Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Elham of Eslami | -- | 5783 | 2023-01-09 15:40:49 | | | |

| 2 | Rita Xu | -15 word(s) | 5768 | 2023-01-10 03:37:11 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Eslami, E.; Carpentieri, S.; Pataro, G.; Ferrari, G. Tomato Processing By-Product Valorization. Encyclopedia. Available online: https://encyclopedia.pub/entry/39923 (accessed on 07 February 2026).

Eslami E, Carpentieri S, Pataro G, Ferrari G. Tomato Processing By-Product Valorization. Encyclopedia. Available at: https://encyclopedia.pub/entry/39923. Accessed February 07, 2026.

Eslami, Elham, Serena Carpentieri, Gianpiero Pataro, Giovanna Ferrari. "Tomato Processing By-Product Valorization" Encyclopedia, https://encyclopedia.pub/entry/39923 (accessed February 07, 2026).

Eslami, E., Carpentieri, S., Pataro, G., & Ferrari, G. (2023, January 09). Tomato Processing By-Product Valorization. In Encyclopedia. https://encyclopedia.pub/entry/39923

Eslami, Elham, et al. "Tomato Processing By-Product Valorization." Encyclopedia. Web. 09 January, 2023.

Copy Citation

The tomato processing industry can be considered one of the most widespread food manufacturing industries all over the world, annually generating considerable quantities of residue and determining disposal issues associated not only with the wasting of invaluable resources but also with the rise of significant environmental burdens.

tomato processing by-products

biorefinery

conventional solvent extraction

novel thecnologies

bioactive compounds

1. Introduction

The food supply chain, including production, processing, consumption, and disposal, generates waste along the different steps, from harvesting and industrial processing to storage, distribution, and households. The food processing industry is responsible for producing a considerable quantity of residues and by-products, making it the second-largest producer after households [1].

In particular, among all food categories, fruits and vegetables are actually the most wasted (45% of the total amount of food globally wasted) [2]. Interestingly, data shows that almost half of all fruits and vegetables produced are discarded along the supply chain [3]. Fruit and vegetable processing by-products, mostly consisting of pomace (peel, pulp, and seeds), are excellent sources of ingredients such as dietary fibers, peptides, proteins, and polysaccharides, as well as bioactive compounds such as polyphenols, antimicrobial compounds, and natural pigments [4].

Currently, the food and beverage industry has been facing a major challenge in handling and disposing of processing wastes and by-products while striving to address the growing consumers’ demand for natural health-beneficial ingredients. To face these challenges, food waste valorization and their transformation into valuable products are widely investigated worldwide [5].

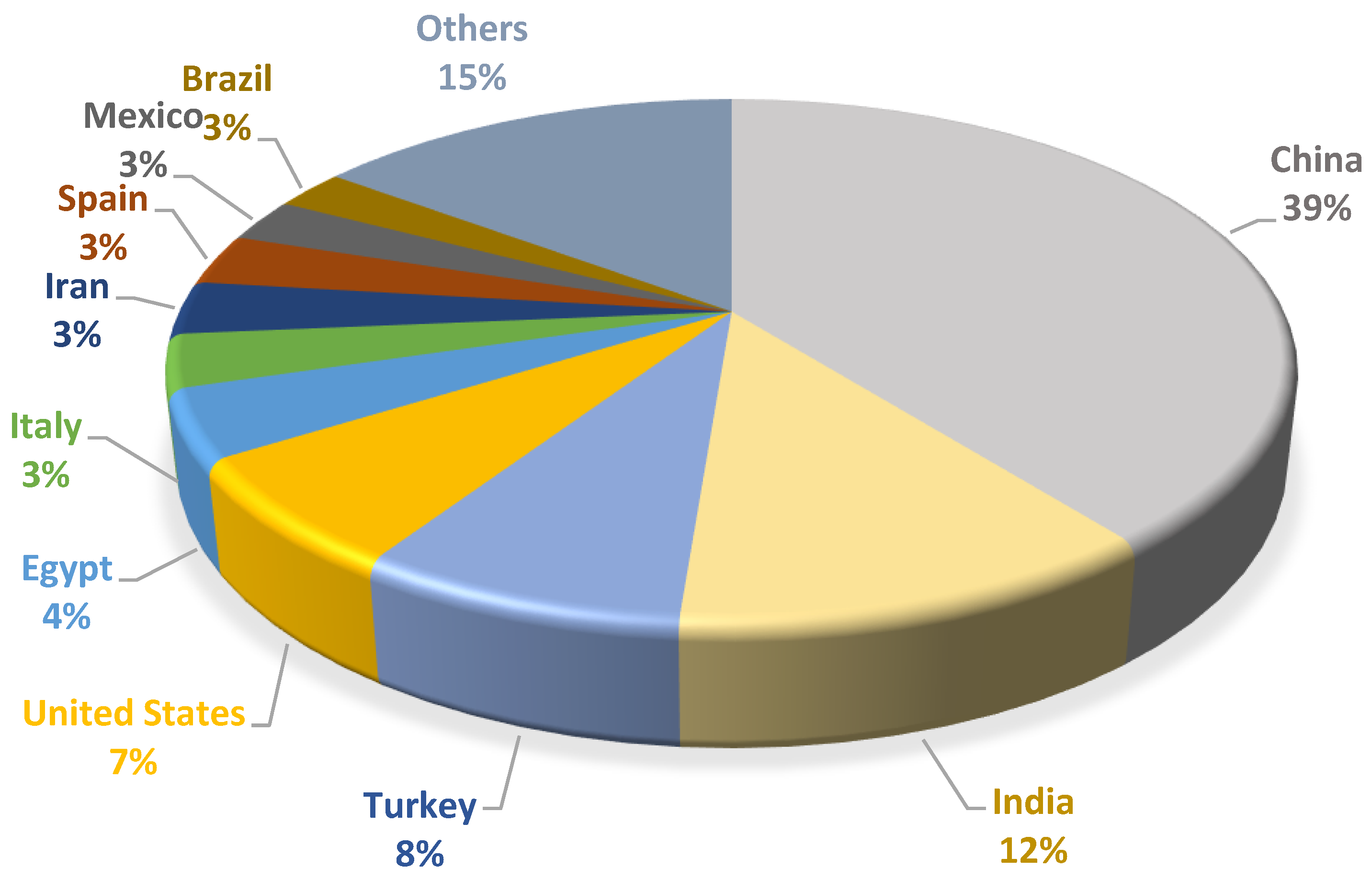

Among fruits and vegetables, tomato is one of the most widespread crops in the world, with a global annual production that exceeded 180 million tons in 2021 [6]. Italy, with a production that, in 2022, reached about 5.5 million tons, accounts for 53% of the total European production, with the Campania Region being the largest Italian production area [7]. The top ten countries for tomato production are illustrated in Figure 1 [8].

Figure 1. Top ten countries for tomato production based on FAOSTAT (2019) [8].

During tomato processing, huge quantities of by-products are generated, accounting for 3–5% (w/w) of the total raw tomatoes [9][10]. They consist of peels, seeds, and a small amount of pulp, named tomato pomace, which causes the main disposal issue for the tomato processing industry. Currently, tomato pomace has low-added-value and is mainly used as animal feed, to produce compost, or is discharged in landfills, creating environmental loads [11]. However, many studies are showing that tomato processing by-products are a rich source of fiber [12][13], polyphenols [14][15], carotenoids (such as lycopene and β-carotene) [11][16][17][18], oil [19], and proteins [15], which can be very beneficial to human nutrition and health due to their chemical characteristics and biological potential. Thus, the recovery of high-added-value compounds from tomato processing by-products could represent a strategic option that is extremely beneficial for the tomato processing industry and consumers and very valuable from an environmental perspective [17]. However, in order to recover bioactives, which are mainly intracellular compounds, effective extraction processes are required [20].

Generally, high-added-value compounds are firmly locked in the plant cells, with the cell envelopes representing a physical barrier to mass transfer, which could hinder their recovery via conventional solvent extraction (CSE). For decades, conventional extraction methods such as maceration and reflux extraction have been utilized. However, these methods suffer from several drawbacks, such as low yield, long extraction times, requirement of high amounts of organic solvents, isomerization, and degradation of some compounds when higher processing temperatures are utilized, all of which affect processing costs while also exacerbating environmental concerns [21]. To overcome these drawbacks, the application of novel technologies weakening the cell membranes of plant tissues, thus enhancing the extraction yield of the bioactive compounds from tomato residues while reducing the solvent consumption and the extraction time at once, has been proposed. Their utilization to complement traditional extraction methods can represent a suitable, effective, and environmentally friendly approach for the valorization of tomato by-products [22].

Indeed, the increasing consumers’ interest in chemical-free products has created motivation for producers to apply innovative technologies for the recovery of natural compounds to be used in the food, cosmetic, and pharmaceutical industries [4]. High-pressure homogenization (HPH), pulsed electric fields (PEF), supercritical fluid extraction (SFE-CO2), ultrasound-assisted extraction (UAE), and microwave-assisted extraction (MAE) have been demonstrated to effectively enhance the extraction yields of bioactive compounds from a wide variety of agri-food by-products, including those from tomato processing [11][14][15][17][23].

2. Chemical Composition and Characteristics of Tomato Pomace, Peels, and Seeds

Tomato pomace generally consists of 56% pulp and peels and 44% seeds on a dry basis [24]. However, the composition of tomato pomace is simultaneously dependent on the type of final product and the peeling methods applied in the production line. The tomato pomace generated during the peeling phase of peeled tomato production only consists of peels without seeds. However, in the case of tomato juice and paste production, tomato pomace is a mixture of peels, seeds, and a small amount of pulp [25].

According to the literature, tomato pomace contains several high-added-value compounds, particularly lycopene, proteins, oil, and dietary fibers. More specifically, fibers are the main component of tomato pomace (39.11–59.03% on a dry basis), and other compounds, such as oil and proteins, range between 2–16.24% and 15.08–24.67%, respectively, depending on the variety, geographical location of the cultivation areas, growing stages, ripening, type of processing, extraction conditions, as well as analytical techniques utilized [24][26].

However, due to differences in the chemical composition of tomato peels and seeds, the main valuable compounds that can be recovered are largely different, as summarized in Table 1.

Table 1. Main compounds in tomato pomace, peels, and seeds.

| Material | Fibres [g/100 g dw] |

Proteins [g/100 g dw] |

Oil [g/100 g dw] |

Lycopene × 103 [g/100 g dw] |

References |

|---|---|---|---|---|---|

| Pomace | 39.11–59.03 | 15.08–24.67 | 2.00–16.24 | 9.82–611.105 | [27][28][29][30] |

| Peels | 62.79–78.56 | 1.85–11.13 | 1.63–5.50 | 50–1930 | [15][31][32][33][34] |

| Seeds | 16.00 | 20.2–40.94 | 17.80–24.50 | 22.01–37.43 | [19][29][35][36][37] |

In particular, tomato peels are a rich source of lycopene, representing 80–90% of the total carotenoids, polyphenols, and dietary fibers, as reported in Table 2 [31]. Tomato seeds are mostly composed of oil, containing 80% unsaturated fatty acids, mainly linoleic (48.2–56.1%), oleic (22.2–23.8%), and palmitic (12.3–17.2%) acids [35][36][38][39], and proteins, with glutamic acid (19.44–24.37%) and aspartic acid (8.82–10.32%) being the most abundant amino acids in tomato seed oil [40].

