Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Xiuyu Wang | -- | 1056 | 2022-11-24 17:38:51 | | | |

| 2 | Amina Yu | + 2 word(s) | 1058 | 2022-11-25 01:54:25 | | | | |

| 3 | Amina Yu | Meta information modification | 1058 | 2022-11-25 01:54:27 | | | | |

| 4 | Amina Yu | Meta information modification | 1058 | 2022-11-28 08:51:35 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Wang, X.; Wang, F.; Taleb, M.A.M.; Wen, Z.; Chen, X. Alkaline–Surfactant–Polymer Flooding Mechanisms. Encyclopedia. Available online: https://encyclopedia.pub/entry/36405 (accessed on 08 February 2026).

Wang X, Wang F, Taleb MAM, Wen Z, Chen X. Alkaline–Surfactant–Polymer Flooding Mechanisms. Encyclopedia. Available at: https://encyclopedia.pub/entry/36405. Accessed February 08, 2026.

Wang, Xiuyu, Fuqiong Wang, Mohanad A. M. Taleb, Zhiyuan Wen, Xiulin Chen. "Alkaline–Surfactant–Polymer Flooding Mechanisms" Encyclopedia, https://encyclopedia.pub/entry/36405 (accessed February 08, 2026).

Wang, X., Wang, F., Taleb, M.A.M., Wen, Z., & Chen, X. (2022, November 24). Alkaline–Surfactant–Polymer Flooding Mechanisms. In Encyclopedia. https://encyclopedia.pub/entry/36405

Wang, Xiuyu, et al. "Alkaline–Surfactant–Polymer Flooding Mechanisms." Encyclopedia. Web. 24 November, 2022.

Copy Citation

Chemical flooding, expecially alkali–surfactant–polymer (ASP) injection plays an important role in enhancing oil recovery under many synergetic mechanisms, in which there are four main mechanisms that have been widely used, including improving the mobility ratio between the heavy oil and the displacing phase, lowering the interfacial tension between oil and water (IFT), altering the rock wettability (oil-wet to water-wet) and emulsifying oil and water. Laboratory tests and pilot trials of ASP injection showed that the oil recovery of the emulsified system is 5% more than the cases where no emulsions existed.

chemical flooding

ASP flooding

emulsions

enhance oil recovery

1. Introduction

The alkaline–surfactant–polymer (ASP) flooding technology consists of a mixture of chemicals and methods that is used to optimize the recovery of heavy oil [1]. The scenario of how this technique works is manifested in the main mechanisms of ASP flooding. Therefore, before presenting the interactions and synergy of ASP, the main mechanisms of each component are first discussed individually.

2. Polymer Flooding Mechanisms

Polymer flooding is an EOR technique in which a high-viscosity polymer solution is injected into the formation to reduce the mobility ratio, increase the swept volume, and, hence, improve the oil recovery [2]. In other words, polymer injection is similar to waterflooding except that the polymer is diluted in water to increase the viscosity of the solution [3]. Consequently, increasing the viscosity of the polymer slug widens the swept area by preventing viscous fingering [4]. Over the past decade, many studies have focused on polymer flooding and how it works under different conditions. After many extensive types of research, it was found that polymer viscoelastic behavior results in some mechanisms that enhance heavy oil recovery. Sheng et al. [5]. summarized four recovery mechanisms related to polymer viscoelasticity: (1) the pulling mechanism, (2) oil-thread flow mechanism, (3) stripping mechanism and (4) shear-thickening mechanism.

2. Surfactant Flooding Mechanisms

Surfactants are generally used to overcome the immiscibility between water and oil by reducing the interfacial tension (IFT) between them and changing the wettability of the reservoir rocks to water-wet so that the seepage and, eventually, the recovery of the residual oil in the formation are enhanced. According to the nature of the hydrophilic head, surfactants can be classified into four main categories: anionic surfactants, cationic surfactants, non-ionic surfactants, and zwitterionic (amphoteric) surfactants [6][7]. The effects of surfactants are generally linked to four main mechanisms: reduction in the interfacial tension, alteration of the wettability, and emulsification and foam generation, through which surfactants prove to be beneficial as a chemical EOR (CEOR) method.

