| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Yoha K S | -- | 2454 | 2023-01-23 10:24:35 | | | |

| 2 | Catherine Yang | Meta information modification | 2454 | 2023-01-28 04:05:04 | | |

Video Upload Options

With increasing evidence of their relevance to resource recovery, waste utilization, zero waste, a circular economy, and sustainability, food-processing waste streams are being viewed as an aspect of both research and commercial interest. Accordingly, different approaches have evolved for their management and utilization. With excellent levels of customization, three-dimensional (3D) printing has found numerous applications in various sectors. The focus of this work is to explain the state of the art, innovative interventions, and promising features of 3D printing technology for the valorization of agri-food processing waste streams. Based on recent works, this article covers two aspects: the conversion of processing waste streams into edible novel foods or inedible biodegradable materials for food packing and allied applications. However, this application domain cannot be limited to only what is already established, as there are ample prospects for several other application fields intertwining 3D food printing and waste processing. In addition, this entry presents the key merits of the technology and emphasizes research needs and directions for future work on this disruptive technology, specific to food-printing applications.

1. Introduction

Food loss and food waste are aspects of global concern. Specifically, agri-food processing waste streams pose a serious challenge to the environment. Judicious usage of such processing waste streams is linked with sustainable food processing. Agri-food processing wastes consist of nutrients and bioactive compounds; reintroducing them into the value chain is a strategy consistent with the zero-waste circular economy [1]. In addition, the waste or by-products of one food-processing sector can be used as a resource for another. Hence, a biorefinery approach can provide a way to encourage an emerging technological revolution with a sustainability focus. Importantly, the conversion of waste biomass to various compounds facilitates better waste management.

Among various trends in the food industry, 3D printing is emerging as a novel approach, capable of changing the way food is manufactured. Particularly, in the past decade, an array of applications has been established, ranging from their scope in developing meals tailored to personalized nutrition to the delivery of nutraceutical ingredients. The technology supports food model prototyping, is highly versatile, supports digitization, and has the possibility of simplifying manufacturing processes and supply chains [2]. As an additive manufacturing process, 3D printing can support the concept of zero waste in the food industry and can also be used for better utilization of processing waste streams.

2. 3D Printing Approach to Waste Valorization

Unlike most conventional food manufacturing approaches, 3D printing can provide high levels of customization and exceptionally high aesthetic appeal. This can be exploited for the development of nutrient-dense snacks and foods from ingredients (including food waste fractions) that are often otherwise not viewed as desirable. 3D-printed foods can also be designed to deliver essential micro and macronutrients. It is also possible to optimize the design and manufacturing practices of 3D food printing for high-volume production processes. Given its high flexibility and subtlety, it is easy to fabricate a customizable design with intrinsic complex structures using a computer-aided design (CAD) software programming, and it can quickly scale up to meet the demand for desired products [3].

3. Application Range

3.1. Development of 3D-Printed Foods from Waste Fractions

3D printing is perceived as a sustainable technology that can transform low-value agri-food processing waste into high-value 3D-printed functional foods [4]. The waste produced from the primary food processing line, such as peels, shreds, stalks, fines, and pomace from the vegetable and fruit processing sector; off-cuts, trimmings, shell, skin, and bone wastes from the meat and fish processing sector; and broken grains, bran, husks, and other fractions from the mill processing sector can potentially be utilized as direct resources or additive ingredients for 3D food printing [5].

