You're using an outdated browser. Please upgrade to a modern browser for the best experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Bartłomiej Igliński | -- | 3772 | 2023-05-26 20:14:33 | | | |

| 2 | Lindsay Dong | Meta information modification | 3772 | 2023-05-29 02:54:41 | | | | |

| 3 | Lindsay Dong | Meta information modification | 3772 | 2023-05-29 11:15:22 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Bartolucci, L.; Cordiner, S.; De Maina, E.; Kumar, G.; Mele, P.; Mulone, V.; Igliński, B.; Piechota, G. Sustainable Valorization of Bioplastic Waste. Encyclopedia. Available online: https://encyclopedia.pub/entry/44899 (accessed on 22 December 2025).

Bartolucci L, Cordiner S, De Maina E, Kumar G, Mele P, Mulone V, et al. Sustainable Valorization of Bioplastic Waste. Encyclopedia. Available at: https://encyclopedia.pub/entry/44899. Accessed December 22, 2025.

Bartolucci, Lorenzo, Stefano Cordiner, Emanuele De Maina, Gopalakrishnan Kumar, Pietro Mele, Vincenzo Mulone, Bartłomiej Igliński, Grzegorz Piechota. "Sustainable Valorization of Bioplastic Waste" Encyclopedia, https://encyclopedia.pub/entry/44899 (accessed December 22, 2025).

Bartolucci, L., Cordiner, S., De Maina, E., Kumar, G., Mele, P., Mulone, V., Igliński, B., & Piechota, G. (2023, May 26). Sustainable Valorization of Bioplastic Waste. In Encyclopedia. https://encyclopedia.pub/entry/44899

Bartolucci, Lorenzo, et al. "Sustainable Valorization of Bioplastic Waste." Encyclopedia. Web. 26 May, 2023.

Copy Citation

Plastics-based materials have a high carbon footprint, and their disposal is a considerable problem for the environment. Biodegradable bioplastics represent an alternative on which most countries have focused their attention to replace of conventional plastics in various sectors, among which food packaging is the most significant one. The evaluation of the optimal end-of-life process for bioplastic waste is of great importance for their sustainable use.

bioplastics

chemical recycling

pyrolysis

waste management

circular economy

1. Introduction

In recent years, the world has been involved in a transition process from the fossil–linear economy toward renewable–circular economy.

In this context, the reduction of the utilization of fossil-based plastics plays a significant role due to their carbon footprint, environmental pollution, and waste management problem. In fact, plastic materials have been involved in a process of exponential growth over the past few decades. From the 1950s of the last century, the excellent features and low costs of these oil-derived products have made them essential for a wide range of applications [1][2][3][4]. Nowadays, the production of traditional virgin plastic is more than 360 million tons yearly (55 in Europe) [5], and its manufacturing involves around 6% of the global oil production [6].

These data point out the impact of traditional plastics, which starts from the early stage of their life cycle due to their fossil-based feedstock and related emissions, and bioplastics are a great opportunity for reducing GHG emissions related to the use of traditional plastics [7].

The other main critical aspect of conventional plastic materials is their disposal. The enormous spread of this material has caused a huge amount of waste over the past few years. The durability of these items and the carelessness with respect to the end-of-life process have resulted in the “invasion” of plastic materials in the environment, creating great concerns about the “plastic pollution” phenomenon [7][8].

Bioplastics have been recognized as a possible solution to these issues [1][9][10][11][12][13]. According to “European Bioplastics” [14], the term “bioplastic” includes all plastic materials that have at least one of the following characteristics:

- -

-

It is made from biological feedstocks.

- -

-

It is biodegradable.

All the different bioplastics can be categorized into three different families:

-

Bio-based (or partly bio-based) plastics, non-biodegradable (bio-based PE, PP, PET,);

-

Bio-based and biodegradable plastics (PLA, starch blends, PHA, PBS);

-

Fossil-based biodegradable plastics (PBAT, PCL).

Bioplastics are usually considered more sustainable materials due to the advantages of not involving fossil sources (for families 1 and 2) in the production and/or the possibility of biodegrading them at the end of their life (for families 2 and 3) by reducing their environmental impact.

According to the European bioplastic forecast, the global bioplastic production capacity in the next 5 years will triple [14]. Moreover, production growth involves all the continents, in particular Asia (more than 300% increase) and Europe (more than 100% increase).

The EU promotes designs with easier recyclability, expanding and improving the sorting of different plastic waste to simplify logistics and ensure high quality for the recycling industry, while creating viable markets for recycled plastics [15]. The EU approach to bioplastics is also quite prudent [16], as bioplastics are considered “contributing to reduce ‘unavoidable’ littering, still not fully solving the littering problem of the single-use items”.

Another concern has been raised due to the lack of a clear framework on the actual biodegradability of these materials and the lack of awareness from consumers about the government guidelines for an efficient and correct way of recycling [17][18]. Several types of bioplastics are considered “biodegradable” (bioplastic family 2 and 3), and each of them has different biodegradability characteristics. The main problem is the distance between composting standards and the real operating conditions of industrial composting [19] or other common disposals for organic waste, such as composting at home, soil burial disposal, etc. [20][21][22].

When it comes to bioplastic materials, there are several types of recycling routes. Mechanical recycling—primary or secondary—is the “shorter” route for waste reuse. Primary recycling methods ensure the obtainment of products with the same characteristics of virgin materials; for bioplastics, they usually involve only manufacturing waste, as the use of waste materials would not provide the same performance as virgin feedstock [7][23][24]. Secondary recycling processes usually involve reprocessing and downgrading of bioplastic characteristics [7][23][25]. General reprocessing techniques include, for example, screw extrusion, injection molding, blow molding, etc. [23]. Chemical recycling techniques are often referred to as tertiary and consist of conversion of the bioplastic waste into chemicals that could be used as polymer precursors and/or chemicals for other purposes [7][23][26]. Different processes may be considered: pyrolysis or gasification separates chemical compounds by a thermal depolymerization of bioplastics, while solvolysis methods (hydrolysis, alcoholysis) operate by chemical depolymer

2. The Most Widespread Bioplastics

2.1. PBAT

2.1.1. PBAT Introduction and Characteristics

Among all fossil-based biodegradable plastics, one of the most widely used is poly (Butylene Adipate-co-Terephthalate), which is usually called PBAT. According to the data from European Bioplastics [14], in 2021 the global production capacities of PBAT have represented 19.2% of the overall bioplastic production (including: biobased nonbiodegradable, biobased biodegradable and fossil-based biodegradable), with more than 460 thousand tons per year produced [14].