3. Alkali Flooding Mechanisms

Alkaline (or caustic) flooding is a chemical method that can be used to increase the oil displacement efficiency and, consequently, more of the remaining oil can be produced [8]. The benefits of this process are based on the reaction between sodium hydroxide (NaOH) with the naturally occurring organic acids in crude oil, which results in soap production at the oil–water interface. In situ production of this type of surfactant results in a reduction in the interfacial tension (IFT) between oil and water. Alkaline basicity (pH) ranges from 8 to 14, where 14 is considered to be a very strong alkaline agent. The use of a strong alkali does not necessarily provide incremental oil recovery because the use of strong alkalis is more likely to result in a loss in production capacity and scaling problems [9].

4. ASP Flooding Synergy and Its EOR Applications

ASP flooding is a mixture technique that injects alkali (A), surfactant (S), and polymer (S) solutions into the reservoir formation to improve the exploitation of crude oil. After carrying out extensive studies, it was proved that the integrated synergistic mechanism of each component of the injected alkali–surfactant–polymer slugs is the main reason for the significant success of ASP injection and why it is regarded as the most prominent CEOR technique [1]. Chen et al. [10] conducted a laboratory experiment on several core samples to investigate the impact of the synergistic mechanisms of injecting a multi-component chemical system (ASP) on improving crude oil recovery compared to single-component (polymer, alkali, surfactant) and double-component chemical systems (AS, AP, SP). The results of these experiments showed that the injection of the multi-component chemical system (ASP) achieved the highest recovery percentage of crude oil compared to the other systems, which proves the effects of the contribution of the synergistic mechanisms within the ASP flooding components.

Now, to provide a deeper insight into ASP synergy, which makes it more efficient than other CEOR techniques, the potential effects of ASP components were investigated on the solution viscosity, IFT, and the amount of A/S/P adsorption [11]:

