| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Saman Davari | -- | 2830 | 2023-05-23 15:17:22 | | | |

| 2 | Lindsay Dong | -5 word(s) | 2825 | 2023-05-24 05:18:59 | | |

Video Upload Options

The transition towards a Circular Economy (CE) has been receiving an increasing amount of attention in the built asset industry. One of the key aspects of CE is traceability, which can enable the identification and tracking of materials, products, and their associated value throughout their entire lifecycle. However, achieving traceability has been challenging in the built asset industry due to the complex nature of construction projects and a lack of awareness about the benefits of traceability in achieving the circularity of building products and materials. A limited number of frameworks or guidelines exist to support traceability in the built asset industry. In many cases, several of the existing traceability standards, strategies, and guidelines must be identified and framed to support development and implementation of theories and models applicable within the built asset domain.

1. Introduction

2. Traceability Framework in Built Environment

2.1. Circular Economy in the Built Environment

-

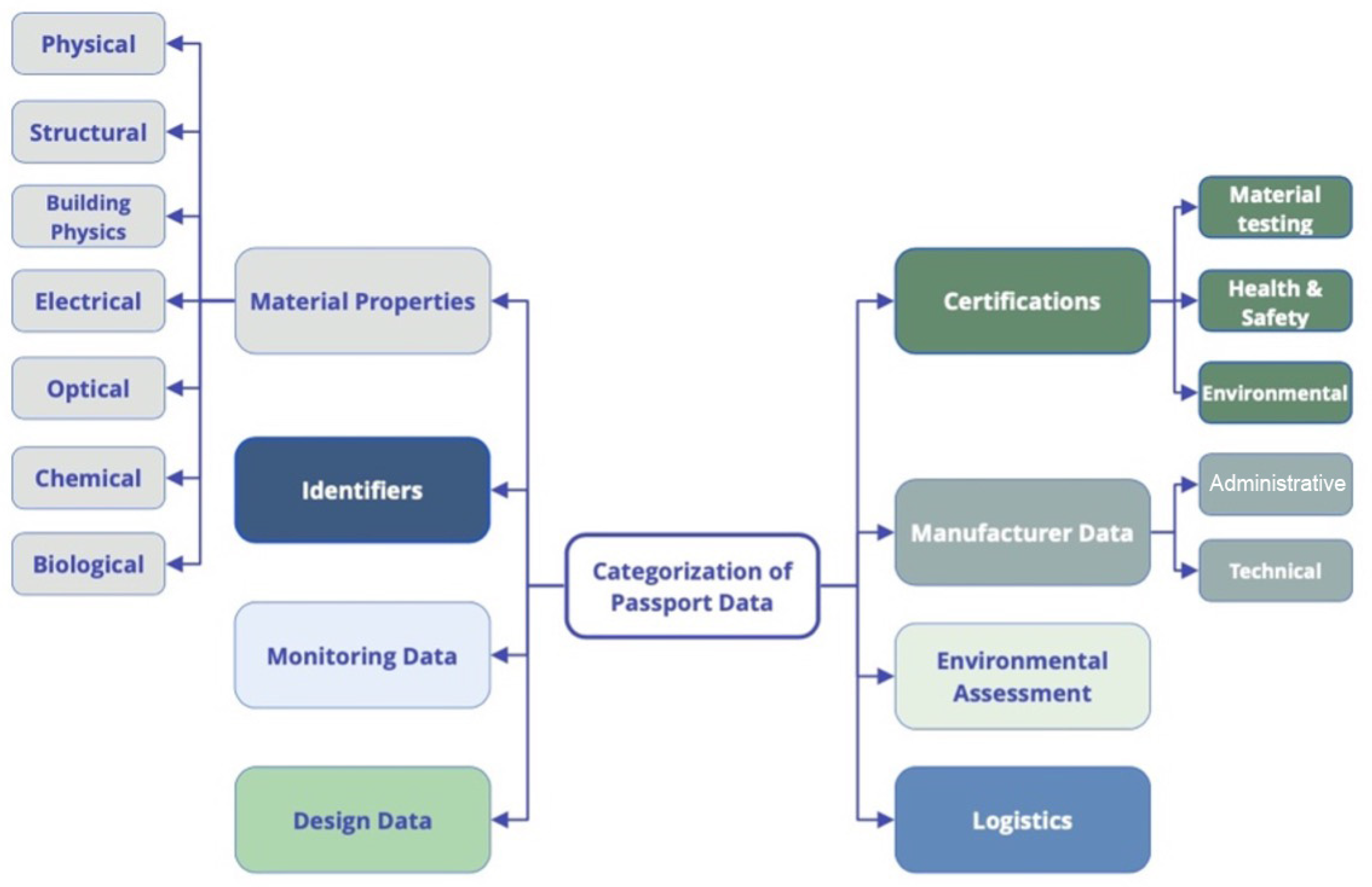

Buildings As Material Banks (BAMB): this MP describes data and their implementation strategies in the built environment. All necessary information about materials and products pertaining to CE is hierarchically categorized into several levels (Figure 1) such as material properties, certifications, logistics, etc. The project has also established a digital platform which connects individual components of the buildings by displaying their uses and values in the marketplace [30].

-

3XN Architects: this MP provides guidelines to collect CE data across a building’s lifecycle stages. The collected data need to be linked to a database enabling traceability of all building components and parts with their technical and functional specifications [36].