3.1.1. 3D Printing of Vegetable Wastes Incorporated Foods

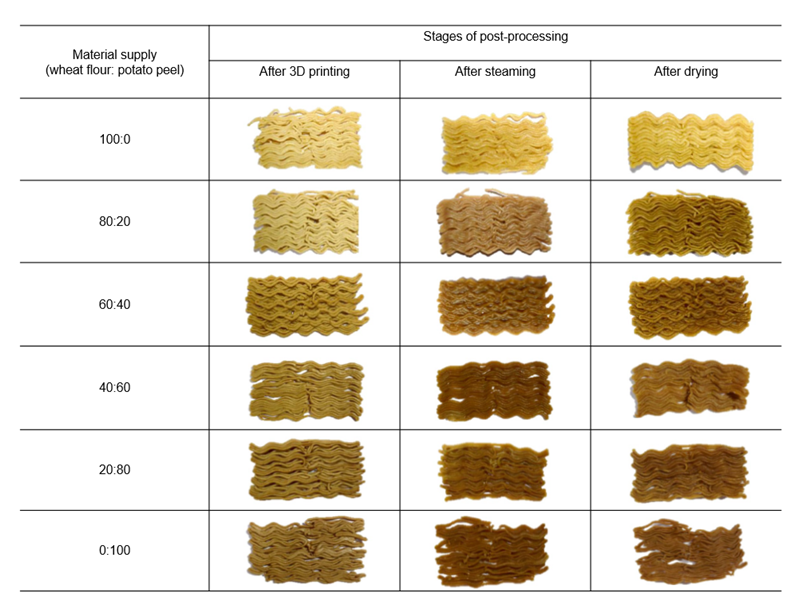

Potato peel has been identified as a significant source of dietary fiber, accounting for 40-45% of its dry weight. It is also a good source of starch, protein, and phenolic compounds. It is regarded as a zero-value waste. Muthurajan et al. [6] developed ready-to-cook 3D-printed noodles from potato peel waste and wheat flour. They have reported that the printability of potato peel fine fractions with particles smaller than 0.125 mm was superior compared to other coarse fractions with particle size > 0.125 mm due to less fiber content (1.2%) in fine fractions. Enhanced printability of the material supply was achieved at the ratio of 60:40 (wheat flour:potato peel powder) using a nozzle size of 1.28 mm, at 6 bar pressure with a printing speed of 600 mm/min and extrusion motor speed of 600 rpm (Figure 1). Post-processing of the printed noodles was optimized with subsequent steaming (5 min) and drying (68℃ for 2.5 h) processes. The calorific value of the prepared noodles was reported as 414.39 kcal per 100 g. Muthurajan et al. [6] also compared the cooking quality, texture, and consumer acceptance with commercial noodles. Another recent study utilized the wastes from green leafy vegetables such as kale stalks and spinach stems for the development of 3D-printed soft and easy-to-chew foods for dysphagia (swallowing difficulty) patients [7]. These studies provide a novel perspective on how to better utilize food waste streams.

Figure 1. Optimization of material supply for 3D-printed noodles from potato peel waste “Re-printed/adapted with permission from Ref. [6]. Copyright © 2021, exclusive license to Springer Science Business Media, LLC, part of Springer Nature”

