Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Thomas Rumetshofer | -- | 1488 | 2023-04-24 18:43:10 | | | |

| 2 | Camila Xu | Meta information modification | 1488 | 2023-04-25 08:08:59 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Rumetshofer, T.; Fischer, J. Plastic Material Tracking for Circular Economy. Encyclopedia. Available online: https://encyclopedia.pub/entry/43407 (accessed on 28 February 2026).

Rumetshofer T, Fischer J. Plastic Material Tracking for Circular Economy. Encyclopedia. Available at: https://encyclopedia.pub/entry/43407. Accessed February 28, 2026.

Rumetshofer, Thomas, Jörg Fischer. "Plastic Material Tracking for Circular Economy" Encyclopedia, https://encyclopedia.pub/entry/43407 (accessed February 28, 2026).

Rumetshofer, T., & Fischer, J. (2023, April 24). Plastic Material Tracking for Circular Economy. In Encyclopedia. https://encyclopedia.pub/entry/43407

Rumetshofer, Thomas and Jörg Fischer. "Plastic Material Tracking for Circular Economy." Encyclopedia. Web. 24 April, 2023.

Copy Citation

Plastics are very versatile materials used in many different applications in everyday life all over the world, with substantial benefits such as durability, flexibility, low weight, and lower cost compared to other alternatives.

plastic material

traceability

circular economy

physical tracking

1. Introduction

Plastics are very versatile materials used in many different applications in everyday life all over the world, with substantial benefits such as durability, flexibility, low weight, and lower cost compared to other alternatives [1][2]. Global plastics production in 2020 without recycled plastics was 367 million tons, with a share of 55 million tons attributed to Europe [3]. The majority of these materials are fossil-based and contribute to a linear economy.

This linear economy of plastics, consisting of produce-use-dispose, creates problems such as the leaking of materials into the environment and the emitting of CO2 through incineration. Every year, an estimated amount of 4.8 to 12.7 million tons of plastics enters the ocean from coastal countries [4]. In 2020, an amount of 29.5 million tons of post-consumer plastic waste (PCW) was collected within Europe. From this PCW stream, 23.4% was landfilled, 42.0% went into incineration, and 34.6% passed toward recycling [3]. The gap of approximately 25.5 million tons between plastic production and plastic waste collection comes mainly from the different lifespan of products leading to the accumulation of plastic products, which reflects its future potential as feedstock for recycling.

One proposed solution to overcome the above-mentioned hurdles connected to the use of plastics in a linear economy is a transformation into a circular economy to keep materials in the loop and reduce the consumption of fossil resources [5]. Circular economy models are inspired by natural processes and can be applied in many areas. There is no archetypal form of circular economy available that enables the solution of every problem. The prevention of waste, optimized material flow, maximized resource recovery, and energy-from-waste are a few advantages of circular economy models [6]. In the literature, more than 30 different definitions of “circular economy” are known, closely related to resource and environmental concepts [7].

Politicians from the European Commission have also realized problems around plastics and published in 2015 an action plan for a circular economy dealing with marine litter, hazardous chemical additives, and the recycling of plastic packaging [8]. Based on this action plan, a European strategy for plastics was brought on the way in 2018 as a framework for driving innovation, investments, and circular solutions [9].

