Biochar has gained attention as an alternative source of solid energy and for the proper disposal of agricultural biomass waste (ABW). Microwave-assisted pyrolysis (MAP) is a promising approach for the production of biochar. The use of biochar as a soil amendment can be an attractive option for farmers. The incorporation of biochar into soil has been shown to improve soil fertility, water retention, and crop productivity. This can lead to reduced dependence on synthetic fertilizers and increased agricultural yields. The development of a biochar economy has the potential to create new job opportunities and increase the national gross domestic product (GDP). Small-scale enterprises can play a significant role in the production and distribution of biochar, providing value-added products and helping to promote sustainable agriculture.

1. Introduction

Climate change and greenhouse gas emissions are the main concerns of the researchers, as well as tackling the rising demand for alternate energy. Toxic gases and emissions from the industrial sectors should be curtailed by the use of renewable resources. The conversion of biomass into useful products provides a solution to inorganic emissions and wastes. Biochar production has recently emerged as a simple, productive, and scalable process. Production of biochar using the steam pyrolysis process is very cost effective and efficient. The production of biochar from agricultural biomass waste will serve society in an economic manner

[1]. As biomass is highly carbonaceous, such as rice husks, sugarcane bagasse, corn husks, corn straw, wheat straw, and so on, it is considered one of the sources of excess GHG emissions. Almost all biomass contains more than 78 wt.% carbon

[2].

Agriculture is an important sector in several countries, as reflected by its contribution to the national GDP in 2017. Agriculture was identified as a significant economic backbone in Pakistan, Nigeria, India, Indonesia, Malaysia, China, Denmark, and Thailand. Agriculture contributes to approximately 25% of Pakistan’s GDP, making it one of the largest sectors in the country’s economy. In Nigeria, agriculture contributed to 21.60% of the national GDP in 2017. Similarly, in India, agriculture accounted for 15.40% of the GDP, which is a significant contribution given the size of the country’s economy. In Indonesia, agriculture contributed 13.90% to the national GDP in 2017, making it a vital sector for the country’s economy. Similarly, in Malaysia, agriculture accounted for 8.40% of the GDP, which is a significant contribution given the country’s level of development. In China, agriculture contributed 8.30% to the national GDP in 2017, which is significant given the size of China’s economy. Denmark, a developed country, also relies heavily on agriculture, with the sector contributing 8.30% to the national GDP. Finally, in Thailand, agriculture accounted for 8.20% of the GDP, making it an important sector in the country’s economy. Overall, this demonstrates the importance of agriculture in several countries with arable lands and the significant contribution the sector makes to their national economies

[3][4]. Each country produces different crops and have become major producers, shown in

Table 1.

Table 1. Major producers of agricultural crops.

| Countries |

Major Crops |

Agricultural Biomass Waste Generated |

| Asian countries |

Rice |

Husk, straw, hull |

| India, China, Pakistan, and Thailand |

Sugarcane |

Bagasses |

| Indonesia, Malaysia, Thailand, and Nigeria |

Palm |

Kernel shells, palm fibres |

| Thailand, Indonesia, and Malaysia |

Rubber |

Roots, barks, leaves, unproductive rubber trees |

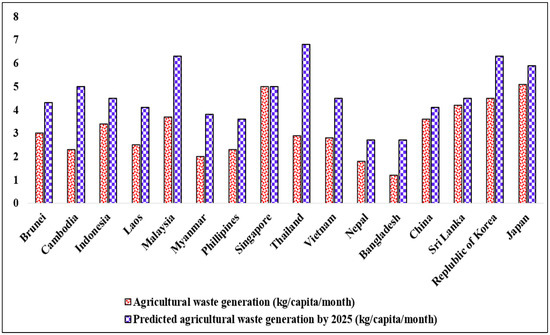

After the harvest of crop products, there is abundant generation of ABW. It is predicted that Asian countries will produce four to five kilograms of ABW/per capita/per month by 2025

[5][6][7][8].

Figure 1 shows the agricultural waste generation in Asian countries, in which Japan tops the other countries with an agricultural waste generation of 5.1 kg/capita/month. A multifold increase in waste can be predicted for the year 2025 exclusively for Thailand. Apart from this, the huge amount of ABW occupies land but also poses a potential threat to the environment. By dumping on the land, it can also cause environmental problems. Natural biodegradation of ABW releases greenhouse gases such as methane and CO

2 and increases global warming

[9]. ABW can be frequently loaded with soluble organics, so the unfavorable leaching that takes place in rainy seasons can pollute and clog the waterways. Direct disposal of ABW should be avoided and efficient technologies should be incorporated for its disposition.

Figure 1. Agricultural waste generation in Asian countries.

Lignocellulosic ABW is a highly available, sustainable, renewable, and affordable source to generate bioenergy. In general, there are six main ways to convert ABW: (a) thermochemical conversion to biofuels, (b) combustion, (c) hydrothermal liquefaction, (d) torrefaction, (e) pyrolysis, and (f) gasification. Among these methods, pyrolysis is an efficient technique to convert ABW into residues, gases, and oil. These products are value-added, which has a huge demand in industry: they produce less NO

x and SO

x emissions than combustion techniques

[10], less pressure than hydrothermal liquefaction

[11], less tar formation than torrefaction

[12], and less energy consumption than gasification

[13]. ABW can be used as a renewable source of lignocellulosic feedstock for applications such as fiberboard through mechanical recycling, bioproducts through fermentation, and biofuels using thermochemical processes. Exponential population growth necessitates a search for alternate energy sources.