Table 2. Carotenoids composition in tomato peels [29].

| Lycopene [g/100 g of TC] |

Phytoene [g/100 g of TC] |

Phytofluene [g/100 g of TC] |

β-Carotene [g/100 g of TC] |

Cis-Lycopene [g/100 g of TC] |

Lutein [g/100 g of TC] |

|---|---|---|---|---|---|

| 86.12 | 3.15 | 2.31 | 2.11 | 1.71 | 1.51 |

Therefore, tomato pomace has a great potential use as a rich and low-cost source of diverse high-added-value compounds that, due to their different natures and characteristics, have been demonstrated to possess antioxidant, anti-inflammatory, anti-aging, and anti-cancer properties, retard degenerative diseases, and control cholesterol and blood sugar levels [41].

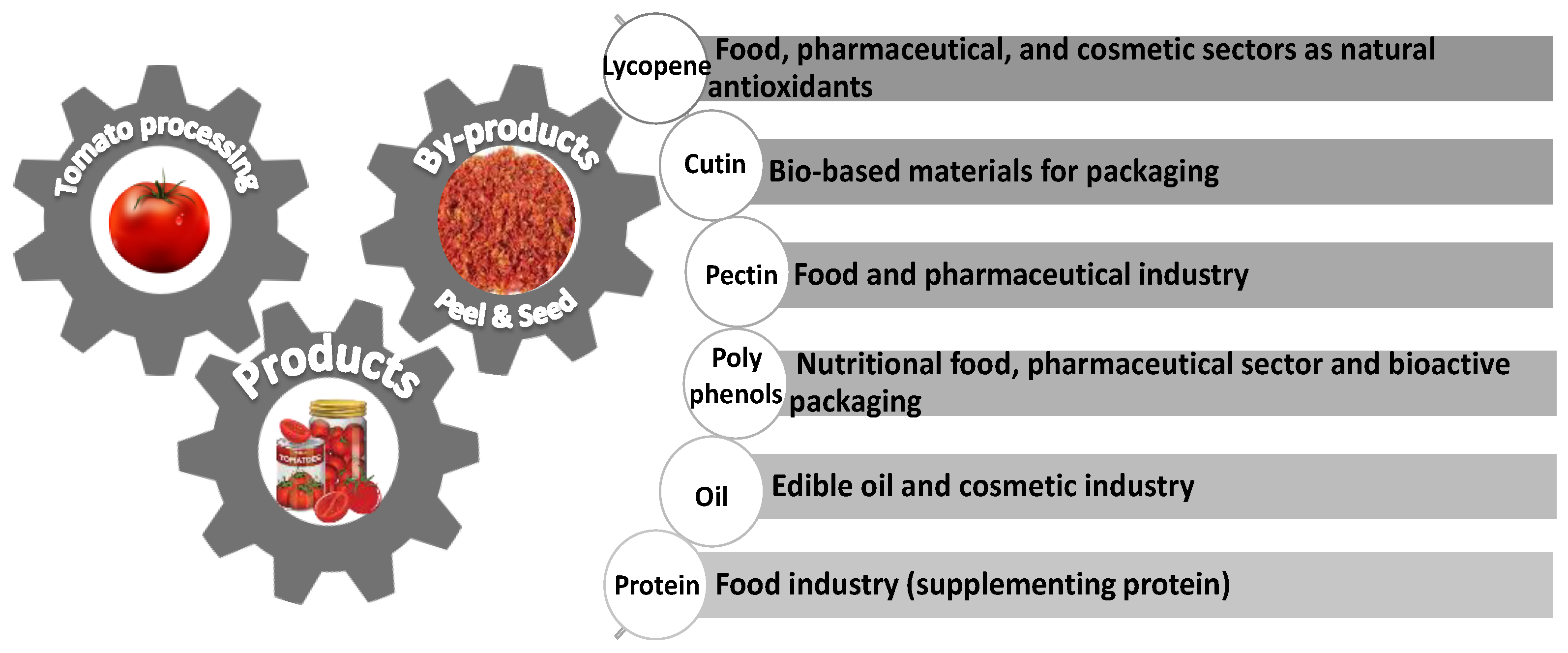

The most recovered target compounds from tomato processing by-products and their potential diversified applications in several industrial sectors are summarized in Figure 2.

Figure 2. Schematic of tomato processing by-product valorization, compounds recovered, and their potential fields of application.

3. Separation of Peels and Seeds from Tomato Pomace

As discussed in the previous section, tomato peels and seeds have some differences in their chemical composition, consequently resulting in different valorization procedures and the production of different compounds with wide potential utilization in different industrial sectors. In this respect, the first necessary step to effectively valorize by-products, particularly peels and seeds, is the separation of these two fractions [42].

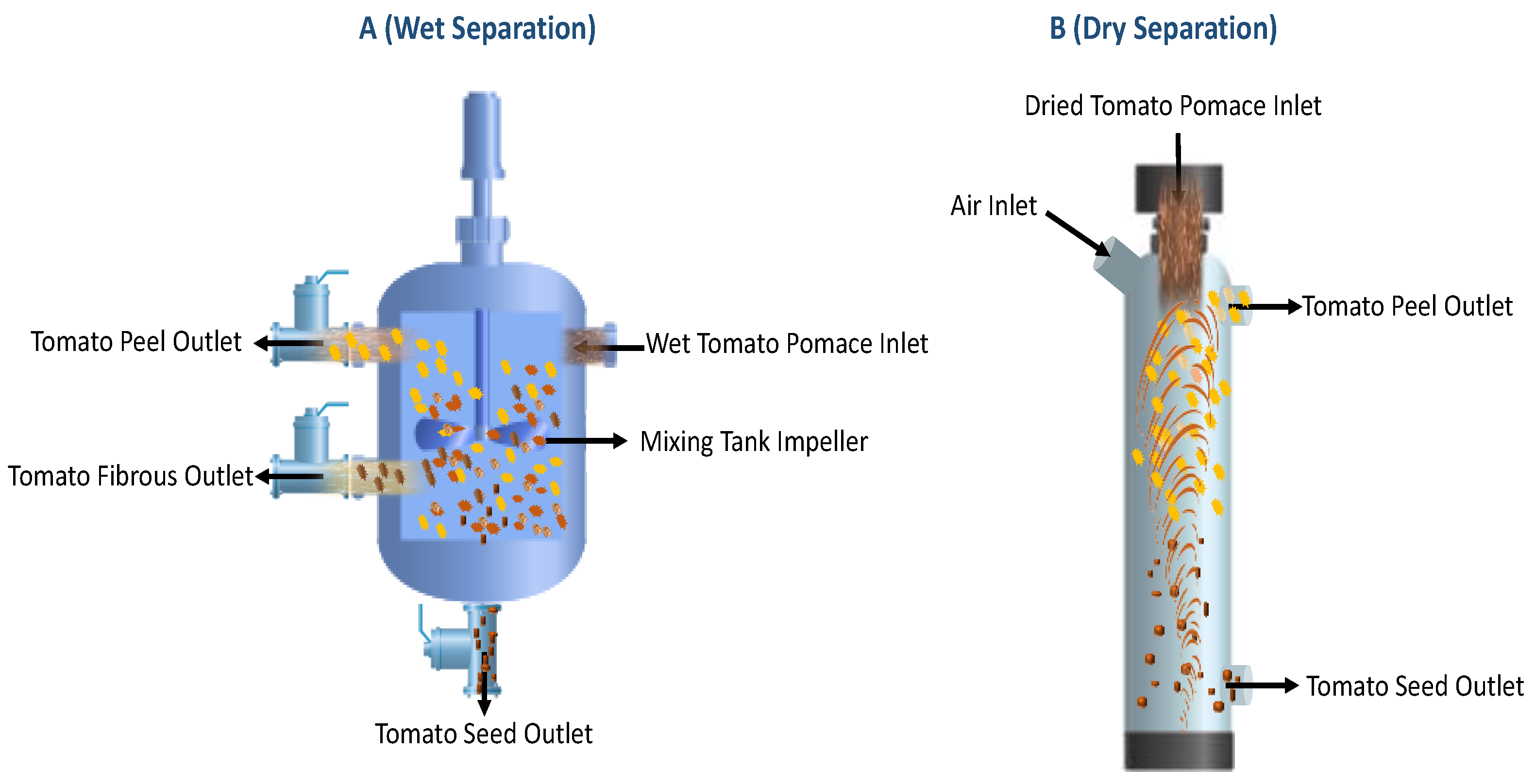

Two possible routes can be used to separate tomato peels and seeds, constituting the pomace, namely wet and dry separation. Wet separation is based on the difference in density between the tomato peels and seeds. The pomace is mixed with water in a mixer-settler where seeds sink to the bottom, while peels, having a lower density, float at the top [40]. Kaur et al. (2005) designed a flotation system for tomato pomace componentization characterized by separation efficiencies of 69.17% and 48.29% for peels and seeds, respectively [43]. Shao et al. (2013) applied the wet separation method for tomato pomace and stated that by repeating the separation several times by reprocessing the obtained fractions, the purity of the tomato peels and seeds separation can be improved up to 90% (89.65% and 96.6% for peels and seeds, respectively), although this method caused significant loss of micronutrients [28].

The dry separation method consists of a drying step for tomato pomace, which is then fed onto a cyclone by an air flow where the separation of the two fractions takes place. The peels move upward, exiting the cyclone from the upper outlet section with air, while the seeds, which are heavier, move downward in the opposite direction of air flow and leave the cyclone from the bottom outlet section. Shao et al. (2015) optimized the separation step of tomato pomace using an air aspirator system using response surface methodology (RSM). They reported that tomato pomace with a moisture content of 8% had a separation efficiency of 68.56% when the air velocity and feed rate were 6.4 m/s and 40 kg/h, respectively [42].

Wet and dry separation methods have advantages and disadvantages. Wet separation is a water-consuming process and is suitable for fresh pomace to obtain seeds with high purity. In contrast, dry separation is an energy-consuming process and allows acquiring peels with high purity (mostly due to the lower yield). However, although the dry separation is energy intensive, it is superior in preserving valuable water-soluble compounds present in peels and seeds with respect to the wet counterpart, which causes significant losses of micronutrients. In addition, from an environmental perspective, wet separation generates wastewater and consequently water pollution, while dry separation results in air pollution and dust, which can lead to health issues among workers. Overall, the selection of the two alternative separation methods for the peels and seeds from tomato pomace should be closely linked to the requirements of the subsequent extraction stage, the eventual pre-treatment processes of the biomass, and the technologies applied for the recovery of the compounds of interest [26][28]. A schematization of the wet and dry methods for tomato peel and seed separation has been presented in Figure 3.