It is a biodegradable synthetic aliphatic aromatic copolyester composted with 1,4-butanediol with both adipic and terephthalic acids [27][28][29][30][31][32][33]. The biodegradability of PBAT depends on the presence of the butylene adipate group [27][28][34] by increasing the susceptibility to hydrolysis and biological degradability [27]. The concentration of terephthalic acid is a trade-off between mechanical properties [27][30][31], which depends on the presence of aromatic acid in the copolyester and the reduction in its biodegradability, also caused by terephthalic acid. A balanced condition is obtained for the concentration of terephthalic acid below 40 wt.% [30][31] or 30–50 mol% [31].

Another crucial aspect for the biodegradability of PBAT is its amorphous structure characterized by a low crystallization [29]: biodegradability improves as crystallinity decreases [27]. Furthermore, due to its low crystallization, PBAT has low modulus and stiffness [27]; it is more flexible and has a greater elongation at break, with good processability properties, than other biodegradable polyesters [32][33][35][36][37].

2.1.2. PBAT Blends

Both industry and scientific communities have been exploring research on various aspects of PBAT blends. Several companies in different countries have developed PBAT-based material, such as, for example: Mater-Bi by Novamont in Italy, Ecoflex by BASF in Germany, Biomax by DuPount in USA, Biotech by Biotech in Germany, and others [34][38][39]. In the recent scientific literature, many types of blends have been studied to evaluate new ways to improve the widespread diffusion of PBAT applications.

Lule et al. in [35] studied the PBAT blend with various concentrations of coffee husks, noting an increase in hydrophobic behavior and better mechanical properties of the compound and a decrease in polymer cost up to 32% for 40 wt% of coffee husks in the matrix [35]. Li et al. in [40] focused on the unsatisfactory water vapor barrier properties of PBAT films, preparing nanocomposite films containing organically modified montmorillonite (OMMT), via film blowing or biaxial orientation.

Some studies focused on the possibility of integrating PBAT and poly(lactic acid) (PLA) (PLA/PBAT blends) to investigate the compatibility of the blend. Li et al. in [32] prepared films of PLA/PBAT blend using a small amount of chain extender containing epoxy functional groups (ADR 4370F) to enhance compatibility of the matrix. In the study, an improvement in mechanical properties was found such as elongation at break, tensile strength, and tear strength, suggesting suitability for applications in shopping bags [32].

2.1.3. PBAT Applications

Due to its mechanical characteristics, PBAT and its blends have been used for plastic film applications such as food packaging, trash bags, film wrapping, diaper back sheets, cotton swabs and mulch film [19][28][30][37][38][41][42]. However, the main problem is the offset between the standard certification criteria and the real conditions of organic waste management. This offset drives problems in end-of-life management of bioplastics. In fact, the requirement EN 13432 for biodegradability and composability is far from the mean condition in European industrial composting plants operating under thermophilic conditions (58 ± 2 °C) for 20 days, followed by a maturation phase (37 ± 2 °C) of approximately 40 days [19], or from the operating conditions achieved, for example, in soil-buried degradation.

2.1.4. PBAT Biodegradation

One of the main routes for biodegradable polymers is composting. Regarding that, Ruggero et al. [41] monitored Mater-Bi® degradation under different composting conditions (20% starch, 10% additives, and 70% PBAT), finding that PBAT was the component more sensitive to moisture and temperature.

The most affecting parameter for PBAT biodegradation was the moisture content. In a report, [41] authors showed that moisture must be higher than 40% during the period of degradation (thermophilic and maturation phase), and below this level the biological activity showed a progressive slowdown until moisture content was approximately 25%, which represents the limit for the final stop of the process [41]. The authors also noticed that PBAT in Mater-Bi® was subject to a higher degradation than that of pure PBAT. They justify their observation by the generation of cavities in to matrix due the faster degradation of starch [19]. Another aspect highlighted in [19] was the discrepancy between the standard conditions (e.g., EN 13432) and the industrial composting conditions.

Relatively to the anaerobic digestion process, Wei Peng et al. [43] observed that the addition of PBAT in a food waste matrix does not provide any advantages in terms of enhancing biogas production, and the material degradation rial occurred only under thermophilic conditions.

2.1.5. PBAT Mechanical Recycling

Only a few studies explored the potential [44][45] of different approaches for waste management of PBAT. La Mantia et al. [44] studied the mechanical recycling of a PLA/PBAT blend using a single screw extruder. The work highlighted how the predrying of the sample enhanced the potential of recycling because of the absence of hydrolysis degradation. The study concluded that five extrusion steps do not significantly decrease the mechanical properties of the blend, enhancing the possibility of using this solution as the end-of-life treatment of PBAT [44].

2.2. Starch Based Biopolymers

2.2.1. Overview and Characteristics

Starch is one of the first biopolymers used for the development of sustainable materials to replace petroleum-based synthetic plastic production. Due to their low cost, renewability, and inherent biodegradability, starch-based polymers are high-potential feedstocks for the large-scale production of bio-plastic films [46][47].

Starch granules consist almost entirely of two main polysaccharides, namely amylopectin, accounting for 70 to 85% of total starch and amylose, present for the remaining 15 to 30%. The relative abundance of amylopectin and amylose can differ significantly between various starch sources [48][49]. Starch granules consist of a semi-crystalline structure with a central amorphous region, mainly composed of amylose, and a circumferential repetition of alternating crystalline and amorphous lamellae [50][51].

Due to its high brittleness and poor mechanical properties, native starch cannot be directly processed as thermoplastic material [52][53]. Plasticizers are generally used to increase the capability of processing starch-based biopolymers. Water is the most used plasticizer for starch, but other substances such as polyols (glycerol, glycol, sorbitol), nitrogen-containing compounds (urea, ammonium derived, and amines), and citric acid have found intensive use [53]. Thermoplastic starch (TPS) results in a flexible and processable material, recognized as one of the most promising materials for the large-scale production of biodegradable materials [48][53][54][55].

2.2.2. TPS Blends

Although TPS has better characteristics with respect to native starch, it is generally unable to meet market requirements [56][57][58]. The most widely reported reinforcing methods are the incorporation of fibers/particles into the starch-based matrix and the blending of TPS with other renewable/fossil-based plastics or biopolymers.

2.2.3. TPS Applications

Food packaging is the sector in which starch-based bioplastics have a more extensive application. Packaging requires different properties depending on the specific function that the film has to perform: rigid packaging needs high mechanical strength and toughness, long-life food requires high water/oxygen barrier properties, while films in contact with fresh products such as fruits, vegetables, and meat demand high permeability, characteristics that can be guaranteed by thermoplastic starch films [48][58]. The high hydrophilicity of TPS films is a property that limits their extensive use for fossil-based plastic replacement [59]. Chemical modifications are particularly effective in improving the barrier properties of TPS films.

2.2.4. TPS Biodegradation

All the studies show how the various techniques to modify the native starch structure, such as starch plasticization, chemical modification, inclusion of natural fibers reinforcement or blending with other polymers, are effective in improving mechanical and barrier properties.

