Carbon-based materials have become an indispensable component in a myriad of domestic and industrial applications. Most of the carbon-based end-of-life products discussed end up in landfills. Where recycling is available, it usually involves the production of lower-value products. The allotropic nature of carbon has been analysed to identify novel materials that could be obtained from used products, which also transform into a secondary carbon resource. Thermal transformation of carbon-rich wastes is a promising and viable pathway for adding value to waste that would otherwise go to landfills. The valorisation routes of four different carbon-rich wastes by thermal transformation are reviewed in the study—automotive shredder residue (ASR), textile wastes, leather wastes, and spent coffee grounds (SCGs). Textile wastes were thermally transformed into carbon fibres and activated carbon, while ASRs were used as a reductant to produce silicon carbide (SiC) from waste glass.

1. Introduction

Rapid urbanisation and socio-economic development throughout the developing and developed countries in the world has ensued a precipitous increase in the generation of municipal, industrial, and agricultural wastes. A typical company value chain includes the extraction of raw materials from international sources, transportation, processing, manufacturing, and packaging into completed products, distribution, and product support, all of which result in the production of a wide variety of wastes. The wastes are generated through various market channels, consumer use of products, and final disposal or recycling of the residuals. These wastes are produced in solid, liquid, and gaseous forms and may contain harmful pollutants and glasshouse gases (GHGs) from fuel burning and improper waste disposal

[1]. Recycling and composting programmes are failing to keep up with waste accumulation, even though various firms and non-governmental organisations (NGOs) are developing and promoting novel solutions ranging from high-tech waste processing to enhanced guidance and assistance for waste management communities. The best opportunity for human civilisations to actually lessen the carbon footprint and advance toward a sustainable waste management ecosystem is to expedite the repurposing of waste materials into marketable raw materials for new goods.

The piling up of landfills in the name of waste management does not contribute to a sustainable environment based on a circular economy. A circular economy is one that keeps the usefulness of materials in the economic system for as long as feasible, decreasing the dependency on natural resources and avoiding the scenario of raw material scarcity and the environmental implications of material consumption and waste disposal. Finding a solution to the dilemma of where and how to dispose of the vast volume of waste produced daily is one of the world’s most pressing concerns, especially given that the volume of waste produced is rising. Different recycling techniques and strategies have been proposed to tackle these environmental issues, such as mechanical, chemical, and hybrid methods. Although these methods boast of individually different extents of applications, advantages, and disadvantages, they have built a framework for clean and cheaper ways of reusing end-of-life products.

The burgeoning concerns over solid waste disposal have indeed promoted research efforts dealing with their valorisation routes. In order to minimise metal and non-metallic wastes ending up in landfills, several valorisation alternatives have been proposed, which range from primary routes of direct recycling to quaternary or multi-step routes of waste valorisation. There has been a surge in demand for raw materials and a risk associated with their supply. The geopolitical challenges and technological complexities involved in acquiring raw materials have spawned an interest in recycling the elements from secondary resources. Recycling plastics and polymer-based products have been prevalent for the last few decades. While an enormous and escalating volume of waste from the ubiquitous plastics of different polymer groups is a threat to the environment and life on earth, they are also considered alternative supply chains for a wide range of products and processes. Generally, polymer-based wastes are recycled, downcycled to a different product with lesser value, or disposed into landfills. The diverse attributes of plastics, namely their light weight, strength, heat resistance, high convenience, and low cost, make them versatile for business and consumer uses. However, these materials are high molecular weight organic polymers composed of elements, such as carbon, hydrogen, oxygen, nitrogen, and sulphur. Despite their attractive hydrocarbon composition, their potential as a secondary carbon resource has been underestimated. Contrastingly, incineration or high-temperature pyrolysis of polymer wastes is an efficient method of managing waste, yet comparatively and energy-intensive, involving higher operating costs and greater levels of pollution, and they could harm the environment. Thus far, only a few researchers have attempted to exploit polymer materials, namely polypropylene (PP), polycarbonate (PC), acrylonitrile butadiene styrene (ABS), polyethylene (PE), and polyurethane (PU), as a secondary source of carbon in the material and metallurgical industries. Different polymer groups possess different carbon-hydrogen compositions, and they determine the extent of their utilisation in the subsequent recycling processes

[2].

Industrialisation and increasing use of private transport are increasing the production and use of motor vehicles. The automobile sector is one of the dominant consumers of polymeric materials for their interiors, body, and upholsteries. Automotive shredder residue, a heterogeneous mixture of all the materials found in cars, ovens, etc., is produced when ELVs and other scrap are shredded into pieces the size of an orange, and the metal chunks (70%) removed from the rest, usually with an air cyclone, or using magnetic and eddy current separation, for steel recycling

[3]. Several researchers have demonstrated the characteristics of ASR because of the presence of a substantial amount of wood and plastic

[4].

