and can increase to the solidus temperature. Figure 1 shows the temperature dependences of RA with a plasticity trough and the corresponding microphotography of fractures.

Figure 1. (a) Temperature dependences of reduction in area; (b) corresponding microphotography of fractures for steel containing wt.%: 0.1 C, <1.2 (Mn + Si), 0.06 Cu, 0.04 Al, <0.03 (Nb + V + Ti), 0.005 S, 0.006 N. Reprinted with permission from ref. [1]. Copyright 2023 Stal’.

The reasons for this phenomenon are due to a number of mechanisms, the implementation of which depends on the temperature interval. The authors of [2][3][4] distinguished three regions of ductility troughs in steels. Region 1 is at high temperatures, typically 20–50 °C below the mean solidus temperature [3]. Fracture surfaces are characterized by interdendritic fractures and the presence of precipitates, such as MnS. The low ductility in this region is associated with the formation of a liquid layer at the interdendritic boundaries and along the boundaries of austenite grains. In region 1, ductility does not depend on the intensity of deformation, but mainly depends on the chemical composition, in particular, on microsegregations of sulfur, manganese, and phosphorus [3].

Region 2 is between 900 and 1200 °C, depending on the composition and test conditions. This region is associated with intergranular fractures. The fracture edges are either covered with small dimples or microvoids, or they are smooth. This suggests two different mechanisms. In the first case, in areas close to the grain boundary, the deformation initiates the formation of voids at the grain boundaries, inclusions, or precipitates, which leads to intergranular fractures due to the merging of microvoids. In the second case, slip occurs along the grain boundaries in a single-phase austenite region, followed by wedge-shaped cracking.

Most often, region 2 is characterized by the formation of small intergranular precipitates of sulfides, oxides, and carbonitrides along the boundaries of austenite grains. This leads to the appearance of so-called “soft zones” — precipitate-free zones (PFZs) along the boundaries of austenite grains on both sides of the boundaries (width 500 nm), or to the formation of microcavities around precipitates and their subsequent coalescence [3][5]. Precipitate-free zones are places of strain concentration, which leads to failure, even for small strains in the continuous casting of steel [2].

In [3], this region was subdivided into two, depending on the stability of various types of precipitates and, accordingly, the mechanisms of ductility reduction. In region IIa, (Mn, Fe)S and MnS precipitates play the main role; in region IIb — Nb(CN), V(CN), Ti(CN), and AlN.

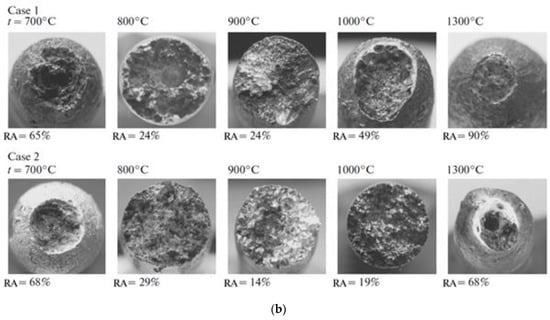

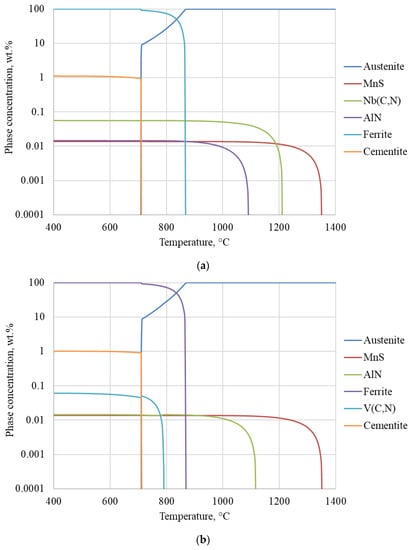

Such a division can be clearly explained from a thermodynamic analysis of the regions of existence of phases in the steels under consideration [6]. Figure 2 shows the results of the thermodynamic calculation for the steel of a model composition microalloyed with niobium. It can be seen that the precipitation of MnS begins at higher temperatures than Nb(CN).

Figure 2. Temperature dependence of the phase composition of steel containing wt.%: 0.08 C, 0.60 Mn, 0.10 Si, 0.045 Al, 0.005 S, 0.005 P, 0.005 N, 0.035 Nb.

Low ductility in region IIa is detected only at sufficiently high strain rates, while in region IIb, ductility worsens with a decreasing strain rate. In region IIa, at lower strain rates or at long holding times before testing, the ductility is quite good [3][7].

Ductility decreasing in region IIa is highly dependent on the composition, in particular, on the Mn/S ratio. In [8], it was suggested that the ductility loss in this case is due to the segregation of S at the boundaries of austenite grains.

Ductility loss in region IIb is initiated by slip along austenite grain boundaries [5][9] and the presence of precipitates of excess phases, such as Nb(CN), V(CN), or AlN. These precipitates play two main roles: they can delay the onset of recrystallization and reduce the stress required for failure.

The authors of reviews [3][4][5] noted that ductility failure in the temperature range of 1000–1150 °C may be associated with a delay in dynamic recrystallization, especially in microalloyed steels. It is well known that microalloying elements, especially niobium, can delay recrystallization [10][11]. If recrystallization can occur before fracture, any developing cracks along the grain boundaries become isolated and no further propagation is possible. Due to the absence of dynamic recrystallization, the austenite grain size increases, thereby reducing the total length of the boundaries, increasing the concentration of inclusions and precipitates along the boundaries of austenite grains. In turn, this leads to intergranular fracture.

