Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Lu, Y.; Wu, T.; Ma, Z.; Mi, Y.; Zhao, Z.; Liu, F.; Cao, X.; Wang, N. Supercapacitors with Triboelectric Nanogenerators. Encyclopedia. Available online: https://encyclopedia.pub/entry/45033 (accessed on 07 February 2026).

Lu Y, Wu T, Ma Z, Mi Y, Zhao Z, Liu F, et al. Supercapacitors with Triboelectric Nanogenerators. Encyclopedia. Available at: https://encyclopedia.pub/entry/45033. Accessed February 07, 2026.

Lu, Yin, Tong Wu, Zimeng Ma, Yajun Mi, Zequan Zhao, Fei Liu, Xia Cao, Ning Wang. "Supercapacitors with Triboelectric Nanogenerators" Encyclopedia, https://encyclopedia.pub/entry/45033 (accessed February 07, 2026).

Lu, Y., Wu, T., Ma, Z., Mi, Y., Zhao, Z., Liu, F., Cao, X., & Wang, N. (2023, May 31). Supercapacitors with Triboelectric Nanogenerators. In Encyclopedia. https://encyclopedia.pub/entry/45033

Lu, Yin, et al. "Supercapacitors with Triboelectric Nanogenerators." Encyclopedia. Web. 31 May, 2023.

Copy Citation

The ever-growing interest in wearable electronic devices has unleashed a strong demand for sustainable and flexible power sources that are represented by the combination of flexible energy harvesting with storage devices/technologies. Triboelectric nanogenerators (TENG), which harvest mechanical energy and charge their matching supercapacitors (SCs), may form a distributed power system with flexibility to tap their potential applications in powering wearable electronic devices.

flexible supercapacitors

triboelectric nanogenerator

energy harvesting

1. Introduction

The fast advancement in wearable electronics is generating a variety of integrated and miniaturized circuits that are revolutionizing our lives in the forms of artificial electronic skin, on-body sensors and wearable displays, with important examples in medical diagnostics and the healthcare industry [1][2][3][4][5]. While the energy usage of these individual devices may be low, their long-term operation requires frequent charging, which makes the need for sustainable, high-performance and biocompatible power supplies even more urgent.

Electrochemical energy storage devices, such as batteries and supercapacitors (SCs), are the most conventional technology to store and supply energy, even with limited lifetime and capacity [6][7][8]. Consequently, the frequent charging or replacement of these devices can cause great inconvenience and high maintenance costs, as well as difficulties with recycling and environmental pollution [9][10][11]. These problems may be solved by enhancing the energy density of the energy storage devices or integrating them with energy-converting devices into self-charging power systems (SCPSs) [12].

Harvesting micro-energy (characterized by low frequency and low amplitude) from our living environment to provide power for portable electronics is considered a suitable approach because it provides long-lasting, maintenance-free, self-driven energy. At present, collecting energy from thermal, solar and biochemical sources is still affected by many factors such as weather and even seasons. In such cases, harvesting mechanical energy from the body and environment and converting it into electricity by triboelectric nanogenerators (TENGs) is an ideal candidate solution [13][14][15][16][17]. On one hand, the TENG is low cost, highly efficient, environmentally friendly, and can be made from a wide variety of raw materials, making it very useful for various self-powered sensors [18][19][20][21]. On the other hand, the power outputs are typically irregularly sized pulses, determined by the strength of the mechanical trigger, and cannot be directly employed to power the majority of electronic devices [22][23][24]. SCs are outstanding in energy storage devices because of their high-power density, long life cycles, and environmental benignancy. Additionally, considering the characteristics of the pulse energy produced by a TENG operating at a low frequency, supercapacitors are excellent candidates to store energy harvested by TENGs due to the advantages of SCs, such as higher peak current, small leakage currents, low cost, and good reversibility.