Figure 3. Schematization of wet (A) and dry (B) methods for tomato peel and seed separation.

4. Application of Green Technologies for Tomato Processing By-Product Valorization

4.1. High Pressure Homogenization (HPH) Technology

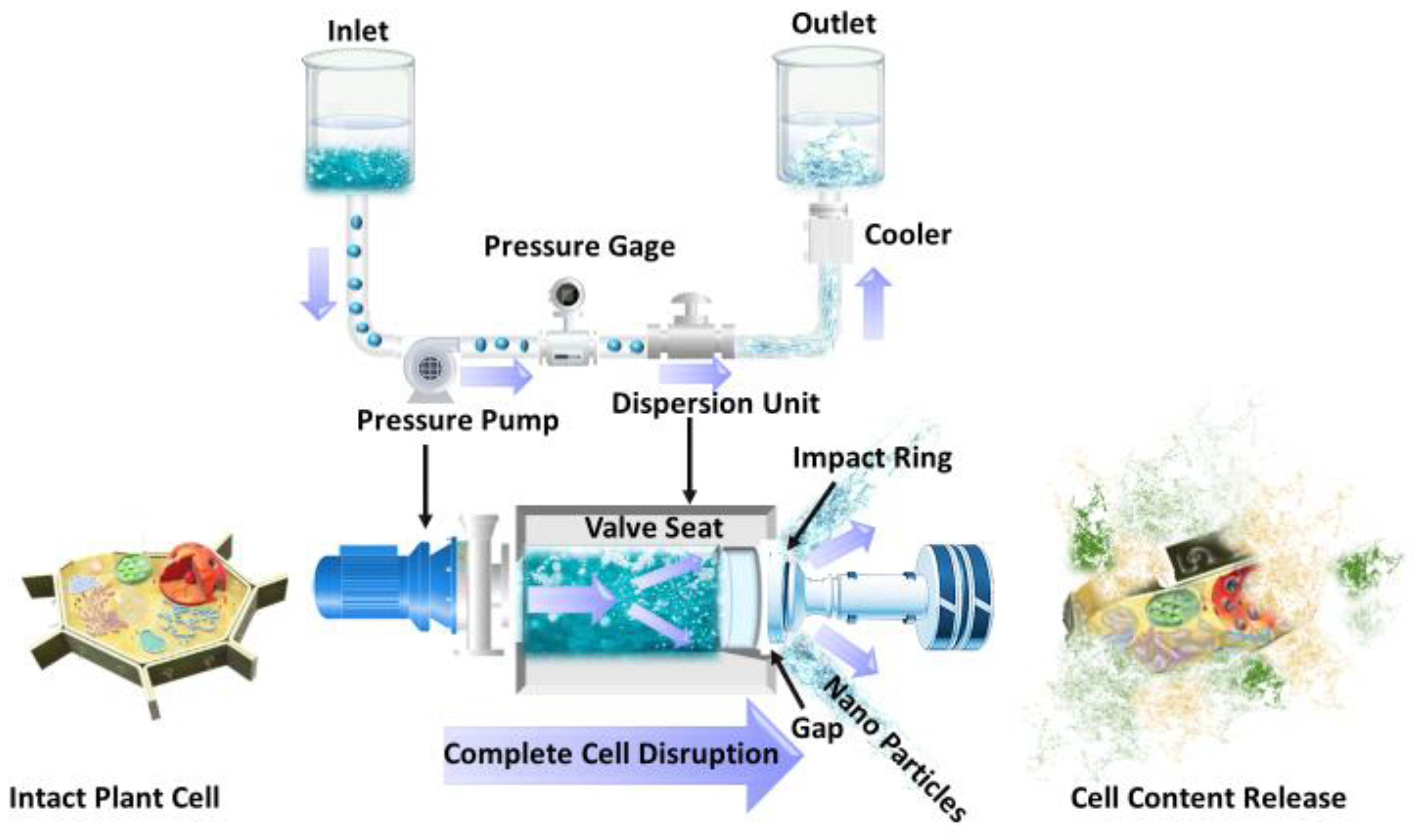

In HPH technology, one of the most effective mechanical methods for large-scale cell disruption, a fluid containing suspended solids is pumped through a tight gap valve utilizing a high-pressure intensifier, followed by depressurization with the subsequent generation of high shear and elongational stresses, and cavitation. Consequently, cells, particles, or macromolecules suspended in the fluid are exposed to a high level of mechanical stress, getting deformed and twisted, as shown in Figure 4 [44]. Many studies have evaluated the use of HPH for microbial inactivation in the food industry. However, this technology has been effectively applied as a method to improve the release of intracellular bioactive compounds from agri-food by-products as a result of the complete disruption of the plant cells induced by HPH [15]. Since HPH is considered a physical treatment and needs no or a little amount of organic solvent, it is considered a very environmentally friendly method to recover target compounds from agro-industrial biomass [15]. However, it is an intrinsically non-selective operation with high energy costs associated and requiring high capital investments [15][45].

Figure 4. Schematic representation of HPH technology and its effect on plant cell.

In 2019, Jurić et al. applied HPH technology (1–10 passes, at 100 MPa) as a disruption technique to recover bioactive compounds from tomato peels by using only water as a solvent. The results showed that HPH reduced the size of tomato peel suspensions, leading to the complete disruption of single plant cells that consequently released high-added-value compounds. Particularly, when the number of HPH passes through the valve increased, the cell disruption occurred completely, and consequently, greater quantities of total polyphenols and proteins were released. The researchers also reported that in comparison with high-shear mixing (5 min at 20,000 rpm), referred to as the control, HPH processing (10 passes) led to higher release of intracellular compounds, including polyphenols (+32.2%) and proteins (+70.5%) and a rise in antioxidant activity (+23.3%). Interestingly, in terms of lycopene yield, the researchers compared HPH with other methods, including CSE [46], SFE-CO2 [47], PEF-assisted extraction [46], and UAE [48]. The results showed that HPH led to the highest lycopene yield among all the compared methods. The quantitative results were also confirmed by the HPLC analyses, confirming that the amount of lycopene recovered from tomato peels (19.3 mg/g dw) was considerably greater than the values reported in the literature (from 0.5–0.8 mg/g dw) [31] and reached the maximum amount of 1.5 mg/g dw [49]. More importantly, its recovery was performed via a sustainable, green, and entirely physical method, and the final products could be applied in the formulation of functional foods or mixed with the peeled tomato products to enhance their bioactivity [15].

Since HPH is a physical treatment that results in the complete disruption of plant cells, it can be very effective in recovering high-molecular-weight compounds from plant cell tissues, such as pectin. Van Audenhove et al. (2021) investigated the application of the HPH-facilitated acid extraction method to recover pectin from tomato processing residues. An industrial method for pectin recovery was applied by carrying out the extraction process in a single step with nitric acid (pH approximately 1.6). Additionally, HPH technology was tested to facilitate a further step for the recovery of the pectin fraction, which remained unextracted after the treatment with nitric acid. The results showed that polysaccharide cell walls were considerably affected by HPH (20 MPa for a single pass), and nearly two thirds of the residual pectin was recovered in the subsequent extraction step. Overall, the results demonstrated the potential of HPH technology to enhance pectin extraction from tomato processing residues compared to the conventional acid extraction [45].

4.2. Pulsed Electric Fields (PEF) Technology

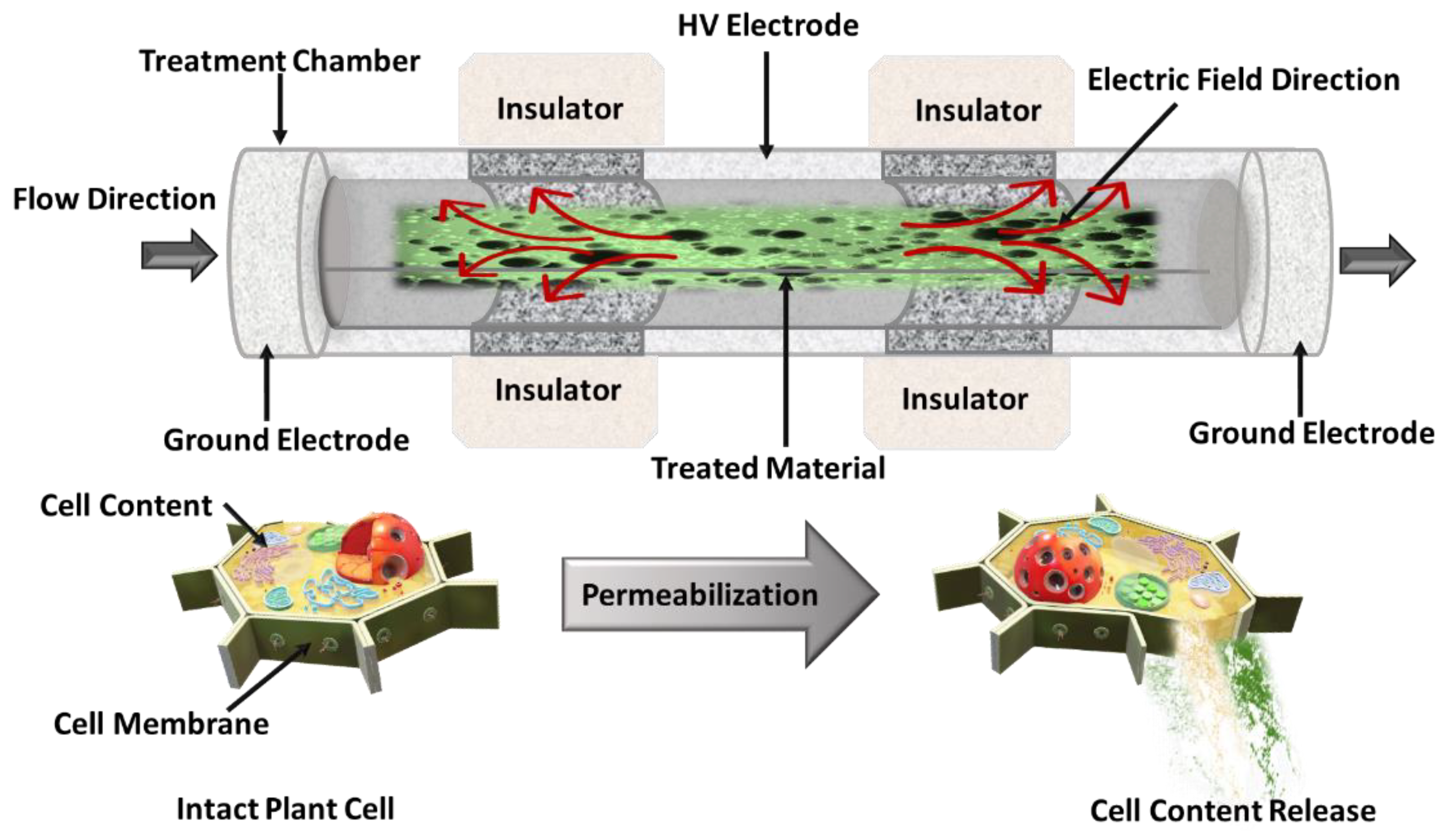

PEF is a non-thermal electrotechnology that involves the exposure of plant tissue suspensions, placed between two metal electrodes, to repetitive short duration pulses (1 μ−1 ms) of moderate electric field (0.5–10 kV/cm) and relatively low energy input (1–20 kJ/kg), leading to the permeabilization of cell membranes by pores formation [50]. Being electroporation the outcome of PEF pre-treatment, mass transfer of the intracellular compounds during the subsequent extraction step is enhanced, whereas the solvent consumption, the extraction time, and the energy costs are decreased [51][52][53]. The schematic of a continuous PEF treatment chamber is depicted in Figure 5.