The decrease in the fracture stress in the presence of precipitates of microalloying elements can occur through a number of possible mechanisms. First, precipitate-free zones are often observed near austenite grain boundaries, which can lead to strain concentration at the grain boundary. Second, particles (or groups of particles) at grain boundaries can act as crack initiation sites. In addition, the formation of inclusions and precipitates throughout the matrix can lead to an increase in strength and a general decrease in ductility [5][12].

As mentioned above, intergranular fracture can occur not only due to the merging of microvoids, but also through sliding along grain boundaries, which is due to plastic deformation of austenite grain boundaries [5]. The destruction of the grain boundary occurs when the stresses in the triple junctions of the grains exceed the maximum allowable stress. This failure mechanism is usually associated with creep ductility. As a rule, this takes place at strain rates below 10−4 s−1. However, cracks characteristic of grain boundary slip failure are often found at the strain rate commonly used in hot tensile testing (10−3 s−1).

Grain boundary slip is enhanced by the presence of various precipitates at the austenite grain boundaries [5]: sulfides, oxides, nitrides and/or carbides act as stress concentrators and promote crack formation. If the stress concentration at such grain boundary particles is produced by grain boundary sliding alone, the dislocation pile-up distance corresponds to the interparticle spacing, so that large applied stresses are required for particle fracture or particle–matrix decohesion. However, for the case of intergranular slip band impingement against a grain boundary particle, much smaller applied stresses are required for particle fracture, since the slip distances are much greater [5].

Region 3 is in the low temperature range of austenite existence, including the austenite to ferrite transformation, and occurs over the approximate temperature range 600–900 °C, depending on the chemical composition of the steel. It is believed that this region of low ductility is associated with the austenite to ferrite transformation. On cooling below the transformation temperature, the formation of ferrite begins at the boundaries of the austenite grains, leading to the formation of ferrite films around the austenite grains with a thickness of 5–20 µm [5]. At temperatures within the transformation range, ferrite is softer than austenite; therefore, there is a concentration of strain within the ferrite along the grain boundaries. The nucleation of voids on phase precipitates (often MnS) are located at the boundaries of austenite grains, and the growth of these voids continues inside the ferrite film.

Strain-induced ferrite can form at temperatures above the undeformed Ar3 temperature (the transformation start temperature at a constant cooling rate) and often reaches Ae3, since the deformation process accelerates the transformation kinetics [13]. Below the Ae3 temperature, the ferrite thickness does not change significantly with temperature [13] until the Ar3 value is reached. At temperatures just below Ar3, there is a thickening of the ferritic films and/or a decrease in the relative differences in strength between the austenite and ferrite phases. Further lowering the test temperature rapidly thickens the ferrite film and the ductility recovers completely when ~50% ferrite is present prior to testing.

Review [5] summarized the following explanations for the accelerating effect of deformation on the nucleation rate of ferrite:

- (a)

-

Deformation causes local grain boundary migration leading to bulges at the austenite boundaries, which act as nuclei;

- (b)

-

Subgrains are formed near the boundaries, which locally increase the stored energy;

- (c)

-

Increased dislocation density in the deformed austenite increases the strain energy, promoting ferrite nucleation.

Thus, the failure of hot plasticity can be caused by various mechanisms depending on the temperature range. As the temperature decreases, these mechanisms can be arranged in the following order:

- –

-

Formation of a liquid layer at the interdendritic boundaries and along the boundaries of austenite grains;

- –

-

Formation of (Mn,Fe)S along the boundaries of austenite grains;

- –

-

Formation of precipitates of excess phases (Nb(CN), AlN, V(CN), etc.) along the boundaries of austenite grains;

- –

-

Inhibition of dynamic recrystallization of austenite;

- –

-

Sliding along the grain boundaries;

- –

-

Formation of zones free from precipitation of dispersed particles adjacent to the boundaries of austenite grains;

- –

-

Formation of the ferrite film along the boundaries of austenite grains.

The implementation of all these mechanisms depends both on the chemical composition of the steel and on the deformation conditions, parameters that also control the formation and growth of phase precipitates.

2. Effect of Sulfides

A detailed review of the effect of sulfur on hot ductility is given in [5]. According to the general opinion of researchers, sulfur worsens the hot ductility of steels. In this case, the degree of effect depends both on the form and on the place where sulfur is present: grain boundaries or matrix. This causes the implementation of various embrittlement mechanisms. First of all, the weakening of the strength of the austenite grain boundaries can be caused by the segregation of sulfur at the grain boundaries [8][14]. For high-strength microalloyed steels, the hot ductility is dominated by sulfides precipitated along the austenite grain boundaries. Any sulfides present in the matrix have little effect on hot ductility. In this case, the Mn/S ratio plays an important role [14][15][16][17][18].