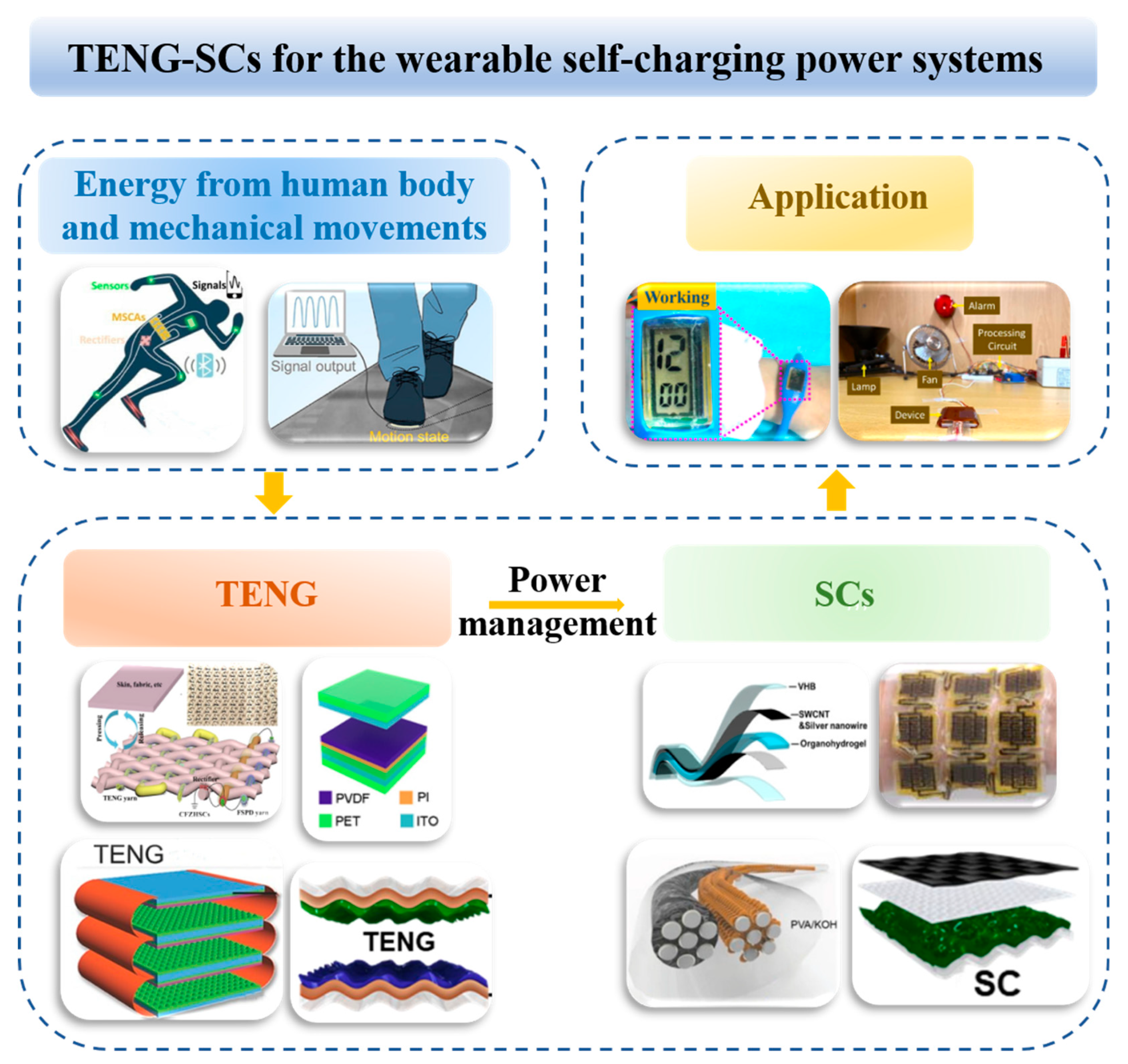

In the past few years, there has been a notable endeavor to integrate SCs with TENGs to create SCPSs [25][26], as depicted schematically in Figure 1.

Figure 1. Illustration of the wearable self-charging power systems that are based on the integration of TENG-SCs.

2. Integration of the TENG with SCs

2.1. The Working Principle of TENG

In 2012, Wang and colleagues developed the TENG, a technology that converts mechanical energy into electricity. It works by utilizing a combination of triboelectric and electrostatic induction based on mechanical interface micro-/nano-energy technology [27]. When two materials come into contact with each other, the contacting surfaces generate equal amounts of charges with opposite polarities [28]. Because materials with strong triboelectric effects are typically insulators or have low conductivity, the charges can remain static on the surface for extended periods [29]. The mobile charges can be induced by attaching electrodes to the backside of electrified materials. Therefore, when the two materials are separated, positive and negative electrostatic charges are separated spatially, and the induced potential difference is generated on the corresponding surface electrodes of the material. This potential difference can drive electron flow between the electrodes, generating electricity when connected to an external circuit load or a short circuit [30].

Up to now, varieties of TENGs have been widely reported and studied, and generally, they can be categorized into four basic working modes, vertical contact–separation mode, sliding mode, single-electrode mode and independent mode [31]. Based on the above modes, TENGs with different kinds of structures are utilized to harvest different types of mechanical energy such as human motion from pressing, sliding and bending, running, heart beating, vibration, wind, water drops or flows, and so on [32][33][34][35][36][37]. On the one hand, TENGs are ideal for self-powered active sensing as they can directly convert mechanical stimuli to electrical signals without the need for additional transducers [38]. On the other hand, TENGs made from flexible and lightweight triboelectric materials (mainly dielectric polymer materials), which have a strong triboelectric effect, can be used for wearable electronics since they are feasible and easy to fabricate. However, the mechanical energy input is typically unstable, and TENGs cannot be directly used to drive most electronic devices due to their pulsed alternative output characteristic. Therefore, an energy storage component is indispensable to store TENG-generated electrical energy to provide a steady, regulated and uninterrupted power output for wearable devices.

2.2. Integration Strategy of TENG-SCs

A supercapacitor, also known as electrochemical capacitor, is a promising energy storage technology that can offer higher power density and longer cycling stability compared to batteries [39][40][41]. In particular, in order to accommodate the need for portable and wearable electronic devices, flexible solid-state SCs have been designed, offering superior portability and security while operating under bending and folding without degrading performance [42][43][44]. Considering that the alternative current (AC) output of the TENG cannot be directly employed to charge the SC, it is necessary to convert it into direct current (DC) using a bridge rectifier before charging SCs, which means that the TENG and SC are connected together with rectifying circuits to build up a sustainable self-charging power system (SCPS). Although it is difficult for the TENG and SC to share electrodes, the triboelectric layer of the TENG can be used as a substrate/package for the SC or designed in a way that the TENG and SC share the package or substrate [45].