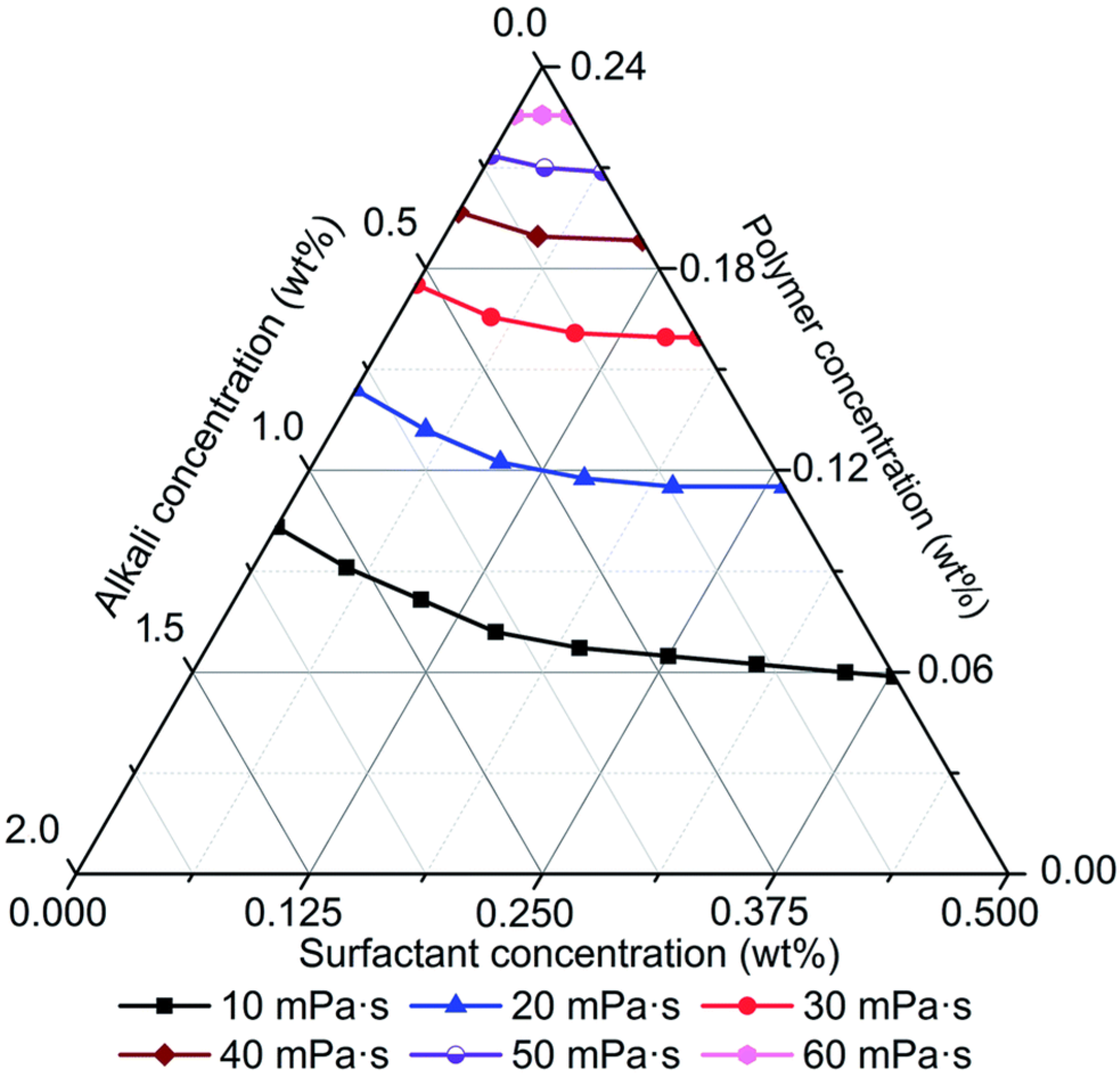

(1) The effects of ASP components on viscosity: The solution viscosity is primarily controlled by the amount of polymer followed by the alkali concentration and lastly, the surfactant concentration, as shown in Figure 1 [10].

Figure 1. Effects of ASP components on viscosity[10].