At a low manganese content, a FeS phase with a low melting temperature forms as a liquid interlayer along the grain boundaries, causing intergranular fracture [17]. The implementation of this embrittlement mechanism is determined by several factors. The mobility of sulfur is about 1000 times greater than the mobility of manganese at 1090 °C. Therefore, upon rapid cooling to a temperature below the solubility limit of sulfur in pure iron, metastable FeS will form at the grain boundaries. At lower cooling rates, manganese has time to diffuse to the grain boundaries and the FeS precipitates will be enriched in Mn. At a sufficiently slow cooling rate, stable MnS will be nucleated. A continuous flat array of small solid particles or small liquid droplets along the grain boundary can result in low ductility and serve as an easy path for crack propagation.

As the Mn/S ratio increases, the hot ductility improves, but the ductility trough remains and the embrittlement mechanism changes. Very small (Fe,Mn)S and MnS precipitates are formed at the boundaries of austenite grains, which leads to the appearance of microcavities around the precipitates (PFZs) and their subsequent coalescence [5][7][19]. Finely dispersed segregations of sulfides inside the grains and the presence of PFZs along the grain boundaries enhance the localization of deformation near the boundaries during deformation. According to [5], the favorable effect of increasing the Mn/S ratio above 2 or 3 by lowering the sulfur level is attributed to a decrease in the volume fraction of MnS inclusions. In [20], to reduce precipitation at grain boundaries, it is recommended to use Ca and/or Ce additives, which cause precipitation of sulfides in the melt.

As the Mn/S ratio is further increased up to 60, the hot ductility continues to improve [17][21]. According to [17], there is an additional positive factor. With an increase in manganese content, the driving force of MnS precipitation increases, contributing to its precipitation in the matrix, and not at a more harmful place — austenite boundaries.

3. Effect of Niobium Carbonitride

According to many studies, steels containing niobium are highly susceptible to transverse cracking during continuous casting [2][3][19][22][23][24][25][26][27]. The works [22][23] indicate three main reasons:

-

Niobium has a strong effect on reducing the Ar3 temperature that expands the trough in the low temperature interval.

-

The precipitation of Nb(CN) in a finely dispersed form during the deformation of austenite in the temperature range of the straightening operation facilitates the connection of cracks, which leads to intergranular fracture. Precipitation also widens the trough in the higher temperature interval.

-

Larger NbCN precipitates at the austenite grain boundaries cause the formation of precipitate free zones. As a result, poor ductility persists at temperatures above Ae3; therefore, the trough expands in the high temperature interval.

Reducing the carbon content in Nb-containing steels leads to a decrease in the amount of harmful precipitates and, thereby, improves hot ductility. However, above 0.1% C, niobium has only a negligible detrimental effect on hot ductility [26]. Not only the amount of precipitates, but also their composition depends on the nitrogen content. The greater the N/C ratio in the steel, the more nitrogen there is in the carbonitride [10]. In [26], it was shown that, at a low nitrogen level (0.002% N), niobium carbide was formed, resulting in good ductility; at higher levels (0.006% N), niobium carbonitride was formed and the ductility deteriorated markedly. It has been suggested that this was due to the easier precipitation of Nb(CN) compared to NbC in the higher temperature region where the straightening operation occurs.

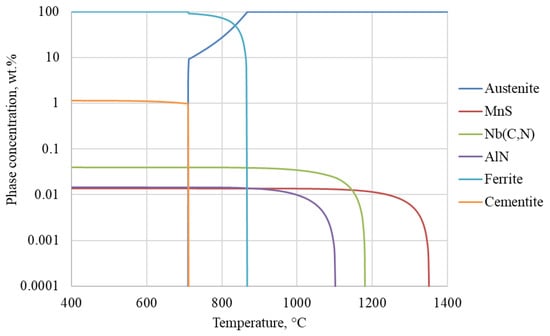

Indeed, as studies show, at higher temperatures, a more nitrogen-saturated carbonitride is formed [10]. Figure 3 shows the results of the thermodynamic calculation of the temperature of formation of niobium carbonitride precipitates at various Nb and N contents conducted using a computer program [6] for steel of basic composition, wt.%: 0.08 C–0.60 Mn–0.10 Si–0.045 Al–0.005 S–0.005 P. It can be seen that, with an increase in the nitrogen content at each given concentration of niobium, the temperature of the beginning of Nb(CN) precipitation increases.

Figure 3. Temperature of the beginning of Nb(CN) precipitation depending on the concentration of nitrogen and niobium during cooling. The base composition of steel, wt.%: 0.08 C–0.60 Mn–0.10 Si–0.045 Al–0.005 S–0.005 P.

The presence of strong nitride-forming elements, such as titanium and aluminum, in the composition of steel affects both the composition of niobium carbonitride and the temperature of its formation. In addition, it was found in [28] that the hot ductility of Nb-microalloyed steel is improved by adding 0.12 wt.% Cr. Chromium atoms prevent the diffusion of carbon atoms, which reduces the thickness of the grain boundary ferrite. The number of fractions of high-angle grain boundaries increases with increasing chromium content, which prevents the propagation of cracks and improves the ductility of the steel.

4. Effect of Titanium Nitride and Carbonitride

Studies of the titanium effect on the hot ductility of steels were conducted in many works, including [3][29][30][31][32][33]. It was found that this influence can be both positive and negative.

The main factor that improves hot ductility is the precipitation of titanium nitride at a high temperature. These particles, on the one hand, are larger; on the other hand, they serve as a substrate for the subsequent precipitation of niobium carbonitride. As a result, the size of the precipitates present in the microstructure is larger and their quantity is reduced. This can be clearly explained from a thermodynamic analysis of the regions of phase existence in the steels under consideration.