3. TENG-SC-Based Flexible Self-Charging Power Systems

3.1. Textile-/Fiber-Based SCPSs

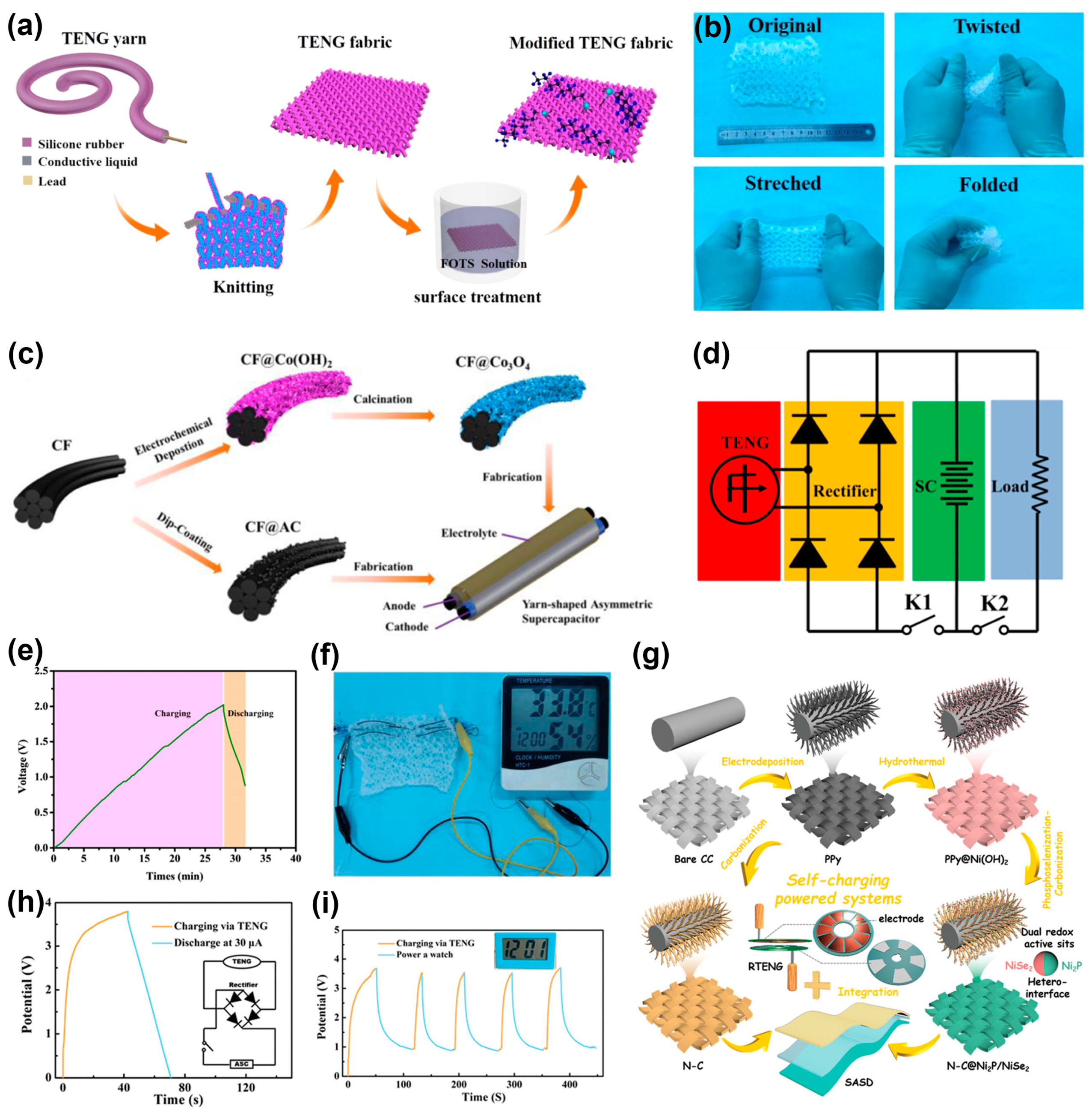

Wearable electronics can benefit greatly from the use of textile or fiber materials, as people wear clothes on a daily basis. The first wearable electronic prototype was proposed by Wang’ s group, which consisted of a fiber-based TENG and fiber-based SC [46]. The RuO2 xH2O@carbon fibers served as two symmetric electrodes of the SC, and received an impressive specific capacitance of 83.5 F cm−3. Meanwhile, the TENG was created using carbon wire electrodes coated in polydimethylsiloxane (PDMS). Further, the SC and the TENG were weaved on a coat to harvest the motion energy while jogging. After being charged by the rectified output of the TENG, the SC obtained an average charging current of 1.28 µA within 10 s, which demonstrates the effectiveness of SCPSs. To achieve a higher specific capacitance, solid-state asymmetric supercapacitor devices (SASD) were developed; Ren et al. [47] prepared an all-yarn SCPS cloth that incorporates a knitted TENG textile with SASD yarns for wearable application. To fabricate the SCPS, a single-electrode mode was employed to design the TENG, which involved sealing the conductive liquid inside a silicone rubber tube modified with trichloro (1H, 1H, 2H, 2H-perfluorooctyl) silane (FOTS) and utilizing a copper wire for electrical connectivity. Additionally, the TENG fabric can work under deformations such as twisting, stretching and bending, as shown in Figure 2a,b. For the SC yarn, Co3O4 nanosheet arrays grown on carbon fiber bundles were used as the positive electrode and activated carbon (AC) was the negative electrode material, and polyvinyl alcohol (PVA)/KOH was used as the gel electrolyte (Figure 2c). Then, the TENG and SCs were connected in series, and an AC–DC converter bridge rectifier was employed. Then, the external load was connected in parallel to the SC yarns (Figure 2d). The three supercapacitor yarns in series were charged to 2 V in 28 s and successfully drove a temperature–humidity meter (Figure 2e,f). Using the same knitting strategy, Hu et al. [48] developed a PDMS/MnO2NW hybrid elastomer sheathed with polytetrafluoroethylene (PTFE) yarn as a TENG device and wearable textile. MnO2 NW on carbon cloth (CC) was the positive electrode, and AC on CC was the negative electrode for the SC. Recently, Guo et al. [49] designed a SASD based on dual redox active sites Ni2P/NiSe2 heterostructure inlaid on N-doped carbon nanowires (N-C@Ni2P/NiSe2) (Figure 2g), achieving a high energy density of 60.4 Wh kg–1 at 1598.8 W kg–1. This SASD can be charged by a designed rotational TENG to 4 V after 50 s by hand-held rotation at a rotation speed of 200 rpm. The power of the SCPS is enough to drive a watch for 70 s with the potential dropping to 1 V, after which it could be charged back to 4 V within 25 s and repeatedly power the watch (Figure 2h,i). This work presents broad application prospects in next-generation SCPSs.

Figure 2. (a,b) Fabrication of the TENG textile, which can be operated under various deformations. (c) Fabrication of the supercapacitor yarn. (d–f) Circuit diagram of the SCPS to power a temperature–humidity meter. (g) Schematic illustration for the fabricated of N-C@Ni2P/NiSe2 and N-C; the construction of SASD, RTENG and SCPS. (h,i) The charge–discharge curves of the SCPS and a charged watch for 5 cycles.

