| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Kinga Korniejenko | -- | 1614 | 2023-02-09 12:29:08 | | | |

| 2 | Peter Tang | Meta information modification | 1614 | 2023-02-10 02:12:07 | | |

Video Upload Options

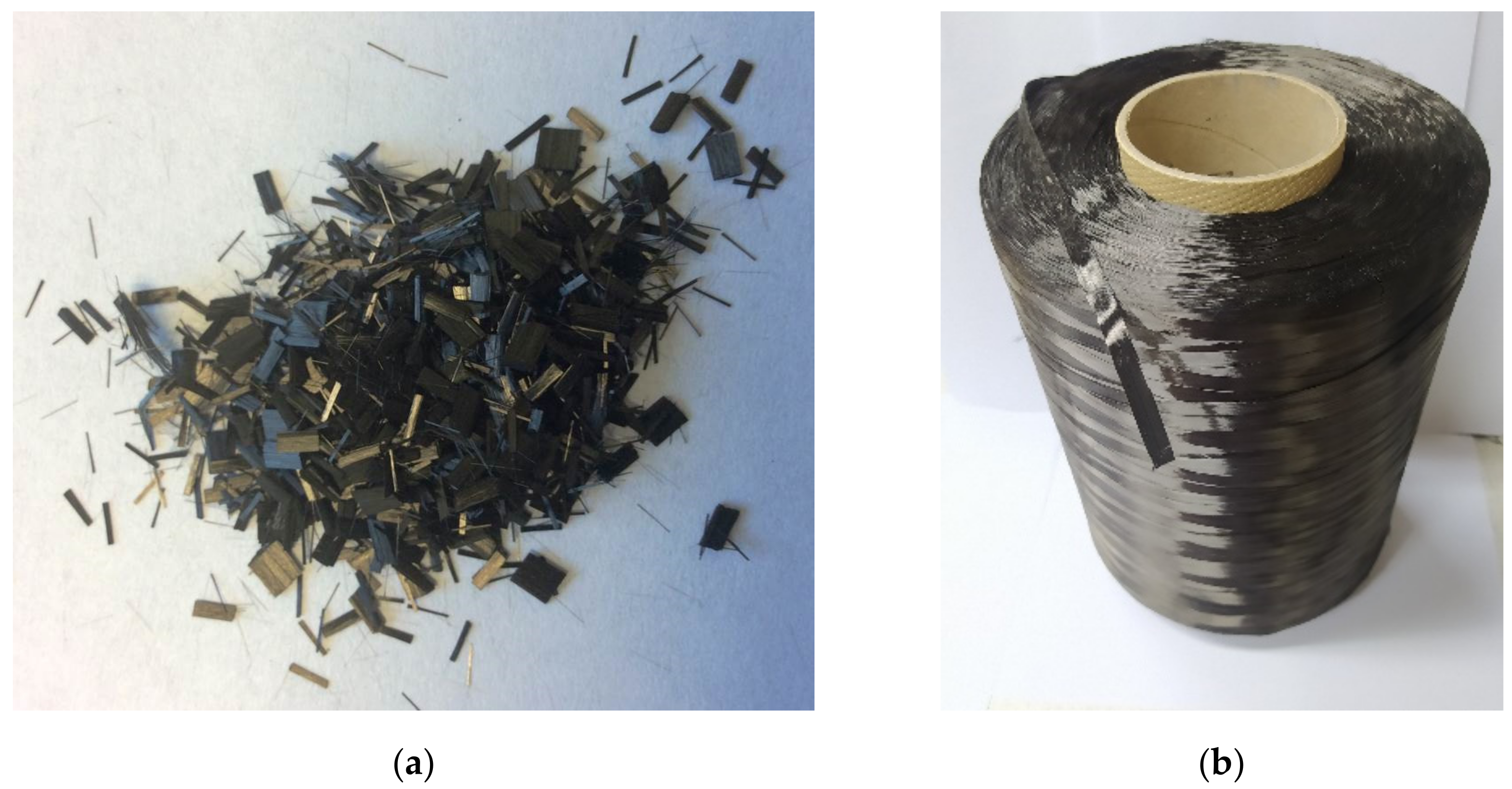

Carbon fibers (CFs) can be applied in different forms of occurrence in the geopolymer matrix. The most popular seem to be short CFs because they are easy to use for different applications. Most manufacturing methods do not require significant changes to implement the short fibers, despite the application of long fibers or textiles. However, several research works involved short fibers; a significant part of them concerns work made with the addition of long fiber fabrics as composite elements, carbon fiber felt, or similar forms, as well as the addition of other forms of carbon, i.e., graphene, graphite, or waste CF used in the manufacture of aviation products. The last three additives were introduced most frequently into geopolymers in the form of particles.