An Investigation of two Nb-microalloyed steels showed that the addition of 0.015 wt.% Ti significantly improves hot ductility from a minimum RA value of 19.4% at 750 °C to 41.4% at 800 °C [31]. The failure of hot plasticity is mainly associated with the formation of a ferrite films at the boundaries of austenite grains. In steel without titanium, Nb(C,N) precipitates form at the grain boundaries, which greatly increase the sensitivity to cracking and leads to a failure of hot ductility. When titanium is added, only (Ti, Nb)(C, N) particles are observed inside the grain. In this case, (Ti, Nb)(C, N) nucleation occurs on the surface of the existing TiN precipitates.

Similar results were obtained in [32] when studying the distribution of precipitates at a cooling rate of 25 K/min: large TiN particles serve as a substrate for the precipitation of niobium at high temperatures. As a result, there remains a smaller amount of niobium available for precipitation during deformation in the temperature range of 800–1000 °C. In addition, in steels containing aluminum, the formation of TiN prevents the precipitation of more harmful AIN and contributes to the improvement of ductility, which was observed in [32] at a cooling rate of 60 K/min.

In contrast to the results [31][32] in [30], even at a cooling rate of 25 K/min, titanium had a negative effect on the hot ductility of Nb-microalloyed steels. The levels of titanium and nitrogen varied within 0.014–0.045 and 0.004–0.011 wt.%, respectively, which made it possible to study a wide range of Ti/N ratios. An improvement in hot ductility was observed with coarsening precipitates due to a decrease in the cooling rate and an increase in the Ti/N ratio above the stoichiometric one, which increases the amount of Ti in solution and promotes particle growth.

Thus, when large TiN precipitates may form, such as in the case of low cooling rates or high Ti/N values, hot ductility can be slightly improved by titanium addition. However, under conditions where a high volume fraction of TiN fine particles is formed, such as the stoichiometric Ti/N ratio in low-nitrogen steels, hot ductility may deteriorate when titanium is added [3]. In addition, as noted in [3], when studying the effect of titanium on hot ductility, it is important to take into account the size of the austenite grain, since, when adding titanium, an increase in hot ductility can occur due to a decrease in grain size.

In addition to the previous studies, in [29][34], it was shown that the effect of titanium on Nb-microalloyed steels depends on the cooling conditions. The ductility of Ti-containing steels, upon melting and cooling, to the test temperature at a constant cooling rate, as a rule, decreased due to the appearance of smaller and more numerous Ti-containing precipitates. At the same time, under production conditions, a positive effect of titanium is observed. The difference between the cooling mode under production conditions is as follows. In the commercial casting operation, the primary cooling underneath the mold is very rapid. The temperature at the foot rolls reaches a minimum, rises again, and then falls gradually during secondary cooling until the unbending temperature is reached. Additional temperature losses are also incurred when the strand passes over the guide rolls. A cooling mode similar to that of industrial continuous casting was used in [29]. In this case, cooling from the melt stability temperature starts rapidly, reaches a minimum, and then reheating occurs, after which the temperature drops more slowly to the test temperature. The use of such a mode led to an improvement in the hot ductility of steels below 900 °C. At the same time, the Ti/N ratio was of great importance. With the addition of 0.01 wt.% Ti, this improvement, although noticeable, resulted in only a slight improvement in ductility compared to steel without Ti, and then only in the temperature range of 800–900 °C. In steel with a high niobium content (>0.03 wt.% Nb), increasing the Ti content to 0.036 wt.% so that the Ti/N ratio is high (7.5/1) resulted in much better ductility in the temperature range of 800–900 °C, while the RA value was 60%. The ductility was now significantly better than the ductility of steel with the same composition, but without titanium.

5. Effect of Aluminum Nitride

According to [22], for C-Mn-Al steels with a low N content, by having a C content in the peritectic range (0.10–0.17 wt.% C) with an Al content <0.04 wt.% (solubility product of [Al][N] < 20 × 10−5) as a rule, there is no significant problem with transverse cracking. An increase in the solubility product of [Al][N] leads to both the deepening and widening of the through. A significant negative effect of aluminum is observed when [Al][N] exceeds 30 × 10−5.

The hot ductility of Al-containing steels in the as-cast state can often be worse than when examining samples after solution treatment (1350 °C). This appears to be because casting results in the segregation of Al towards the boundaries, and high supersaturation promotes AlN precipitation there, a situation that is not present when samples’ tensile specimens are only solution-treated. In [35], AlN precipitation was observed in a slab made of steel with composition, wt.%: 0.1–0.2 C, 0.3–0.4 Si, 1.0–2.0 Mn, <0.02 P, <0.015 S, <0.04 Al. AlN particles precipitate at the grain boundary and inside the grains when the steel is cooled. As the temperature increased, the AlN precipitates’ size increased and the number of AlN precipitates decreased. The most intense formation of AlN precipitates with a size of about 20 nm occurred at 850 °C. At the same time, hot plasticity was the lowest: RA was 15%.