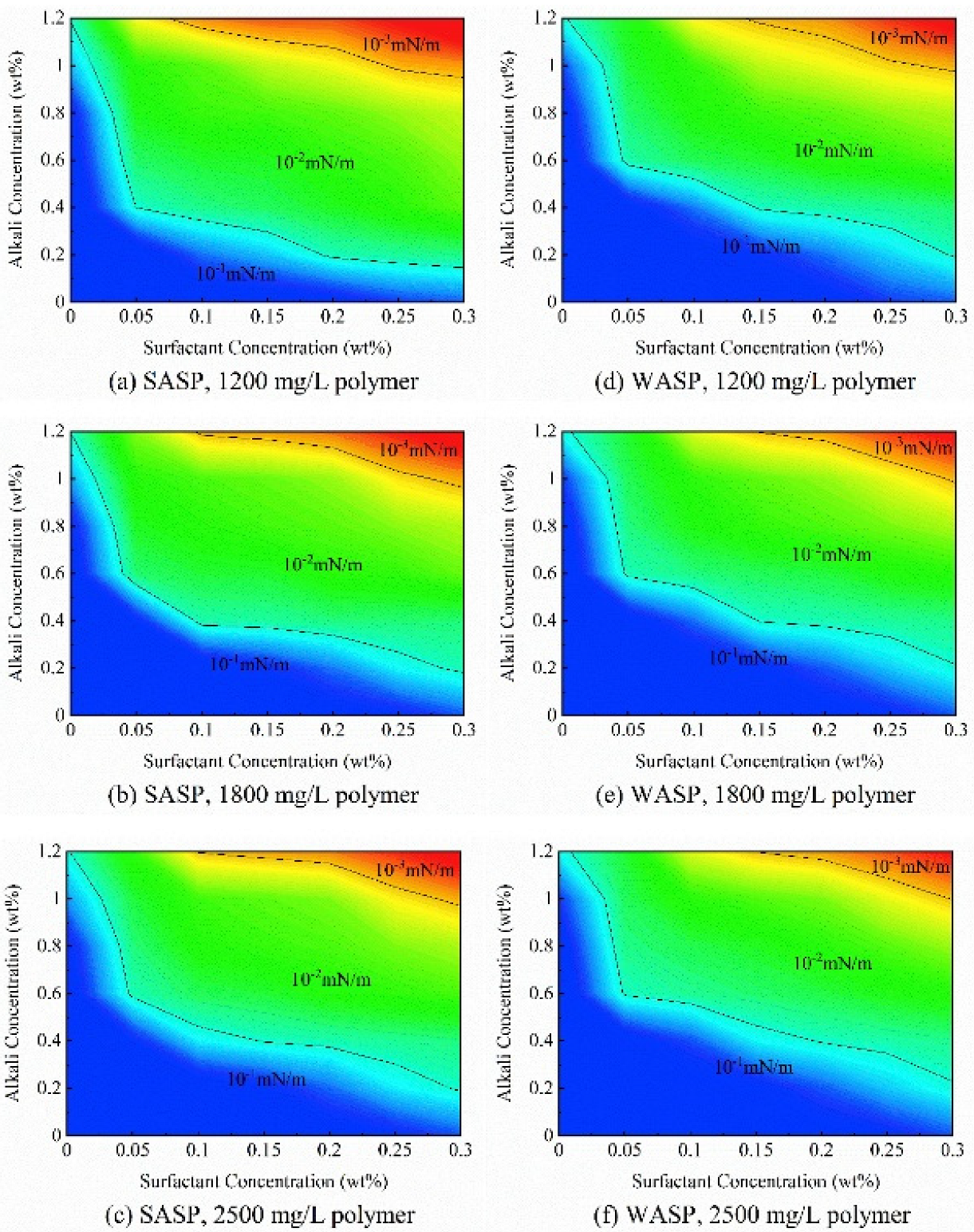

(2) The effects of ASP components on the interfacial tension (IFT): The surfactant is the primary component that controls the changes in IFT during ASP injection, followed by alkali and, finally, polymer, as shown in Figure 2, in which SASP means strong alkali-surfactant-polymer, while, WASP means weak alkali-surfactant-polymer.

Figure 2. Effects of ASP components on IFT [12].

Field trials are considered to be essential for ASP flooding projects to move from the stage of laboratory experiments to the final stage of field applications. During the implementation of pilot tests, petroleum engineers should carry out proper measurements of the injection system, i.e., the injection mode and well pattern/spacing, to ensure the highest, most economic oil recovery is achieved under a certain set of conditions. According to several previous studies, 32 ASP flooding field trials have been reported so far worldwide, including 19 inshore projects in China, 7 inshore projects in the USA, 3 inshore projects in Canada, 2 inshore projects in India, and finally, one offshore project in Venezuela. The basic information of these projects is summarized in Table 2 [1][13][14][15][16][17][18][19][20][21][22][23][24][25].