2. Production of Biochar

Biomass was initially burned in an open flame to produce charcoal and ashes. Then, the charcoal was used for domestic purposes. Open burning of biomass releases air pollutants and limits charcoal yields; hence, the process of open-air burning of biomass was interrupted. Researchers and industrialists have found advanced technologies to obtain maximum potential energy outputs from biomass

[14]. Biochar can be produced using different methods, such as torrefaction, combustion, gasification, and slow and fast pyrolysis. Among these processes, pyrolysis is a better option and an effective process for producing biochar. Gasification and combustion are exothermic processes. They convert the biomass material into gas in the presence of oxygen

[15][16]. These technologies generate energy; however, they are very ineffective, costly, and emit a large number of hydrocarbons. In view of this, pyrolysis finds its place in the process of biomass pyrolysis and produces three kinds of yield: solid, char, and gas. Biochar is used in different applications, such as additives in bitumen, precursors for catalysts, carbon sources, and soil enhancers

[17][18][19]. From the literature studied, the different components identified in biochar are shown in

Table 2, in which corn cob and sugarcane bagasse have more than 70 wt.% carbon content. Industrial processes have incorporated the use of biomass as their source of energy production and this has reduced their operational costs

[20][21].

Table 2. Elemental composition of biochar.

| Biochar Feedstock |

Temperature °C |

Components (wt.%) |

Reference |

| C |

N |

O |

H |

K |

S |

P |

| Rice straw |

800 |

36.2 |

|

39.8 |

- |

- |

- |

- |

[22] |

| Corn cob |

600 |

79.1 |

4.25 |

- |

- |

10.1 |

- |

- |

[23] |

| Corn stover |

600 |

69.8 |

1.01 |

- |

- |

9.95 |

0.181 |

2.461 |

| Peanut hull |

600 |

65.5 |

2.0 |

- |

- |

10.0 |

0.0016 |

0.0015 |

| Corn stover |

400 |

59.5 |

1.16 |

- |

- |

7.33 |

0.137 |

1.705 |

| Corn stover and cob |

300 |

57.51 |

1.62 |

35.12 |

- |

0.28 |

- |

- |

| Rice husk and high-density polyethylene |

500 |

46.8 |

0.67 |

- |

0.036 |

- |

- |

- |

[24] |

| Sugarcane bagasse and PP |

600 |

76.5 |

3.03 |

19.8 |

2.93 |

- |

- |

- |

[10] |

| Wheat straw and PS |

600 |

62.9 |

- |

- |

- |

- |

- |

- |

[24] |

| Walnut shell |

900 |

55.3 |

0.47 |

1.6 |

0.89 |

- |

- |

- |

[25] |

3. Agricultural Uses of Biochar

Addition of biochar can greatly influence the soil characteristics. It also provides better aeration for the soil and has a large surface area to increase moisture penetration.

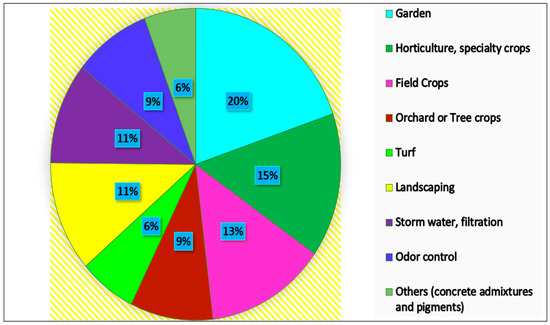

Figure 2 depicts the various uses of biochar in agriculture and shows that around 20% of biochar can be utilized in horticulture and specialty crops to induce soil nutrients. Biochar can be effectively used for odor control in water treatment methods

[26]. Biochar-based fertilizers are currently widely used as plant nutrients. They can improve and modify the soil characteristics. Researchers have identified that use of biochar-based fertilizers can help in te unfavorable agricultural soils, such as sandy soils and heavily worn soils prevalent in the tropics and has an effect on the microbial concentration of the biomass.

Figure 2. Agricultural uses of biochar.

Biochar is often used in soil improvement and researchers are interested in this area of soil enhancers using biochar. It was identified from the studies that the penetration of biochar into the soil must be slower to be more advantageous. These are: (1) decrease in nutrient leaching; (2) reduced irrigation frequency; and (3) reduced greenhouse gas emissions

[27][28][29]. However, a detailed analysis is recommended by the researchers before the application of biochar-based solid enhancers. The detailed analysis must include:

-

Climatic conditions

-

Characteristics of soil

-

Environmental parameters

-

Topography

-

Frequency of application

This detailed analysis should be completed, and the use of biochar will be determined after the report is evaluated. Regular monitoring of crop performance and its effects on soil should be undertaken in field settings with different rates of application

[30].

Recently, biochar has been used for the mitigation of NO

x emissions. NO

x emissions can be reduced in a sewage treatment plant by the addition of ammonium nitrate with biochar

[31]. This proves the biochar’s versatility.