The work [5] considered the implementation of two embrittlement mechanisms in the case of the influence of aluminum. At the high-temperature end of the through, the samples with cracks showed intergranular fractures with flat faces and no signs of coalescence of microvoids or ferrite formation. Therefore, it was assumed that embrittlement occurred due to the slip of grain boundaries in austenite, which was accompanied by the initiation of cracks at triple points. In the case of steels with high [Al][N] product, it was likely that AIN precipitates formed at the austenite grain boundaries, pinning them and allowing grain boundary slip cracks to join. Lowering the temperature below Ae3 leads to strain-induced ferrite, resulting in embrittlement due to the coalescence of microvoids. Thus, in these steels, the ductility trough is the result of both slip along the grain boundaries and the coalescence of microvoids in the ferrite. It is interesting to note that the transition from one type of fracture mechanism to another, as a rule, Is not accompanied by any discontinuity in the hot plasticity curve, which indicates that both mechanisms involve the same stress intensification at the boundaries.

In Nb-microalloyed steels, the addition of aluminum leads to a marked deterioration in hot ductility [12][27]. It was suggested that the lower ductility obtained with the aluminum addition is not only due to AlN precipitation [12]. The presence of aluminum slows down the precipitation of Nb(CN), which leads to finer Nb(CN) precipitates. Possibly, this is due to the fact that the precipitation of niobium carbonitride is kinetically difficult [36], and the difference in the start temperatures of AlN and Nb(CN) precipitation is small. It can be seen that the difference in the start temperatures of AlN and Nb(CN) precipitation is only a few tens of degrees. Therefore, it can be assumed that the precipitation of these two phases occurs in competition; therefore, the particles of niobium carbonitride do not have time to grow.

The study [37] described the symbiotic character of MnS and AlN co-precipitation in the austenitic region of low-carbon steel with composition, wt.%: 0.104 C–0.044 Si–0.43 Mn–0.009 S–0.046 Al–0.025 Cu–0.0009 Ti–0.004 N. The effect of two different heat treatments was investigated: “mild cooling”, which simulates the usual cooling conditions for the concast strand and “rapid cooling with reheating”. It was shown that almost no MnS/AlN co-precipitation was observed during mild cooling. Instead, only pure MnS precipitates were found, which were predominantly nucleated at dislocations. After rapid cooling with reheating, most precipitates were MnS/AlN co-precipitations on dislocations. In this case, there was a significant widening of the ductility trough compared to the mild-cooling heat treatment.

6. Effect of Vanadium Carbonitride

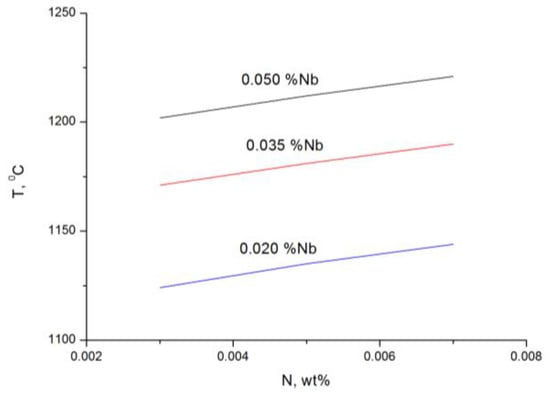

The peculiarity of the influence of vanadium is due to the higher solubility in austenite and the lower temperature of the precipitation of its carbonitride compared to titanium and niobium. Figure 4 shows the calculated phase composition of low-carbon steels for 0.05 wt.% Nb and 0.05 wt.% V. It can be seen that the difference in the temperature of the onset of carbonitride precipitation is about 400 degrees. Due to low temperatures and competition with the simultaneous reaction of cementite formation, V(C,N) precipitation is kinetically inhibited. At the same time, the temperature of the beginning of its precipitation falls within the temperature range of straightening in the industrial production process; therefore, the presence of these particles affects the hot ductility.

Figure 4. Temperature dependence of the phase composition of model steel containing, wt.%: 0.08 C, 0.60 Mn, 0.10 Si, 0.045 Al, 0.005 S, 0.005 P, 0.005 N and (a) 0.05 Nb, (b) −0.05 V.

With an increase in the vanadium and nitrogen concentration, the temperature of the beginning of the vanadium carbonitride precipitation increases. At the same time, the fraction of nitrogen in its composition increases, approaching VN. As a result, its effect on hot ductility is stronger, approaching that of niobium carbonitride. However, under the same test conditions, the hot ductility of V-containing steels is superior to that of steels with Nb [3]. For example, steel containing 0.16 wt.% V and 0.011 wt.% N had better hot ductility than steel with 0.039 wt.% Nb. This is explained by the fact that vanadium forms a smaller amount of precipitates with nitrogen than niobium. Moreover, the VN particles are larger than the NbCN particles, which is less harmful to the hot ductility of the steel [38]. At the same time, when comparing V-Ti and Nb-Ti microalloyed steels, it was found that both types of steel had the same hot ductility.

The results of [3] show that additions of vanadium up to 0.1 wt.% with a low-nitrogen content (<0.005 wt.%) had only very little detrimental effect on hot ductility by widening the ductility trough. At higher nitrogen levels, the effect of vanadium additions becomes more pronounced and the ductility trough becomes deeper and wider. In [39], it was also noted that the effect of vanadium on the hot ductility of steel was detected only with an increased vanadium content (0.095 wt.%) in a complex with a high nitrogen content (0.014 wt.%).