Soil burial tests outlined a general biodegradability of all the samples. Ilyas et al. and Oluwasina et al. found similar degradation rates for thermoplastic starch films without reinforcing elements, but the addition of fillers had a different impact on biodegradability: in Oluwasina et al., the biodegradation rates of oxidized cassava starch experienced a significant reduction [46], while in Ilyas et al., nanofillers of sugar palm nanocrystalline cellulose had a smaller impact on the sugar palm–starch matrix biodegradation [47].

PLA inclusion in the polymeric composite had a positive effect on the mechanical properties, but there are serious drawbacks in terms of biodegradability of the films. Del Rosario Salazar-Sánchez et al. studied the structural change in 22/78 (% wt) PLA/TPS composite during biodegradation and found a significant mass loss, 65% wt in 32 days, a biodegradation rate that is not significantly influenced by the presence of PLA and is able to match the standard required for aerobic composting processes.

2.2.5. TPS Mechanical Recycling

Soil burial tests were performed to assess the biodegradability of thermoplastic starch polymer composites; the studies concluded that the greater the modification to the native structure are, the greater the impact on the biodegradability of the samples tested.

In the literature, some studies have been presented on the mechanical recycling of thermoplastic starch biopolymers. Ibáñez-García et al. demonstrated that commercial Mater-Bi starch-based biopolymer can be reprocessed four times by injection molding without the addition of virgin material [60]. In the study, reprocessing did not have a significant effect on the strength of the composite, but a negative impact on toughness [60].

2.3. PLA Introduction and Characteristics

2.3.1. Overview and Characteristics

Polylactic acid or polylactide (PLA) is a biobased, biodegradable, widely used bioplastic. It is a linear thermoplastic aliphatic polyester synthesized from lactic acid molecules [7][25][61][62][63][64].

In 2021, global production capacities of PLA covered 19.2% of overall bioplastics [14].

Lactic acid is obtained by fermenting sugar contained in various sources, such as: corn starch, sugar beet, tapioca roots, potato starch, and others. [7][25][61][62][63].

Lactic acid is a chiral molecule that can exist in three different stereochemical forms: L-lactide (PLLA), D-lactide (PDLA) and D-L-lactide (or meso lactide) (PDLLA) [7][25][62][64][65]. The ratio utilized for these isomers determines the overall properties of future synthetized PLA [25]; generally, commercial PLLA has a small amount of D-lactide (2–4%) [7].

2.3.2. PLA Blends

Statistics show a growing interest in PLA-based blends, in particular, blends with other biodegradable polymers [66]. One of the most frequently investigated problems is related to PLA blends that increase the degradability of the material. For this purpose, starch is a good biopolymer. In fact, as previously described, it has a greater biodegradability and it is cheaper than PLA [64].

2.3.3. PLA Applications

PLA and its blends are usually employed for packaging applications, compost bags, and food and beverages such as disposable tableware, plates, cups, and bottles. Moreover, in the form of fibers and non-woven textiles, it also has several applications such as upholstery, disposable garments, and awnings [7][63][64]. Other particular fields of use are biomedical applications and 3D printing. In fact, due to its biocompatibility, it is widely used in the biomedical and healthcare fields for drug delivery microspheres, sutures, bone fixation materials, stents, tissue engineering, feminine hygiene products and nappies [25][64].

2.3.4. PLA Biodegradation

PLA degradation of PLA occurs through hydrolysis of the ester bond [27][67] and the biodegradation activity of aerobic and anaerobic microorganisms [25][68][69]. The main parameters that affect its degradation are: temperature, humidity, size, and shape of the samples. At ambient temperature, biodegradation is slow and requires up to 2 years for complete degradation [23]. This makes the polymer unsuitable for soil or domestic composting [25][61]. The high humidity environment promotes the hydrolysis and growth of biodegradation microorganisms [27][68][69]. The ideal condition for PLA degradation requires thermophilic conditions at which degradation is achieved between 90 and 120 days [23][65][68].

2.3.5. PLA Mechanical Recycling

Due to its low degradation rates with respect to the other bioplastics, PLA has received more attention in the scientific literature by exploring alternative pathways for the end-of-life process. PLA soil biodegradation can take years with the risk of increasing environmental pollution [22][70][71][72]. An accurate control of the conditions of the composting process in terms of temperature and humidity is required for a correct biodegradation of PLA, feasible only in industrial applications, different from residential ones [61][73].

Mechanical recycling is a widely studied solution and represents an effective alternative to the biodegradation of PLA. Many authors have studied, using various analysis techniques, the impact of reprocessing on the structure and composition of PLA polymers and the consequent changes in mechanical, thermal, and optical properties [74].

2.4. PHA

2.4.1. PHA Overview and Characteristics

Polyhydroxyalkanoates (PHAs) are bio-based polyesters accumulated by more than 75 different species of bacteria as energy and carbon storage in the cell [1][2].

Potential production from abundantly available renewable resources, biodegradability in both the soil and marine environment, and the intrinsic biocompatibility make PHA biopolymers attractive to replace fossil-based plastics in a wide range of applications [75][76][77][78][79].

PHAs are classified into the short-chain length class, characterized by monomeric building blocks with 3–5 carbons such as poly (3-hydroxyvalerate) (PHV) and poly (3-hydroxybutyrate) (PHB), and medium-chain class (monomeric units of 6–14 carbons), such as poly (3-hydroxyoctanoate) (PHO) [77][80][81].

2.4.2. PHA Blends

Physical modifications of PHAs are aimed at improving the mechanical properties of PHA-based biopolymers and lowering the production cost, which is several times higher than petroleum-based plastics [82]. Blending with natural materials such as starch, fibers, and cellulose derivatives is the most widely diffuse physical modification technique for PHAs.

2.4.3. PHA Applications

Many studies have focused on PHA blends for their suitability for a wide range of applications. Synchronically, the requirements for specific applications are crucial for the selection of the optimal carbon source for microorganisms and downstream processing [75]. Due to intrinsic biocompatibility and non-toxicity, PHAs are optimal biopolymers for tissue engineering for medical/pharmaceutical applications [75]. Extensive research has been carried out on PHA for the construction of biodegradable scaffolds and the replacement of heart valves of living tissue [77].

2.4.4. PHA Biodegradation

Biodegradation is considered the preferred disposal strategy for PHA-based biopolymers since they can be degraded both in soil (under aerobic and anaerobic conditions) and in marine environments, without the release of toxic products [83][84]. Various studies have reported that PHA biodegradation is influenced by an elevated number of factors, such as microbial activity of the environment (different bacteria produce different PHA-depolymerases to degrade PHAs), moisture, temperature, degree of crystallinity, pH of the environment, and exposed surface area [75][83][84].