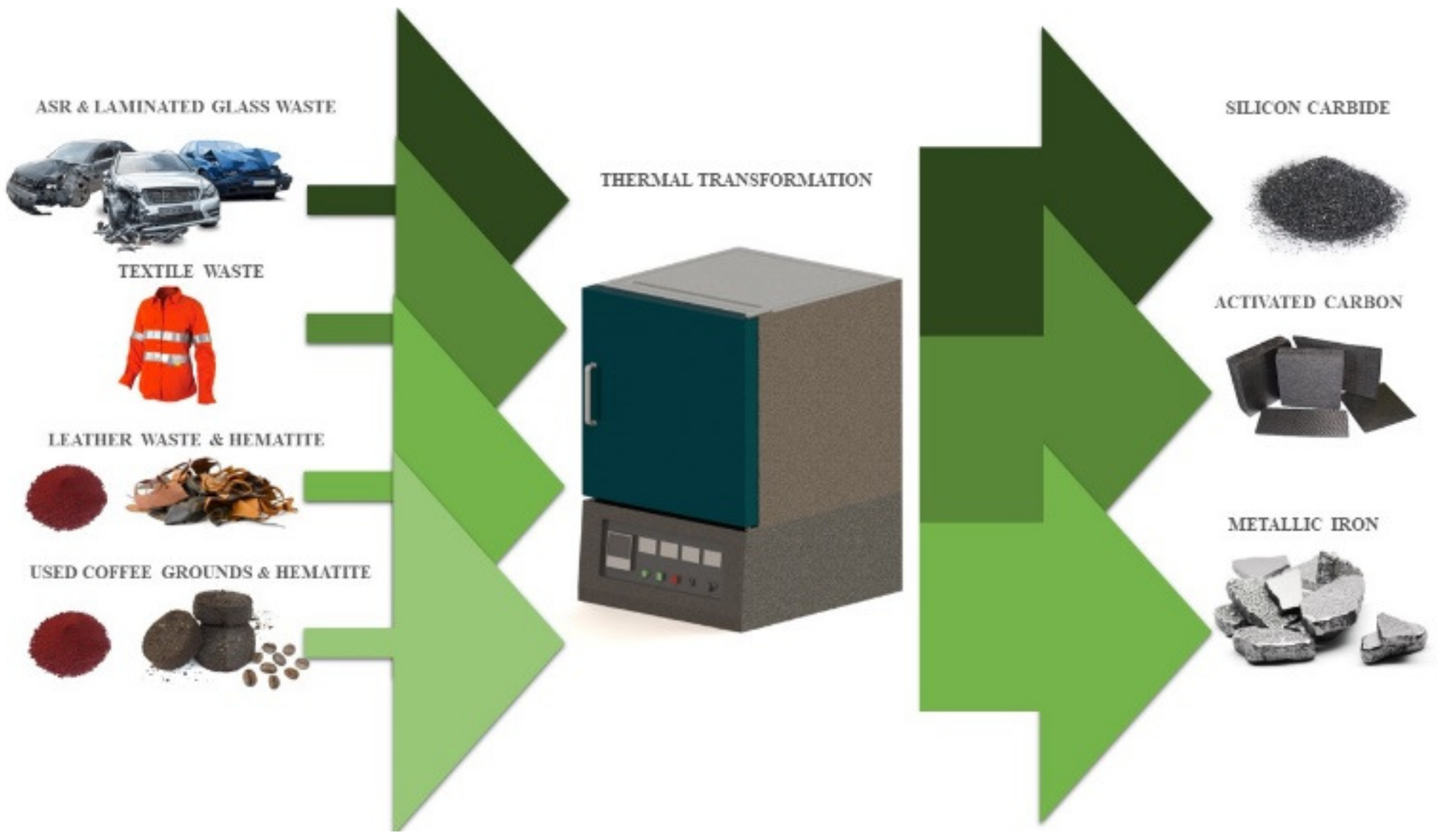

2. Waste Products: Secondary Resources of Carbon

Four different groups of wastes were focused on as secondary carbon sources, namely used uniform clothing (cotton textile wastes), pre- and post-consumer use leather wastes, automotive shredder residues (ASRs), and Spent Coffee Grounds (SCGs). The current entry converges on innovative technologies to uncover high-quality recycled materials, often from unexpected or underutilised sources. A pictorial representation of how different secondary carbon resources disposed into landfills are valorised in the processes of producing value-added industrial materials is presented in Figure 1.

Figure 1. Thermal transformation of secondary resources of carbon (wastes).