Figure 5. Schematic representation of a continuous co-filed PEF treatment chamber.

Andreou et al. (2020) applied PEF technology in three different stages of industrial tomato processing, including peeling, juice extraction, and tomato waste valorization. The recovery of high-added-value compounds from residues of the juicing process assisted by PEF was investigated. As a result, the application of PEF at 2 kV/cm and 700 pulses enhanced the extraction yield of carotenoids by 56.4% and doubled the concentration of total phenolics compared to the untreated samples [54].

With the aim of decreasing the required thermal energy in the thermophysical peeling stage, PEF technology can be implemented in the washing stage of tomato processing, with the consequent extent of improving lycopene extraction from tomato peels [54][55]. Pataro et al. (2018) demonstrated that PEF pretreatment enabled the permeabilization of the plant cells and facilitated the detachment of the peels from the fruits in the following steam blanching (SB) and peeling steps. The application of PEF contributed, at the same time, to the promotion of an increase in the recovery yield of bioactive compounds from tomato peels. The combination of PEF (0.5 kV/cm, 1 kJ/kg) and SB (at 60 °C for 1 min) synergistically enhanced carotenoids extraction, resulting in 37.9 mg/100 g of fresh tomato peels, 1.7 times higher than that obtained by applying only SB [17].

In addition, the same researchers evaluated the influence of PEF pre-treatment and extraction temperature on the recovery of carotenoids from tomato peels in 2019. Different PEF treatment conditions were applied with field strengths, E, in the range 0.5–5 kV/cm and energy input, WT, in the range 0.5–20 kJ/kg, and the effects of different temperatures (20 to 50 °C) on lycopene extraction yield were assessed by using acetone as solvent. The optimal PEF processing conditions were E = 5 kV/cm and WT = 5 kJ/kg, which resulted in an extraction yield of total carotenoids that was 47% higher than that obtained from untreated peels, and the antioxidant power of the extract was 68% higher than that of the untreated tomato peels. Moreover, regardless of the PEF treatment, increasing the extraction temperature from 20 to 50 °C increased the lycopene extraction yield by about 22% [56].

Industrial tomato by-products provided by a canning company were used by Pataro et al. (2020) to investigate the effect of PEF pre-treatment on the recovery yield of lycopene from industrial tomato peels. PEF processing was carried out at different field strength (E= 1–5 kV/cm) and energy input (WT = 5–10 kJ/kg), and ethyl lactate and acetone were used as solvents. In line with the study previously discussed, the results demonstrated that the application of PEF pre-treatment (5 kV/cm, 5 kJ/kg) considerably increased the lycopene extraction rate (27–37%), the antioxidant power of the extract (18.0–18.2%), and the lycopene recovery yield (12–18%) with respect to the untreated samples. Moreover, acetone allowed to extract a higher amount of lycopene (17.5 mg/g dw) with respect to ethyl lactate (10.14 mg/g dw), indicating a higher ability of this solvent to penetrate into the plant cells, enabling a higher amount of intracellular lipophilic compounds to dissolve in it [11]. The application of PEF technology for carotenoid extraction from tomato wastes was also investigated by Luengo et al. (2014). The researchers applied PEF pre-treatment of different intensities (3–7 kV/cm and 0–300 µs) and used a mixture of hexane: acetone: ethanol (50:25:25) as solvent, with the aim of improving extraction yield and reducing the total amount of solvent in the extraction step. PEF pre-treatment (at 5 kV/cm and 90 µs) on tomato peels increased carotenoid extraction by 39% compared to the untreated samples. More importantly, RSM results showed that the application of PEF reduced the hexane consumption from 45 to 30% at the same extraction yield [46].

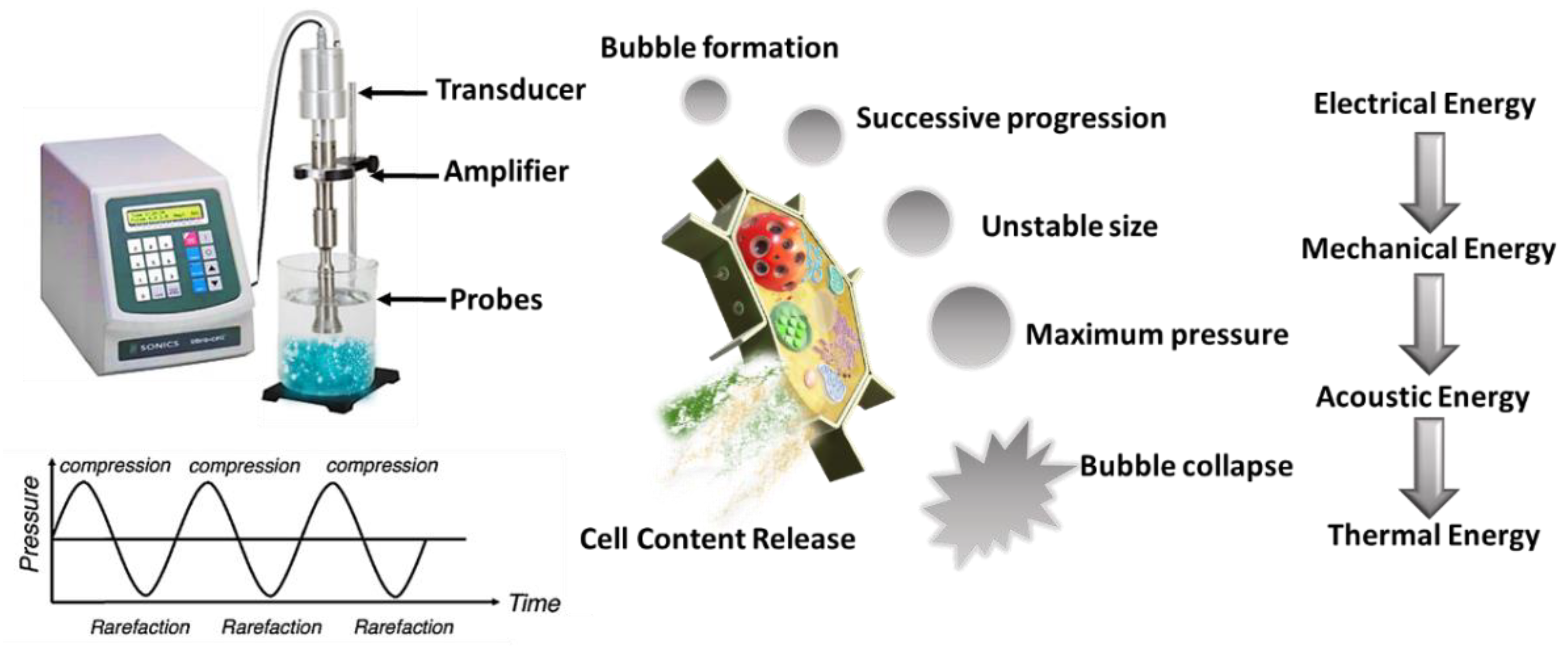

4.3. Ultrasound Technology

Ultrasound-assisted extraction (UAE) is an alternative process to CSE that is able to induce cell wall disruption, principally attributed to acoustic cavitation. Cavitation is produced by the interaction between the liquid, the ultrasonic waves, and the gas dissolved in the liquid. As presented in Figure 6, UAE creates cavitation bubbles using high frequency pulses, and local hotspots at the macroscopic scale with high shear stress and temperature. The penetration of the solvent into the plant cells is favored, as well as the release of intracellular compounds [57]. Low-frequency ultrasound (16–100 kHz) can be applied for the extraction of valuable compounds such as hydrophobic carotenoids (lycopene, beta-carotene, capsaicin, and lutein) and hydrophilic flavonoids (anthocyanins, tannins) from agricultural by-products [58]. In general, the application of relatively mild ultrasonic conditions stimulates the release of the compounds entrapped in the intracellular and extracellular spaces of the plant tissues, allows increasing the mass transfer rate and decreasing the extraction temperature and time, and, consequently, improves the extraction efficiency. However, US is a non-selective extraction method, and its application could damage thermolabile compounds due to the local increase in temperature [22][59][60][61].

Figure 6. Schematic representation of ultrasound technology and its effect on plant cells.

Kumcuoglu et al. (2013) investigated the application of ultrasound technology for lycopene extraction from tomato paste processing by-products. The researchers compared the recovery yield of lycopene obtained with UAE and conventional organic solvent extraction (COSE) [48], using as solvent a mixture of BHT (butylated hydroxytoluene) 0.05% (w/v), hexane, acetone and ethanol (2:1:1). The maximum extraction yield was obtained by applying ultrasounds at a power of 90 W, a liquid/solid ratio of 35:1 (v/w), and an extraction time of 30 min, while the processing conditions for COSE were a liquid/solid ratio of 50:1 (v/w), a temperature of 60 °C, and an extraction time of 40 min. Results revealed that UAE could extract about 80% of lycopene after 10 min of treatment, whereas the extraction time was at least 20 min using COSE. Overall, the comparison between COSE and UAE revealed that UAE is a more efficient method that requires a lower amount of solvent (a reduction of about 30%) and a shorter extraction time than COSE [48].

Silva et al. (2019) investigated the application of UAE for the extraction of lycopene from tomato wastes using a mixture of eco-friendly solvents, namely ethyl lactate and ethyl acetate, to increase the sustainability of the process. The highest amount of lycopene (1.33 mg/g dw) was obtained in the optimized UAE processing conditions. The extraction yield of lycopene obtained utilizing the same solvents without sonication was 1.209 mg/g dw, thus 9.4% lower than that obtained upon UAE. By coupling less harsh solvents, such as ethyl lactate and ethyl acetate, with ultrasound technology, the lycopene extraction yield was enhanced, this representing a greener approach for the lycopene recovery in comparison to organic solvents [62]. In 2019, the same researchers studied a sustainable method for lycopene extraction from tomato processing waste by applying UAE and hydrophobic eutectic solvents (HEMs), namely lactic acid as hydrogen-bond donor (HBD), and DL-menthol as hydrogen-bond acceptor (HBA). The extraction conditions that maximized the lycopene content in the extract (1.45 mg/g dw), as determined by RSM, were 120 mL/g solvent-solid ratio, 70 °C, and 10 min [63].