The authors of [12][22][38][40] attributed the influence of vanadium to the presence of nitrogen in steel. Steels with a carbon content in the peritectic range in the case of V-microalloying had better ductility than 0.03% Nb-containing steels with 0.005 wt.% N, provided that the [V][N] product did not exceed 1.2 × 10−3 (corresponds to 0.1 wt.% V and 0.012 wt.% N). However, an increase in the concentration of vanadium or nitrogen led to a deeper and wider trough with low plasticity, which was due to a large amount of precipitates.

In [41], for steel with 0.07 wt.% V, as the nitrogen concentration increased from 0.0053 to 0.016 wt.%, the ductility trough became wider and deeper. The low ductility intervals were 780–860 °C and 770–920 °C, and the minimum RA value was 47% and 35% at 800 °C, respectively. A similar situation occurred with an increasing vanadium concentration.

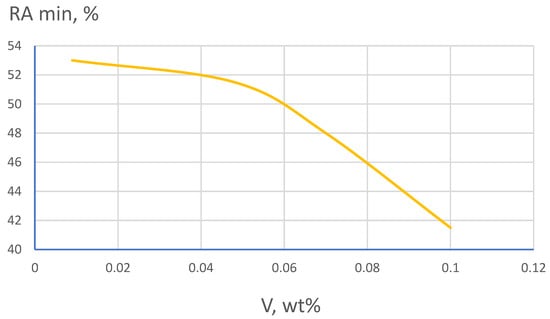

Two steels with various vanadium contents, wt.%: 0.151 C–0.374 Si–1.520 Mn–0.047 Nb–0.020 Ti–0.029 V and 0.156 C–0.370 Si–1.601 Mn–0.047 Nb–0.020 Ti–0.041 V, were studied in [42]. Steel with a high vanadium content (0.041 wt.%) has a deeper trough: the smallest redaction of area is 66.5% at a fracture temperature of 700 °C, while steel with 0.029% V has 75.5%. Figure 5 shows the decrease in the minimum value of RA for steel of the base composition, wt.%: 0.11–0.13 C, 0.3–0.34 Si, 1.39–1.43 Mn, 0.016–0.02 P, 0.003–0.004 S, 0.005–0.0053 N, with increasing concentration V from 0.009 to 0.1 wt.% [43]. The best ductility was in steel with 0.009 wt.% V: the minimum redaction of area was about 53% at 800 °C.

Figure 5. Dependence of the minimum value of hot ductility on vanadium content for steel of basic composition, wt.%: 0.11–0.13 C, 0.3–0.34 Si, 1.39–1.43 Mn, 0.016–0.02 P, 0.003–0.004 S, 0.005–0.0053 N.

It should be noted that the effect of the size of precipitates in low-carbon vanadium microalloyed steels was studied in the works [44][45]. An analysis of the hot ductility loss in [44] showed that small particles (~6 nm) were more harmful than larger ones (~20 nm), since they slowed down dynamic recrystallization more strongly. The results of the study [45] of steel with composition, wt.%: 0.06 C–0.4 Si–1.0 Mn–0.01 P–0.005 S–0.01 Ti—0.07 V–0.2 Cu–0.5 Cr–0.25 Ni, show that hot ductility changes dramatically from 975 up to 825 °C, when the size of the precipitates changes in the range from 10 to 30 nm. The authors explained this by the fact that finer precipitates weakened the grain boundaries and were the sites of nucleation of ferrite films.

In [40], vanadium was found to be a useful additive for Nb-microalloyed with a low nitrogen content, probably because vanadium retards niobium precipitation by increasing Nb(CN) solubility. A positive effect of niobium addition on V-microalloyed steel was also established. Although a small addition of niobium (0.015 wt.%) to steel with 0.05 wt.% C, 0.0065–0.012 wt.% N, and 0.085 wt.% V increased the temperature at which ductility began to deteriorate, in the low-temperature region of austenite (800–900 °C), ductility improved. Studies have shown that this was due to the fact that niobium delays dynamic and post-dynamic NbV(CN) precipitation.

7. Effect of Boron Nitride

Since boron can form BN with nitrogen, the presence of these dispersed precipitates adversely affects hot plasticity. Therefore, the influence of boron strongly depends on the rate and cooling conditions, which determines the form of the presence of boron, as well as the size of BN precipitates.

In 2010, Mintz et al. [22], based on a summary of a large number of works on the study of the hot ductility of steels, identified the following reasons for the favorable effect of boron:

- –

-

Since the boron atom is a small atom, it segregates easily at austenite grain boundaries, reducing the boundary slip, which improves creep ductility. In addition, it may take up vacant sites that would otherwise form nucleation sites for fine precipitates, such as Nb(CN) and TiN;

- –

-

Boron prevents the formation of ferrite at the austenite grain boundaries causing it to precipitate within the matrix allowing the strain to be accommodated more uniformly;

- –

-

Boron causes a coarse precipitation to occur at the boundaries instead of a fine precipitation within the matrix reducing the stress acting on the boundaries.

Ductility generally improves with an increasing B/N ratio, and a ratio of 0.8:1 (stoichiometric) has been found to provide the greatest ductility at high cooling rates. While there is a window in which boron additions are beneficial to ductility and can help avoid cracking, it is quite narrow and explains the increased cracking often seen when conditions are not tightly controlled.