2. Complexity in Plastics Recycling and Scope

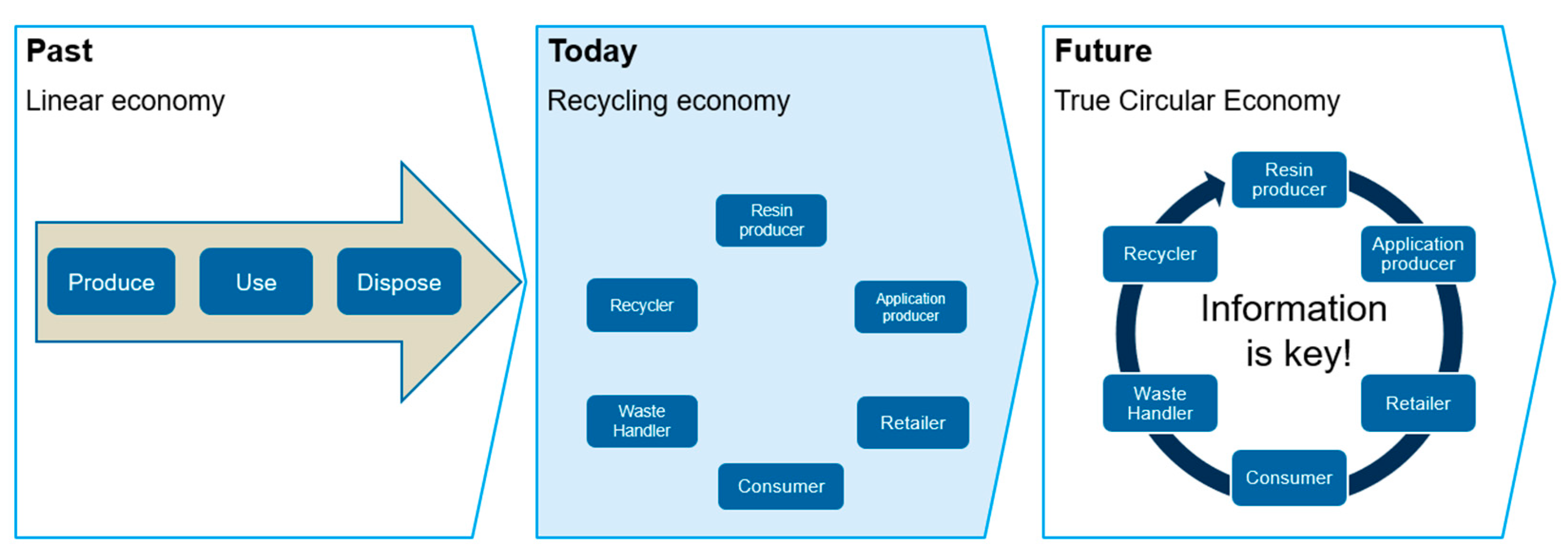

Figure 1 illustrates business models for the past, current, and future plastics industry. In the past, a linear economy model consisting of make, use, and dispose was favored, whereas, nowadays, the preferred model reflects a circular economy and consists of the connection and interaction of all players along the plastic value chain (VC). The main obstacles in today’s recycling model are the lack of information sharing between all players along the VC and its increasing complexity.

Figure 1. Business models of plastics industry for past, present, and future.

One side of the increasing complexity and pressure for the plastics industry comes from European legislation through increased recycling targets, as mentioned in the section above. Simultaneously, clear guidance and definitions around recyclability, recycling, recycling technologies, and quality criteria are missing [10]. For example, food contact material (FCM) obtained from recyclates is a legally very complex topic in European law [11].

In some cases, the use of alternative materials instead of fossil-based plastics is realized without considering implications for all players along the value chain. Alternative materials can be bio-degradable polymers, paper, glass, cotton, and others. As consumers, waste management systems, and recycling systems are not suited for these materials, these material changes create additional irritation and complexity within usage, recycling, and end-of-life solutions [12]. It is essential to emphasize that alternative material solutions very often arise only as a result of trends and do not always bring ecological or economic advantages. For example, a recent study on plastic carrier bags and their alternatives showed an environmental benefit of at least 50% for the plastic-based solutions compared to the alternatives in the evaluated scenarios [13]. As another example, the deployment of carbon-only backbone polymers, containing pro-oxidant additives, can help to reduce the breakdown time of littered plastics, with the downside of irritation in the circular economy [14].

A further reason to enhance the complexity of plastics recycling is the high variability in material type and composition. Multilayer and composite materials, often not designed to be recyclable in established recycling streams, lead to more efforts in separation and recycling operations. Furthermore, already recycled material enters the plastic value chain in large volumes, along with other newly established routes such as bio-based, chemically recycled, or bio-degradable materials. For example, wood-plastic composites (WPCs), which contain up to 80% wood fibers, are now entering packaging applications [15]. The high filler content of these material solutions often has a negative impact on the recycling rates or the property profiles of the recyclates. In addition, colored plastics can influence recycling processes. In particular, carbon-black-colored polymers, which are not detectable by state-of-the-art sorting systems, pose a problem. They represent a large volume in automotive and electronic product applications [16]. These materials are lost for further recycling.