In order to improve the extraction of lycopene from tomato waste, the combination of sonication and edible solvents (sunflower oil) was exploited as a green extraction strategy by Rahimi et al. (2019). Response surface methodology (RSM) was used to select the best experimental conditions, including the solid to oil ratio (S/O), ultrasonic intensity (W/m2), and extraction time (min), that maximize the lycopene yield. Results showed that, while the ratio of solid to oil had a slight impact on the yield of extraction, the time and ultrasonic intensity significantly affected the total lycopene recovery. The maximum lycopene yield (81.57%) was achieved using an ultrasonic power of 70 W/m2, a solid-to-liquid ratio of 20 (v/w), and an extraction time of 10 min. The proposed approach complies with the concept of green processes since it permits the use of renewable resources, ensures product safety and quality, and allows to obtain pigmented oils that can be used as sources of lycopene in a variety of products [64].

Similarly, Pettinato et al. (2022) focused on the UAE optimization using ethanol as solvent, analyzing the effects of the different variables involved on the lycopene extraction yield from tomato waste. The optimal extraction conditions were 65 °C, 20 min, liquid-solid ratio of 72 mL/g, US amplitude of 65%, and 33 s for pulse duration, resulting in a lycopene yield of 1.54 ± 0.05 mg/g dw [65]. However, a slightly lower temperature and a longer extraction time were required to obtain lycopene extraction yields comparable to those reported by Silva et al. (2019).

Said et al. (2020) investigated the lycopene extraction from both lab-prepared and industrial tomato wastes by using US (45 min at 50 Hz) and freeze drying. US, freeze-drying, and the combination of the two processes resulted in a recovery of 45.51 ± 1.84, 104.10 ± 1.23, and 138.82 ± 6.64 µg lycopene/g fresh tomato waste, with an increase of the lycopene extraction yield from industrial tomato waste of 0.8, 2.8, and 4.12 folds, respectively [66].

Sonication can also be applied for pectin recovery from tomato by-products. It has been demonstrated that US intensifies the extraction process, avoiding the long extraction times (12–24 h) required with the most common conventional methods [59]. Grissino et al. (2016) explored the possibility of using UAE (at 37 kHz) and CSE (by ammonium oxalate/oxalic acid in two steps) for the recovery of pectin from tomato residues. The highest pectin yields in the first step were 18.5% and 21.1% for UAE and CSE, respectively. However, for rich similar pectin extraction yields, CSE required 1440 min, which is two orders of magnitude higher than that required for UAE (15 min). Moreover, the second extraction step was ensuring higher pectin yields compared to the first step not only for CSE (31.2%), but also for UAE (36%). Therefore, the researchers concluded that the main advantage of UAE was to considerably shorten the extraction time, making the process more environmentally friendly [67]. In another study, Singh Sengar et al. (2020) studied pectin extraction from tomato peels by using five different extraction methods, namely UAE, MAE, ohmic heating-assisted extraction (OHAE), ultrasound-assisted microwave extraction (UAME), and ultrasound-assisted ohmic heating extraction (UAOHE) at different power levels. According to their results, the yield of extracted pectin ranged from 9.30% for OHAE to 25.42% for MAE. They reported that although MAE led to a higher yield, UAME can be regarded as a greener extraction method with respect to the other extraction processes tested, allowing for comparable extraction yield as well as higher pectin quality [59].

US technology has also been proposed to increase the oil extraction yield from tomato seeds. Aarabi Arabani et al. (2015) applied sonication as a pre-treatment stage of tomato seeds to extract oil. Results demonstrated that the particle surface bonds can be weakened by combining US pre-treatment with other physical techniques, effectively enhancing the extraction yield. Immersion of tomato seeds in water for 24 h at 40 °C, followed by grinding and sonication (at 550 W and 37 kHz for 90 min), resulted in about 28.11% yield in oil extraction from tomato seeds. In fact, soaking the seeds in water before milling provided the needed texture of the lignocellulosic samples and prevented them from absorbing nonpolar and hydrophobic solvents or effusing the oil. Additionally, the milling process led to better penetration of the solvent into the sample. Overall, using combined pre-treatment processes (Hot water + Grinding + US) increased the oil extraction yield by 15.91% with respect to that obtained from untreated samples [60].

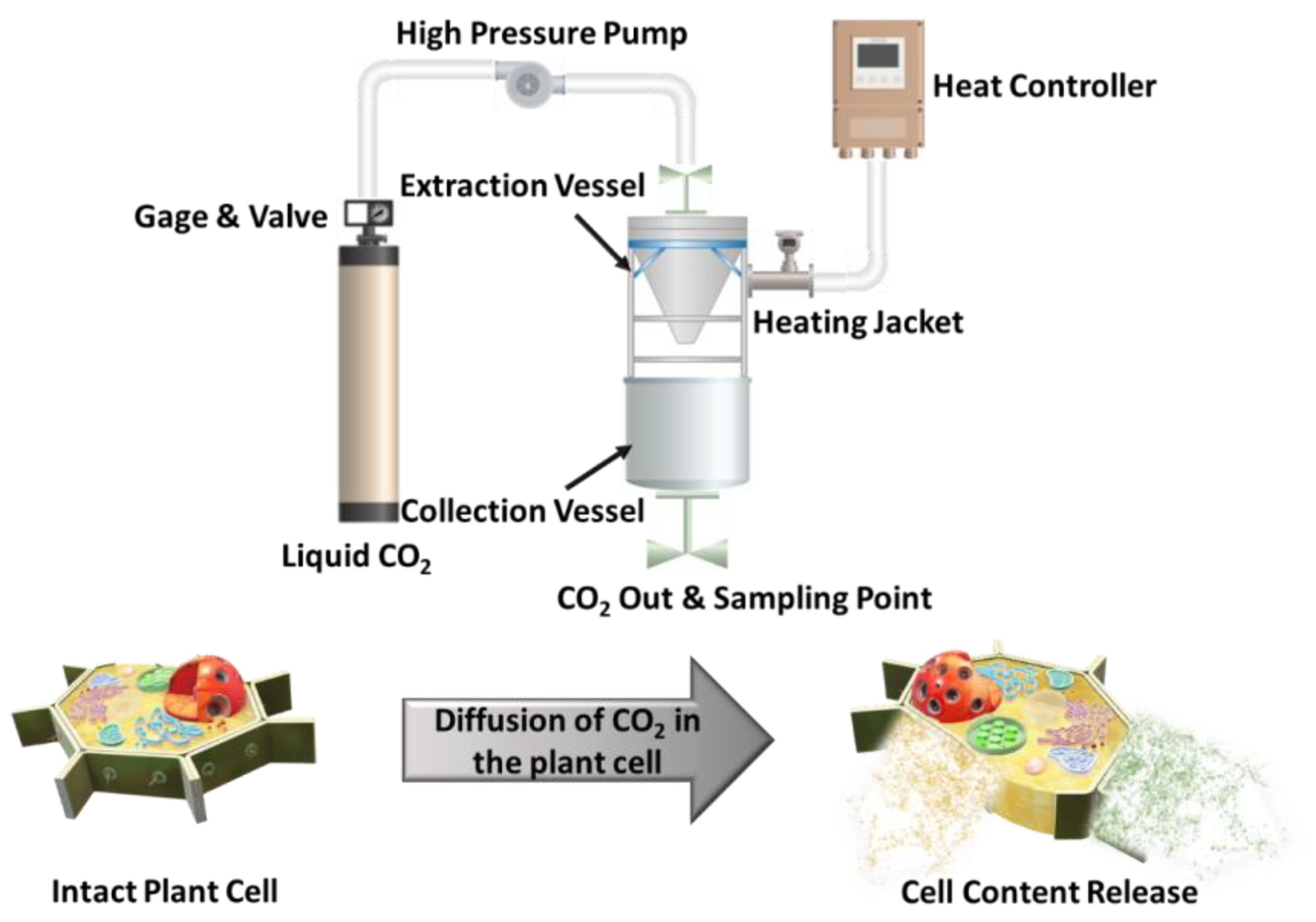

4.4. Supercritical Fluid Extraction

Supercritical fluid extraction (SFE) is an environmentally friendly method operated at the pilot and industrial scales. The schematic of the process is shown in Figure 7. This method is based on the increased solvating power of gases beyond their critical point [68]. Currently, one of the most frequently used supercritical fluids is carbon dioxide due to its beneficial characteristics, including low critical temperature and pressure, high purity, and low cost. More importantly, carbon dioxide can be applied for the extraction of compounds that are thermally unstable and cannot be purified by steam distillation. Since lycopene is a high-added-value bioactive compound and degrades easily when subjected to thermal processing, supercritical carbon dioxide-assisted extraction (SFE-CO2) can be applied as a green extraction process to recover tomato oleoresin rich in lycopene. Moreover, the selectivity of the extraction process can be increased by adjusting and monitoring the pressure and temperature of the system [69][70].

Figure 7. Schematic representation of a supercritical carbon dioxide extraction system.

Mihalcea et al. (2021) studied the application of SFE-CO2 to tomato peels for lycopene-enriched oleoresin extraction and its microencapsulation to produce high-added-value ingredients with several potential applications. The optimization step of the processing conditions showed that SFE-CO2 carried out for 155 min at a pressure of 400 bar and a temperature of 74 °C resulted in the recovery of oleoresin form tomato peels with the highest lycopene content (5.28 mg/g dw) [71]. To evaluate the effect of SFE-CO2 on the extractability of intracellular bioactive compounds from industrial tomato residues, also Kehili et al. (2017) investigated the recovery of lycopene and β-carotene from tomato peels obtained in tomato industrial processing. The results showed that SFE conducted at the optimal operating conditions, namely 400 bars, 80 °C, 105 min, 4 g CO2/min, and 0.4 g CO2/g peels, led to a maximum lycopene recovery of 0.73 ± 0.03 mg/g dw. Moreover, these results were compared to those obtained by applying the conventional extraction methods (overnight at 200 rpm and 25 °C) using ethanol, ethyl acetate, and hexane as solvents. Interestingly, the SFE-CO2 extraction technique resulted in a higher yield of lycopene in comparison with conventional methods (+156%, +128%, +20%, by using ethanol, ethyl acetate, and hexane, respectively) [72]. Additionally, Hatami et al. (2019) evaluated, both experimentally and by applying mathematical modeling, the lycopene recovery yield by SFE-CO2 from tomato pomace, demonstrating that the greatest effect on lycopene recovery is related to the peel/seed ratio, followed by pressure, and temperature [47]. Considerably, the combination of pressure–temperature showed a positive synergistic effect on the lycopene recovery. Pressure affected lycopene recovery more effectively at higher temperature. Due to the higher availability of lycopene in the peels compared to the seeds, the optimized experimental conditions (80 °C, 500 bar, and a peel/seed ratio of 70/30) resulted in the highest lycopene recovery (0.358 mg of extract/kg of raw material) [47]. The effect of these parameters on lycopene extractability from tomato peels under SFE-CO2 was also investigated by Pellicano et al. (2020). The researchers stated that applying SFE-CO2 at 550 bar for 80 min resulted in the highest oil extraction yield (79%), being the oil rich in lycopene (8.6 mg/kg dw) and β-carotene (15 mg/kg dw) [73].

