Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | LEONIE ASFORA SARUBBO | -- | 3785 | 2023-02-14 13:06:55 | | | |

| 2 | Jason Zhu | Meta information modification | 3785 | 2023-02-15 03:33:06 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Roque, B.A.C.; Brasileiro, P.P.F.; Brandão, Y.B.; Casazza, A.A.; Converti, A.; Benachour, M.; Sarubbo, L.A. Self-Healing Concrete. Encyclopedia. Available online: https://encyclopedia.pub/entry/41215 (accessed on 08 February 2026).

Roque BAC, Brasileiro PPF, Brandão YB, Casazza AA, Converti A, Benachour M, et al. Self-Healing Concrete. Encyclopedia. Available at: https://encyclopedia.pub/entry/41215. Accessed February 08, 2026.

Roque, Bruno Augusto Cabral, Pedro Pinto Ferreira Brasileiro, Yana Batista Brandão, Alessandro Alberto Casazza, Attilio Converti, Mohand Benachour, Leonie Asfora Sarubbo. "Self-Healing Concrete" Encyclopedia, https://encyclopedia.pub/entry/41215 (accessed February 08, 2026).

Roque, B.A.C., Brasileiro, P.P.F., Brandão, Y.B., Casazza, A.A., Converti, A., Benachour, M., & Sarubbo, L.A. (2023, February 14). Self-Healing Concrete. In Encyclopedia. https://encyclopedia.pub/entry/41215

Roque, Bruno Augusto Cabral, et al. "Self-Healing Concrete." Encyclopedia. Web. 14 February, 2023.

Copy Citation

The production of cement accounts for 5 to 7% of carbon dioxide emissions in the world, and its broad-scale use contributes to climate imbalance. As a solution, biotechnology enables the cultivation of bacteria and fungi for the synthesis of calcium carbonate as one of the main constituents of cement. Through biomineralization, which is the initial driving force for the synthesis of compounds compatible with concrete, and crystallization, these compounds can be delivered to cracks in concrete. Microencapsulation is a method that serves as a clock to determine when crystallization is needed, which is assisted by control factors such as pH and aeration.

carbon dioxide

cement

biomineralization

energy saving

1. Concrete vs. Bioconcrete

Concrete is a basic mixture of cement, aggregates, and water that is widely used in civil construction. The high performance of concrete is attributed to the presence of chemical additives and mineral compounds in its composition, which are blended to obtain different characteristics and properties [1][2]. However, to fit into the definition of sustainable building material, some environmental burdens need to be minimized. One of the main reasons for this problem is the huge production of solid waste and frequently improper or clandestine disposal in dumps [3][4]. As a result, civil construction companies have established and mostly adopted the implementation of an environmental policy involving the definition of strategies, actions, and investments as well as institutional and juridical guidelines. The purpose is to ensure the quality of the environment, the conservation of biodiversity, and sustainable development [4].

Discussion on environmental issues is required, whose main goal should be sustainability in an attempt to find adequate solutions to eliminate or to reduce impacts that affect the environment and human health. To meet the demands of society, the civil construction industry has invested in new technologies, such as recycling, exploitation of solid waste, improvement of chemical products, etc. [5].

More than 1 m3 of concrete is produced per person every year, with the emission of approximately 100 kg of CO2 into the atmosphere during the production of one ton of concrete. This is mainly caused by the use of cement for the production of concrete to be used in most types of construction. Indeed, after water, cement is the most widely consumed material throughout the world. Cement production requires high energy consumption in the form of thermal energy through fuel burning to heat the rotary ovens to produce clinker, which is the basic material necessary for cement manufacture. Fuels that feed the ovens come mainly from non-renewable sources, such as oil, coal, coke, gasoline, and natural gas. During its life, concrete slowly absorbs CO2 in the process of carbonation, by which the Ca(OH)2 of concrete is converted into CaCO3. However, the quantity of concrete produced remains a significant source of anthropogenic CO2 emissions [6][7][8].

Cement is a ceramic material that produces an exothermic reaction when in contact with water and the crystallization of hydrated products, gaining mechanical strength. This favors the construction of dams, bridges, buildings, electricity posts, etc., which are subject to degradation due to atmospheric agents [9][10]. To repair cracks is more expensive than the manufacturing cost. Nowadays, some countries are investing a large amount of money in the maintenance and development of infrastructure. For example, the Netherlands spent one-third of the annual budget for major construction works on inspection, maintenance, and repair, while in the UK, this accounts for more than 45%. Therefore, all costs of production, as well as the repair of structures, need to be taken into consideration [3].