-

Madaster: this project frames MP data based on the building’s layers (e.g., structure, skin, services, etc.). The MP also provides circularity indicators to calculate the amount of virgin, recycled, reused, and renewable materials that are incorporated within a building. Madaster’s cloud platform can connect to Building Information Modeling (BIM)-based models and allows users to create and develop a unique passport for buildings or objects [37].

2.2. Concept of Traceability across Domains

Traceability of materials and products is recognized as one of the major concerns in an increasing number of CE studies and practices across various domains [44]. Although there is no definitional ambiguity that encompasses all aspects of traceability [17], the notion of “traceability” has been defined in the literature as listed in Table 1.

| Ref | Definition | Context | Year |

|---|---|---|---|

| [45] | “The ability to trace the history, application, or location of an entity by means of recorded identifications”. | ISO8402 | 1994 |

| [40] | “The ability to access any or all information relating to that which is under consideration, throughout its e tire lifecycle, by means of recorded identifications”. | Food industry | 2018 |

| [46] | “Client requirements have to be presented in a manner that will facilitate: (…) [t]he traceability of design decisions to original requirements throughout the life cycle of the facility”. | AEC 1 | 2000 |

| [47] | “Traceability involves knowing where the product or raw material comes from, real-time location throughout the supply chain, and its conditions regarding pre-set quality at each stage of the roadmap”. | AEC | 2021 |

| [13] | “The ability to follow information related to a product through its supply chain” (p. 3) providing a number of uses: quality and safety, minimizing scandals that damage company reputations, improved supply chains, and enhancing trust”. | AEC | 2017 |