3.1.2. 3D-Printed Salmon Gelatin Gel from Valorized Salmon Skin Waste

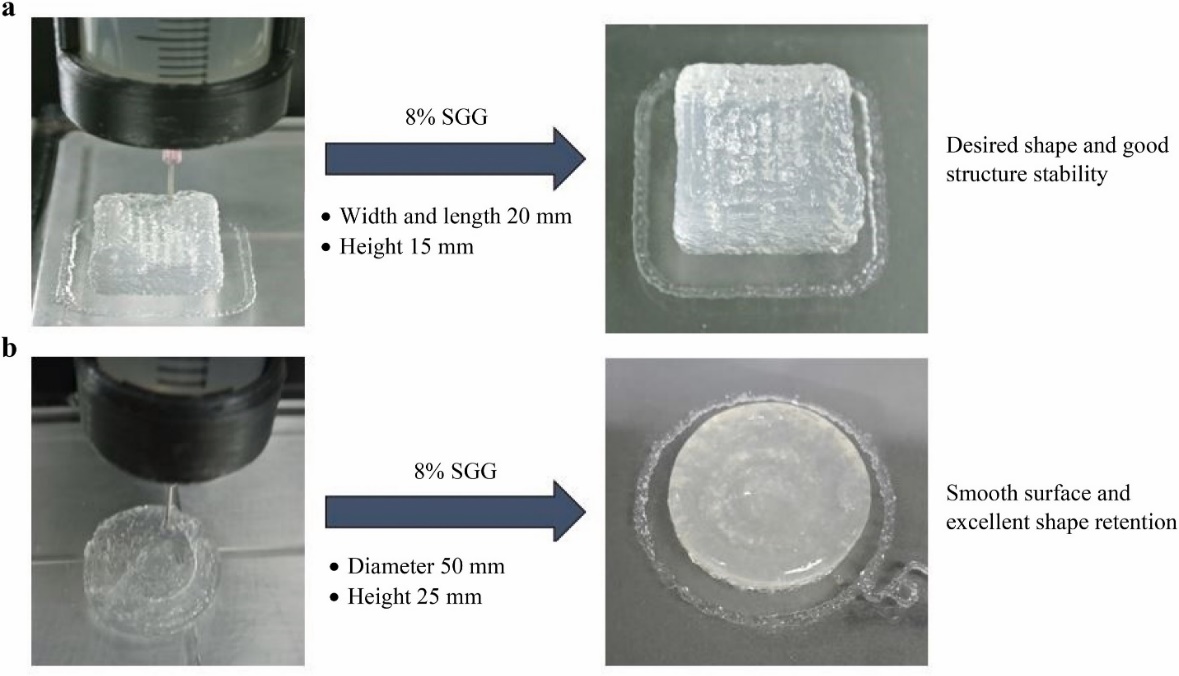

Gelatin has typically been extracted from porcine and bovine skin, but interest in marine gelatin is steadily growing. Carvajal-Mena et al. [8] effectively utilized the gelatin gel from salmon skin for the development of 3D-printed salmon gelatin cubes. The printability of the salmon gelatin gel (SGG) at five different concentrations (2, 5, 8, 11, and 14%) was optimized by examining its rheological characteristics, gelling properties, extrudability, and dimensional stability. The results showed that enhanced printability was achieved at 8% SGG concentration using a nozzle size of 0.7 mm with an extrusion speed of 20 mm/s, at a fixed initial layer height and height between layers of 0.5 mm and 0.65 mm, respectively (Figure 2). The temperature conditions were optimized for better stability and the printing and printing bed temperatures were set at 15℃ and 6℃, respectively. This research provides important information on the suitability and printability of SGG for 3D food-printing applications.

Figure 2. 3D-printed salmon gelatin gel (SGG) with the desired shape “Reprinted/adapted with permission from Ref. [8]. Copyright © 2021, Elsevier”

3.2. Utilizing Inedible Food Waste Fractions

Several food wastes are rich in inedible fractions. While one promising application is the scope of developing biopolymers, recent works have demonstrated the capability of 3D printing technology to fabricate customized food packaging. This section summarizes these works and highlights the scope for the development of replacements for single-use plastics and the design and development of biodegradable cutlery (and possibly edible cutlery and packaging).

3.2.1. 3D-Printed Food Packaging from Rice-Husk Fractions

Conversion of non-printable material into a printable formulation is a challenging task in 3D printing technology. Nida et al. [9] explored the 3D printing of rice husk fractions for food packaging applications. In this study, rice husk fraction wastes from milling industries were utilized to develop novel food packaging. While rice husk is not a naturally printable material, it was improved with the addition of guar gum as a binding material for better printability. The results showed that the desired printability was achieved with the addition of 1% guar gum and printing conditions using a nozzle size of 0.82 mm diameter at 4 bar pressure with a printing speed of 2100 mm/min and extrusion motor speed of 300 rpm (Figure 3). Food packaging materials made from biodegradable waste can significantly reduce the use of non-biodegradable petroleum-based plastics. Furthermore, this research highlights novel and cutting-edge 3D printing applications for food packaging.

Figure 3. Optimization of material supply for 3D-printed food casings from milled rice husk with 1% guar gum using a nozzle diameter of 0.82 mm at 300 rpm motor speed and 4 bar pres-sure “Reprinted/adapted with permission from Ref. [9]. Copyright © 2020, Springer Nature”