A self-healing bioconcrete containing a mixture of a composite with additives and bacteria can be used to provide greater protection and a better appearance. Bioconcrete can be used in posts, dams, and other construction projects to make the material stronger and avoid subsequent microcracks [11][12]. A bioconcrete based on a composite, additives (sand, gravel, etc.), spheres, and bacterial cells is in fact able to assist in diminishing the occurrence of corrosion, making the structures stronger through the healing of reinforced concrete. In particular, additives give the bioconcrete special characteristics or improvements in its properties, with each of them playing a specific role in its manufacturing [13][14].

As a sustainable option, self-healing concrete should reduce greenhouse gas emissions to the atmosphere. This can be achieved indirectly with lower CO2 emissions, since cement production alone is estimated to account for 7% of the total anthropogenic CO2, particularly due to the high temperatures in the production process (around 1500 °C). In this set of ideas, if inevitable cracks could be sealed without needing reparation, concrete structures will serve a longer service life, making it sustainable and reducing CO2 emissions on maintenance, repair, and production of new material. Since emissions should be avoided, reducing ammonia emissions by changing the hydrolysis of urea into calcium lactate should be also considered in order to increase the viability of the concrete [3].

Furthermore, bacterial cells can play a vital role in particular properties and self-healing processes via the precipitation process of CaCO3, which may help in accelerating the process of CO2 sequestration into bioconcrete. The process in which bacterial cells accelerate the sequestrations of CO2 could be explained as the result of the acceleration of the chemical hydration reaction used in the carbonation process. In this process, the CO2 gas diffuses through the solution producing CO2 (aq), HCO3− (aq), and CO32− (aq). The hydration reactions lead to the release of bicarbonate ions into the concrete mixture, which reacts with Ca in the cementation materials to form CaCO3 [15].

Alshalif et al. [16] carried out a survey to show the CO2 sequestration process in bio-foamed concrete bricks (B-FCB) using Bacillus tequilensis 401 as an acceleration factor of natural carbonation. The results revealed that the Bacillus tequilensis 401 accelerated CO2 sequestration in B-FCB by 30% compared to foamed concrete bricks (FCB). The highest carbonation depths were 9.2 mm and 11.9 mm for FCB and B-FCB at the optimized conditions, respectively. The increase in carbonation depth resulted in increased formation of calcium carbonate (CaCO3) in B-FCB compared to FCB, which was confirmed by microstructure analysis using a scanning electron microscope (SEM), energy dispersive X-ray (EDX), and X-ray diffraction (XRD).

2. Crack Repair and Healing Agents

Conventional reinforced concrete is subject to diverse physical and chemical factors that can exert a negative impact on its physical and mechanical characteristics over time, leading to the emergence of internal and external cracks [17].

Seasonal changes in temperature favor the formation of cracks in concrete due to thermal expansion and retraction, which causes the loss of a greater quantity of heat on the surface compared to the center, thereby increasing the temperature in the interior of the concrete in summer. Recurrent freezing and thawing in winter also degrade concrete. Moreover, as concrete is porous, the lixiviation of water and gases further favors its degradation [17][18].

A complementary solution is to increase the effectiveness of concrete structures, thereby reducing the need for replacement materials. Recovery is currently achieved through the periodic inspection and repair of the structure, which is a slow and expensive process. Concrete degradation generally occurs with the emergence of microcracks, difficult to see with the naked eye, which slowly grow to the point of enabling water and salt to reach the steel of the reinforced concrete, thus leading to corrosion and, ultimately, structural failure. Thus, there has been increasing interest by researchers in innovative technologies and the search for better additives. Self-healing concrete, i.e., a material with the incorporation of microorganisms, is one such technology, as certain bacteria are capable of repairing cracks, thereby prolonging the useful life of concrete structures [9][10][11].

Concrete is highly alkaline and a hostile environment for most microorganisms, but some bacteria are capable of growing in alkaline media with a pH of around 10–11 and can fill cracks in concrete through the production of CaCO3. However, such bacteria have been applied manually after the emergence of a crack, which means that regular inspection of the concrete structure is still necessary. Bacteria can be incorporated into the concrete along with calcium lactate and remain viable in a dormant state as spores. When a crack is formed, water infiltrates the concrete, activates the bacteria, and oxidizes calcium lactate, and the resulting insoluble calcium carbonate, precipitating, fills and repairs the crack. Thus, the combination of a high pH and CO2 helps bacteria further in the formation of carbonate [6][8][9][10].