2.4.5. PHA Mechanical Recycling

With biodegradation in the soil as the designed cradle-to-grave route, there are limited studies in the literature for alternative PHA recycling routes [23]. Rivas et al. investigated the effect of multiple reprocessing cycles on PHB properties, assessing the extrusion process for mechanical recycling. PHB was heated up to 170 °C without the use of additives/plasticizers [85]. The study revealed that reprocessing had a strong effect on PHB mechanical properties, which degraded significantly after three cycles. These changes were attributed to the changes in the PHB structure, probably ascribed to the reduction of molecular weight due to chain scission reactions caused by thermal degradation [85].

3. Thermal Process for Biopolymers Recycling

The different biopolymers discussed above have peculiar behaviors with respect to biodegradation. Starch-based films show good biodegradation rates under controlled temperature and humidity conditions; however, the blending of starch with other polyesters has a high impact on slowing down the rate of biodegradation. For PBAT, PLA and PHA biomaterials, many studies report evident difficulties in biodegradation or limited biodegradation rates, opening up alternative recycling routes. Furthermore, biodegradation makes it hardly possible to recover energy and bioresources from PLA waste, in contrast to the main pillars of sustainable development and the circular economy [72][86].

Mechanical recycling is a widely studied end-of-life strategy for bioplastic materials, which leads to the conversion of waste into secondary raw material with limited impact on the original structure. However, the mechanical recycling process involves several steps before extrusion/injection, in which the feedstock must be separated and sorted, treated by washing and dried [74][87]. Bioplastic sorting is a crucial phase because even small traces of different biopolymers can have a significant impact on the efficiency of the entire process [25][61][88][89]. Moreover, highly efficient sorting technologies, such as near-infrared spectroscopy (NIR), with a separation efficiency of about 97.5%, require further improvement and are still not economically advantageous. Washing and drying are very expensive steps in terms of energy and water resources and represent an environmental risk of possible water contamination [90].

In chemical recycling processes, depolymerization reactions occur to degrade the polymer backbones into their monomers for a new synthesis and recovery of other highly valuable chemicals [23][74]. The principal advantage of chemical recycling over mechanical recycling is that it is tolerant of contamination of feedstock with other bio-plastics, and could potentially extend useful life for indefinite cycles [61].

Chemical recycling processes can be distinguished into processes where bioplastic matrices are depolymerized into their precursors immersed in organic solvents (often called solvolysis, such as hydrolysis and alcoholysis) and dry-thermal processes where biopolymers are depolymerized into their monomers and valuable chemicals in oxygen-free environments. For both solvolysis and thermal processes, feedstock characteristics and the operative condition deeply affect bioplastic conversion rates and product yield.

From an energy point of view, solvolysis processes are cost-effective because they require less energy input than thermal processes [23]. However, the flexibility of thermal processes with the variation of operating conditions and system design is an important aspect that makes it possible to drive the process toward the desired product (i.e., solid, liquid, or syngas). However, reducing the energy input of the process, recirculation, and combustion of syngas is an advantageous strategy [24].