Engineers around the globe try to solve the problems around plastics recycling with the development of new technologies and production routes in the areas of gasification [17], solvent-based recycling [18], or chemical recycling [19]. This leads to a more complex landscape of possible technologies and products in the future.

On top of all the complexity that comes from legislation, materials, processes, and technologies, plastics recycling lacks comprehensive data management. Data on processes and products are generated but only used in the company’s own isolated premises, and are not shared with others [20].

A future business model needs to be able to transform the plastics industry into a true circular economy. Therefore, many changes are required, starting with the feedstock, the energy supply, and the collection system. A very important aspect is traceability and information exchange between all partners in the future value chain of the plastics industry. This solution can help overcome current hurdles and complexities.

3. Tracking Solutions for Plastics

In the context of this entry, tracking means the consistent following of material and information from feedstock to final product and beyond. Tracking without disruption is already established in some food supply chain areas to ensure food safety and quality without commercial fraud [21].

A reliable and consistent tracking system is always linked to additional efforts and costs along the value chain. On the other hand, for some applications, traceability is a prerequisite for a circular economy or can lead to a competitive advantage. Closed-loop systems, for example, require a certain knowledge on the origin and history of the material used. Mechanical recycling for FCM needs a defined amount of material previously used in food contact applications and the resulting recyclates should be free of harmful substances predetermined by the FDA or EFSA [11]. Consistently, the traceability of material and origin is inevitable if the carbon tax proposed by the European Commission or environmentally modulated taxes become a reality [22]. In all these cases, consistent and intelligent tracking can support bringing plastic products with a competitive advantage to the market. In addition, technological advances in physical and chemical tracking can contribute to circular economy ambitions [23].

A sustainable business model for plastics is defined as minimizing environmental damage through improved waste management, recovery of plastics from the environment, or reuse of plastics [24]. Traceability can support enhancing existing business models to make them more sustainable and it opens possibilities for different business models going along with the plastic value chain.

For the enhancement of an existing business model toward a more sustainable or circular business model, an additional value in one of the four following categories needs to be added [20]:

-

Generation of additional revenue through increased sales or market share generated by sustainability.

-

Sustainability enhancement of the own brand for employee engagement or to attract investors.

-

Cost savings from lower consumption of material or energy.

-

Risk reduction by increased reputation or decreased regulatory risk.

Besides improvements on already established businesses, consistent traceability can offer possibilities for a completely new set of business models linked to the circular economy of plastics [20]:

-

New products by circular inputs, including the use of bio-based or completely recyclable materials and the rethinking of product designs.

-

Data sharing platforms that provide access to data about products or materials.

-

Product as a service. Complete change in product ownership combined with a lease or rent model for products and resources.

-

Recovery of all forms of resources, by-products, and energy.