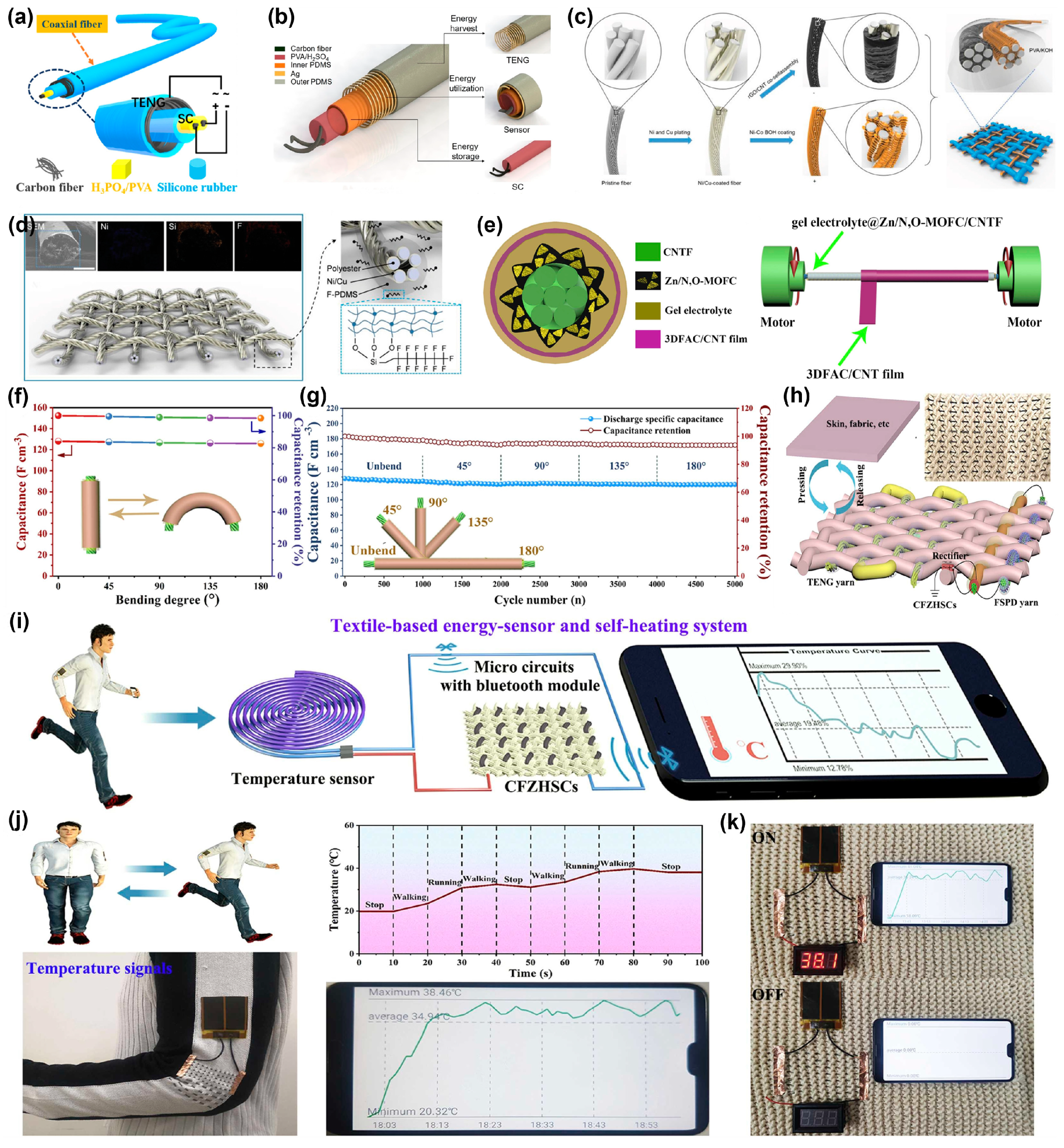

To simplify the structure of the SCPS, Sun et al. [50] proposed a versatile coaxial fiber-based SCPS that utilizes carbon fiber bundles as both the electrode material for the TENG and the active electrode material for the SC. Additionally, they employed silicone rubber as the triboelectric material for the TENG, as well as the separator between the SC and TENG, as well as the encapsulation material for the entire fiber (Figure 3a). Recently, Han et al. [51] developed an all-fiber shaped SCPS, including the TENG and SC and a pressure sensor, assembled in a coaxial geometry. As shown in Figure 3b, the inner core is an SC based on two twisted carbon fibers for energy storage, and is covered by a PDMS layer and an Ag electrode. The outer sheath consists of a TENG in single-electrode mode, with a layer of PDMS supported by a metallic spring. Simultaneously, another coaxial TENG in contact–separation mode is created by the outer PDMS friction layer and the inner PDMS layer coated with Ag. The structure of this SCPS is extremely simple and realizes multiple functions, leading the potable textile wearable electronics in a more intelligent, more accessible direction. Pu et al. [52] also designed an SCPS in which the TENG and SC can be interlaced into a single tissue for real-time energy collection and storage. They initially manufactured polyester yarns coated with Ni and Cu films as substrates for the TENG and SC. As shown in Figure 3c, for the SC, the negative yarn electrode was coated with hydrothermally self-assembled rGO/CNT, and the positive electrode was the electroplated Ni-Co bimetallic oxyhydroxide (NiCo BOH) coating. The SASD exhibited an area energy density of 78.1 µWh cm−2, a power density of 14 mW cm−2, and a retention rate of 82.7% after 5000 cycles. For the TENG, PDMS was coated on the Cu-plated polyester yarn as an electrification layer, as shown in Figure 3d. Park et al. [53] presented an SCPS based on woven carbon fiber (WCF), and P-doped Cu0.5Mn0.5Se2 nanowires were coated on its surface, which can simultaneously act as the active materials of SC and the positive triboelectric layer of the TENG. Then, PDMS grown on the nanowires was used as the negative triboelectric material. This TENG can generate a maximum VOC (open-circuit voltage) and current at 443.2 V and 132.5 μA. The specific capacitance of the SC was 47.34 F g−1, and the energy density and power density were 97.21 Wh kg−1 and 54.25 W kg−1, respectively. Later, they reported an SCPS based on WCF with the same structure, but with a N-doped ZnCuSe2 nanoporous material used to enhance the storage capacity. Compared with the above results, a higher performance of the 636.5 VOC and 165.4 µA current was obtained [54]. Wang et al. [55] fabricated a Zn–ion hybrid SC by utilizing AC coated on CNT film (AC/CNT) as a cathode and electrodeposited Zn nanosheet arrays on MOF-derived carbon with a functional group scaffold as an anode, while the PVA/Zn (CF3SO3)2 was used as the gel electrolyte (Figure 3e). As a result, this SC device shows a high volumetric specific capacitance of 128.06 F cm−3 and capacitance retention, as well as outstanding mechanical flexibility performance (Figure 3f,g). Further, they developed an integrated SCPS textile using the SC, a TENG, a heater, a temperature sensor, and a Bluetooth device (Figure 3h,i). This system is capable of powering the heater and temperature sensor, as well as detecting temperature changes in the human body (Figure 3j,k). This work provides a promising direction that the SCPS can take in not only charging wearable electronics, but also monitoring and sensing body conditions.

Figure 3. (a) Schematic illustration of the coaxial TENG and SC fiber. (b) Schematic structure diagrams of the fiber-based TENG, SC and sensor. Additionally, the energy fiber can be operated under different mechanical deformations. (c) Schematic illustration of the fabrication of yarn ASC. (d) Schematic illustration of a TENG textile. The insets are cross-sectional SEM images and EDS elementary mapping of the yarn. (e) The cross-sectional view of the SC device and the wrapping 3DFAC/CNT film cathode. (f) Specific capacitance and capacitance retention of the SC device at a scan rate of 25 mV s−1. (g) Capacity and capacitance retention of the SC device evaluated after 5000 cycles at various bending angles. (h) Schematic illustration and photograph of a textile-based SCPS. (i) Schematic illustration to depict the incorporation of a temperature sensor and Bluetooth module into the textile-based device. (j) Temperature monitoring at various motion states. (k) Response signals of the detected temperature.

As a conclusion, the CC yarns and carbon fiber are always used as current collectors for both wearable TENGs and SCs because of their good conductivity, flexibility and wearability. Textile/fiber materials, such as nylon, polyester, silk, etc., can be woven into fabrics and textiles to harvest energy from motion, making them suitable platforms for fabricating flexible TENGs due to their wearability and excellent electrification. Moreover, numerous microfibers can provide large surface areas for triboelectrification. At the same time, the lightweight/comfortability are also maintained.