3.2.2. 3D-Printed Biomaterial Scaffold from Marine Bio-Wastes

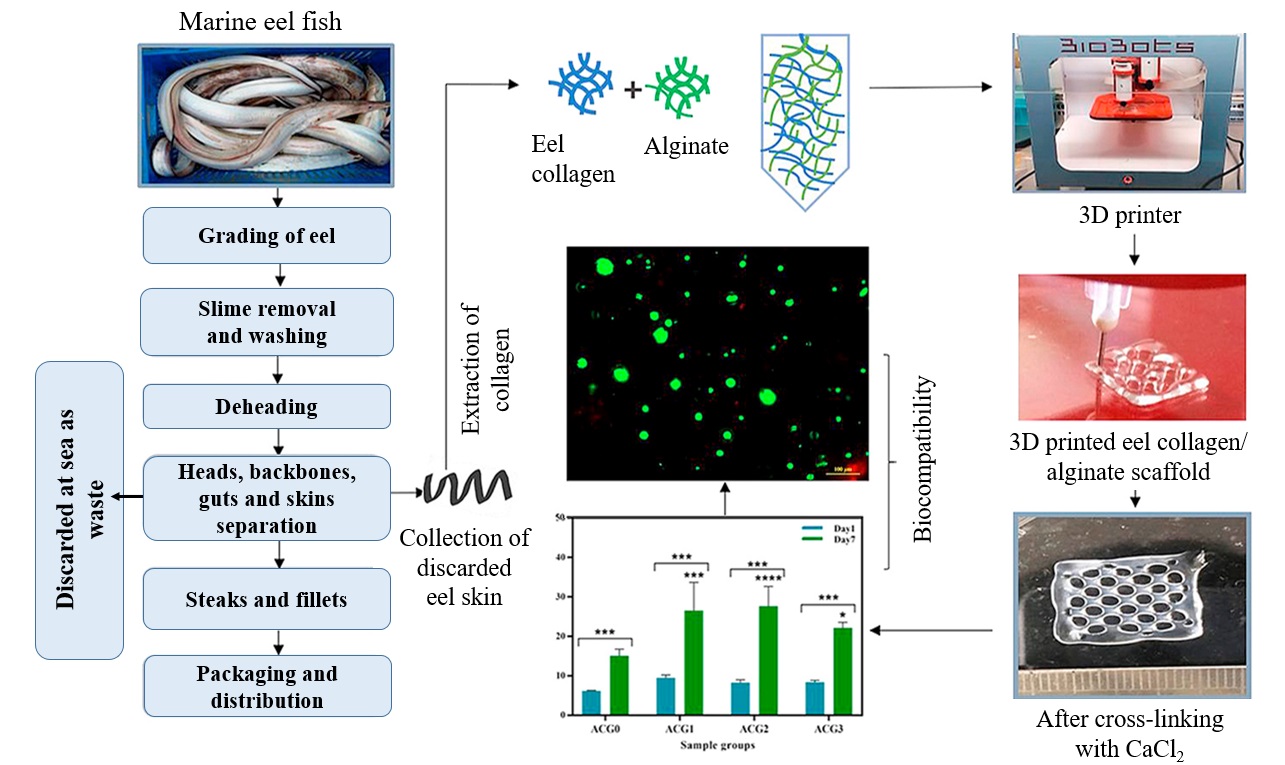

Fish-skin waste is disposed of in enormous quantities, which pollutes the environment. To address this problem, Govindharaj et al. [10] studied the development of a biocompatible collagen-based scaffold from discarded marine eel fish waste. In this study, the alginate hydrogel (5%) was formulated with different concentrations (0, 10, 20, and 30 mg/mL) of collagen obtained from discarded eel skin, and 100 mM calcium chloride was used as a chemical cross-linking agent. An alginate–collagen scaffold was printed in a layer-by-layer mode in a cuboidal shape (15 x 15 x 3 mm) using a nozzle size of 26 G at 20 KPa extrusion pressure (Figure 4). They also examined the biocompatibility of scaffolds and the feasibility of stem cell proliferation. The results revealed that the scaffolds exhibited excellent biocompatibility. Furthermore, the study reported that the 3D-printed scaffold showed improved metabolic activity based on the concentration of marine-derived collagen. A similar study conducted by Cestari et al. [11] reported the application of bio-hydroxyapatite synthesized from cuttlefish bones, mussel shells, and chicken eggshells for the development of 3D-printed poly(ε-caprolactone)/bio-hydroxyapatite scaffolds. In another study, gelatin and alginate extracted from lizardfish (Saurida spp.) scale waste and seaweed (Phaeophyceae), respectively, were utilized for the development of a 3D-bioprinted hydrogel scaffold [12]. The biocompatibility and nontoxicity of hydrogels derived from marine bio-wastes make them suitable for tissue-engineering applications.

Figure 4. Biocompatible collagen-based scaffold from marine eel fish waste. *(p<0.05) indicates statistical significance between different groups and different time points. “Reprinted/adapted with permission from Ref. [10]. Copyright © 2019, Elsevier”

4. Future Perspectives on Food Waste Valorization and 3D Printing

Waste valorization can contribute to the environment and society in many ways. A 3D printing approach to waste valorization, particularly food waste, can be promising. Firstly, the approach involves printing on demand, in turn reducing waste by producing more enticing and palatable edible or useful non-edible products. This is supported by the fact that 3D printing is an additive manufacturing process, explaining the great differences from conventional subtractive manufacturing processes in terms of resource utilization. In the context of the environment, 3D printing can offer other benefits in terms of scalability, tenability, energy usage, and safety. From a process economics point of view, it can be scalable, cost-effective, customizable in design, and a nonthermal approach.