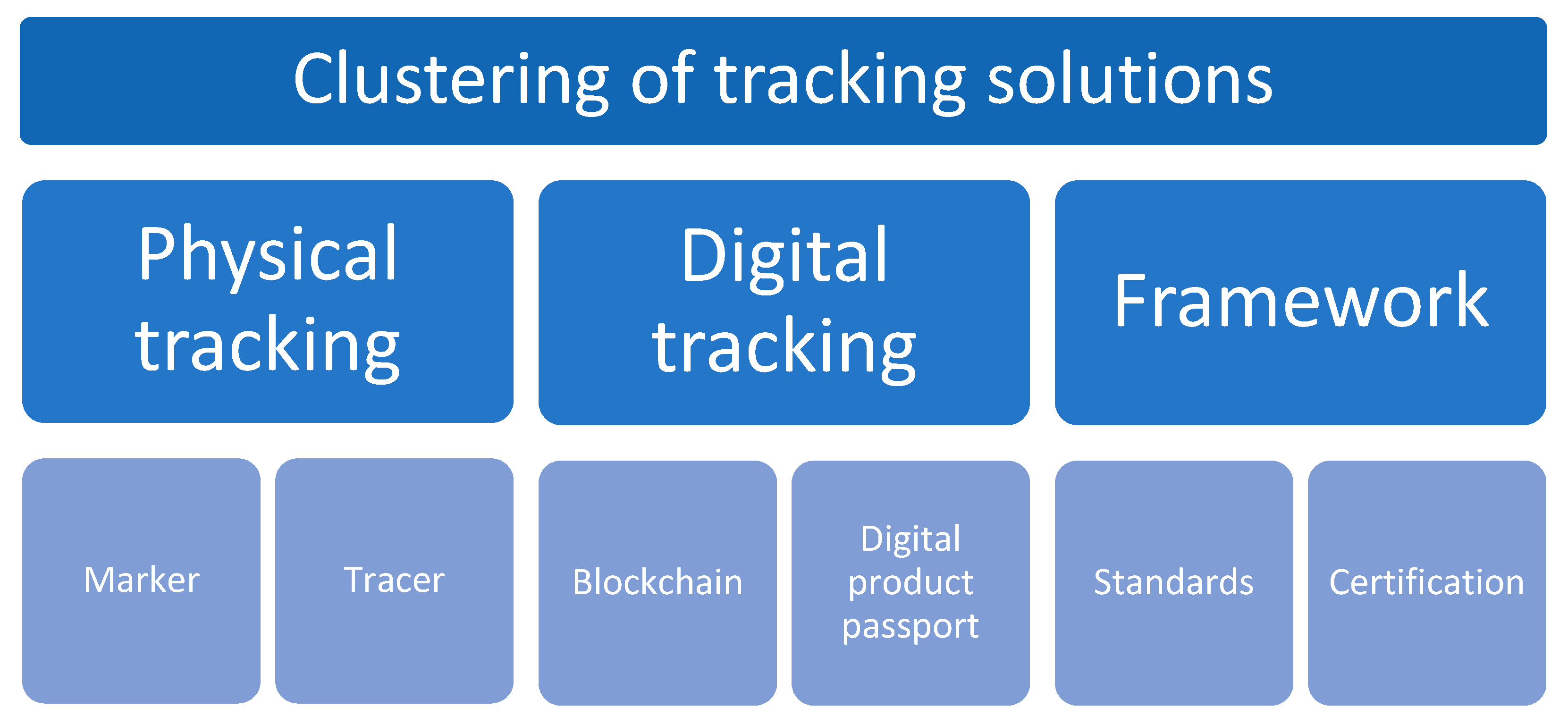

Traceability in the plastics industry can take a variety of forms, ranging from physical marking to a purely digital value. In many cases, it is necessary to combine a physical marking of materials and products with digital data to ensure uninterrupted information sharing. Figure 2 illustrates an overview of the different solutions for tracking in the plastics industry. In general, the various solutions can be divided into four categories:

Figure 2. Clustering of tracking solutions.

-

Marker or tracer for plastics.

-

Blockchain for plastics.

-

Digital product passport for plastics.

-

Certification systems for plastics.

References

- Eriksen, M.K.; Pivnenko, K.; Faraca, G.; Boldrin, A.; Astrup, T.F. Dynamic Material Flow Analysis of PET, PE, and PP Flows in Europe: Evaluation of the Potential for Circular Economy. Environ. Sci. Technol. 2020, 54, 16166–16175.

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastics recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 364, 2115–2126.

- Europe, P. Plastics—The Facts 2021—An Analysis of European Plastics Production, Demand and Waste Data; PlasticsEurope: Brussels, Belgium, 2021; Volume 34.

- Jambeck, J.R.; Geyer, R.; Wilcox, C.; Siegler, T.R.; Perryman, M.; Andrady, A.; Narayan, R.; Law, K.L. Plastic waste inputs from land into the ocean. Science 2015, 347, 768–771.