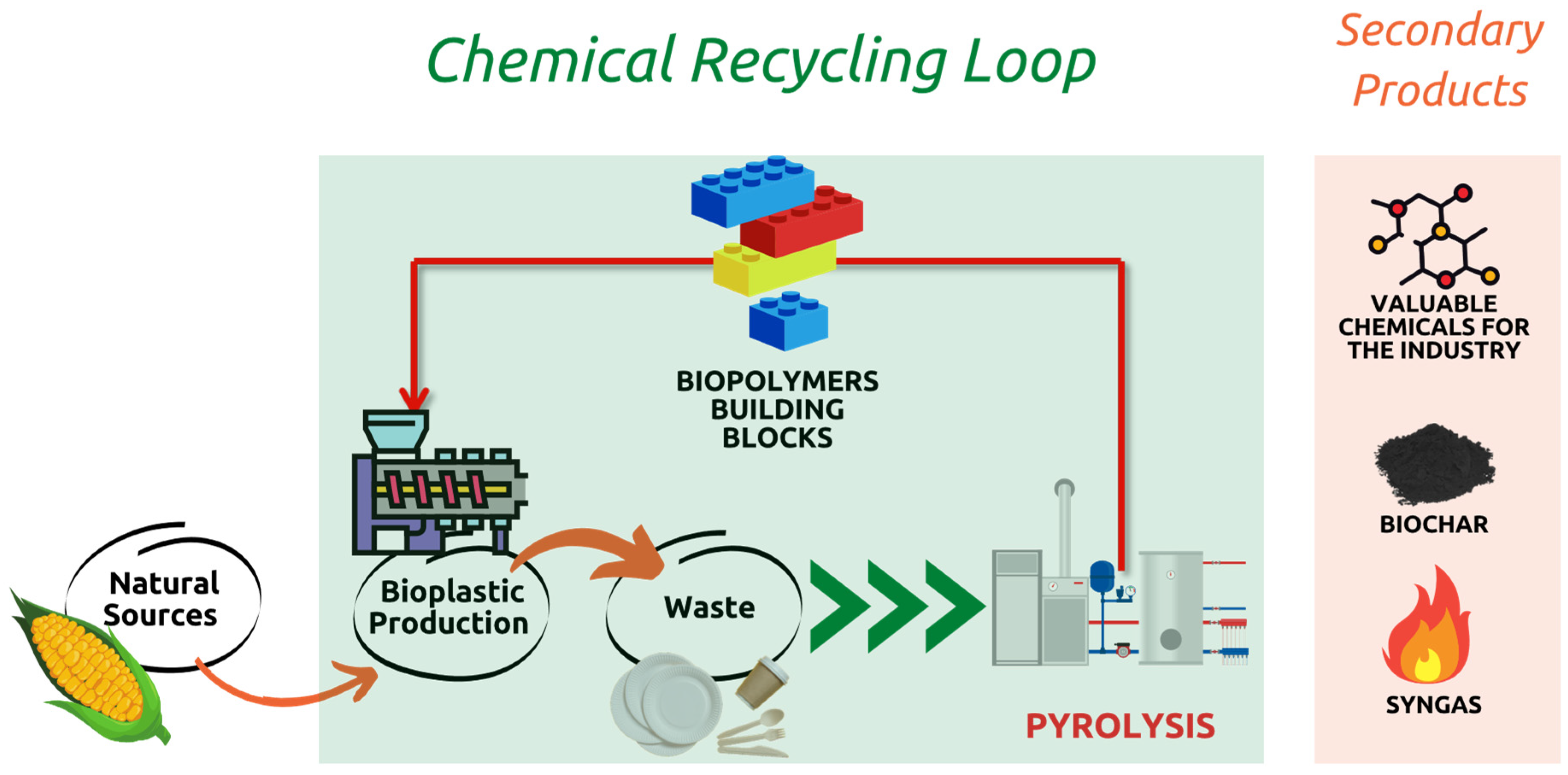

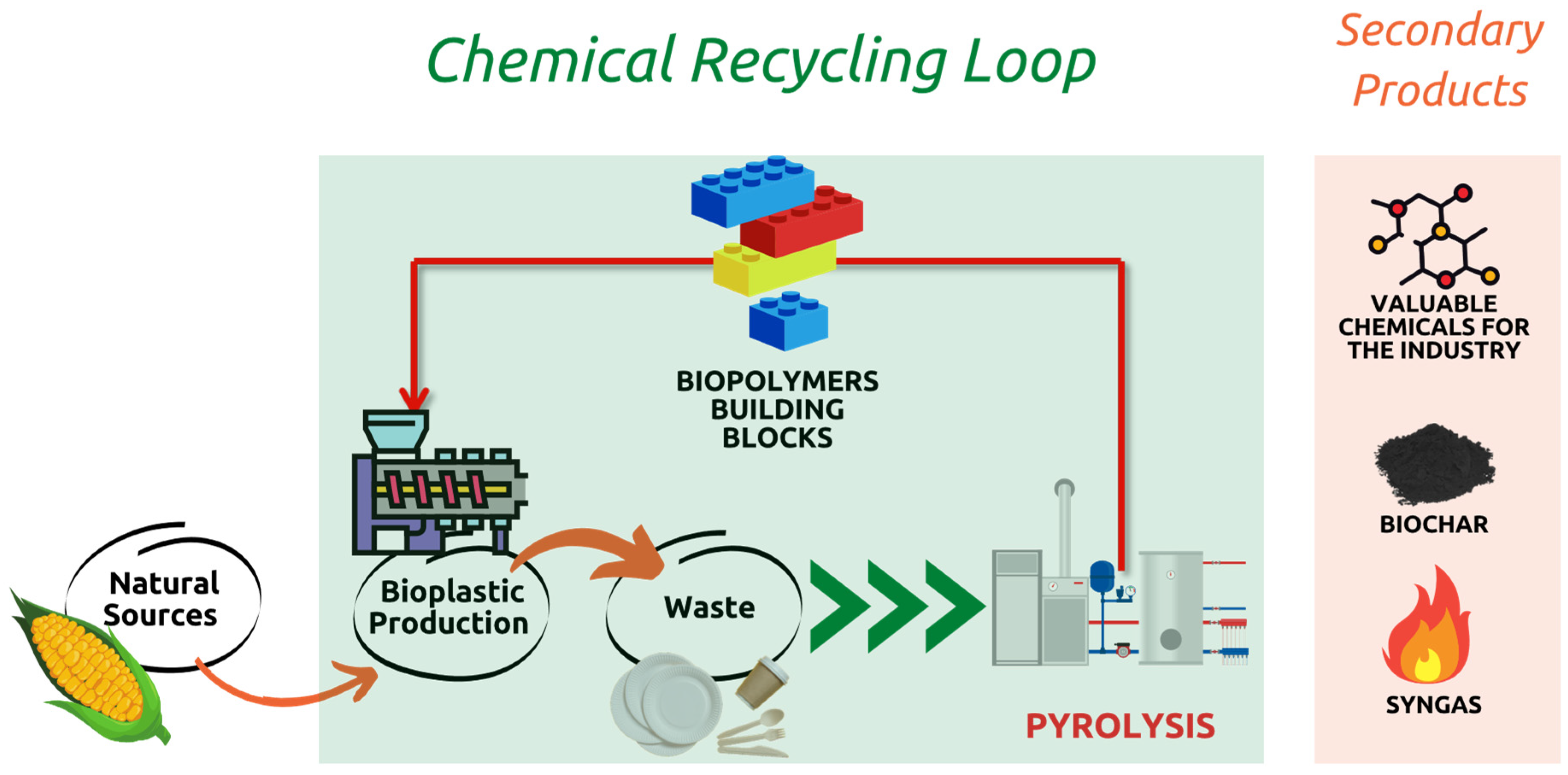

Moreover, the extensive use of solvents is an aspect that can have an environmental impact if not considered carefully [7]. Furthermore, compared to other chemical recycling technologies, the scale-up of pyrolysis to the industrial scale is more straightforward, as it is already considered a well-established technology with various commercial plants for biomass and plastic pyrolysis [24]. In combination with the production of building blocks for bioplastics, other products, such as valuable chemicals present in bio-oil, which are of great interest for the industry, biochar (solid fraction) and syngas, can be reused to sustain the energy requirements of the process or made available as a fuel for other use. Therefore, as reported in Figure 1, pyrolysis is described as a sustainable route, especially if the valorization includes most of the outputs of the process.

Figure 1. Concept of sustainable recycling of bioplastics waste by thermal process.

For all these reasons, over the last few years, several articles have proposed kinetic models for bioplastic heating depolymerization, leading to an estimation of the activation energy of the main reactions, providing possible strategies to make the process as cost-effective as possible [87][90]. Synergistic effects of biopolymers and biomass co-pyrolysis were also investigated, highlighting how the interaction between natural fibers/agro-industrial residues and bioplastics promotes the recoverability of precursors and valuable chemicals, reducing the activation energy of co-pyrolysis [91]. Only in some cases the studies included validation on laboratory scale reactors, which contributed to the assessment of the actual potentiality of the thermal process as an effective end-of-life route.

References

- European Commission. Green Paper—A 2030 Framework for Climate and Energy Policies. COM(2013) 169 Final. 2013, pp. 1–16. Available online: http://ec.europa.eu/clima/policies/strategies/2030/documentation_en.htm (accessed on 3 March 2013).

- European Commission. A Clean Planet for All: A European Strategic Long-Term Vision for a Prosperous, Modern, Competitive and Climate Neutral Economy; European Commission: Brussels, Belgium, 2018.

- European Parliament; Council of The European Union. Directive 2008/122/EC of the European Parliament and of the Council. In Fundamental Texts on European Private Law; Bloomsbury Publishing: London, UK, 2008; p. 25.

- European Commission. EU Biodiversity Strategy for 2030; European Commission: Brussels, Belgium, 2020.

- European Commission. The European Green Deal. 2019. Available online: https://eur-lex.europa.eu/resource.html?uri=cellar:b828d165-1c22-11ea-8c1f-01aa75ed71a1.0002.02/DOC_1&format=PDF (accessed on 11 December 2019).

- United Nations General Assembly. Transforming Our World: The 2030 Agenda for Sustainable Development; United Nations General Assembly: New York, NY, USA, 2015.

- Fredi, G.; Dorigato, A. Recycling of bioplastic waste: A review. Adv. Ind. Eng. Polym. Res. 2021, 4, 159–177.

- Reshmy, R.; Paulose, T.; Philip, E.; Thomas, D.; Madhavan, A.; Sirohi, R.; Binod, P.; Awasthi, M.K.; Pandey, A.; Sindhu, R. Updates on high value products from cellulosic biorefinery. Fuel 2022, 308, 122056.