Adapting to the zero-emission process concept, the application of SFE-CO2 technology for the extraction of high-quality oil from tomato processing by-products (seeds and peels) was also investigated by Lisichkov et al. (2011). The researchers evaluated the effects of different parameters on the oil extraction yield. The maximum solubility of oil was obtained at operating pressures ranging from 210 bar to 280 bar at 40 °C for 2.5 h, which resulted in 0.25 g/g tomato seeds and peels with a solubility of 14 mg/dm3s [74].

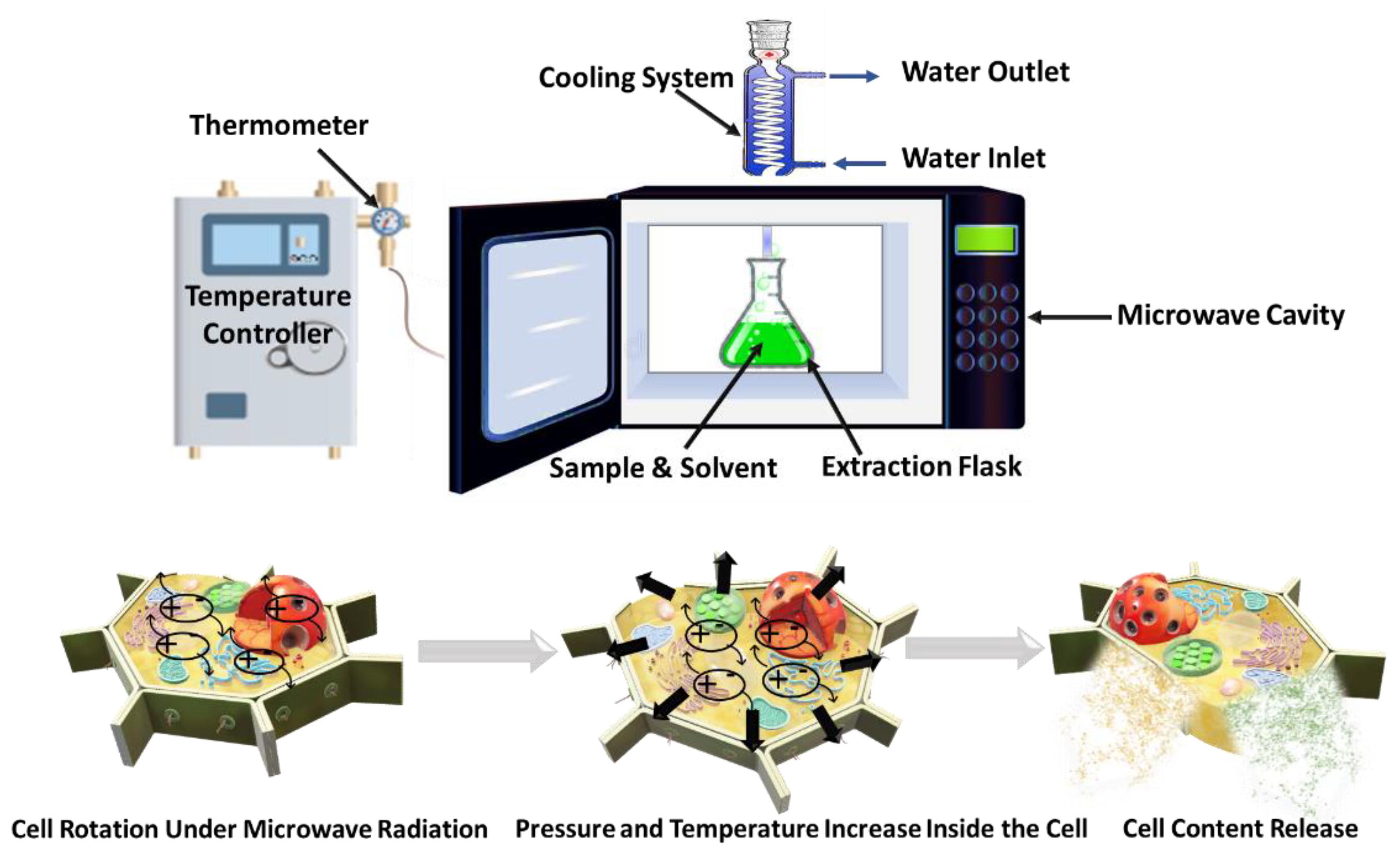

4.5. Microwave Technology

Microwave technology consists of an indirect way of heating materials by means of electromagnetic radiation at wavelengths comprised between ordinary radio waves, and infrared radiation in the frequency range between 300 MHz and 300 GHz, although in most common applications the frequency range is comprised between 1–40 GHz. This process leads to the evaporation of moisture inside the plant cells, which in turn causes an increase in the pressure exerted on the cell wall. Subsequently, modifications of the physical and biological characteristics of the vegetable tissue occur, leading to improved penetration of the extracting solvent into the biomass and increased extraction yields of the target intracellular compounds [75]. A schematic of MAE is reported in Figure 8. A large variety of factors can affect MAE, such as frequency, time and microwave power, moisture content and size of the sample, solvent type and concentration, solid/liquid ratio, extraction time as well as the number of extraction cycles [57]. The MAE process has been shown to be an environmentally friendly technology that enables greater extraction yields in shorter time and energy usage than traditional processes, and that can even be carried out without the use of solvents. However, this technology also has some drawbacks that need to be monitored, such as poor selectivity, non-uniform heating, and limited penetration of the microwaves, which could lead to reduced extraction efficiencies. In addition, thermal degradation of phenolic compounds and changes in the chemical structure of the target compounds due to overheating might occur, causing undesired effects on their bioactivity and hindering their usability [57][61][75][76].

Figure 8. Schematic of microwave technology and its mechanism.

Lycopene and beta-carotene, the main polyphenols in tomato wastes, are very thermosensitive compounds that can be detrimentally affected by the extraction conditions. Lasunon et al. (2021) evaluated the effectiveness of MAE at different processing conditions to extract bioactive compounds from tomato processing by-products. According to their results, the higher the microwave power and the extraction time, the greater the degradation of bioactive compounds would occur. Furthermore, bioactive compounds extracted under MAE processing conditions, which allowed the highest recovery yield, showed low antioxidant activity, indicating that degradation phenomena were likely to occur. Moreover, the overall performance indicator showed that at the best MAE conditions, namely 300 W applied for 60 s at a temperature not exceeding 77 °C, the bioactive compounds were recovered with a high yield and characterized by a high quality (lycopene: 5.74 mg/100 g dw and beta-carotene: 4.83 mg/100 g dw) [77].

With the aim of assessing the effect of MAE processing parameters, such as temperature, type of solvent, and time, on total flavonoids (TF), total phenols (TP), and phenolic compound recovery, Tranfić Bakić et al. (2019) utilized this technology for tomato peel valorization [78]. The researchers demonstrated that the extraction time had a limited effect (p > 0.05) on TF, TP, and phenolic compound extraction, while temperature and type of solvent significantly affected the polyphenols extraction yield. According to their results, the average TP content was 53.12 g/kg, and the highest recovery yields were obtained at 55 and 90 °C with the minimum processing time (5 min). Interestingly, the use of pure water as a solvent, which is characterized by a higher dielectric constant than less polar solvents and absorbs more microwave energy mainly in the low temperature range (25 °C–55 °C), resulted in a better extraction efficiency of phenolic compounds [78].

4.6. Sequential Extraction of High-Added-Value Compounds

With the aim of adopting a circular economy approach and reaching near-zero discharge, many studies have focused on the full valorization of tomato processing by-products through effective sequential extraction methods, consisting of the utilization of novel or conventional technologies in cascade, to recover the compounds of potential interest for application in different sectors.

Ouatmani et al. (2022), to increase the sustainability of industrial tomato processing waste valorization, considered the sequential recovery of oil from seeds and optimized antioxidant extraction by applying MAE. Soxhlet extraction was used to recover the oil from tomato seeds, resulting in a product rich in unsaturated fatty acids (79.83%). MAE was then applied to defatted tomato seeds to extract phenolic compounds. To identify the optimal operative conditions (solid/solvent ratio, microwave power, and processing time), the researchers used RSM. The application of microwaves at 700 W for 70 s with a 32.41% ethanol concentration resulted in an amount of total phenolic compounds extracted of 268.47 mg GAE/100 g with an antioxidant activity of 84.27%. MAE enhanced the recovery of phenolic compounds compared to conventional methods, including maceration and stirring, which led to the extraction of 171.3 and 181.6 mg GAE/100 g, respectively [79].

In addition, novel technologies can be utilized in combination with each other with the aim of achieving the valorization of tomato processing by-products.

Grassino et al. (2020) investigated the combination of high hydrostatic pressure extraction (HHPE) and UAE to improve the recovery of pectin, polyphenols, and fatty acids from tomato peels. The researchers reported that the application of HHPE and UAE coupled with a conventional extraction method (Soxhlet) provided an appropriate and effective solution for the successive extraction of pectin, polyphenols, and fatty acids from tomato processing by-products. Pectin extraction yield by HHPE in 45 min was 9.2%, while conventional extraction in 360 min was 7.7%. Results showed that tomato peels, both with pectin or depectinized, subjected to UAE had a high content of total phenolic compounds (TPC) (922.53–3643.88 mg/100 g), depending on the extraction time and solvent used. However, although TPC is significantly lower in depectinized residues, suggesting that a part of the phenols possibly migrated during HHPE and were released into pectin during nitric acid extraction, the amount remaining in the residual biomass is still appreciable. Interestingly, the residues obtained after UAE had high saturated FA content, such as lauric, palmitic, and stearic acids, indicating that UAE residues could be exploited for the recovery of these compounds. The researchers concluded that HHPE and UAE allowed for a considerable decrease in the extraction time, and the implementation of these technologies in the extraction process can be considered an appropriate alternative to conventional methods [80].

Grassino et al. (2020) also studied other processing methods for the concurrent recovery of pectin, polyphenols, and fatty acids from tomato peels, utilizing conventional extraction methods. Before extracting polyphenols and fatty acids, pectin was recovered from tomato peels and tested as a potential tin corrosion inhibitor. The researchers demonstrated that depectinized peels were effective bio-substrates for polyphenol extraction, possessing higher amounts of total phenols (2485.68–4064.46 mg/100 g) in comparison with the samples containing pectin. Additionally, depectinized samples contained more FAs (~45%) than those with pectin (~26%). Therefore, the researchers demonstrated that depectinized tomato peels can be used to recover polyphenols and fatty acids, and that the pectin recovered is a more effective and efficient tin corrosion inhibitor than the apple pectin commercially available (+26%) [81].

References

- Nicastro, R.; Carillo, P. Food Loss and Waste Prevention Strategies from Farm to Fork. Sustainability 2021, 13, 5443.

- Www.Ifco.Com. Available online: https://www.ifco.com/countries-with-the-least-and-most-food-waste%0A (accessed on 5 July 2022).