Since bacterial spores can survive for decades without water and nutrients, concrete containing spores would ideally maintain its self-healing properties. However, Knoben [6] found that bioconcrete was unable to continue healing itself after only four weeks; nonetheless, the incorporation of bacteria and nutrients in clay capsules prior to mixing them with concrete greatly prolonged the useful life of structures.

The literature reports that the bacteria Bacillus pseudofirmus and Sporosarcina pasteurii have great efficiency in the production of calcium carbonate. They were found in alkaline lakes in the proximity of volcanoes and can remain dormant for up to 200 years. When cracks emerge in concrete, the bacteria are activated due to contact with air and moisture, and the calcium lactate incorporated into the concrete is transformed into CaCO3 sealing the cracks [17].

Biomineralization for the reconstitution of the concrete matrix has been studied mainly with regard to crack repair. Feurgard et al. [19], who studied the application of colloidal thickeners for the retention and cultivation of B. pseudofirmus, reported the repair of 150 to 800 µm cracks, while Su et al. [20] repaired even 4000 µm cracks using encapsulated Bacillus megaterium and calcium lactate.

3. Microencapsulation

Surface deterioration revealed by cracks can be repaired with materials such as silicates or mortar. Since such repair methods are time-consuming and expensive, the focus has recently been changed to the use of intelligent materials and techniques, such as microencapsulation, to prevent damage and minimize the deterioration of concrete structures [21].

Microencapsulation consists of the use of small solid particles, liquid droplets, or gases in a lining that can be used to protect, transport, and control the release of active compounds [22]. Microcapsules containing healing agents are incorporated into the concrete, and, when a crack emerges, it breaks the microcapsule shell, releasing the healing agents, whose interaction with a catalyst leads to the formation of a hydrated calcium silicate gel that fills the crack and avoids its propagation [21].

The advantage of microencapsulating microorganisms together with nutrients is the preservation of their metabolic activity by the creation of a microenvironment suitable for their development [23]. Microencapsulation also protects the cells from harm during the mechanical mixing of concrete [24].

Immobilization with polyurethane is widely used to prepare microcapsules containing bacteria and nutrients to be incorporated into bioconcrete, as this polymer is chemically stable, strong, and inert. Silica gel and expanded clay are other options [25]. Studies report that the addition of bacteria capable of inducing the biological production of calcium carbonate can significantly enhance the mechanical properties of mortar and concrete thanks to the deposition of a new layer of calcium carbonate among the particles, which serves as a ligand, diminishing the empty spaces between the sand and cement matrix [26].

4. pH and Aeration

Bacterial production of CaCO3 depends on several variables that affect self-regeneration performance, such as the concentration of dissolved organic carbon, calcium, pH, and location of nucleation [27]. Concrete has a pH of approximately 12 and is exposed to environmental conditions that can inhibit bacterial metabolism; therefore, a selection of bacteria that can tolerate high pH and also precipitate CaCO3 under such conditions is a major aspect of designing sustainable bioconcrete [28].

Studies indicate that the increase in pH accelerates CaCO3 precipitation. As the bacterial production of CaCO3 occurs under different environmental conditions, it is important to investigate the effect of pH on the efficiency of the biomineralization process. Thus, the bacteria selected for the process need to be well adapted to grow under alkaline conditions and induce CaCO3 precipitation [27].

Oxygen availability is another significant factor influencing the biomineralization of CaCO3. Aerobic microorganisms use oxygen for their growth, leading to the production of bioproducts under certain conditions; therefore, their production of CaCO3 can be enhanced if a sufficient quantity of oxygen is available in the medium.

Since metabolic pathways and fluxes can be affected by the oxygen transfer rate, the effect of oxygen on microbial growth and bioproducts has been widely documented. Zhang et al. [29] observed that the supply of oxygen can increase bacterial CaCO3 production. Some bioprocesses require a high oxygen transfer rate, whereas others, such as the calcium lactate pathway mentioned above, require a lower one to regulate oxygen uptake [27].