- Plastics Europe. Plastics—The Facts 2021: An Analysis of European Plastics Production, Demand and Waste Data. Brussels, Belgium. 2021. Available online: https://plasticseurope.org/knowledge-hub/plastics-the-facts-2021/ (accessed on 1 March 2021).

- Letcher, T.M. (Ed.) Plastic Waste and Recycling: Environmental Impact, Societal Issues, Prevention, and Solutions; Academic Press: Cambridge, MA, USA, 2020.

- Van Roijen, E.C.; Miller, S.A. A review of bioplastics at end-of-life: Linking experimental biodegradation studies and life cycle impact assessments. Resour. Conserv. Recycl. 2022, 181, 106236.

- Solarte-Toro, J.C.; Laghezza, M.; Fiore, S.; Berruti, F.; Moustakas, K.; Alzate, C.A.C. Review of the impact of socio-economic conditions on the development and implementation of biorefineries. Fuel 2022, 328, 125169.

- Kee, S.H.; Ganeson, K.; Rashid, N.F.M.; Yatim, A.F.M.; Vigneswari, S.; Amirul, A.-A.A.; Ramakrishna, S.; Bhubalan, K. A review on biorefining of palm oil and sugar cane agro-industrial residues by bacteria into commercially viable bioplastics and biosurfactants. Fuel 2022, 321, 124039.

- European Bioplastics. Available online: https://www.european-bioplastics.org/ (accessed on 15 January 2022).

- European Commission. A European Strategy for Plastics in a Circular Economy; European Commission: Brussels, Belgium, 2018.

- The European Parlament and The European Council. Directive (Eu) 2019/904: On the Reduction of the Impact of Certain Plastic Products on the Environment. 2019. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:32019L0904&from=EN (accessed on 5 June 2019).

- Ansink, E.; Wijk, L.; Zuidmeer, F. No clue about bioplastics. Ecol. Econ. 2022, 191, 107245.

- Friedrich, D. What makes bioplastics innovative for fashion retailers? An in-depth analysis according to the Triple Bottom Line Principle. J. Clean. Prod. 2021, 316, 128257.

- Ruggero, F.; Onderwater, R.C.A.; Carretti, E.; Roosa, S.; Benali, S.; Raquez, J.-M.; Gori, R.; Lubello, C.; Wattiez, R. Degradation of Film and Rigid Bioplastics During the Thermophilic Phase and the Maturation Phase of Simulated Composting. J. Polym. Environ. 2021, 29, 3015–3028.

- Cucina, M.; de Nisi, P.; Tambone, F.; Adani, F. The role of waste management in reducing bioplastics’ leakage into the environment: A review. Bioresour. Technol. 2021, 337, 125459.

- García-Depraect, O.; Lebrero, R.; Rodriguez-Vega, S.; Bordel, S.; Santos-Beneit, F.; Martínez-Mendoza, L.J.; Börner, R.A.; Börner, T.; Muñoz, R. Biodegradation of bioplastics under aerobic and anaerobic aqueous conditions: Kinetics, carbon fate and particle size effect. Bioresour. Technol. 2022, 344, 126265.

- Maga, D.; Hiebel, M.; Thonemann, N. Life cycle assessment of recycling options for polylactic acid. Resour. Conserv. Recycl. 2019, 149, 86–96.

- Lamberti, F.M.; Román-Ramírez, L.A.; Wood, J. Recycling of Bioplastics: Routes and Benefits. J. Polym. Environ. 2020, 28, 2551–2571.

- Dogu, O.; Pelucchi, M.; Van de Vijver, R.; Van Steenberge, P.H.; D’Hooge, D.R.; Cuoci, A.; Mehl, M.; Frassoldati, A.; Faravelli, T.; Van Geem, K.M. The chemistry of chemical recycling of solid plastic waste via pyrolysis and gasification: State-of-the-art, challenges, and future directions. Prog. Energy Combust. Sci. 2021, 84, 100901.

- Di Bartolo, A.; Infurna, G.; Dintcheva, N.T. A Review of Bioplastics and Their Adoption in the Circular Economy. Polymers 2021, 13, 1229.

- Ioannidou, S.M.; Pateraki, C.; Ladakis, D.; Papapostolou, H.; Tsakona, M.; Vlysidis, A.; Kookos, I.K.; Koutinas, A. Sustainable production of bio-based chemicals and polymers via integrated biomass refining and bioprocessing in a circular bioeconomy context. Bioresour. Technol. 2020, 307, 123093.

- Gioia, C.; Giacobazzi, G.; Vannini, M.; Totaro, G.; Sisti, L.; Colonna, M.; Marchese, P.; Celli, A. End of Life of Biodegradable Plastics: Composting versus Re/Upcycling. ChemSusChem 2021, 14, 4167–4175.

- Jian, J.; Xiangbin, Z.; Xianbo, H. An overview on synthesis, properties and applications of poly(butylene-adipate-co-terephthalate)–PBAT. Adv. Ind. Eng. Polym. Res. 2020, 3, 19–26.

- Shahlari, M.; Lee, S. Biodegradable polymer/clay nanocomposites based on poly(butylene adipate-co-terephthalate) and poly(lactic acid). In Proceedings of the AIChE Annual Meeting, Conference Proceedings, Philadelphia, PA, USA, 20 November 2008; pp. 16–21.

- Raquez, J.M.; Nabar, Y.; Narayan, R.; Dubois, P. Novel High-Performance Talc/Poly Hybrid Materials. Macromol. Mater. Eng. 2008, 293, 310–320.

- Zhou, X.; Mohanty, A.; Misra, M. A New Biodegradable Injection Moulded Bioplastic from Modified Soy Meal and Poly (butylene adipate-co-terephthalate): Effect of Plasticizer and Denaturant. J. Polym. Environ. 2013, 21, 615–622.

- Li, X.; Ai, X.; Pan, H.; Yang, J.; Gao, G.; Zhang, H.; Yang, H.; Dong, L. The morphological, mechanical, rheological, and thermal properties of PLA/PBAT blown films with chain extender. Polym. Adv. Technol. 2018, 29, 1706–1717.

- Someya, Y.; Sugahara, Y.; Shibata, M. Nanocomposites based on poly(butylene adipate-co-terephthalate) and montmorillonite. J. Appl. Polym. Sci. 2005, 95, 386–392.

- Vroman, I.; Tighzert, L. Biodegradable Polymers. Materials 2009, 2, 307–344.

- Lule, Z.C.; Kim, J. Properties of economical and eco-friendly polybutylene adipate terephthalate composites loaded with surface treated coffee husk. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106154.