- Caldeira, C.; De Laurentiis, V.; Corrado, S.; van Holsteijn, F.; Sala, S. Quantification of Food Waste per Product Group along the Food Supply Chain in the European Union: A Mass Flow Analysis. Resour. Conserv. Recycl. 2019, 149, 479–488.

- Sharma, M.; Usmani, Z.; Gupta, V.K.; Bhat, R. Valorization of Fruits and Vegetable Wastes and By-Products to Produce Natural Pigments. Crit. Rev. Biotechnol. 2021, 41, 535–563.

- Capanoglu, E.; Nemli, E.; Tomas-Barberan, F. Novel Approaches in the Valorization of Agricultural Wastes and Their Applications. J. Agric. Food Chem. 2021, 70, 6787–6840.

- Tomato News. Available online: https://www.tomatonews.com/en/top10-of-global-processing-countries_2_640.html (accessed on 10 July 2022).

- Anicav. Available online: https://anicav.it/ (accessed on 7 June 2022).

- FAO: Food and Agriculture Organization of the United Nations. Available online: https://www.fao.org (accessed on 19 December 2022).

- Bugatti, V.; Brachi, P.; Viscusi, G.; Gorrasi, G. Valorization of Tomato Processing Residues through the Production of Active Bio-Composites for Packaging Applications. Front. Mater. 2019, 6, 34.

- Szabo, K.; Cătoi, A.F.; Vodnar, D.C. Bioactive Compounds Extracted from Tomato Processing By-Products as a Source of Valuable Nutrients. Plant Foods Hum. Nutr. 2018, 73, 268–277.

- Pataro, G.; Carullo, D.; Falcone, M.; Ferrari, G. Recovery of Lycopene from Industrially Derived Tomato Processing By-Products by Pulsed Electric Fields-Assisted Extraction. Innov. Food Sci. Emerg. Technol. 2020, 63, 102369.

- Li, Y.; Xu, F.; Li, Y.; Lu, J.; Li, S.; Shah, A.; Zhang, X.; Zhang, H.; Gong, X.; Li, G. Reactor Performance and Energy Analysis of Solid State Anaerobic Co-Digestion of Dairy Manure with Corn Stover and Tomato Residues. Waste Manag. 2018, 73, 130–139.

- Pirozzi, A.; Ferrari, G.; Donsì, F. Cellulose Isolation from Tomato Pomace Pretreated by High-Pressure Homogenization. Foods 2022, 11, 266.

- Coelho, M.; Pereira, R.; Rodrigues, A.S.; Teixeira, J.A.; Pintado, M.E. Extraction of Tomato By-Products’ Bioactive Compounds Using Ohmic Technology. Food Bioprod. Process. 2019, 117, 329–339.

- Jurić, S.; Ferrari, G.; Velikov, K.P.; Donsì, F. High-Pressure Homogenization Treatment to Recover Bioactive Compounds from Tomato Peels. J. Food Eng. 2019, 262, 170–180.

- Tiwari, S.; Yawale, P.; Upadhyay, N. Carotenoids Extraction Strategies and Potential Applications for Valorization of Under-Utilized Waste Biomass. Food Biosci. 2022, 48, 101812.

- Pataro, G.; Carullo, D.; Bakar Siddique, M.A.; Falcone, M.; Donsì, F.; Ferrari, G. Improved Extractability of Carotenoids from Tomato Peels as Side Benefits of PEF Treatment of Tomato Fruit for More Energy-Efficient Steam-Assisted Peeling. J. Food Eng. 2018, 233, 65–73.

- Ubeyitogullari, A.; Ciftci, O.N. Enhancing the Bioaccessibility of Lycopene from Tomato Processing Byproducts via Supercritical Carbon Dioxide Extraction. Curr. Res. Food Sci. 2022, 5, 553–563.

- Mechmeche, M.; Kachouri, F.; Chouabi, M.; Ksontini, H.; Setti, K.; Hamdi, M. Optimization of Extraction Parameters of Protein Isolate from Tomato Seed Using Response Surface Methodology. Food Anal. Methods 2017, 10, 809–819.

- Ferrari, G.; Donsì, F. High-Pressure Homogenization for the Recovery of Value-Added Compounds from Vegetable Matrices. Chem. Eng. Trans. 2021, 87, 235–240.

- Chan, C.H.; Yusoff, R.; Ngoh, G.C. Modeling and Kinetics Study of Conventional and Assisted Batch Solvent Extraction. Chem. Eng. Res. Des. 2014, 92, 1169–1186.

- Roohinejad, S.; Nikmaram, N.; Brahim, M.; Koubaa, M.; Khelfa, A.; Greiner, R. Potential of Novel Technologies for Aqueous Extraction of Plant Bioactives; Elsevier Inc.: Amsterdam, The Netherlands, 2017; ISBN 9780128096154.

- Scaglia, B.; D’Incecco, P.; Squillace, P.; Dell’Orto, M.; De Nisi, P.; Pellegrino, L.; Botto, A.; Cavicchi, C.; Adani, F. Development of a Tomato Pomace Biorefinery Based on a CO2-Supercritical Extraction Process for the Production of a High Value Lycopene Product, Bioenergy and Digestate. J. Clean. Prod. 2020, 243, 118650.

- Jawad, M.; Schoop, R.; Suter, A.; Klein, P.; Eccles, R. Chemical Characterization of Tomato Pomace. Rev. Fitoter. 2013, 13, 125–135.

- Dolatabadi, Z.; Elhami Rad, A.H.; Farzaneh, V.; Akhlaghi Feizabad, S.H.; Estiri, S.H.; Bakhshabadi, H. Modeling of the Lycopene Extraction from Tomato Pulps. Food Chem. 2016, 190, 968–973.

- Lu, Z.; Wang, J.; Gao, R.; Ye, F.; Zhao, G. Sustainable Valorisation of Tomato Pomace: A Comprehensive Review. Trends Food Sci. Technol. 2019, 86, 172–187.

- Savadkoohi, S.; Farahnaky, A. Dynamic Rheological and Thermal Study of the Heat-Induced Gelation of Tomato-Seed Proteins. J. Food Eng. 2012, 113, 479–485.

- Shao, D.; Atungulu, G.G.; Pan, Z.; Yue, T.; Zhang, A.; Chen, X. Separation Methods and Chemical and Nutritional Characteristics of Tomato Pomace. Am. Soc. Agric. Biol. Eng. 2013, 56, 261–268.

- Fuentes, E.; Carle, R.; Astudillo, L.; Guzmán, L.; Gutiérrez, M.; Carrasco, G.; Palomo, I. Antioxidant and Antiplatelet Activities in Extracts from Green and Fully Ripe Tomato Fruits (Solanum Lycopersicum) and Pomace from Industrial Tomato Processing. Evid.-Based Complement. Altern. Med. 2013, 2013, 867578.

- Pandya, D.P.; Akbari, S.H.; Bhatt, H.G.; Joshi, D.C.; Darji, V. Standardiztion of Solvent Extraction Process For Lycopene Extraction From Tomato Pomace. Int. J. Eng. Sci. Res. 2015, 3, 43–53.

- Nour, V.; Panaite, T.D.; Ropota, M.; Turcu, R.; Trandafir, I.; Corbu, A.R. Nutritional and Bioactive Compounds in Dried Tomato Processing Waste. CYTA—J. Food 2018, 16, 222–229.

- Grassino, A.N.; Halambek, J.; Djaković, S.; Rimac Brnčić, S.; Dent, M.; Grabarić, Z. Utilization of Tomato Peel Waste from Canning Factory as a Potential Source for Pectin Production and Application as Tin Corrosion Inhibitor. Food Hydrocoll. 2016, 52, 265–274.

- Elbadrawy, E.; Sello, A. Evaluation of Nutritional Value and Antioxidant Activity of Tomato Peel Extracts. Arab. J. Chem. 2016, 9, S1010–S1018.

- Wang, Q.; Xiong, Z.; Li, G.; Zhao, X.; Wu, H.; Ren, Y. Tomato Peel Powder as Fat Replacement in Low-Fat Sausages: Formulations with Mechanically Crushed Powder Exhibit Higher Stability than Those with Airflow Ultra-Micro Crushed Powder. Eur. J. Lipid Sci. Technol. 2016, 118, 175–184.

- Yilmaz, E.; Aydeniz, B.; Güneşer, O.; Arsunar, E.S. Sensory and Physico-Chemical Properties of Cold Press-Produced Tomato (Lycopersicon esculentum L.) Seed Oils. JAOCS J. Am. Oil Chem. Soc. 2015, 92, 833–842.

- Szabo, K.; Dulf, F.V.; Teleky, B.E.; Eleni, P.; Boukouvalas, C.; Krokida, M.; Kapsalis, N.; Rusu, A.V.; Socol, C.T.; Vodnar, D.C. Evaluation of the Bioactive Compounds Found in Tomato Seed Oil and Tomato Peels Influenced by Industrial Heat Treatments. Foods 2021, 10, 110.

- Giuffrè, A.M.; Capocasale, M. Physicochemical Composition of Tomato Seed Oil for an Edible Use: The Effect of Cultivar. Int. Food Res. J. 2016, 23, 583–591.

- Botineştean, C.; Gruia, A.T.; Jianu, I. Utilization of Seeds from Tomato Processing Wastes as Raw Material for Oil Production. J. Mater. Cycles Waste Manag. 2015, 17, 118–124.

- Giuffrè, A.M.; Capocasale, M. Sterol Composition of Tomato (Solanum lycopersicum L.) Seed Oil: The Effect of Cultivar. Int. Food Res. J. 2016, 23, 116–122.

- Mohamad Meshkani, S.; Ali Mortazavi, S.; Hosein Elhami Rad, A.; Beigbabaei, A. Optimization of Protein Extraction and Evaluation of Functional Properties of Tomato Waste and Seeds from Tomato Paste Plants. Biosci. Biotechnol. Res. Asia 2016, 13, 2387–2401.

- Silva, Y.P.A.; Borba, B.C.; Pereira, V.A.; Reis, M.G.; Caliari, M.; Brooks, M.S.L.; Ferreira, T.A.P.C. Characterization of Tomato Processing By-Product for Use as a Potential Functional Food Ingredient: Nutritional Composition, Antioxidant Activity and Bioactive Compounds. Int. J. Food Sci. Nutr. 2019, 70, 150–160.

- Shao, D.; Venkitasamy, C.; Shi, J.; Li, X.; Yokoyama, W.; Pan, Z. Optimization of Tomato Pomace Separation Using Air Aspirator System by Response Surface Methodology. Trans ASABE 2015, 58, 1885–1894.

- Kaur, D.; Sogi, D.S.; Garg, S.K.; Bawa, A.S. Flotation-Cum-Sedimentation System for Skin and Seed Separation from Tomato Pomace. J. Food Eng. 2005, 71, 341–344.

- Yong, S.X.M.; Song, C.P.; Choo, W.S. Impact of High-Pressure Homogenization on the Extractability and Stability of Phytochemicals. Front. Sustain. Food Syst. 2021, 4, 593259.