5. Biodeterioration of Concrete

Corrosion of steel reinforcement is a major durability issue of reinforced concrete structures using Portland cement concrete in many parts of the world. Concrete cracks are inevitable due to cement hydration shrinkage, hydration heat, and mechanical loading. The presence of cracks in concrete, regardless of their source and form, can have a considerable influence on the mechanism and dynamics of reinforcement corrosion of reinforced structures. Reinforcement corrosion in concrete is affected by moisture, chloride ions, and oxygen concentration and is closely related to the exposed area of reinforcement [30][31].

Corrosion is defined as an irreversible interfacial reaction between a metal, ceramic, or polymer material and the environment, which results in the consumption of the material or dissolution of a component of the environment in the material [32]. Corrosion of reinforcing steel, which leads to loss of its cross-sectional area, is considered the dominant type of deterioration of concrete infrastructure and is generally initiated due to the degradation of the protective barrier around the steel rod. Microorganisms can produce acids in concrete, lowering its pH, which enables the penetration of corrosion-causing agents, such as chloride ions, carbon dioxide, and moisture, into the concrete/steel interface [33].

The corrosion process is a complicated process related to external factors (the concentration of chloride and oxygen) and internal factors (resistance of mortar substrate and steel) that can be summarized as passivation–de-passivation–initial corrosion and corrosion propagation. Chloride, which participates in the formation of intermediate iron–chloride complexes and, ultimately, is not consumed, plays a vital role in the whole process of corrosion. The uncracked mortar can provide effective protection for steel from the invasion of corrosion agents. Although microcracks have a certain self-healing ability, microcracks can facilitate the initial corrosion of steel, and wider cracks seriously enhance corrosion [31].

Besides chemical processes, the durability of concrete is also influenced by biological agents including microorganisms. Hydrolytic enzymes and corrosive metabolites secreted by microorganisms such as acids can react with the bonding material on the concrete surface [34]. The production of sulfuric acid as a result of microbial activity and its subsequent reactions with concrete components that form expansive low-strength products is believed to be the mechanism underlying the deterioration of concrete, weakening its structural integrity, and diminishing its useful life. Favorable conditions, such as high relative humidity, a high concentration of carbon dioxide, chloride ions, other salts, sulfates, and small quantities of acids (low pH), stimulate microbial growth on the surface of concrete and increase the biodeterioration rate [33].

Biodeterioration occurs when biological activity results in the degradation of a desirable property of a structure [35]. This process can occur in concrete structures and other materials located in marine environments, including bridges and piers, or in conventional buildings and is often found in sanitation structures [36][37]. In recent decades, biodeterioration has become the focus of attention due to its significant economic impact [33].

Concrete structures are prone to deterioration by microorganisms that starts at the aggregate–cement paste interface [38]. These microorganisms may be algae, bacteria, fungi, or lichens [35][39][40], whose role in the biodeterioration of concrete can be classified as follows [33].

- (1)

-

Physical deterioration: the material structure is affected by microbial growth or movement (physical or mechanical breaking) [33];

- (2)

- (3)

-

Chemical deterioration: excretion of metabolites or other compounds, such as hydrogen sulfide and acids, adversely affects the concrete structural properties, e.g., increasing porosity, weakening mineral matrix, etc. [33].

Biological activity is often associated with the emission of acids that can dissolve minerals such as calcite, dolomite, and hydrated calcium silicate, which is the main component of cement. Moreover, even if the resulting salt is solid and insoluble (i.e., calcite or calcium oxalate), the reduction in pH of the solution in concrete pores causes the de-passivation of reinforcing steel, which initiates a process of concrete structure deterioration due to steel corrosion [36][42].

A sulfate attack is a deterioration process exclusive to concrete. Hydrated calcium aluminate and calcium aluminate monosulfate react with sulfur to form ettringite (hydrated calcium aluminum hydroxide sulfate), while hydrated calcium silicate reacts to form thaumasite. Both minerals have a greater volume than reagents and cause the disintegration of concrete [43].

6. Mechanical Properties, Durability, and Analysis Methods

The addition of bacteria in concrete is commonly reported to improve the mechanical (compressive and flexural strengths, modulus of elasticity, and toughness) and durability properties of concrete. This can be due to the reduction in the number of pores and the increase in compaction in the microstructure of the concrete, decreasing the potential entrance of chemicals and acids into the concrete [44].