2.3. Traceability in the Built Asset Industry

2.4. Summary

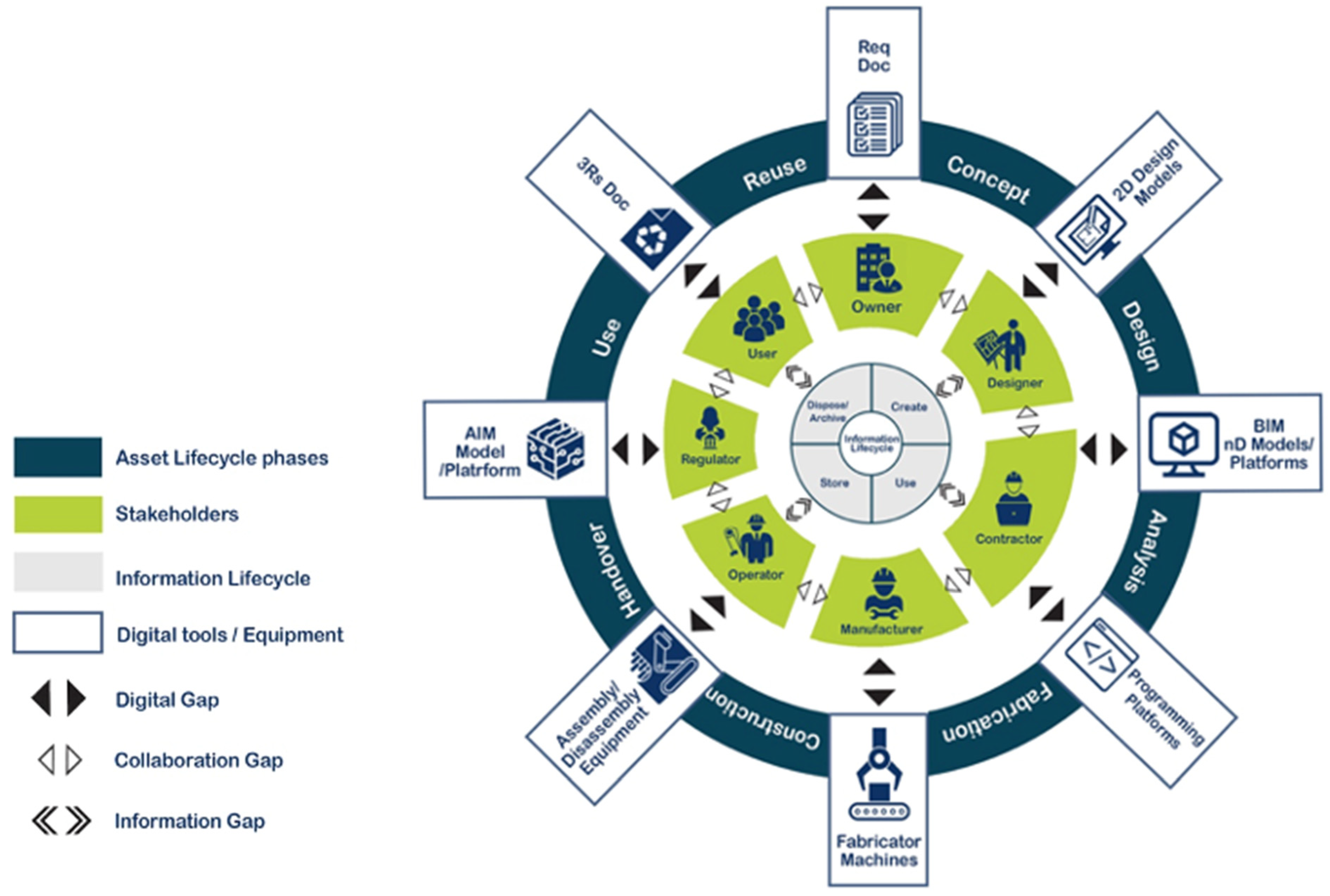

Despite the increasing interest in traceability of materials and products throughout built asset lifecycle stages, there is a notable lack of research and understanding around its framing, application and integration into existing standards, strategies, and guidelines to support implementation [13]. Stantana and Ribeiro [11] conducted a comprehensive literature review to map the existing traceability models and frameworks across domains. The authors of the study listed a few traceability models in the construction sector with a focus on effectiveness of technological systems (e.g., RFID system, GPS tags, blockchain technology) for tracking the building fabrication process or construction site logistics [60][61]. To date, only a few studies have highlighted other aspects of traceability in the built asset industry and discussed the actions needed to enable circularity of building materials and products across lifecycle stages [13][14]. This includes poor understanding of the main types of data enabling traceability, lifecycle stages where data can be potentially traced, key technologies to facilitate traceability in data management and documentation, and the relationship among stakeholders involved in the traceability process. These gaps in the literature are significant, as they prevent a complete understanding of the concept of traceability through the lens of CE. Current research often emphasizes single aspects of traceability, such as documentation management or change control, rather than examining the broader impact of traceability on the circularity of products and materials. Therefore, there is a need for further research to investigate the relationship between different aspects of traceability and their potential to support CE principles in the built asset industry. Such research can provide valuable insights for industry practitioners and policymakers, deriving progress towards a more sustainable and circular built environment.

References

- Laski, J.; Burrows, V. From Thousands to Billions: Coordinated Action Towards 100% Net Zero Carbon Buildings by 2050. 2017. Available online: https://apo.org.au/node/118366 (accessed on 13 March 2023).

- Geissdoerfer, M.; Savaget, P.; Bocken, N.M.P.; Hultink, E.J. The Circular Economy—A new sustainability paradigm? J. Clean. Prod. 2017, 143, 757–768.

- MahmoumGonbadi, A.; Genovese, A.; Sgalambro, A. Closed-loop supply chain design for the transition towards a circular economy: A systematic literature review of methods, applications and current gaps. J. Clean. Prod. 2021, 323, 129101.