- Van Audenhove, J.; Bernaerts, T.; De Smet, V.; Delbaere, S.; Van Loey, A.M.; Hendrickx, M.E. The Structure and Composition of Extracted Pectin and Residual Cell Wall Material from Processing Tomato: The Role of a Stepwise Approach versus High-Pressure Homogenization-Facilitated Acid Extraction. Foods 2021, 10, 1064.

- Luengo, E.; Álvarez, I.; Raso, J. Improving Carotenoid Extraction from Tomato Waste by Pulsed Electric Fields. Front. Nutr. 2014, 1, 12.

- Hatami, T.; Meireles, M.A.A.; Ciftci, O.N. Supercritical Carbon Dioxide Extraction of Lycopene from Tomato Processing By-Products: Mathematical Modeling and Optimization. J. Food Eng. 2019, 241, 18–25.

- Kumcuoglu, S.; Yilmaz, T.; Tavman, S. Ultrasound Assisted Extraction of Lycopene from Tomato Processing Wastes. J. Food Sci. Technol. 2013, 51, 4102–4107.

- Machmudah, S.; Zakaria; Winardi, S.; Sasaki, M.; Goto, M.; Kusumoto, N.; Hayakawa, K. Lycopene Extraction from Tomato Peel By-Product Containing Tomato Seed Using Supercritical Carbon Dioxide. J. Food Eng. 2012, 108, 290–296.

- Carpentieri, S.; Mazza, L.; Nutrizio, M.; Jambrak, A.R.; Ferrari, G.; Pataro, G. Pulsed Electric Fields- and Ultrasound-Assisted Green Extraction of Valuable Compounds from Origanum vulgare L. and Thymus serpyllum L. Int. J. Food Sci. Technol. 2021, 56, 4834–4842.

- Kandušer, M.; Belič, A.; Čorović, S.; Škrjanc, I. Modular Serial Flow Through Device for Pulsed Electric Field Treatment of the Liquid Samples. Sci. Rep. 2017, 7, 8115.

- Joannes, C.; Sipaut, C.S.; Dayou, J. The Potential of Using Pulsed Electric Field ( PEF ) Technology as the Cell Disruption Method to Extract Lipid from Microalgae for Biodiesel Production. Int. J. Renew. Energy Res. 2015, 5, 598–621.

- Martínez, J.M.; Delso, C.; Álvarez, I.; Raso, J. Pulsed Electric Field-Assisted Extraction of Valuable Compounds from Microorganisms. Compr. Rev. Food Sci. Food Saf. 2020, 19, 530–552.

- Andreou, V.; Dimopoulos, G.; Dermesonlouoglou, E.; Taoukis, P. Application of Pulsed Electric Fields to Improve Product Yield and Waste Valorization in Industrial Tomato Processing. J. Food Eng. 2020, 270, 109778.

- Arnal, Á.J.; Royo, P.; Pataro, G.; Ferrari, G.; Ferreira, V.J.; López-Sabirón, A.M.; Ferreira, G.A. Implementation of PEF Treatment at Real-Scale Tomatoes Processing Considering LCA Methodology as an Innovation Strategy in the Agri-Food Sector. Sustainability 2018, 10, 979.

- Pataro, G.; Carullo, D.; Ferrari, G. Effect of PEF Pre-Treatment and Extraction Temperature on the Recovery of Carotenoids from Tomato Wastes. Chem. Eng. Trans. 2019, 75, 139–144.

- Strati, I.F.; Oreopoulou, V. Recovery of Carotenoids from Tomato Processing By-Products—A Review. Food Res. Int. 2014, 65, 311–321.

- Vilkhu, K.; Mawson, R.; Simons, L.; Bates, D. Applications and Opportunities for Ultrasound Assisted Extraction in the Food Industry—A Review. Innov. Food Sci. Emerg. Technol. 2008, 9, 161–169.

- Sengar, A.S.; Rawson, A.; Muthiah, M.; Kalakandan, S.K. Comparison of Different Ultrasound Assisted Extraction Techniques for Pectin from Tomato Processing Waste. Ultrason. Sonochem. 2020, 61, 104812.

- Aarabi Arabani, A.; Hosseini, F.; Anarjan, N. The Effects of Ultrasound Pretreatment Processes on Oil Extraction from Tomato Wastes. Int. J. Biosci. 2015, 6, 8–15.

- Aarabi Arabani, A.; Hosseini, F.; Anarjan, N. Pre-Processing and Oil Extraction from the Seeds of Tomato Wastes Using Microwave and Ultrasound Treatments. J. Appl. Environ. Biol. Sci. 2014, 4, 125–130.

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Celli, G.B.; Brooks, M.S. Optimization of Lycopene Extraction from Tomato Processing Waste Using an Eco-Friendly Ethyl Lactate–Ethyl Acetate Solvent: A Green Valorization Approach. Waste Biomass Valorization 2019, 10, 2851–2861.

- Silva, Y.P.A.; Ferreira, T.A.P.C.; Jiao, G.; Brooks, M.S. Sustainable Approach for Lycopene Extraction from Tomato Processing By-Product Using Hydrophobic Eutectic Solvents. J. Food Sci. Technol. 2019, 56, 1649–1654.

- Rahimi, S.; Mikani, M. Lycopene Green Ultrasound-Assisted Extraction Using Edible Oil Accompany with Response Surface Methodology (RSM) Optimization Performance: Application in Tomato Processing Wastes. Microchem. J. 2019, 146, 1033–1042.

- Li, J.; Pettinato, M.; Casazza, A.A.; Perego, P. A Comprehensive Optimization of Ultrasound-Assisted Extraction for Lycopene Recovery from Tomato Waste and Encapsulation by Spray Drying. Processes 2022, 10, 308.

- Ajlouni, S.; Premier, R.; Tow, W.W. Improving Extraction of Lycopene from Tomato Waste By-Products Using Ultrasonication and Freeze Drying. World J. Adv. Res. Rev. 2020, 2020, 2581–9615.

- Grassino, A.N.; Brnčić, M.; Vikić-Topić, D.; Roca, S.; Dent, M.; Brnčić, S.R. Ultrasound Assisted Extraction and Characterization of Pectin from Tomato Waste. Food Chem. 2016, 198, 93–100.

- Uwineza, P.A.; Waśkiewicz, A. Recent Advances in Supercritical Fluid Extraction of Natural Bioactive Compounds from Natural Plant Materials. Molecules 2020, 25, 3847.

- Barros, H.D.F.Q.; Grimaldi, R.; Cabral, F.A. Lycopene-Rich Avocado Oil Obtained by Simultaneous Supercritical Extraction from Avocado Pulp and Tomato Pomace. J. Supercrit. Fluids 2017, 120, 1–6.

- Lenucci, M.S.; De Caroli, M.; Marrese, P.P.; Iurlaro, A.; Rescio, L.; Böhm, V.; Dalessandro, G.; Piro, G. Enzyme-Aided Extraction of Lycopene from High-Pigment Tomato Cultivars by Supercritical Carbon Dioxide. Food Chem. 2015, 170, 193–202.

- Mihalcea, L.; Crăciunescu, O.; Gheonea, I.; Prelipcean, A.M.; Enachi, E.; Barbu, V.; Bahrim, G.E.; Râpeanu, G.; Oancea, A.; Stănciuc, N. Supercritical CO2 Extraction and Microencapsulation of Lycopene-Enriched Oleoresins from Tomato Peels: Evidence on Antiproliferative and Cytocompatibility Activities. Antioxidants 2021, 10, 222.

- Kehili, M.; Kammlott, M.; Choura, S.; Zammel, A.; Zetzl, C.; Smirnova, I.; Allouche, N.; Sayadi, S. Supercritical CO2 Extraction and Antioxidant Activity of Lycopene and β-Carotene-Enriched Oleoresin from Tomato (Lycopersicum esculentum L.) Peels by-Product of a Tunisian Industry. Food Bioprod. Process. 2017, 102, 340–349.

- Pellicanò, T.M.; Sicari, V.; Loizzo, M.R.; Leporini, M.; Falco, T.; Poiana, M. Optimizing the Supercritical Fluid Extraction Process of Bioactive Compounds from Processed Tomato Skin By-Products. Food Sci. Technol. 2020, 40, 692–697.

- Lisichkov, K.; Kuvendziev, S.; Lisichkov, B. Isolation of Tomato Seed Oil From Tomato Waste by Application of Supercritical Fluid CO2 Extraction. Qual. Life (Banja Luka)—APEIRON 2011, 3, 5–12.

- Alvi, T.; Asif, Z.; Iqbal Khan, M.K. Clean Label Extraction of Bioactive Compounds from Food Waste through Microwave-Assisted Extraction Technique-A Review. Food Biosci. 2022, 46, 101580.

- Al Jitan, S.; Alkhoori, S.A.; Yousef, L.F. Phenolic Acids From Plants: Extraction and Application to Human Health, 1st ed.; Elsevier B.V.: Amsterdam, The Netherlands, 2018; Volume 58, ISBN 9780444640567.

- Lasunon, P.; Phonkerd, N.; Tettawong, P.; Sengkhamparn, N. Effect of Microwave-Assisted Extraction on Bioactive Compounds from Industrial Tomato Waste and Its Antioxidant Activity. Food Res. 2021, 5, 468–474.

- Bakić, M.T.; Pedisić, S.; Zorić, Z.; Dragović-Uzelac, V.; Grassino, A.N. Effect of Microwave-Assisted Extraction on Polyphenols Recovery from Tomato Peel Waste. Acta Chim. Slov. 2019, 66, 367–377.

- Ouatmani, T.; Haddadi-Guemghar, H.; Boulekbache-Makhlouf, L.; Mehidi-Terki, D.; Maouche, A.; Madani, K. A Sustainable Valorization of Industrial Tomato Seeds (Cv Rio Grande): Sequential Recovery of a Valuable Oil and Optimized Extraction of Antioxidants by Microwaves. J. Food Process. Preserv. 2022, 46, e16123.

- Ninčević Grassino, A.; Ostojić, J.; Miletić, V.; Djaković, S.; Bosiljkov, T.; Zorić, Z.; Ježek, D.; Rimac Brnčić, S.; Brnčić, M. Application of High Hydrostatic Pressure and Ultrasound-Assisted Extractions as a Novel Approach for Pectin and Polyphenols Recovery from Tomato Peel Waste. Innov. Food Sci. Emerg. Technol. 2020, 64, 102424.

- Ninčević Grassino, A.; Djaković, S.; Bosiljkov, T.; Halambek, J.; Zorić, Z.; Dragović-Uzelac, V.; Petrović, M.; Rimac Brnčić, S. Valorisation of Tomato Peel Waste as a Sustainable Source for Pectin, Polyphenols and Fatty Acids Recovery Using Sequential Extraction. Waste Biomass Valorization 2020, 11, 4593–4611.

More

Information

Subjects:

Engineering, Chemical

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.2K

Revisions:

2 times

(View History)

Update Date:

10 Jan 2023

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No