3.2. Film-Based SCPSs

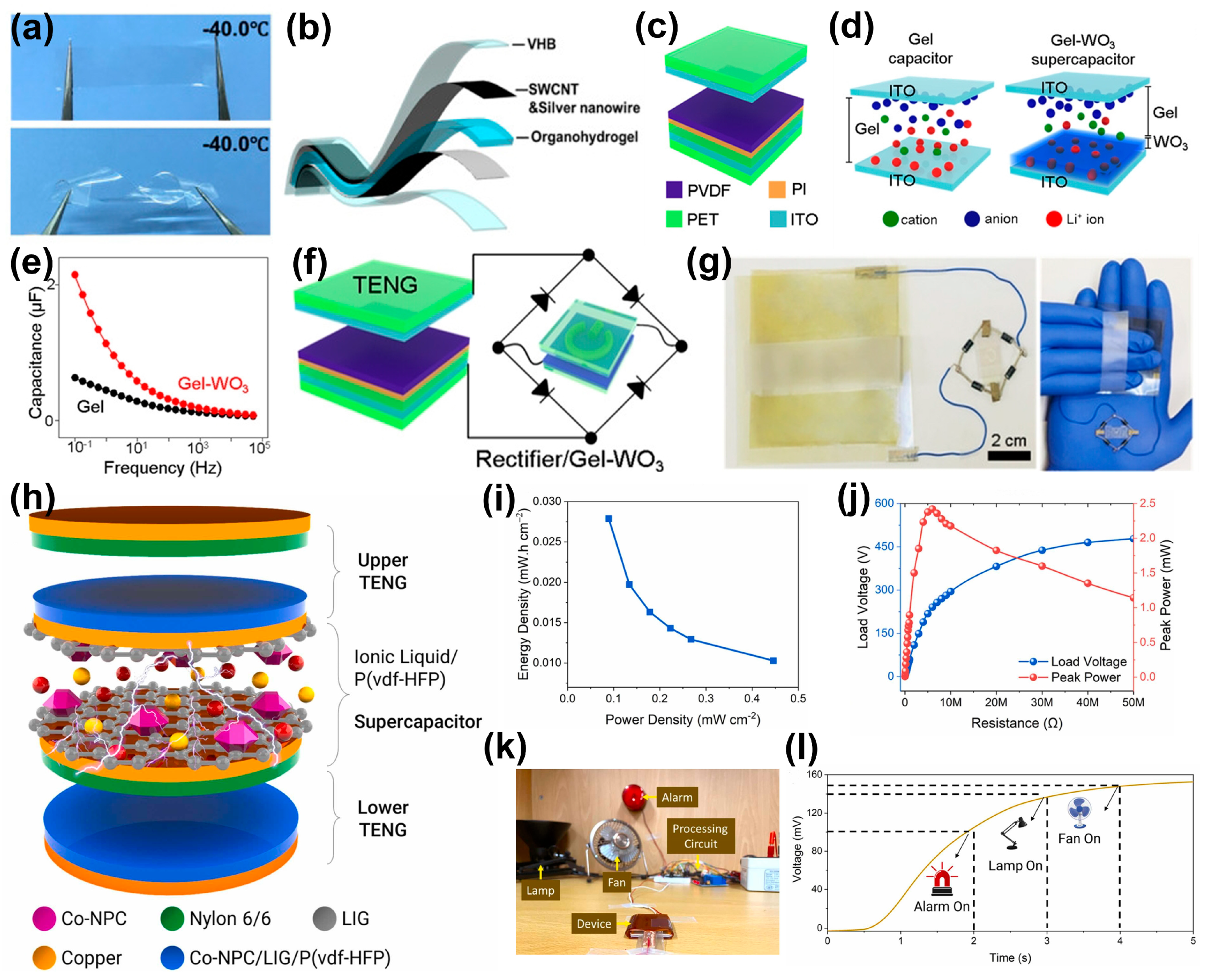

For wearable SCPSs, being lightweight and convenient is one of the future trends. Lu et al. [56] prepared an SCPS composed of cellulose-organohydrogel-based TENG and SC with an impressive anti-freezing property down to −54.3 °C. Firstly, the cellulose was dispersed in BzMe3NOH aqueous with poly (ethylene glycol) diglycidyl ether (PEGDE) as a crosslinking agent. After the crosslinking process, the hydrogel was soaked in NaCl/EG/H2O solution to obtain organohydrogel, where the EG acted as anti-freezing agent. As shown in Figure 4a, the organohydrogel displayed remarkable optical transparency and could endure twisting without any harm, both at room temperature and −40.0 °C. For the SC, as depicted in Figure 4b, a flexible SWCNT paper coated with Ag nanowires served as the electrodes, while organo-hydrogels acting as both the separator and the electrolyte. For the TENG, latex and VHB were used as the friction layers, and the organohydrogels embedded in the VHB were the electrodes. The SCPS was demonstrated via charging the SC by the rectified output of TENG, and then driving an electronic calculator. This work shows the potential of cellulose-based SCPS with flexibility and low-temperature tolerance for harsh conditions. Ni and coworkers [57] also developed an SCPS based on organohydrogel, which was designed with a triple network composed of PVA, sodium alginate (SA) and cellulose nanofibrils. To enhance the conductivity, the MXene nanosheets were functionalized by graphene oxide (MX-GO) and added to the organohydrogel. Furthermore, by incorporating MX-GO, conductive pathways were established, which enabled the hydrogel to possess direction recognition and tensile strain sensing, as well as sensitive pressure- and temperature-sensing capabilities. This work shows the multifunctionality of a flexible SCPS. Jeong et al. [58] investigated the characterization and modulation of the DC voltage produced by the SCPS utilizing an ion gel/WO3 electrochromic supercapacitor. The multilayer film structure of the TENG was composed of polyvinylidene fluoride/polyimide/poly(ethylene terephthalate)/Indium tin oxide (PVDF/PI/PET/ITO) and ITO/PET film, which acted as the negative and positive triboelectric layer, respectively (Figure 4c). The SC was composed of multilayers (ITO/ion gel/WO3/ITO). Compared to the SC without WO3, the capacitance increased from 0.08 μF < C < 0.63 μF to 0.11 μF < C < 2.15 μF (Figure 4d,e). Figure 4f,g show the scheme of the SCPS and the camera image of the integrated SCPS. When placed in hand, the SCPS was in a deformed state, but its output voltage remained the same as that produced on a flat, rigid substrate. Furthermore, the author also investigated how factors such as contact frequency, contact area, capacitor area and the type of capacitor connection influenced the average DC voltage. Caironi et al. [59] proposed a novel approach to fabricating TENGs using edible composites. They developed a bilayer film consisting of ethylcellulose (EC) and AC, with the top layer acting as an insulator and the bottom layer as a conductive electrode that can serve as the positive triboelectric layer of the TENG. Additionally, the edible AC/EC composite (90:10 wt%) can also be applied as the electrode of the SC. This innovative technology holds great potential for the development of edible electronics, which can be used for a variety of applications, including drug release monitoring through intra-body communication.