3D food printing must be both technologically and economically feasible, as well as appealing to consumers [13][14]. Agriculture and food processing industries generate a significant amount of edible waste. An idea that converts food waste into nutrient-dense foods can prove extremely beneficial. The advancement of technology in agri-food systems toward food security and nutrition necessitates a focus on utilizing and valorizing food waste for better applications. It is possible to make edible 3D-printed products out of food waste. However, consumers’ perceptions and preferences for foods from agri-food processing wastes also require to be taken into account for exploring the creation of sustainable novel foods using 3D printing [2]. Consumers' attitudes continue to be largely determined by their willingness to consume and their fear of new foods [13]. The benefits of 3D-printed foods can captivate consumers and can also have a big impact on their nutritional choices. The choices and preferences people have when it comes to food are incredibly varied and are influenced by a number of societal, cultural, environmental, and personal factors. In this context, perhaps, an attempt to taste novel 3D-printed foods made from unusual raw materials may be hampered by a few factors, including social and ethnic concerns, food neophobia, and the perception of 3D-printed foods as an unnatural method of processing regardless of the extent to which food can be presumed "real" or "food-like" [15]. Hence, to encourage people to accept this technology and these products, these attributes must be taken into account.

The market’s strategic vision, such as innovation economics and business planning of 3D printing applications, needs to be systematically monitored and controlled, which will help to predict the future societal effects of 3D printing. As a result, innovative thinking is required for policy implementation and decision-making. 3D printing is able to synchronously access digital design concepts at different production facilities due to the possibility of mass customization, which offers a lot of potential for increasing production volume [3]. Many business companies and industries are still investigating the technological possibilities of 3D printing [16]. Further research into the printability of food waste materials would be beneficial for developing new products. As a result, it is anticipated that 3D printing technology will promote significant improvement in economic growth in the coming years. The technological innovation of 3D printing supports a zero-waste economy through the collaboration of experts in waste management and the 3D printing industry [17].

With a focus on a circular economy, waste streams from one industry can be conveniently used as raw material for another industry in the development of innovative products. This provides a promising strategy to valorize wastes and by-products from agri-food processing. The food industry is influenced by rapidly developing digital technologies. The entry of 3D printing into the food sector provides enormous scope for the development of customized and personalized foods. As a manufacturing process, 3D printing is more integrated, allowing the effective use of energy and resources, in turn benefitting the environment by reducing waste production and carbon footprint. It is essential to note that detailed investigations of the techno-economic and socio-economic status of 3D printing are constrained.

Ideally, the following questions must be addressed before venturing into the commercialization of this subject:

- Why the 3D printing approach for the valorization of food waste?

- Are there any potential risks associated with the utilization of waste in edible products?

- What is required to promote the use of 3D printing to valorize food waste?

- Are food waste resources printable in their natural form? If not, how can they be converted into a printable form?

- Can fractions from food waste streams be utilized as direct resources or additive ingredients for 3D printing?

- How can 3D printing be used to create customized products from waste? Who is the end-user?

- What about process times and costs? What about the investments to be made?

- Will raw materials be available year-round?

- What about the quality of products from food waste and the affordability of 3D printing technology?

- What is the possibility of upscaling 3D printing technology to reliable mass production?

- How versatile and sustainable is the technology?

- What challenges are associated with consumer acceptance of such foods?

5. Conclusion

Emerging 3D printing technology permits high levels of product customization and on-demand production. It also has potential advantages, including waste reduction and assistance with the value-addition of food waste. Among various valorization approaches, the idea of involving 3D printing technology is novel and requires significant research focus, in addition to addressing a sustainable approach to food waste management. To support future interventions, this article concludes with a series of questions to be answered before the commercialization of the technology is implemented. Overall, given the uniqueness and merits of the approach, in a broad context, 3D food printing has a strong possibility of transforming our food manufacturing processes.

References

- Ben-Othman, S.; Jõudu, I.; Bhat, R. Bioactives from Agri-Food Wastes: Present Insights and Future Challenges. Molecules 2020, 25, 510. https://doi.org/10.3390/molecules25030510.

- Anandharamakrishnan, C.; Moses, J.A.; Anukiruthika, T. Food Industry Market Trends and Consumer Preferences. In 3D Printing of Foods; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 493–524. ISBN 9781119669838. https://doi.org/10.1002/9781119669838.ch15.

- Anandharamakrishnan, C.; Moses, J.A.; Anukiruthika, T. Introduction to 3D Printing Technology. In 3D Printing of Foods; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2022; pp. 1–27. ISBN 9781119669838. https://doi.org/10.1002/9781119669838.ch1.