In addition, the benefit of adding boron is to prevent the formation of aluminum nitride. Although AlN is much more thermodynamically stable than BN, its precipitation is very slow and on cooling it always forms BN first. Then its effect on hot ductility depends on the particle size. Of the two, AlN is the more harmful. Perhaps this is due to the fact that the nucleation and growth of AlN is much slower, and the dynamic precipitation is usually more dispersed, and AlN precipitation occurs mainly at the boundaries.

References

- Kolbasnikov, N.G.; Matveev, M.A.; Zotov, O.G.; Mishin, V.V.; Mishnev, P.A.; Nikonov, S.V. Physicochemical simulation of hot plasticity of microalloyed pipe steel in continuous casting and hot rolling. Steel Transl. 2014, 2, 59–64.

- Suzuki, H.G.; Nishimura, S.; Yamaguchi, S. Characteristics of hot ductility in steels subjected to the melting and solidification. Trans. ISIJ 1982, 22, 48–56.

- Crowther, D.N. The effects of microalloying elements on cracking during continuous casting. In Proceedings of the Vanitec Symposium—The Use of Vanadium in Steel, Beijing, China, 12–14 October 2001; pp. 99–131. Available online: https://vanitec.org/images/papers/2001-The-Effects-of-Microalloying-Elements-on-Cracking-During-Continuous-Casting.pdf (accessed on 1 February 2023).

- Lanjewar, H.A.; Tripathi, P.; Singhai, M.; Patra, P.K. Hot ductility and deformation behavior of C-Mn/Nb-microalloyed steel related to cracking during continuous casting. J. Mater. Eng. Perform. 2014, 23, 3600–3609.

- Mintz, B.; Yue, S.; Jonas, J.J. Hot ductility of steels and its relationship to the problem of transverse cracking during continuous casting. Int. Mater. Rev. 1991, 36, 187–220.

- Shaposhnikov, N.G.; Rodionova, I.G.; Pavlov, A.A. Thermodynamic development of austenite-martensite class corrosion-resistant steels intended for a bimetal cladding layer. Metallurgist 2015, 59, 1195–1200.

- Yasumoto, K.; Maehara, Y.; Ura, S.; Ura, S.; Ohmori, Y. Effects of sulphur on hot ductility of low-carbon steel austenite. Mater. Sci. Technol. 1985, 1, 111–116.

- Kobayashi, H. Hot-ductility recovery by manganese sulphide precipitation in low manganese mild steel. ISIJ Int. 1991, 31, 268–277.

- Suzuki, H.G.; Nishimura, S.; Imamura, J.; Nakamura, Y. Embrittlement of steels occurring in the temperature range from 1000 to 600 °C. Trans ISIJ 1984, 24, 169–177.

- DeArdo, A.J. Niobium in modern steels. Int. Mater. Rev. 2003, 48, 371–402.

- Hutchinson, C.R.; Zurob, H.; Sinclair, C.; Brechet, Y. The comparative effectiveness of Nb solute and NbC precipitates at impeding grain-boundary motion in Nb steels. Scr. Mater. 2008, 59, 635–637.

- Mintz, B. The Influence of composition on the hot ductility of steels and to the problem of transverse cracking. ISIJ Int. 1999, 39, 833–855.

- Crowther, D.N.; Mintz, B. Influence of carbon on hot ductility of steels. Mater. Sci. Technol. 1986, 2, 671–676.

- Osinkolu, G.A.; Tacikowski, M.; Kobylanski, A. Combined effect of AIN and sulphur on hot ductility of high purity iron-base alloys. Mater. Sci. Technol. 1985, 1, 520–525.

- Harada, S.; Tanaka, S.; Misumi, H.; Mizoguchi, S.; Horiguchi, H. A Formation mechanism of transverse cracks on CC slab surface. ISIJ Int. 1990, 30, 310–316.

- Brune, T.; Senk, D.; Walpot, R.; Steenken, B. Hot ductility behavior of boron containing microalloyed steels with varying manganese contents. Metall. Mater. Trans. B 2015, 46, 1400–1408.

- Lankford, W.T. Some considerations of strength and ductility in the continuous-casting process. Metall. Trans. 1972, 3, 1331–1357.

- Carpenter, K.R.; Killmore, C.R.; Dippenaar, R. Influence of isothermal treatment on MnS and hot ductility in low carbon, low Mn steels. Metall. Mater. Trans. B 2014, 45, 372–380.

- Mintz, B.; Wilcox, R.; Crowther, D.N. Hot ductility of directly cast C–Mn–Nb–Al steel. Mater. Sci. Technol. 1986, 2, 589–594.

- Coleman, T.H.; Wilcox, J.R. Transverse cracking in continuously cast HSLA slabs—Influence of composition. Mater. Sci. Technol. 1985, 1, 80–83.

- Weinberg, F. The strength and ductility of continuously cast steels above 800 °C. Metall. Trans. B 1979, 10, 513–522.

- Mintz, B.; Crowther, D.N. Hot ductility of steels and its relationship to the problem of transverse cracking in continuous casting. Int. Mater. Rev. 2010, 55, 168–196.

- Banks, K.M.; Tuling, A.; Mintz, B. The influence of N on hot ductility of V-, Nb-, and Nb-Ti- containing steels using improved thermal simulation of continuous casting. J. S. Afr. Inst. Min. Metall. 2011, 111, 711–716. Available online: http://www.scielo.org.za/scielo.php?script=sci_arttext&pid=S2225-62532011001000010 (accessed on 1 February 2023).