Figure 4. (a) Photograph of the cellulose organohydrogel at −40.0 °C. (b) Schematic for supercapacitor assembly with cellulose organohydrogel. (c) Scheme of TENG. (d) Structures of the Gel capacitor and the Gel-WO3 supercapacitor. (e) The capacitance of both the Gel and Gel-WO3 was measured as a function of frequency. (f) Scheme of the SCPS. (g) Camera images of the power unit (left) and the measurement on hand (right). (h) Illustration of the layer-by-layer structure of the self-charging SCPS. (i) The relationship between energy density and power density of the SC. (j) Load voltage and peak power of the TENG. (k) Photograph of the experimental setup. (l) Charging curve of turning on smart home appliances.

Park et al. [60] designed an SCPS that can be used without the need for power management or rectifier circuits due to its “tribo-electrochemical mechanism”. The layer–by-layer structure of the SCPS is illustrated in Figure 4h, which comprises an upper and lower TENG with a solid polymer electrolyte (SPC) sandwiched between them. The solid polymer electrolyte is composed of a poly(vinylidene fluoride-co-hexafluoropropylene) (P(vdf-HFP)) separator infused with an ionic liquid (1-ethyl-3-methylimidazolium bis(trifluoromethylsulfonyl) imide [TFSI]). The electrode is made up of a MOF-derived cobalt nanoporous carbon/laser-induced graphene/copper (Co-NPC/LIG/Cu). The triboelectric materials of the TENG consist of a Nylon 66 and Co-NPC/LIG/P(vdf-HFP) layer, while the Cu layer serves as the electrodes. When a compressive force is applied, the upper and lower TENGs come into contact with the SC, generating an electric field. This electric field drives the ions in the SC electrolyte towards the electrode layer, forming an electrical double layer near the interface of the electrolyte and electrode, which charges the SC. This is the first SCPS prototype that does not use any external circuitry, and the SC can deliver an energy density of 0.0278 mW.h.cm−2, and the power density is 0.089 mW cm−2 (Figure 4i). Additionally, the TENG can generate a power of 2.5 mW in a single integrated device, which can successfully charge the SC (Figure 4j). Further, the SCPS can serve as smart switches for activating intelligent appliances (Figure 4k,l). This research highlights the process of converting energy into self-charging supercapacitors in a simpler and more effective way.

References

- Zhu, M.; Li, J.; Yu, J.; Li, Z.; Ding, B. Superstable and Intrinsically Self-Healing Fibrous Membrane with Bionic Confined Protective Structure for Breathable Electronic Skin. Angew. Chem. Int. Ed. 2022, 61, e202200226.

- Yang, H.; Li, J.; Xiao, X.; Wang, J.; Li, Y.; Li, K.; Li, Z.; Yang, H.; Wang, Q.; Yang, J. Topographic design in wearable MXene sensors with in-sensor machine learning for full-body avatar reconstruction. Nat. Commun. 2022, 13, 5311.

- Nakamura, J.; Lopez, G.; Shuzo, M.; Yamada, I. Collaborative Processing of Wearable and Ambient Sensor System for Blood Pressure Monitoring. Sensors 2011, 11, 6760–6770.

- Yi, J.; Xianyu, Y. Gold Nanomaterials-Implemented Wearable Sensors for Healthcare Applications. Adv. Funct. Mater. 2022, 32, 2113012.

- Wang, Y.; Yang, B.; Hua, Z.; Zhang, J.; Guo, P.; Hao, D.; Gao, Y.; Huang, J. Recent advancements in flexible and wearable sensors for biomedical and healthcare applications. J. Phys. D Appl. Phys. 2022, 55, 134001.

- Dou, Q.; Park, H. Perspective on High-Energy Carbon-Based Supercapacitors. Energy Environ. Mater. 2020, 3, 286–305.

- Khan, T.; Garg, A.; Gupta, A.; Madan, A.; Jain, P. Comprehensive review on latest advances on rechargeable batteries. J. Energy Storage 2023, 57, 106204.

- Sedajova, V.; Bakandritsos, A.; Blonski, P.; Medved, M.; Langer, R.; Zaoralova, D.; Ugolotti, J.; Dzibelova, J.; Jakubec, P.; Kupka, V. Nitrogen doped graphene with diamond-like bonds achieves unprecedented energy density at high power in a symmetric sustainable supercapacitor. Energy Environ. Sci. 2022, 15, 740–748.

- Han, X.; Lu, L.; Zheng, Y.; Feng, X.; Li, Z.; Li, J.; Ouyang, M. A review on the key issues of the lithium-ion battery degradation among the whole life cycle. eTransportation 2019, 1, 100005.

- Huang, J.; Xie, Y.; You, Y.; Yuan, J.; Xu, Q.; Xie, H.; Chen, Y. Rational Design of Electrode Materials for Advanced Supercapacitors: From Lab Research to Commercialization. Adv. Funct. Mater. 2023, 33, 2213095.

- Li, D.; Li, S.; Zhang, S.; Sun, J.; Wang, L.; Wang, K. Aging state prediction for supercapacitors based on heuristic kalman filter optimization extreme learning machine. Energy 2022, 250, 123773.

- Mi, Y.; Lu, Y.; Wang, X.; Zhao, Z.; Cao, X.; Wang, N. From Triboelectric Nanogenerator to Uninterrupted Power Supply System: The Key Role of Electrochemical Batteries and Supercapacitors. Batteries 2022, 8, 215.

- Li, R.; Xu, Z.; Li, L.; Wei, J.; Wang, W.; Yan, Z.; Chen, T. Breakage-resistant hydrogel electrode enables ultrahigh mechanical reliability for triboelectric nanogenerators. Chem. Eng. J. 2023, 454, 140261.

- Duque, M.; Murillo, G. Tapping-Actuated Triboelectric Nanogenerator with Surface Charge Density Optimization for Human Motion Energy Harvesting. Nanomaterials 2022, 12, 3271.

- Xing, F.; Jie, Y.; Cao, X.; Li, T.; Wang, N. Natural triboelectric nanogenerator based on soles for harvesting low frequency walking energy. Nano Energy 2017, 42, 138–142.