Studies carried out by Nasser et al. [45] were capable to produce calcite crystals to block the micro-cracks in mortar matrix using Bacillus pasteurii and Bacillus sphaericus. The Bacillus sphaericus and Bacillus pasteurii improved the physico-mechanical properties with high restoration for load-deflection of bioconcrete. Scanning electron microscopy (SEM), energy Dispersive X-ray Spectrometer (EDAX), and differential thermal analysis (DTA) analyses verified that both strains induced bio-precipitation of calcite, which filled up the matrix pores, and decreased water absorption, capillary permeability, and volume of permeable voids, thus enhancing the physico-mechanical properties of bioconcrete. The bacterial bioactivity induced stiffer behavior when under the same load. Treated samples had less deformation as compared with the control. Both bacterial strains were considered promising for bio-application, and treated samples revealed better physical properties, mechanical performance, and self-healing of bioconcrete.

Smitha et al. [46] investigated the influence of Bacillus megaterium on the mechanical and durability properties of concrete. Based on the outcome of the study, it was found that the induction of B. megaterium into concrete mixtures can be used to improve the mechanical and durability properties of concrete. The optimal concentration of B. megaterium was found 105 cells/mL. Concrete made with 105 cells/mL B. megaterium exhibited compressive strength, split tensile strength, and flexural strength at 11.3%, 97.5%, and 8.6%, respectively, higher than that of the control at 28 days. Similarly, the chloride ion penetration and coefficient of water permeability of concrete incorporating the optimum cell concentration of B. megaterium was 26.8% and 98.7% lower than that of the control concrete. The enhancement in the properties of the concrete incorporating bacteria can be ascribed to the precipitation of the calcite and the presence of bacteria biomass within the matrix of the concrete, which results in the refinement of the microstructure. Scanning electron microscopy (SEM) images of the concrete mixtures showed that more calcite was produced in concrete made with B. megaterium at a concentration of 105 cells/mL. Energy Dispersive X-ray Analysis (EDX) results also confirmed the formation of calcite in concrete incorporating B. megaterium as it contains a higher amount of calcium compared to that of the control.

6.1. X-ray Microtomography

X-ray microtomography is a nondestructive method for the percentage determination of the volume of a self-regenerating agent in a cement matrix. The differentiation of phases is more difficult in more complex matrices. With this method, the volume is analyzed three-dimensionally and is separated into multiple regions. Image analysis is applied to classify and quantify each region of interest, which is analyzed to determine the characteristics of the control volume, such as the percentage of self-regenerating agents and distribution of particle size [47].

6.2. X-ray Diffractometry

X-ray diffractometry (XRD) is used for the determination of the purity of CaCO3 in concrete self-regeneration. This method enables the comparison of crystallographic profiles of minerals found in nature and the microbially produced CaCO3. An X-ray diffractometer basically has three main components: an X-ray source, an X-ray detector, and a plate with a crystal sample. The source and detectors have an angular range of 0 to 80°. The X-rays fired by the source diffract in the crystalline arrangement of the sample at a given angle and proceed to the detector under two forms of interference: constructive or destructive. If the rays are constructive, the amplitudes of the X-ray waves are summed, resulting in high wave intensities. Otherwise, the amplitudes of the waves are subtracted, resulting in low or null wave intensities [48].

When a sample with CaCO3 crystals is submitted to XRD analysis, three polymorphs are possible in the diffractograms: calcite, aragonite, and vaterite [49]. The diffractometer furnishes the diffractogram but does not analyze the crystal. Hence, an option for crystallographic analysis is to use software programs that are able to compare the diffractograms of pure components to those generated by the diffractometer. For instance, the HighScore Plus program has a vast crystallographic library and also enables the treatment of noise in the diffractograms, as well as the percentage analysis of intensity peaks, to determine the sample crystallographic distribution.

6.3. Scanning Electron Microscopy

Scanning electron microscopy (SEM) involves the use of an electron beam through the lenses of the microscope, which direct and focus the beam on the sample. This method enables obtaining a three-dimensional topography of chemical compounds and even microorganisms [50]. After XRD, SEM constitutes a confirmatory analysis for the elucidation of the ordered arrangement of atoms corresponding to CaCO3 [51]. With SEM, it is also possible to investigate the porosity of the material, possible microorganisms adhered to the surface of the concrete, and impurities that may be synthesized or crystallized after the biomineralization process [51].

6.4. Compression, Tensile, and Flexion Strength

The most practical applications that determine whether a concrete sample can support high loads are tests of compression, tensile, and flexion strength. To determine compression and tensile strength, the sample is submitted to two opposing axial forces at the extremities. The difference is that the sample is forced to diminish in volume during the compression test and forced to increase in volume during the tensile test. To determine flexion strength, the sample is submitted to three radial forces, two in one direction at the extremities and one in the opposite direction in the center [1].