- Abushosha, R.; Vipond, R.; Mintz, B. Influence of sulphur and niobium on hot ductility of as cast steels. Mater. Sci. Technol. 1991, 7, 1101–1107.

- Crowther, D.N.; Green, M.J.W.; Mitchell, P.S. The influence of composition on the hot cracking susceptibility during casting of microalloyed steels processed to simulate thin slab casting conditions. Mater. Sci. Forum 1998, 284–286, 469–476.

- Ouchi, C.; Matsumoto, K. Hot ductility in Nb-bearing high strength low-alloy steels. Trans. ISIJ 1982, 22, 181–189.

- Mintz, B.; Arrowsmith, J.M. Hot-ductility behavior of C-Mn-Nb-Al steels and its relationship to crack propagation during the straightening of continuously cast strand. Met. Technol. 1979, 6, 24–32.

- Liu, Y.; Sun, Y.-h.; Wu, H.-t. Effects of chromium on the microstructure and hot ductility of Nb-microalloyed steel. Int. J. Miner. Metall. Mater. 2021, 28, 1011–1021.

- Banks, K.M.; Tuling, A.; Klinkenberg, C.; Mintz, B. Influence of Ti on hot ductility of Nb containing HSLA steels. Mater. Sci. Technol. 2011, 27, 537–545.

- Commineli, O.; Abushosa, R.; Mintz, B. Influence of titanium and nitrogen on hot ductility of C-Mn-Nb-Al steels. Mater. Sci. Technol. 1999, 15, 1058–1068.

- Zhang, M.; Li, H.; Gan, B.; Huang, C.; Li, H.; Zhong, Y.; Li, L. Effects of micro-Ti addition on improving hot ductility of Nb-bearing ultra high strength steels. In Frontiers in Materials Processing, Applications, Research and Technology; Muruganant, M., Chirazi, A., Raj, B., Eds.; Springer: Singapore, 2018; pp. 277–285.

- Abushosa, R.; Vipond, R.; Mintz, B. Influence of titanium on the hot ductility of as-cast steels. Mater. Sci. Technol. 1991, 7, 613–621.

- Chervonnyj, A.V.; Ringinen, D.A.; Astafev, D.S.; Efron, L.I. Investigation of hot ductility of microalloyed pipe steels produced at foundry-rolling complex. Probl. Chern. Met. Materioloved. 2015, 2, 49–56. Available online: https://www.elibrary.ru/item.asp?id=23592748 (accessed on 1 February 2023).

- Carpenter, K.R.; Dippenaar, R.; Killmore, C.R. Hot ductility of Nb- and Ti-bearing microalloyed steels and the Influence of thermal history. Metall. Mater. Trans. A 2009, 40, 573–580.

- Li, G.Y.; Li, X.F.; Ao, L.G. Investigation on hot ductility and strength of continuous casting slab for AH32 steel. Acta Metall. Sin. Engl. Lett. 2006, 19, 75–78.

- Koldaev, A.V.; D’yakonov, D.L.; Zaitsev, A.I.; Arutyunyan, N.A. Kinetics of the formation of nanosize niobium carbonitride precipitates in low-alloy structural steels. Metallurgist 2017, 60, 1032–1037.

- Lückl, M.; Wojcik, T.; Povoden-Karadeniz, E.; Zamberger, S.; Kozeschnik, E. Co-precipitation behavior of MnS and AlN in a low-carbon steel. Steel Res. Int. 2018, 89, 1700342.

- Mintz, B.; Abushosha, R. The influence of vanadium on hot ductility of steel. Ironmak. Steelmak. 1993, 20, 445–452. Available online: http://pascal-francis.inist.fr/vibad/index.php?action=getRecordDetail&idt=3908493 (accessed on 1 February 2023).

- Mintz, B.; Qaban, A. The influence of precipitation, high levels of Al, Si, P and a small B addition on the hot ductility of TWIP and TRIP assisted steels: A critical review. Metals 2022, 12, 502.

- Banks, K.M.; Tuling, A.; Mintz, B. Influence of V and Ti on hot ductility of Nb containing steels of peritectic C contents. Mater. Sci. Technol. 2011, 27, 1309–1314.

- Chen, B.; Yu, H. Hot ductility behavior of V-N and V-Nb microalloyed steels. Int. J. Miner. Metall. Mater. 2012, 19, 525–529.

- Song, S.; Tian, J.; Xiao, J.; Fan, L.; Yang, Y.; Yuan, Q.; Gan, X.; Xu, G. Effect of vanadium and strain rate on hot ductility of low carbon microalloyed steels. Metals 2022, 12, 14.

- Mohamed, Z. Hot ductility behavior of vanadium containing steels. Mater. Sci. Eng. A 2002, 326, 255–260.

- Banks, K.; Koursaris, A.; Verdoorn, F.F.; Tuling, A. Precipitation and hot ductility of low C-V and low C-V-Nb microalloyed steels during thin slab casting. Mater. Sci. Technol. 2001, 17, 1596–1604.

- Sun, Y.H.; Zeng, Y.N.; Cai, K.K. Hot ductility of Ti-V bearing microalloyed steel in continuous casting. J. Iron Steel Res. Int. 2014, 21, 451–458.

More

Information

Subjects:

Others

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

2 times

(View History)

Update Date:

25 Jun 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No