- Phetwarotai, W.; Phusunti, N.; Aht-Ong, D. Preparation and Characteristics of Poly(butylene adipate-co-terephthalate)/Polylactide Blend Films via Synergistic Efficiency of Plasticization and Compatibilization. Chin. J. Polym. Sci. 2019, 37, 68–78.

- Xing, Q.; Buono, P.; Ruch, D.; Dubois, P.; Wu, L.; Wang, W.-J. Biodegradable UV-Blocking Films through Core–Shell Lignin–Melanin Nanoparticles in Poly(butylene adipate-co-terephthalate). ACS Sustain. Chem. Eng. 2019, 7, 4147–4157.

- Ferreira, F.V.; Cividanes, L.S.; Gouveia, R.F.; Lona, L.M. An overview on properties and applications of poly(butylene adipate-co-terephthalate)-PBAT based composites. Polym. Eng. Sci. 2019, 59, E7–E15.

- Gross, R.A.; Kalra, B. Biodegradable Polymers for the Environment. Science 2002, 297, 803–807.

- Li, J.; Lai, L.; Wu, L.; Severtson, S.J.; Wang, W.-J. Enhancement of Water Vapor Barrier Properties of Biodegradable Poly(butylene adipate-co-terephthalate) Films with Highly Oriented Organomontmorillonite. ACS Sustain. Chem. Eng. 2018, 6, 6654–6662.

- Ruggero, F.; Carretti, E.; Gori, R.; Lotti, T.; Lubello, C. Monitoring of degradation of starch-based biopolymer film under different composting conditions, using TGA, FTIR and SEM analysis. Chemosphere 2020, 246, 125770.

- Soulenthone, P.; Tachibana, Y.; Muroi, F.; Suzuki, M.; Ishii, N.; Ohta, Y.; Kasuya, K.-I. Characterization of a mesophilic actinobacteria that degrades poly(butylene adipate-co-terephthalate). Polym. Degrad. Stab. 2020, 181, 109335.

- Peng, W.; Wang, Z.; Shu, Y.; Lü, F.; Zhang, H.; Shao, L.; He, P. Fate of a biobased polymer via high-solid anaerobic co-digestion with food waste and following aerobic treatment: Insights on changes of polymer physicochemical properties and the role of microbial and fungal communities. Bioresour. Technol. 2022, 343, 126079.

- La Mantia, F.P.; Botta, L.; Mistretta, M.C.; Di Fiore, A.; Titone, V. Recycling of a Biodegradable Polymer Blend. Polymers 2020, 12, 2297.

- Oliveira, T.A.; Oliveira, R.R.; Barbosa, R.; Azevedo, J.B.; Alves, T.S. Effect of reprocessing cycles on the degradation of PP/PBAT-thermoplastic starch blends. Carbohydr. Polym. 2017, 168, 52–60.

- Oluwasina, O.O.; Olaleye, F.K.; Olusegun, S.J.; Oluwasina, O.O.; Mohallem, N.D. Influence of oxidized starch on physicomechanical, thermal properties, and atomic force micrographs of cassava starch bioplastic film. Int. J. Biol. Macromol. 2019, 135, 282–293.

- Ilyas, R.A.; Sapuan, S.M.; Ishak, M.R.; Zainudin, E.S. Development and characterization of sugar palm nanocrystalline cellulose reinforced sugar palm starch bionanocomposites. Carbohydr. Polym. 2018, 202, 186–202.

- Khan, B.; Niazi, M.B.K.; Samin, G.; Jahan, Z. Thermoplastic Starch: A Possible Biodegradable Food Packaging Material—A Review. J. Food Process Eng. 2016, 40, e12447.

- Prabhu, T.N.; Prashantha, K. A review on present status and future challenges of starch based polymer films and their composites in food packaging applications. Polym. Compos. 2016, 39, 2499–2522.

- Bertoft, E. Understanding Starch Structure: Recent Progress. Agronomy 2017, 7, 56.

- Wang, S.; Li, C.; Copeland, L.; Niu, Q.; Wang, S. Starch Retrogradation: A Comprehensive Review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585.

- Sanyang, M.L.; Sapuan, S.M.; Jawaid, M.; Ishak, M.R.; Sahari, J. Effect of Plasticizer Type and Concentration on Dynamic Mechanical Properties of Sugar Palm Starch–Based Films. Int. J. Polym. Anal. Charact. 2015, 20, 627–636.

- Ren, J.; Zhang, W.; Lou, F.; Wang, Y.; Guo, W. Characteristics of starch-based films produced using glycerol and 1-butyl-3-methylimidazolium chloride as combined plasticizers. Starch-Stärke 2016, 69, 1600161.

- Ibrahim, M.I.J.; Sapuan, S.M.; Zainudin, E.S.; Zuhri, M.Y.M. Preparation and characterization of cornhusk/sugar palm fiber reinforced Cornstarch-based hybrid composites. J. Mater. Res. Technol. 2019, 9, 200–211.

- Encalada, K.; Aldás, M.B.; Proaño, E.; Valle, V. An overview of starch-based biopolymers and their biodegradability. Ciencia e Ingeniería 2018, 39, 245–258.

- Ilyas, R.; Sapuan, S.M.; Ibrahim, R.; Abral, H.; Ishak, M.R.; Zainudin, E.S.; Atiqah, A.; Atikah, M.S.N.; Syafri, E.; Asrofi, M.; et al. Thermal, Biodegradability and Water Barrier Properties of Bio-Nanocomposites Based on Plasticised Sugar Palm Starch and Nanofibrillated Celluloses from Sugar Palm Fibres. J. Biobased Mater. Bioenergy 2019, 14, 234–248.

- Bulatović, V.O.; Mandić, V.; Grgić, D.K.; Ivančić, A. Biodegradable Polymer Blends Based on Thermoplastic Starch. J. Polym. Environ. 2021, 29, 492–508.

- Zhao, X.; Cornish, K.; Vodovotz, Y. Narrowing the Gap for Bioplastic Use in Food Packaging: An Update. Environ. Sci. Technol. 2020, 54, 4712–4732.

- Anugrahwidya, R.; Armynah, B.; Tahir, D. Bioplastics Starch-Based with Additional Fiber and Nanoparticle: Characteristics and Biodegradation Performance: A Review. J. Polym. Environ. 2021, 29, 3459–3476.

- Ibáñez-García, A.; Martínez-García, A.; Ferrándiz-Bou, S. Recyclability Analysis of Starch Thermoplastic/Almond Shell Biocomposite. Polymers 2021, 13, 1159.

- McKeown, P.; Jones, M.D. The Chemical Recycling of PLA: A Review. Sustain. Chem. 2020, 1, 1–22.

- Ristić, I.S.; Tanasić, L.; Nikolic, L.B.; Cakić, S.M.; Ilić, O.Z.; Radičević, R.; Budinski-Simendić, J.K. The Properties of Poly(l-Lactide) Prepared by Different Synthesis Procedure. J. Polym. Environ. 2011, 19, 419–430.