6.5. Water Permeability

Pores in concrete have different size scales and, depending on their quantity, can enable water and other dissolved substances in the universal solvent to percolate through the concrete, carrying undesirable substances, such as chloride ions, which accelerate the corrosion process in reinforced concrete. Another disadvantage of excessive porosity is the formation of water paths in the concrete structure, reducing the strength of the material and causing accelerated wear [52].

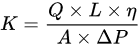

Experimentally, concrete blocks are immersed in water for the saturation of pores and the application of a flux. Equation (16) enables calculating the permeability (K) in a block of concrete of a given length (L) [52]:

where Q is the flux applied over an area A, η is the liquid dynamic viscosity, and ΔP is the difference in pressure.

References

- Neville, A.M. Properties of Concrete, 5th ed; Pearson: Bangalore, India, 2013; ISBN 978-8131791073.

- Shanks, W.; Dunant, C.F.; Drewniok, M.P.; Lupton, R.C.; Serrenho, A.; Allwood, J.M. How much cement can we do without? Lessons from cement material flows in the UK. Resour. Conserv. Recycl. 2019, 141, 441–454.

- Hossain, M.R.; Sultana, R.; Patwary, M.M.; Khunga, N.; Sharma, P.; Shaker, S.J. Self-healing concrete for sustainable buildings. A review. Environ. Chem. Lett. 2022, 20, 1265–1273.

- Ogunmakinde, O.E.; Egbelakin, T.; Sher, W. Contributions of the circular economy to the UN sustainable development goals through sustainable construction. Resour. Conserv. Recycl. 2022, 178, 106023.

- Xu, J.; Tang, Y.; Wang, X.; Wang, Z.; Yao, W. Application of ureolysis-based microbial CaCO3 precipitation in self-healing of concrete and inhibition of reinforcement corrosion. Constr. Build. Mater. 2020, 265, 120364.

- Knoben, W. Bacteria care for concrete. Mater. Today 2011, 14, 444.

- Vijay, K.; Murmu, M.; Deo, S.V. Bacteria based self healing concrete–A review. Constr. Build. Mater. 2017, 152, 1008–1014.

- Sidiq, A.; Gravina, R.; Giustozzi, F. Is concrete healing really efficient? A review. Constr. Build. Mater. 2019, 205, 257–273.

- Brasileiro, P.P.F.; Brandão, Y.B.; Sarubbo, L.A.; Benachour, M. Self-healing concrete: Background, development, and market prospects. Biointerface Res. Appl. Chem. 2021, 11, 14709–14725.

- Brasileiro, P.P.F.; Da Silva, R.C.F.S.; Silva, F.C.P.R.; Brandão, Y.B.; Sarubbo, L.A.; Benachour, M. Biomineralization of calcium carbonate by Bacillus cereus for self-healing biocement. Chem. Eng. Trans. 2020, 79, 97–102.

- Bai, C.P.; Varghese, S. An experimental investigation on the strength properties of fly ash based bacterial concrete. Int. J. Innov. Res. Adv. Eng. 2016, 3, 64–69.

- Ali, A.S.; Ojamy, S.T. Behavior of bio-concrete thick slab under repeated loading. Int. J. Innov. Res. Adv. Eng. 2017, 12, 1157–1170.

- Krishnapriya, S.; Venkatesh, B.D.L.; Prince, A.G. Isolation and identification of bacteria to improve the strength of concrete. Microbiol. Res. 2015, 174, 48–55.

- De Belie, N. Application of bacteria in concrete: A critical evaluation of the current status. RILEM Tech. Lett. 2016, 1, 56–61.

- Alshalif, A.F.; Irwan, J.M.; Othman, N.; Al-Gheethi, A.A.; Shamsudin, S. A systematic review on bio-sequestration of carbon dioxide in bio-concrete systems: A future direction. Eur. J. Environ. Civ. 2022, 26, 1209–1228.

- Alshalif, A.F.; Irwan, J.M.; Othman, N.; Al-Gheethi, A.A.; Shamsudin, S.; Nasser, I.M. Optimisation of carbon dioxide sequestration into bio-foamed concrete bricks pores using Bacillus tequilensis. J. CO2 Util. 2021, 44, 101412.