- Wang, Y.; Qian, Z.; Zhao, C.; Wang, Y.; Jiang, K.; Wang, J.; Meng, Z.; Li, F.; Zhu, C.; Chen, P. Highly Adaptive Triboelectric-Electromagnetic Hybrid Nanogenerator for Scavenging Flow Energy and Self-Powered Marine Wireless Sensing. Adv. Mater. Technol. 2023, 8, 2201245.

- Zhao, J.; Zhen, G.; Liu, G.; Bu, T.; Liu, W.; Fu, X.; Zhang, P.; Zhang, C.; Wang, Z.L. Remarkable merits of triboelectric nanogenerator than electromagnetic generator for harvesting small-amplitude mechanical energy. Nano Energy 2019, 61, 111–118.

- Yan, L.; Mi, Y.; Lu, Y.; Qin, Q.; Wang, X.; Meng, J.; Liu, F.; Cao, X.; Wang, N. Weaved piezoresistive triboelectric nanogenerator for human motion monitoring and gesture recognition. Nano Energy 2022, 96, 107135.

- Dinh Le, T.; Jianing, A.; Huang, Y.; Vo, Q.; Boonruangkan, J.; Tran, T.; Kim, S.; Sun, G.; Kim, Y. Ultrasensitive Anti-Interference Voice Recognition by Bio-Inspired Skin-Attachable Self-Cleaning Acoustic Sensors. ACS Nano 2019, 13, 13293–13303.

- Dong, L.; Wang, M.; Wu, J.; Zhu, C.; Shi, J.; Morikawa, H. Stretchable, Adhesive, Self-Healable, and Conductive Hydrogel-Based Deformable Triboelectric Nanogenerator for Energy Harvesting and Human Motion Sensing. ACS Appl. Mater. Interfaces 2022, 14, 9126–9137.

- Yu, B.; Zhou, L.; Zhang, X.; Hu, G.; Min, H.; Qiu, Y.; Huang, T.; Wang, Y.; Zhu, M. Respiration-mediated self-switched triboelectric nanogenerator for wearable point-of-care prevention and alarm of asthma. Nano Energy 2023, 106, 108058.

- Jo, S.; Kitchamsetti, N.; Cho, H.; Kim, D. Microwave-Assisted Hierarchically Grown Flake-like NiCo Layered Double Hydroxide Nanosheets on Transitioned Polystyrene towards Triboelectricity-Driven Self-Charging Hybrid Supercapacitors. Polymer (Basel) 2023, 15, 454.

- Yang, P.; Zhou, L.; Gao, Y.; Xiao, J.; Liu, D.; Zhao, Z.; Qiao, W.; Liu, J.; Wang, Z.L.; Wang, J. Achieving High-Performance Triboelectric Nanogenerator by DC Pump Strategy. Adv. Mater. Technol. 2023, 2201957.

- Xiang, H.; Yang, J.; Cao, X.; Wang, N. Flexible and highly sensitive triboelectric nanogenerator with magnetic nanocomposites for cultural heritage conservation and human motion monitoring. Nano Energy 2022, 101, 107570.

- Luo, J.; Wang, Z.L. Recent advances in triboelectric nanogenerator based self-charging power systems. Energy Storage Mater. 2019, 23, 617–628.

- Yang, Y.; Guo, X.; Zhu, M.; Sun, Z.; Zhang, Z.; He, T.; Lee, C. Triboelectric Nanogenerator Enabled Wearable Sensors and Electronics for Sustainable Internet of Things Integrated Green Earth. Adv. Energy Mater. 2023, 13, 2203040.

- Zhu, G.; Pan, C.; Guo, W.; Chen, C.Y.; Zhou, Y.; Yu, R.; Wang, Z.L. Triboelectric-generator-driven pulse electrodeposition for micropatterning. Nano Lett. 2012, 12, 4960–4965.

- Liu, Y.H.; Mo, J.L.; Fu, Q.; Lu, Y.X.; Zhang, N.; Wang, S.F.; Nie, S.X. Enhancement of Triboelectric Charge Density by Chemical Functionalization. Adv. Funct. Mater. 2020, 30, 2004714.

- Seol, M.; Kim, S.; Cho, Y.; Byun, K.; Kim, H.; Kim, J.; Kim, S.; Kim, S.; Shin, H.; Park, S. Triboelectric Series of 2D Layered Materials. Adv. Mater. 2018, 30, 1801210.

- Fan, F.R.; Lin, L.; Zhu, G.; Wu, W.; Zhang, R.; Wang, Z.L. Transparent triboelectric nanogenerators and self-powered pressure sensors based on micropatterned plastic films. Nano Lett. 2012, 12, 3109–3114.

- Zhu, G.; Bai, P.; Chen, J.; Jing, Q.; Wang, Z.L. Triboelectric Nanogenerators as a new energy technology: From Fundamentals, Devices, to applications. Nano Energy 2015, 14, 126–138.

- Zhu, Q.; Cao, X.; Wang, N. Triboelectric Nanogenerators in Sustainable Chemical Sensors. Chemosensors 2022, 10, 484.

- Ma, M.; Kang, Z.; Liao, Q.; Zhang, Q.; Gao, F.; Zhao, X.; Zhang, Z.; Zhang, Y. Development, applications, and future directions of triboelectric nanogenerators. Nano Res. 2018, 11, 2951–2969.

- He, L.; Zhang, C.; Zhang, B.; Yang, O.; Yuan, W.; Zhou, L.; Zhao, Z.; Wu, Z.; Wang, J.; Wang, Z.L. A Dual-Mode Triboelectric Nanogenerator for Wind Energy Harvesting and Self-Powered Wind Speed Monitoring. ACS Nano 2022, 16, 6244–6254.

- Zhao, H.; Xu, M.; Shu, M.; An, J.; Ding, W.; Liu, X.; Wang, S.; Zhao, C.; Yu, H.; Wang, H. Underwater wireless communication via TENG-generated Maxwell’s displacement current. Nat Commun. 2022, 13, 3325.

- Li, W.; Pei, Y.; Zhang, C.; Kottapalli, A. Bioinspired designs and biomimetic applications of triboelectric nanogenerators. Nano Energy 2021, 84, 105865.

- Lian, M.; Sun, J.; Jiang, D.; Xu, M.; Wu, Z.; Xu, B.; Algadi, H.; Huang, M. Waterwheel-inspired high-performance hybrid electromagnetic-triboelectric nanogenerators based on fluid pipeline energy harvesting for power supply systems and data monitoring. Nanotechnology 2023, 34, 025401.

- Lu, Y.; Mi, Y.; Wu, T.; Cao, X.; Wang, N. From Triboelectric Nanogenerator to Polymer-Based Biosensor: A Review. Biosensors 2022, 12, 323.