1. Short and Long Carbon Fibers

2. Textiles, Grids, and Fabrics

3. Carbon Microfibers, Nanofibers, and Carbon Nanotubes

4. Hybrid Reinforcement

References

- Yuan, J.; He, P.; Jia, D.; Yan, S.; Cai, D.; Xu, L.; Yang, Z.; Duan, X.; Wang, S.; Zhou, Y. SiC fiber reinforced geopolymer composites, part 1: Short SiC fiber. Ceram. Int. 2016, 42, 5345–5352.

- Amran, M.; Fediuk, R.; Abdelgader, H.S.; Murali, G.; Ozbakkaloglu, T.; Lee, Y.H.; Lee, Y.Y. Fiber-reinforced alkali-activated concrete: A review. J. Build. Eng. 2022, 45, 103638.

- Korniejenko, K.; Łach, M.; Mikuła, J. The Influence of Short Coir, Glass and Carbon Fibers on the Properties of Composites with Geopolymer Matrix. Materials 2021, 14, 4599.

- Korniejenko, K.; Figiela, B.; Ziejewska, C.; Marczyk, J.; Bazan, P.; Hebda, M.; Choińska, M.; Lin, W.-T. Fracture Behavior of Long Fiber Reinforced Geopolymer Composites at Different Operating Temperatures. Materials 2022, 15, 482.

- Farhan, K.Z.; Megat Johari, M.A.; Demirboğa, R. Impact of fiber reinforcements on properties of geopolymer composites: A review. J. Build. Eng. 2021, 44, 102628.

- Korniejenko, K. The Influence of Short Fibres on the Properties of Composites with Geopolymer Matrix. Ph.D. Thesis, Cracow University of Technology, Cracow, Poland, 2019.

- Diblíková, L.; Masek, Z.; Král, M. The effect of carbon fiber plasma treatment on the wettability and interlaminar shear strength of geopolymer composite. J. Aust. Ceram. Soc. 2019, 55, 1139–1145.

- Sun, J.; Zhao, F.; Yao, Y.; Jin, Z.; Liu, X.; Huang, Y. High efficient and continuous surface modification of carbon fibers with improved tensile strength and interfacial adhesion. Appl Surf Sci. 2017, 412, 424–435.

- Růžek, V.; Louda, P.; Buczkowska, K.; Just, P.; Prałat, K.; Ciemnicka, J.; Przemysław, P. Modifying geopolymer wettability by plasma treatment and high-carbon fly ash. Front. Built Environ. 2022, 8, 991496.

- Zhao, J.; Liebscher, M.; Tzounis, L.; Mechtcherine, V. Role of sizing agent on the microstructure morphology and mechanical properties of mineral-impregnated carbon-fiber (MCF) reinforcement made with geopolymers. Appl. Surf. Sci. 2021, 567, 150740.

- de Castro Silva, R.M.; Zhao, J.; Liebscher, M.; Curosu, I.; de Andrade Silva, F.; Mechtcherine, V. Bond behavior of polymer- and mineral-impregnated carbon fiber yarns towards concrete matrices at elevated temperature levels. Cem. Concr. Compos. 2022, 133, 104685.

- Silva, R.M.C.; Trindade, A.C.C.; Silva, F.A. Interface Evaluation of Carbon Textile Reinforced Composites. In Proceedings of the 3rd RILEM Spring Convention and Conference (RSCC 2020), Guimarães, Portugal, 9–14 March 2020; Valente, I.B., Ventura Gouveia, A., Dias, S.S., Eds.; Publisher RILEM Bookseries; Springer: Cham, Switzerland, 2021; Volume 33.

- Amran, M.; Huang, S.S.; Debbarma, S.; Rashid, R.S.M. Fire resistance of geopolymer concrete: A critical review. Constr. Build. Mater. 2022, 324, 126722.

- Samal, S.; Phan Thanh, N.; Petríková, I.; Marvalová, B.; Vallons, K.A.M.; Lomov, S.V. Correlation of microstructure and mechanical properties of various fabric reinforced geo-polymer composites after exposure to elevated temperature. Ceram. Int. 2015, 41, 12115–12129.

- Hajimohammadi, A.; Masoumi, S.; Kim, T.; McCaslin, E.; Alnahhal, M.F.; Almer, J.D.; White, C.E. Chemo-mechanical properties of carbon fiber reinforced geopolymer interphase. J. Am. Ceram. Soc. 2022, 105, 1519–1532.

- Le, C.H.; Louda, P.; Ewa Buczkowska, K.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751.

- Le Chi, H.; Louda, P. Flexural performance evaluation of various carbon fibre fabric reinforced geopolymer composite. Ceram.-Silik. 2020, 64, 215–226.

- Svobodová, L.; Bakalova, T.; Tunáková, V.; Le Chi, H.; Ryvolova, M.; Kavánová, A.; Voleský, L. Geopolymers with carbon or basalt grids and incorporated MgO nanoparticles for shielding electromagnetic radiation. In Proceedings of the 11th International Conference on Nanomaterials-Research and Application, NANOCON 2019, Brno, Czech Republic, 16–18 October 2019.

- Chen, M.; Qin, X.; Zeng, G. Biodegradation of Carbon Nanotubes, Graphene, and Their Derivatives. Trends in Biotechnology 2017, 35, 836–846.