- Araujo, C.E.S.B.; Abreu, B.G.; Órfão, R.B.; Amarante, M.S. Bioconcreto. Revis. Dial. Interdisci. 2019, 8, 45–55.

- Lin, H.; Han, Y.; Liang, S.; Gong, F.; Han, S.; Shi, C.; Feng, P. Effects of low temperatures and cryogenic freeze-thaw cycles on concrete mechanical properties: A literature review. Constr. Build. Mater. 2022, 345, 128287.

- Feugard, I.; Lors, C.; Gagné, R.; Damidot, D. Use of colloidal thickeners to inject and retain bacterial growth media to repair cracked concrete. Constr. Build. Mater. 2020, 262, 1–8.

- Su, Y.; Zheng, T.; Qian, C. Application potential of Bacillus megaterium encapsulated by low alkaline sulphoaluminate cement in self-healing concrete. Constr. Build. Mater. 2021, 273, 1–13.

- Al-Ansari, M.; Abu-Taqa, A.G.; Hassan, M.M.; Senouci, A.; Milla, J. Performance of modified self-healing concrete with calcium nitrate microencapsulation. Constr. Build. Mater. 2017, 149, 525–534.

- Nazzaro, F.; Orlando, P.; Fratianni, F.; Coppola, R. Microencapsulation in food science and biotechnology. Curr. Opin. Biotechnol. 2012, 23, 182–186.

- Wang, J.; Mignon, A.; Snoeck, D.; Wiktor, V.; Van Vliergerghe, S.; Boon, N.; De Belie, N. Application of modified-alginate encapsulated carbonate producing bacteria in concrete: A promising strategy for crack self-healing. Front. Microbiol. 2015, 6, 1–14.

- Souradeep, G.; Kua, H.W. Encapsulation technology and techniques in self-healing concrete. J. Mater. Civ. Eng. 2016, 28, 1–15.

- Choi, S.G.; Hoang, T.; Park, S.S. Undrained behavior of microbially induced calcite precipitated sand with polyvinyl alcohol fiber. Appl. Sci. 2019, 9, 1–11.

- Wu, M.; Hu, X.; Zhang, Q.; Xue, D.; Zhao, Y. Growth environment optimization for inducing bacterial mineralization and its application in concrete healing. Constr. Build. Mater. 2019, 209, 631–643.

- Seifan, M.; Samani, A.K.; Berenjian, A. New insights into the role of pH and aeration in the bacterial production of calcium carbonate (CaCO3). Appl. Microbiol. Biotechnol. 2017, 101, 3131–3142.

- Kim, H.J.; Eom, H.J.; Park, C.; Jung, J.; Shin, B.; Kim, W.; Chung, N.; Choi, I.; Park, W. Calcium carbonate precipitation by Bacillus and sporosarcina strains isolated from concrete and analysis of the bacterial community of concrete. J. Microbiol. Biotechnol. 2015, 26, 540–548.

- Zhang, J.L.; Wang, C.G.; Wang, Q.L.; Feng, J.L.; Pan, W.; Zheng, X.C.; Liu, B.; Han, N.X.; Xing, F.; Deng, X. A binary concrete crack self-healing system containing oxygen-releasing tablet and bacteria and its Ca2+-precipitation performance. Appl. Microbiol. Biotechnol. 2016, 100, 10295–10306.

- Huyen Vu, T.; Dang, L.C.; Kang, G.; Sirivivatnanon, V. Chloride induced corrosion of steel reinforcement in alkali activated slag concretes: A critical review. Case Stud. Constr. Mater. 2022, 16, e01112.

- Feng, G.; Jin, Z.; Zhu, D.; Xiong, C.; Li, Z.; Wang, X. Corrosion propagation of steel reinforcement in pre-cracked mortar attacked by seawater using wire beam electrode. Corros. Sci. 2022, 208, 110655.

- International Union of Pure and Applied Chemistry (IUPAC). Compendium of Chemical Terminology (Gold Book), Version 2.3.3. 2014. Available online: https://goldbook.iupac.org/files/pdf/goldbook.pdf (accessed on 5 November 2021).

- Noeiaghaei, T.; Mukherjee, A.; Dhami, N.; Chae, S. Biogenic deterioration of concrete and its mitigation technologies. Constr. Build. Mater. 2017, 149, 575–586.

- Kip, N.; Van Veen, J. The dual role of microbes in corrosion. ISME J. 2015, 9, 542–551.