- Atiwesh, G.; Mikhael, A.; Parrish, C.C.; Banoub, J.; Le, T.-A.T. Environmental impact of bioplastic use: A review. Heliyon 2021, 7, e07918.

- Nampoothiri, K.M.; Nair, N.R.; John, R.P. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501.

- Hubbe, M.A.; Lavoine, N.; Lucia, L.A.; Dou, C. Formulating bioplastic composites for biodegradability, recycling, and performance: A Review. Bioresources 2020, 16, 2021–2083.

- Nofar, M.; Sacligil, D.; Carreau, P.J.; Kamal, M.R.; Heuzey, M.-C. Poly (lactic acid) blends: Processing, properties and applications. Int. J. Biol. Macromol. 2019, 125, 307–360.

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2002, 9, 63–84.

- Itävaara, M.; Karjomaa, S.; Selin, J.-F. Biodegradation of polylactide in aerobic and anaerobic thermophilic conditions. Chemosphere 2002, 46, 879–885.

- Brdlík, P.; Borůvka, M.; Běhálek, L.; Lenfeld, P. Biodegradation of Poly(lactic acid) Biocomposites under Controlled Composting Conditions and Freshwater Biotope. Polymers 2021, 13, 594.

- Song, X.; Zhang, X.; Wang, H.; Liu, F.; Yu, S.; Liu, S. Methanolysis of poly(lactic acid) (PLA) catalyzed by ionic liquids. Polym. Degrad. Stab. 2013, 98, 2760–2764.

- Song, X.; Wang, H.; Yang, X.; Liu, F.; Yu, S.; Liu, S. Hydrolysis of poly(lactic acid) into calcium lactate using ionic liquid for chemical recycling. Polym. Degrad. Stab. 2014, 110, 65–70.

- Song, X.; Bian, Z.; Hui, Y.; Wang, H.; Liu, F.; Yu, S. Zn-Acetate-Containing ionic liquid as highly active catalyst for fast and mild methanolysis of Poly(lactic acid). Polym. Degrad. Stab. 2019, 168, 108937.

- de Andrade, M.F.C.; Fonseca, G.; Morales, A.R.; Mei, L.H.I. Mechanical recycling simulation of polylactide using a chain extender. Adv. Polym. Technol. 2018, 37, 2053–2060.

- Badia, J.; Ribes-Greus, A. Mechanical recycling of polylactide, upgrading trends and combination of valorization techniques. Eur. Polym. J. 2016, 84, 22–39.

- Raza, Z.A.; Abid, S.; Banat, I.M. Polyhydroxyalkanoates: Characteristics, production, recent developments and applications. Int. Biodeterior. Biodegradation 2018, 126, 45–56.

- Koller, M.J.M. Biodegradable and Biocompatible Polyhydroxy-alkanoates (PHA): Auspicious Microbial Macromolecules for Pharmaceutical and Therapeutic Applications. Molecules 2018, 23, 362.

- Sharma, V.; Sehgal, R.; Gupta, R. Polyhydroxyalkanoate (PHA): Properties and Modifications. Polymer 2021, 212, 123161.

- Omura, T.; Goto, T.; Maehara, A.; Kimura, S.; Abe, H.; Iwata, T. Thermal degradation behavior of poly. Polym. Degrad. Stab. 2021, 183, 109460.

- Dietrich, K.; Dumont, M.-J.; Del Rio, L.F.; Orsat, V. Producing PHAs in the bioeconomy—Towards a sustainable bioplastic. Sustain. Prod. Consum. 2017, 9, 58–70.

- Ahmed, S.; Kanchi, S.; Kumar, G. Handbook of Biopolymers; Springer: Berlin/Heidelberg, Germany, 2018.

- Pession, A.; Bosco, F. Produzione di Poliidrossialcanoati da Biomassa Lignocellulosica di Scarto; Politecnico di Torino: Turin, Italy, 2019.

- Crutchik, D.; Franchi, O.; Caminos, L.; Jeison, D.; Belmonte, M.; Pedrouso, A.; del Rio, A.V.; Mosquera-Corral, A.; Campos, J.L. Polyhydroxyalkanoates (PHAs) Production: A Feasible Economic Option for the Treatment of Sewage Sludge in Municipal Wastewater Treatment Plants? Water 2020, 12, 1118.

- Reddy, C.; Ghai, R.; Rashmi; Kalia, V. Polyhydroxyalkanoates: An overview. Bioresour. Technol. 2003, 87, 137–146.

- Bugnicourt, E.; Cinelli, P.; Lazzeri, A.; Alvarez, V. Polyhydroxyalkanoate (PHA): Review of synthesis, characteristics, processing and potential applications in packaging. Express Polym. Lett. 2014, 8, 791–808.

- Rivas, L.F.; Casarin, S.A.; Nepomuceno, N.C.; Alencar, M.I.; Agnelli, J.A.; Medeiros, E.S.; Wanderley, A.D.; Oliveira, M.P.; Medeiros, A.M.; Santos, A.S. Reprocessability of PHB in extrusion: ATR-FTIR, tensile tests and thermal studies. Polímeros 2017, 27, 122–128.

- Undri, A.; Rosi, L.; Frediani, M.; Frediani, P. Conversion of poly(lactic acid) to lactide via microwave assisted pyrolysis. J. Anal. Appl. Pyrolysis 2014, 110, 55–65.

- Feng, L.; Feng, S.; Bian, X.; Li, G.; Chen, X. Pyrolysis mechanism of Poly(lactic acid) for giving lactide under the catalysis of tin. Polym. Degrad. Stab. 2018, 157, 212–223.

- Beeftink, M.R.V.; Vendrik, J.; Bergsma, G. PLA Sorting for Recycling; CE Delft: Delft, The Netherlands, 2021.

- Banu, J.R.; Kannah, R.Y.; Kumar, M.D.; Preethi; Kavitha, S.; Gunasekaran, M.; Zhen, G.; Awasthi, M.K.; Kumar, G. Spent coffee grounds based circular bioeconomy: Technoeconomic and commercialization aspects. Renew. Sustain. Energy Rev. 2021, 152, 111721.

- Lv, S.; Zhang, Y.; Tan, H. Thermal and thermo-oxidative degradation kinetics and characteristics of poly (lactic acid) and its composites. Waste Manag. 2019, 87, 335–344.

- Sun, C.; Li, C.; Tan, H.; Zhang, Y. Synergistic effects of wood fiber and polylactic acid during co-pyrolysis using TG-FTIR-MS and Py-GC/MS. Energy Convers. Manag. 2019, 202, 112212.

More

Information

Subjects:

Environmental Sciences

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

879

Revisions:

3 times

(View History)

Update Date:

29 May 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No