- Grafström, J.; Aasma, S. Breaking circular economy barriers. J. Clean. Prod. 2021, 292, 126002.

- Charef, R.; Ganjian, E.; Emmitt, S. Socio-economic and environmental barriers for a holistic asset lifecycle approach to achieve circular economy: A pattern-matching method. Technol. Forecast. Soc. Chang. 2021, 170, 120798.

- Kumar, M.; Raut, R.D.; Jagtap, S.; Choubey, V.K. Circular economy adoption challenges in the food supply chain for sustainable development. Bus. Strateg. Environ. 2022, bse.3191.

- Mousavi, A.; Sarhadi, M.; Lenk, A.; Fawcett, S. Tracking and traceability in the meat processing industry: A solution. Br. Food J. 2002, 104, 7–19.

- Jaeger, B.; Upadhyay, A. Understanding barriers to circular economy: Cases from the manufacturing industry. J. Enterp. Inf. Manag. 2020, 33, 729–745.

- Fischer, A.; Pascucci, S. Institutional incentives in circular economy transition: The case of material use in the Dutch textile industry. J. Clean. Prod. 2017, 155, 17–32.

- Giovanardi, M.; Konstantinou, T.; Pollo, R.; Klein, T. Internet of Things for building façade traceability: A theoretical framework to enable circular economy through life-cycle information flows. J. Clean. Prod. 2023, 382, 135261.

- Santana, S.; Ribeiro, A. Traceability Models and Traceability Systems to Accelerate the Transition to a Circular Economy: A Systematic Review. Sustainability 2022, 14, 5469.

- Corallo, A.; Latino, M.E.; Menegoli, M.; Pontrandolfo, P. A systematic literature review to explore traceability and lifecycle relationship. Int. J. Prod. Res. 2020, 58, 4789–4807.

- Katenbayeva, A.; Jacqui, G.; Anvuur, A.; Ghumra, S. Developing a Theoretical Framework of Traceability for Sustainability in the Construction Sector. 2017. Available online: https://hdl.handle.net/2134/23842 (accessed on 13 March 2023).

- Trautman, D.; Goddard, E.; Nilsson, T. Traceability—A Literature Review. Available online: https://era.library.ualberta.ca/items/921e1026-7e1a-4add-a631-5114d6a2171f (accessed on 13 March 2023).

- Garcia-Torres, S.; Albareda, L.; Rey-Garcia, M.; Seuring, S. Traceability for sustainability—Literature review and conceptual framework. Supply Chain Manag. Int. J. 2019, 24, 85–106.

- Hackitt, D.J. Building a Safer Future. 2018. Available online: https://www.longworth-uk.com/wp-content/uploads/2018/07/Building-a-Safer-Future-Overview.pdf (accessed on 20 January 2023).

- Watson, R.; Kassem, M.; Li, J. Traceability for Built Assets: Proposed Framework for a Digital Record. In Proceedings of the Creative Construction Conference 2019, Budapest, Hungary, 29 June–2 July 2019; Budapest University of Technology and Economics: Budapest, Hungary, 2019; pp. 496–501.

- Voorter, J.; Koolen, C. The Traceability of Construction and Demolition Waste in Flanders via Blockchain Technology: A Match Made in Heaven? J. Eur. Environ. Plan. Law 2021, 18, 347–369.

- Falleri, J.-R.; Huchard, M.; Nebut, C. Towards a traceability framework for model transformations in Kermeta. In ECMDA-TW’06: ECMDA Traceability Workshop; Sintef ICT: Trondheim, Norway, 2006.

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232.

- Michelini, G.; Moraes, R.N.; Cunha, R.N.; Costa, J.M.H.; Ometto, A.R. From Linear to Circular Economy: PSS Conducting the Transition. Procedia CIRP 2017, 64, 2–6.

- Sohal, A.; De Vass, T. Australian SME’s experience in transitioning to circular economy. J. Bus. Res. 2022, 142, 594–604.

- Dan, M.C.; Østergaard, T. Circular Fashion: The New Roles of Designers in Organizations Transitioning to a Circular Economy. Des. J. 2021, 24, 1001–1021.

- Wuni, I.Y. Mapping the barriers to circular economy adoption in the construction industry: A systematic review, Pareto analysis, and mitigation strategy map. Build. Environ. 2022, 223, 109453.