- Kenny, A. Bio-deterioration of stone and concrete by Melanopsis praemorsa in Gan-HaShlosha national par–A case study. Case Stud. Constr. Mater. 2020, 13, 1–9.

- Joorabchian, S.M. Durability of Concrete Exposed to Sulfuric Acid Attack. Masters Dissertation, Ryerson University, Toronto, ON, Canada, January 2010.

- Wei, S.; Sanchez, M.; Tejo, D.; Gills, C. Microbial mediated deterioration of reinforced concrete structures. Int. Biodeterior. Biodegra. 2010, 64, 748–754.

- Hughes, P.; Fairhurst, D.; Sherrington, I.; Renevier, N.; Morton, L.H.G.; Robery, P.C.; Cunningham, L. Microscopic study into biodeterioration of marine concrete. Int. Biodeterior. Biodegra. 2013, 79, 14–19.

- Antonelli, F.; Esposito, A.; Calvo, L.; Licursi, V.; Tisseyre, P.; Ricci, S.; Romagnoli, M.; Piazza, S.; Guerrieri, F. Characterization of black patina from the Tiber river embankments using next-generation sequencing. PLoS ONE 2020, 15, 1–24.

- George, R.P.; Ramya, S.; Ramachandran, D.; Kamachi, M.U. Studies on biodegradation of normal concrete surfaces by fungus Fusarium sp. Cem. Concr. Res. 2013, 47, 8–13.

- Coombes, M.A.; Naylor, L.A.; Viles, H.A.; Thompson, R.C. Bioprotection and disturbance: Seaweed, microclimatic stability and conditions for mechanical weathering in the intertidal zone. Geomorphology 2013, 202, 4–14.

- Turick, C.E.; Berry, C.J. Review of concrete biodeterioration in relation to nuclear waste. J. Environ. Radioact. 2016, 151, 12–21.

- Rahman, M.M.; Bassuoni, M.T. Thaumasite sulfate attack on concrete: Mechanisms, influential factors and mitigation. Constr. Build. Mater. 2014, 73, 652–662.

- Nodehi, M.; Ozbakkaloglu, T.; Gholampour, A. A systematic review of bacteria-based self-healing concrete: Biomineralization, mechanical, and durability properties. J. Build. Eng. 2022, 49, 104038.

- Nasser, A.A.; Sorour, N.M.; Saafan, M.A.; Abbasc, R.N. Microbially-Induced-Calcite-Precipitation (MICP): A biotechnological approach to enhance the durability of concrete using Bacillus pasteurii and Bacillus sphaericus. Heliyon 2022, 8, e09879.

- Smitha, M.P.; Suji, D.; Shanthi, M.; Adesina, A. Application of bacterial biomass in biocementation process to enhance the mechanical and durability properties of concrete. Clean. Mater. 2022, 3, 100050.

- Wang, X.; Chen, Z.; Ren, J.; Chen, S.; Xing, F. Object status identification of X-ray CT images of microcapsule-based self-healing mortar. Cem. Concr. 2022, 125, 1–15.

- Zhou, X.; Liu, D.; Bu, H.; Deng, L.; Liu, H.; Yuan, P.; Du, P.; Song, H. XRD-based quantitative analysis of clay minerals using reference intensity ratios, mineral intensity factors, Rietveld, and full pattern summation methods: A critical review. Solid Earth Sci. 2018, 3, 16–29.

- Visscher, A.D.; Vanderdeelen, J. IUPAC-NIST solubility data series: Alkaline earth carbonates in aqueous systems—Ca. J. Phys. Chem. 2012, 95, 1–137.

- Mazumder, M.; Ahmed, R.; Ali, A.W.; Lee, S.-J. SEM and ESEM techniques used for analysis of asphalt binder and mixture: A state of the art review. Constr. Build. Mater. 2018, 186, 313–329.

- Rais, M.S.; Khan, R.A. Effect of biomineralization technique on the strength and durability characteristics of recycled aggregate concrete. Constr. Build. Mater. 2021, 290, 1–16.

- Li, K.; Xu, L.; Stroeven, P.; Shi, C. Water permeability of unsaturated cementitious materials: A review. Constr. Build. Mater. 2021, 302, 1–19.

More

Information

Subjects:

Materials Science, Biomaterials

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.2K

Revisions:

2 times

(View History)

Update Date:

15 Feb 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No