2.1. Textile Waste—Source of Activated Carbon

Cotton is one of the most commonly used materials in the textiles industry, either as pure cotton or in a blend with other fibres

[5]. One of the more prominent is ‘polycotton’, which typically involves blends of polyester and cotton in ratios of 50:50, 35:65, and 65:35, respectively. The focus of this study is cotton textiles of 100% purity, which are commonly used for clothing and personal protective equipment because of their thermal resistance and strength. Cotton textiles are appealing to consumers because it is ‘breathable’, durable, and low maintenance. The fibres within a cotton plant are almost entirely cellulose, and the stem is lignin

[6]. Only cotton fibres are used in cotton textiles, wherein they are separated from the seeds in a process commonly referred to as ‘ginning’. The fibre is then spun into yarn and subjected to dyeing and manufacturing processes to prepare a textile. Being a rich source of cellulose, textile wastes are a promising precursor to activated carbon. There is no best approach to recycling cotton waste textiles. All solutions should be guided by the waste hierarchy. For these reasons, thermal transformation processes to create carbon fibres and activated carbon fibres are considered a commercially viable solution in situations where simpler recycling processes compete with inexpensive primary materials (for example, many consumer cloths or rags used for washing or cleaning are primary materials despite recycled cloths being a better choice for the environment). For higher-value materials, consumers are more likely to be more thoughtful in their choice and look for cost savings where available.

2.2. Reductants in Metallurgical Processes

One of the most critical challenges engineers and scientists face to solve is managing the limited resources on our planet and waste material. Australia generated nearly 67 million tonnes of waste in 2016–2017 (2018). Among different industry sectors, the automotive industry is the leading resource-consuming and waste producer

[7]. The volume of waste material from end-of-life-vehicle (ELVs) is immense and necessitates applicable management. The end-of-life-vehicle (ELVs) waste management process is classified into three broad stages, including (I) depollution, (II) dismantling, and (III) shredding

[8]. The entire shredded output encompasses about 70–75% ferrous fraction and nonferrous metals, as the 20% to 25% residual from shredded production is known as the automotive shredder residue (ASR)

[3]. Waste glass is commonly recycled into new glass products, such as bottles and jars, in traditional recycling processes. Industries and researchers use waste glass in the construction sector. However, producing recycled glass products such as waste glass containing plastic and other materials is challenging. For instance, recycling the windscreens and windows of automobiles with laminated and tempered float glass is tricky due to the plastic lamination in the interlayers of the glasses and melting points, which vary from glass-to-glass sources such as waste jars and bottles. Due to the presence of glass, recycling laminated plastic from end-of-life automobiles is likewise cumbersome. Removing the glass impurities from the plastic needs extensive mechanical processing, which is expensive. Additionally, automobile waste containing different glasses types cannot be mixed and is unsuitable for conventional glass recycling procedures. Mostly, ASR is the remaining material after the separation of metals from the shredded materials, which usually contain 19–31% plastic, approximately 20% rubber, 10–42% textile and fibre materials, 2–5% wood residues, and 5.2% glass. Owing to the distinct composition of ASR, they can be used as a reductant source in the thermal transformation of glass wastes.

Tanneries are renowned for being dangerous to the environment and public health. Every year, 6 million tons of solid waste is produced from leather production worldwide

[9]. For example, fleshings, splittings, shavings, buffing dust, and leather offcuts are produced in the tanneries. Amongst the most dangerous concerns with leather waste management is the presence of chromium (Cr), which causes a danger to both the environment and human health. Cr

3+ is oxidised to Cr

6+, which risks a dangerous hazard to humans because of its carcinogenic and mutagenic characteristics

[10][11]. A thermal transformation is a novel way to utilise the potential of leather and tannery wastes as a reducing agent and thereby simultaneously treat them as a harmless product.

One of the most popular beverages in the world is coffee, which is also considered to be one of the most traded products. Around 170 million 60 kg bags of coffee were produced globally, while 165 million 60 kg bags were consumed in the period 2018–2019

[12]. SCGs (spent coffee grounds) are the used coffee grounds frequently left over from the extraction of espresso coffee. According to Planet Ark research, 1 kg of coffee grounds yields around 1.9 kg of SCGs

[13]. Since landfills are where most SCGs are disposed of, they release methane gas, which is known to be much more harmful than carbon dioxide. SCGs may contaminate groundwater or water sources close to landfills because they include elements that are detrimental to the environment

[14]. Hence, it is necessary to develop technologies that utilise SCGs as feedstock, thus supporting the concept of a circular economy and reducing the inefficient disposal in landfills. The rich carbon content in SCGs suggests their exceptional reducing capability in the production of iron from their ores. The different approaches to exploit the carbon-rich wastes as secondary resources of carbon, therefore, have significant potential for product development. The products obtained different valorisation processes of textile and leather wastes, automotive shredder residues (ASR), and spent coffee grounds (SCGs) have promising applications as 'activated carbon' and 'reductants in metallurgical industries'.