- Salehan, P.; Ensafi, A.; Andikaey, Z.; Rezaei, B. H-CoNiSe2/NC dodecahedral hollow structures for high-performance supercapacitors. Sci. Rep. 2023, 13, 2070.

- Manikandan, M.; Subramani, K.; Sathish, M.; Dhanuskodi, S. NiTe Nanorods as Electrode Material for High Performance Supercapacitor Applications. ChemistrySelect 2018, 3, 9034.

- Lee, J.; Lee, S.; Park, S. Highly Porous Carbon Aerogels for High-Performance Supercapacitor Electrodes. Nanomaterials 2023, 13, 817.

- Liang, J.; Jiang, C.; Wu, W. Toward fiber-, paper-, and foam-based flexible solid-state supercapacitors: Electrode materials and device designs. Nanoscale 2019, 11, 7041–7061.

- Peng, Y.; Yuan, W.; Liu, X.; Xie, P.; Yang, F.; Zhao, H.; Lu, D.; Yin, Y.; Wu, Z. All-in-one integration of polyaniline-polyvinyl alcohol electrode/electrolyte interface for tailorable solid-state supercapacitors. J. Energy Storage 2023, 61, 106761.

- Huang, Z.; Ji, Z.; Feng, Y.; Wang, P.; Huang, Y. Flexible and stretchable polyaniline supercapacitor with a high-rate capability. Polym. Int. 2021, 70, 437–442.

- Pu, X.; Hu, W.; Wang, Z.L. Toward Wearable Self-Charging Power Systems: The Integration of Energy-Harvesting and Storage Devices. Small 2018, 14, 1702817.

- Wang, J.; Li, X.; Zi, Y.; Wang, S.; Li, Z.; Zheng, L.; Yi, F.; Li, S.; Wang, Z.L. A Flexible Fiber-Based Supercapacitor–Triboelectric-Nanogenerator Power System for Wearable Electronics. Adv. Mater. 2015, 27, 4830–4836.

- Ren, X.; Xiang, X.; Yin, H.; Tang, Y.; Yuan, H. All-yarn triboelectric nanogenerator and supercapacitor based self-charging power cloth for wearable applications. Nanotechnology 2021, 32, 315404.

- Mao, Y.; Li, Y.; Xie, J.; Liu, H.; Guo, C.; Hu, W. Triboelectric nanogenerator/supercapacitor in-one self-powered textile based on PTFE yarn wrapped PDMS/MnO2NW hybrid elastomer. Nano Energy 2021, 84, 105918.

- Gao, X.; Zhang, Y.; Yin, S.; Mao, Y.; Gui, J.; Li, J.; Zhao, Y.; Sun, C.; Guo, S. Dual Redox Active Sites 2P/NiSe2 Heterostructure Supercapacitor Integrated with Triboelectric Nanogenerator toward Efficient Energy Harvesting and Storage. Adv. Funct. Mater. 2022, 32, 2204833.

- Yang, Y.; Xie, L.; Wen, Z.; Chen, C.; Chen, X.; Wei, A.; Cheng, P.; Xie, X.; Sun, X. Coaxial Triboelectric Nanogenerator and Supercapacitor Fiber-Based Self-Charging Power Fabric. ACS Appl. Mater. Interfaces 2018, 10, 42356–42362.

- Han, J.; Xu, C.; Zhang, J.; Xu, N.; Xiong, Y.; Cao, X.; Liang, Y.; Zheng, L.; Sun, J.; Zhai, J.; et al. Multifunctional coaxial energy fiber toward energy harvesting, storage, and utilization. ACS Nano 2021, 15, 1597–1607.

- Liu, M.; Cong, Z.; Pu, X.; Guo, W.; Liu, T.; Li, M.; Zhang, Y.; Hu, W.; Wang, Z.L. High-energy asymmetric supercapacitor yarns for self-charging power textiles. Adv. Funct. Mater. 2019, 29, 1806298.

- Deka, B.; Hazarika, A.; Lee, S.; Kim, D.; Park, Y.; Park, H. Triboelectric-nanogenerator-integrated structural supercapacitor based on highly active P-doped branched Cu–Mn selenide nanowires for efficient energy harvesting and storage. Nano Energy 2020, 73, 104754.

- Deka, B.; Hazarika, A.; Kwak, M.; Kim, D.; Jaiswal, A.; Lee, H.; Seo, J.; Jeong, C.; Jang, J.; Park, Y.; et al. Triboelectric nanogenerator-integrated structural supercapacitor with in situ MXene-dispersed N-doped Zn–Cu selenide nanostructured woven carbon fiber for energy harvesting and storage. Nano Energy 2021, 43, 402–410.

- Zhao, J.; Cong, Z.; Hu, J.; Lu, H.; Wang, L.; Wang, H.; Malyi, O.; Pu, X.; Zhang, Y.; Shao, H.; et al. Regulating zinc electroplating chemistry to achieve high energy coaxial fiber Zn ion supercapacitor for self-powered textile-based monitoring system. Nano Energy 2022, 93, 106893.

- Qin, C.; Lu, A. Flexible, anti-freezing self-charging power system composed of cellulose-based supercapacitor and triboelectric nanogenerator. Carbohydr. Polym. 2021, 274, 118667.

- Hu, K.; Zhao, Z.; Wang, Y.; Yu, L.; Liu, K.; Wu, H.; Huang, L.; Chen, L.; Ni, Y. A tough organohydrogel-based multiresponsive sensor for a triboelectric nanogenerator and supercapacitor toward wearable intelligent devices. J. Mater. Chem. A 2022, 10, 12092–12103.

- Lee, J.; Kim, K.-W.; Kim, J.; Jeong, U. DC Voltage Modulation for Integrated Self-Charging Power Systems of Triboelectric Nanogenerators and Ion Gel/WO3 Supercapacitors. ACS Appl. Electron. Mater. 2020, 2, 2550–2557.

- Lamanna, L.; Pace, G.; Ilic, I.; Cataldi, P.; Viola, F.; Friuli, M.; Galli, V.; Demitri, C.; Caironi, M. Edible cellulose-based conductive composites for triboelectric nanogenerators and supercapacitors. Nano Energy 2023, 108, 108168.

- Shrestha, K.; Sharma, S.; Pradhan, G.B.; Bhatta, T.; Rana, S.M.S.; Lee, S.; Seonu, S.; Shin, Y.; Park, J.Y. A triboelectric driven rectification free self-charging supercapacitor for smart IoT applications. Nano Energy 2022, 102, 107713.

More

Information

Subjects:

Nanoscience & Nanotechnology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

982

Revisions:

2 times

(View History)

Update Date:

31 May 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No