- Cantú, A.; Aguiñaga, E.; Scheel, C. Learning from Failure and Success: The Challenges for Circular Economy Implementation in SMEs in an Emerging Economy. Sustainability 2021, 13, 1529.

- Honic, M.; Kovacic, I.; Sibenik, G.; Rechberger, H. Data- and stakeholder management framework for the implementation of BIM-based Material Passports. J. Build. Eng. 2019, 23, 341–350.

- Pitkänen, K.; Karppinen, T.K.M.; Kautto, P.; Pirtonen, H.; Salmenperä, H.; Savolahti, H.; Schubin, E.; Myllymaa, T. How to measure the social sustainability of the circular economy? Developing and piloting social circular economy indicators in Finland. J. Clean. Prod. 2023, 392, 136238.

- Debacker, W.; Manshoven, S.; Denis, F. D1 Synthesis of the State-of-the-Art: Key Barriers and Opportunities for Materials Passports and Reversible Building Design in the Current System; BAMB Horizon. 2016. Available online: http://www.bamb2020.eu/wp-content/uploads/2016/03/D1_Synthesis-report-on-State-of-the-art_20161129_FINAL.pdf (accessed on 13 March 2023).

- Kedir, F.; Bucher, D.F.; Hall, D.M. A Proposed Material Passport Ontology to Enable Circularity for Industrialized Construction. In Proceedings of the EC3 Conference 2021, Online Events, 19–28 July 2021; pp. 91–98.

- Heinrich, M.; Lang, W. Materials Passports-Best Practice; Technische Universität München, Fakultät für Architektur: Munich, Germany, 2019; p. 74.

- Honic, M.; Kovacic, I.; Rechberger, H. Concept for a BIM-based Material Passport for buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 225, 012073.

- Plociennik, C.; Pourjafarian, M.; Nazeri, A.; Windholz, W.; Knetsch, S.; Rickert, J.; Ciroth, A.; Precci Lopes, A.D.C.; Hagedorn, T.; Vogelgesang, M.; et al. Towards a Digital Lifecycle Passport for the Circular Economy. Procedia CIRP 2022, 105, 122–127.

- Jensen, S.F.; Kristensen, J.H.; Adamsen, S.; Christensen, A.; Waehrens, B.V. Digital product passports for a circular economy: Data needs for product life cycle decision-making. Sustain. Prod. Consum. 2023, 37, 242–255.

- Hoosain, M.S.; Paul, B.S.; Raza, S.M.; Ramakrishna, S. Material Passports and Circular Economy. In An Introduction to Circular Economy; Liu, L., Ramakrishna, S., Eds.; Springer: Singapore, 2021; pp. 131–158. ISBN 9789811585098.

- Holla, A. External Supervisor: Monique Fledderman; VMRG: Nieuwegein, The Netherlands, 2017; p. 180.

- 3XN Architects. Buidling a Circular Future, 3rd ed.; 3XN Architects: Copenhagen, Denmark, 2018.

- Druijff, B. BIM-Based Material Passport in Madaster during the Operational and Maintenance Phase of a Building. Bachelor’s Thesis, University of Twente, Enschede, The Netherlands, 2019.

- Kintscher, L.; Lawrenz, S.; Poschmann, H. A Life Cycle Oriented Data-Driven Architecture for an Advanced Circular Economy. Procedia CIRP 2021, 98, 318–323.

- Lawrenz, S.; Nippraschk, M.; Wallat, P.; Rausch, A.; Goldmann, D.; Lohrengel, A. Is it all about Information? The Role of the Information Gap between Stakeholders in the Context of the Circular Economy. Procedia CIRP 2021, 98, 364–369.

- Saaksvuori, A.; Immonen, A. Product Lifecycle Management; Springer: Berlin/Heidelberg, Germany, 2008; ISBN 978-3-540-78173-8.

- European Environment Agency. Circular Economy in Europe: Developing the Knowledge Base; European Environment Agency: Copenhagen, Denmark, 2016.

- de Lange, P.; Bähre, B.; Finetti-Imhof, C.; Klamma, R.; Oppermann, L. Socio-Technical Challenges in the Digital Gap between Building Information Modeling and Industry 4.0. In Proceedings of the , Essen, Germany, 13 June 2017; pp. 33–46.

- Poirier, E.; Forgues, D.; Staub-French, S. Collaboration through innovation: Implications for expertise in the AEC sector. Constr. Manag. Econ. 2016, 34, 769–789.