- Nachal, N.; Moses, J.A.; Karthik, P.; Anandharamakrishnan, C. Applications of 3D Printing in Food Processing. Food Eng. Rev. 2019, 11, 123–141. https://doi.org/10.1007/s12393-019-09199-8.

- Nayak, A.; Bhushan, B. An Overview of the Recent Trends on the Waste Valorization Techniques for Food Wastes. J. Environ. Manag. 2019, 233, 352–370. https://doi.org/10.1016/j.jenvman.2018.12.041.

- Muthurajan, M.; Veeramani, A.; Rahul, T.; Kumar, R.; Anukiruthika, G.T. Valorization of Food Industry Waste Streams Using 3D Food Printing : A Study on Noodles Prepared from Potato Peel Waste. Food Bioprocess. Technol. 2021, 14, 1817–1834. https://doi.org/10.1007/s11947-021-02675-2.

- Pant, A.; Xin Ni, P.L.; Chua, C.K.; Tan, U.-X. Valorisation of Vegetable Food Waste Utilising Three-Dimensional Food Printing. Virtual Phys. Prototyp. 2023, 18, e2146593. https://doi.org/10.1080/17452759.2022.2146593.

- Carvajal-Mena, N.; Tabilo-Munizaga, G.; Mario, P.; Lemus-Mondaca, R. Valorization of Salmon Industry By-Products: Evaluation of Salmon Skin Gelatin as a Biomaterial Suitable for 3D Food Printing. 2022, 155, 112931. https://doi.org/10.1016/j.lwt.2021.112931.

- Nida, S.; Anukiruthika, T.; Moses, J.A.; Anandharamakrishnan, C. 3D Printing of Grinding and Milling Fractions of Rice Husk. Waste Biomass Valorization 2021, 12, 81–90. https://doi.org/10.1007/s12649-020-01000-w.

- Govindharaj, M.; Roopavath, U.K.; Rath, S.N. Valorization of Discarded Marine Eel Fi Sh Skin for Collagen Extraction as a 3D Printable Blue Biomaterial for Tissue Engineering. J. Clean. Prod. 2019, 230, 412–419. https://doi.org/10.1016/j.jclepro.2019.05.082.

- Cestari, F.; Petretta, M.; Yang, Y.; Motta, A.; Grigolo, B.; Sglavo, V.M. 3D Printing of PCL/Nano-Hydroxyapatite Scaffolds Derived from Biogenic Sources for Bone Tissue Engineering. Sustain. Mater. Technol. 2021, 29, e00318. https://doi.org/10.1016/j.susmat.2021.e00318.

- Boonyagul, S.; Pukasamsombut, D.; Pengpanich, S.; Toobunterng, T.; Pasanaphong, K.; Sathirapongsasuti, N.; Tawonsawatruk, T.; Wangtueai, S.; Tanadchangsaeng, N. Bioink Hydrogel from Fish Scale Gelatin Blended with Alginate for 3D-Bioprinting Application. J. Food Process. Preserv. 2022, 46, e15864. https://doi.org/10.1111/jfpp.15864.

- Brunner, T.A.; Delley, M.; Denkel, C. Consumers’ Attitudes and Change of Attitude toward 3D-Printed Food. Food Qual. Prefer. 2018, 68, 389–396. https://doi.org/10.1016/j.foodqual.2017.12.010.

- Jayaprakash, S.; Paasi, J.; Pennanen, K.; Flores Ituarte, I.; Lille, M.; Partanen, J.; Sozer, N. Techno-Economic Prospects and Desirability of 3D Food Printing: Perspectives of Industrial Experts, Researchers and Consumers. Foods 2020, 9, 1725. https://doi.org/10.3390/foods9121725.

- Lupton, D.; Turner, B. “I Can’t Get Past the Fact That It Is Printed”: Consumer Attitudes to 3D Printed Food. Food Cult. Soc. 2018, 21, 402–418. https://doi.org/10.1080/15528014.2018.1451044.

- FutureBridge. 3D Printing and Its Application Insights in Food Industry. Available online: https://www.futurebridge.com/industry/perspectives-food-nutrition/3d-printing-and-its-application-insights-in-food-industry/ (accessed on 23 December 2022).

- EcoMENA. Waste Management Implications of 3D Printing. Available online: https://www.ecomena.org/3d-printing-waste-management/ (accessed on 23 December 2022).