- Ranjbar, N.; Zhang, M. Fiber-reinforced geopolymer composites: A review. Cem. Concr. Compos. 2020, 107, 103498.

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B. Advancement of nano-based construction materials—A review. Constr. Build. Mater. 2022, 359, 129535.

- Rovnaník, P.; Šimonová, H.; Topolář, L.; Bayer, P.; Schmid, P.; Keršner, Z. Carbon nanotube reinforced alkali-activated slag mortars. Constr. Build. Mater. 2016, 119, 223–229.

- Saafi, M.; Andrew, K.; Tang, P.L.; McGhon, D.; Taylor, S.; Rahman, M.; Yang, S.; Zhou, X. Multifunctional properties of carbon nanotube/fly ash geopolymeric nanocomposites. Constr. Build. Mater. 2013, 49, 46–55.

- Zhang, H.Y.; Kodur, V.; Qi, S.L.; Wu, B. Characterizing the bond strength of geopolymers at ambient and elevated temperatures. Cem Concr Compos 2015, 58, 40–49.

- Behera, P.; Baheti, V.; Militky, J.; Naeem, S. Microstructure and mechanical properties of carbon microfiber reinforced geopolymers at elevated temperatures. Constr. Build. Mater. 2018, 160, 733–743.

- Su, Z.; Hou, W.; Sun, Z. Recent advances in carbon nanotube-geopolymer composite. Constr. Build. Mater. 2020, 252, 118940.

- Abbasi, S.M.; Ahmadi, H.; Khalaj, G.; Ghasemi, B. Microstructure and mechanical properties of a metakaolinite-based geopolymer nanocomposite reinforced with carbon nanotubes. Ceram. Int. 2016, 42, 15171–15176.

- Yuan, J.; He, P.; Jia, D.; Fu, S.; Zhang, Y.; Liu, X.; Cai, D.; Yang, Z.; Duan, X.; Wang, S.; et al. In situ processing of MWCNTs/leucite composites through geopolymer precursor. J. Eur. Ceram. Soc. 2017, 37, 2219–2226.

- Bai, B.; Zhu, Y.; Niu, M.; Ding, E.; Bi, S.; Yin, M.; Liu, W.; Sun, L.; Zhang, L. Modulation of electromagnetic absorption and shielding properties of geopolymer nanocomposites by designing core–shell structure of carbon nanotubes. Ceram. Int. 2022, 48, 26098–26106.

- Zhu, Y.; Bai, B.; Ding, E.; Bi, S.; Liu, W.; Zhang, L. Enhanced electromagnetic interference shielding performance of geopolymer nanocomposites by incorporating carbon nanotubes with controllable silica shell. Ceram. Int. 2022, 48, 11103–11110.

- Yang, T.; Han, E.; Wang, X.; Wu, D. Surface decoration of polyimide fiber with carbon nanotubes and its application for mechanical enhancement of phosphoric acid-based geopolymers. Appl. Surf. Sci. 2017, 416, 200–212.

- Aswathi, R.; Shahla, C.P. Mechanical Properties of Hybrid Fiber Reinforced Geopolymer Concrete. Int. Res. J. Eng. Technol. 2019, 6, 170–173. Available online: https://www.irjet.net/archives/V6/i8/IRJET-V6I830.pdf (accessed on 17 October 2022).

- Sakulich, A.R. Reinforced geopolymer composites for enhanced material greenness and durability. Sustain. Cities Soc. 2011, 1, 195–210.

- Baziak, A.; Pławecka, K.; Hager, I.; Castel, A.; Korniejenko, K. Development and Characterization of Lightweight Geopolymer Composite Reinforced with Hybrid Carbon and Steel Fibers. Materials 2021, 14, 5741.

- Al-Mashhadani, M.M.; Canpolat, O.; Aygörmez, Y.; Uysal, M.; Erdem, S. Mechanical and microstructural characterization of fiber reinforced fly ash based geopolymer composites. Constr. Build. Mater. 2018, 167, 505–513.

- Yan, S.; He, P.; Jia, D.; Wang, J.; Yang, Z.; Duan, X.; Zhou, Y. Preparation and mechanical performance of CfSiCf-(Al2O3p) reinforced geopolymer composites. MATEC Web Conf. 2017, 97, 01044.

- Yan, S.; He, P.; Jia, D.; Wang, J.; Duan, X.; Yang, Z.; Wang, S.; Zhou, Y. Effects of high-temperature heat treatment on the microstructure and mechanical performance of hybrid Cf-SiCf-(Al2O3p) reinforced geopolymer composites. Compos. Part B Eng. 2017, 114, 289–298.

- Yan, S.; He, P.; Zhang, Y.; Jia, D.; Wang, J.; Duan, X.; Yang, Z.; Zhou, Y. Preparation and in-situ high-temperature mechanical properties of Cf-SiCf reinforced geopolymer composites. Ceram. Int. 2017, 43, 549–555.