- Gotel, O.C.Z.; Finkelstein, C.W. An analysis of the requirements traceability problem. In Proceedings of the IEEE International Conference on Requirements Engineering, Colorado Springs, CO, USA, 18–22 April 1994; IEEE Computer Society Press: Colorado Springs, CO, USA, 1994; pp. 94–101.

- Wang, K.-S. Intelligent and integrated RFID (II-RFID) system for improving traceability in manufacturing. Adv. Manuf. 2014, 2, 106–120.

- Kamara, J.M.; Anumba, C.J.; Evbuomwan, N.F.O. Establishing and processing client requirements—A key aspect of concurrent engineering in construction. Eng. Constr. Archit. Manag. 2000, 7, 15–28.

- Brandín, R.; Abrishami, S. Information traceability platforms for asset data lifecycle: Blockchain-based technologies. Smart Sustain. Built Environ. 2021, 10, 364–386.

- de Lusignan, S.; Liaw, S.-T.; Krause, P.; Curcin, V.; Vicente, M.; Michalakidis, G.; Agreus, L.; Leysen, P.; Shaw, N.; Mendis, K. Key Concepts to Assess the Readiness of Data for International Research: Data Quality, Lineage and Provenance, Extraction and Processing Errors, Traceability, and Curation: Contribution of the IMIA Primary Health Care Informatics Working Group. Yearb. Med. Inform. 2011, 20, 112–120.

- Pearson, S.; May, D.; Leontidis, G.; Swainson, M.; Brewer, S.; Bidaut, L.; Frey, J.G.; Parr, G.; Maull, R.; Zisman, A. Are Distributed Ledger Technologies the panacea for food traceability? Glob. Food Secur. 2019, 20, 145–149.

- Moe, T. Perspectives on Traceability in Food Manufacture. Trends Food Sci. Technol. 1998, 9, 211–214.

- Senneset, G.; Forås, E.; Fremme, K.M. Challenges regarding implementation of electronic chain traceability. Br. Food J. 2007, 109, 805–818.

- Anastasiadis, F. Designing a Traceability Framework for Sustainable Agri-Food Supply Chains. In Food Policy Modelling; Mattas, K., Baourakis, G., Zopounidis, C., Staboulis, C., Eds.; Cooperative Management; Springer International Publishing: Cham, Switzerland, 2022; pp. 73–82. ISBN 978-3-031-08316-7.

- BRE Global Ltd. BES 6001: ISSUE 3.0; Framework Standard for Responsible Sourcing; BREGroup: Watford, UK, 2014.

- Norton, T.; Beier, J.; Shields, L. A Guide to Traceability. 2014. Available online: https://bregroup.com/services/standards/bes-6001-the-framework-standard-for-responsible-sourcing/ (accessed on 25 March 2023).

- Beliatis, M.J.; Jensen, K.; Ellegaard, L.; Aagaard, A.; Presser, M. Next Generation Industrial IoT Digitalization for Traceability in Metal Manufacturing Industry: A Case Study of Industry 4.0. Electronics 2021, 10, 628.

- EU. EEA Regulation (EU) No 305/2011 of the European Parliament and of the Council. EUR-Lex; 2011. Available online: https://www.legislation.gov.uk/eur/2011/305/contents (accessed on 20 March 2023).

- Wright, B. Compilation of Various Questions and Answers about EPA Traceability Protocol for Gaseous Calibration Standards. 2020. Available online: https://www.epa.gov/sites/default/files/2020-04/documents/questions_answers_protocol_200331.pdf. (accessed on 20 March 2023).

- Sarsam, S.I. Sustainable and Green Roadway Rating System. Int. J. Sci. Res. Environ. Sci. 2015, 3, 99–106.

- Pinheiro, C. Requirements traceability. Perspect. Softw. Requir. 2004, 91–113.

- Wang, J.; Chi, H.-L.; Shou, W.; Chong, H.-Y.; Wang, X. A Coordinated Approach for Supply-Chain Tracking in the Liquefied Natural Gas Industry. Sustainability 2018, 10, 4822.

- Ergen, E.; Akinci, B.; Sacks, R. Tracking and locating components in a precast storage yard utilizing radio frequency identification technology and GPS. Autom. Constr. 2007, 16, 354–367.