- Foundation, E.M. The New Plastics Economy—Rethinking of Plastics & Catalsing Action; World Economic Forum: Cologny, Switzerland, 2017; Volume 68.

- Velenturf, A.P.M.; Purnell, P. Principles for a sustainable circular economy. Sustain. Prod. Consum. 2021, 27, 1437–1457.

- Homrich, A.S.; Galvão, G.; Abadia, L.G.; Carvalho, M.M. The circular economy umbrella: Trends and gaps on integrating pathways. J. Clean. Prod. 2018, 175, 525–543.

- COM(2015) 614 final; Closing the Loop—An EU Action Plan for the Circular Economy. European Commission: Brussels, Belgium, 2015.

- COM (2018) 28; A European Strategy for Plastics in a Circular Economy. European Commission: Brussels, Belgium, 2018.

- Tonini, D.; Albizzati, P.F.; Caro, D.; De Meester, S.; Garbarino, E.; Blengini, G.A. Quality of recycling: Urgent and undefined. Waste Manag. 2022, 146, 11–19.

- De Tandt, E.; Demuytere, C.; Van Asbroeck, E.; Moerman, H.; Mys, N.; Vyncke, G.; Delva, L.; Vermeulen, A.; Ragaert, P.; De Meester, S.; et al. A recycler’s perspective on the implications of REACH and food contact material (FCM) regulations for the mechanical recycling of FCM plastics. Waste Manag. 2021, 119, 315–329.

- Matthews, C.; Moran, F.; Jaiswal, A.K. A review on European Union’s strategy for plastics in a circular economy and its impact on food safety. J. Clean. Prod. 2021, 283, 125263.

- Gómez, I.D.L.; Escobar, A.S. The dilemma of plastic bags and their substitutes: A review on LCA studies. Sustain. Prod. Consum. 2022, 30, 107–116.

- Chiellini, E.; Corti, A.; D’Antone, S.; Baciu, R. Oxo-biodegradable carbon backbone polymers—Oxidative degradation of polyethylene under accelerated test conditions. Polym. Degrad. Stab. 2006, 91, 2739–2747.

- Friedrich, D. Success factors of Wood-Plastic Composites (WPC) as sustainable packaging material: A cross-sector expert study. Sustain. Prod. Consum. 2022, 30, 506–517.

- Maris, E.; Aoussat, A.; Naffrechoux, E.; Froelich, D. Chapter 28—Recycling and Labeling. In Handbook of Recycling; Worrell, E., Reuter, M.A., Eds.; Elsevier: Boston, MA, USA, 2014; pp. 429–437.

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58.

- Zhao, Y.-B.; Lv, X.-D.; Ni, H.-G. Solvent-based separation and recycling of waste plastics: A review. Chemosphere 2018, 209, 707–720.

- Saebea, D.; Ruengrit, P.; Arpornwichanop, A.; Patcharavorachot, Y. Gasification of plastic waste for synthesis gas production. Energy Rep. 2020, 6, 202–207.

- Innovation, N. Data Sharing for a Circular Economy in the Nordics; Nordic Innovation: Oslo, Norway, 2021; Volume 53.

- Galimberti, A.; De Mattia, F.; Losa, A.; Bruni, I.; Federici, S.; Casiraghi, M.; Martellos, S.; Labra, M. DNA barcoding as a new tool for food traceability. Food Res. Int. 2013, 50, 55–63.

- Hájek, M.; Zimmermannová, J.; Helman, K.; Rozenský, L. Analysis of carbon tax efficiency in energy industries of selected EU countries. Energy Policy 2019, 134, 110955.

- Kahlert, S.; Bening, C.R. Why pledges alone will not get plastics recycled: Comparing recyclate production and anticipated demand. Resour. Conserv. Recycl. 2022, 181, 106279.

- Dijkstra, H.; van Beukering, P.; Brouwer, R. Business models and sustainable plastic management: A systematic review of the literature. J. Clean. Prod. 2020, 258, 120967.

More

Information

Subjects:

Polymer Science

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

781

Revisions:

2 times

(View History)

Update Date:

27 Apr 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No