Table 2. Summary of recent ASP field trails.

| Location | Field | Wells No. (P/J) * |

Well Spacing /ft |

Total Chemicals, PV × Concentration/% | Oil Recovery (%) |

||

|---|---|---|---|---|---|---|---|

| Alkali | Surfactant | Polymer | |||||

| USA | Cambridge | – | – | 38.38 | 3.07 | 4.53 | 28.00 |

| West Kiehl | – | – | 20 | 2.5 | 2.63 | 26.00 | |

| Tanner | 2/1 | 656.5 | 25.1 | 2.51 | 2.51 | 17.00 | |

| Mellot Ranch | 3/2 | – | 30.1 | 3.01 | 3.91 | – | |

| Lawrence | 6/12 | 230.0 | 25 | 43.75 | 5.5 | 24.00 | |

| Sho-Vel-Tum | 4/1 | 233.3 | 88 | 15 | 4.38 | 20.00 | |

| Brookshire | 4/1 | – | – | – | – | 21.00 | |

| Little Bow | – | – | 24 | 15 | 27 | 5.70 | |

| Canada | Taber South | 45/18 | – | 25.5 | 5.1 | 4.08 | 7.30 |

| Mooney | – | – | – | – | – | – | |

| India | Viraj | 9/4 | 738.2 | 30 | 4 | 2.8 | – |

| Jhalora | 6/1 | – | 75 | 7.5 | 6.9 | – | |

| Venezuela | Lagomar | – | – | 17.5 | 7 | 5 | – |

| China (Daqing) |

S-ZX | 9/4 | 347.8 | 40 | 9.6 | 5.54 | 21.40 |

| X5-Z | 4/1 | 459.3 | 48.47 | 11.84 | 8.57 | 25.00 | |

| X2-X | 9/4 | 656.2 | 132.24 | 20.79 | 9.96 | 19.40 | |

| S-B | 4/3 | 246.1 | 57.6 | 12.96 | 10.24 | 23.34 | |

| B1-FBX | 12/6 | 820 | 132.24 | 20.79 | 9.96 | 20.63 | |

| X2-Z | 27/17 | 820.2 | 46.31 | 8.17 | 9.92 | 18.10 | |

| SB-B2-Z | 4/3 | 246.1 | 77 | 10.5 | 12.36 | 24.66 | |

| SL-GDX | 13/6 | 820 | 132.24 | 20.79 | 9.96 | 15.50 | |

| N-5 | 39/29 | 574.1 | – | – | – | 19.80 | |

| B-1E | 63/49 | 410.0 | – | – | – | 30.00 | |

| B-2X | 44/35 | 410.0 | – | – | – | 29.40 | |

| S6 | 160/144 | 574.1 | – | – | – | – | |

| X1-2D | 143/112 | 492.1 | – | – | – | 18.50 | |

| X6-EI | 112/102 | 462.6 | – | – | – | 18.50 | |

| X6-DII | 109/105 | 462.2 | – | – | – | 19.00 | |

| China | Karamay | 9/4 | 164.0 | 47.18 | 10.11 | 6.04 | 25.00 |

| China (Sheng-li) |

Gu-dong | 9/4 | 164.0 | 60 | 15.2 | 4.6 | 26.00 |

| Gu-dao | 13/6 | 695.5 | 37.08 | 9.27 | 8.07 | 15.50 | |

| China (Jilin) |

Hong-gang | – | 656.2 | 13.5 | 1.08 | 2.70 | – |

| China | ZY-HZ-J | 5/4 | – | – | – | – | 0.61 |

| China (Yu-men) |

L-J-M | 4/1 | 229.7 | 95.86 | 214.2 | 4.21 | 1.82 |

* (P/J): The numbers of producers to injectors.

References

- Olajire, A.A. Review of ASP EOR (alkaline surfactant polymer enhanced oil recovery) technology in the petroleum industry: Prospects and challenges. Energy 2014, 77, 963–982.

- Lu, X.; Cao, B.; Xie, K.; Cao, W.; Liu, Y.; Zhang, Y.; Wang, X.; Zhang, J. Enhanced oil recovery mechanisms of polymer flooding in a heterogeneous oil reservoir. Pet. Explor. Dev. 2021, 48, 169–178.

- Asghari, K.; Nakutnyy, P. Experimental results of polymer flooding of heavy oil reservoirs. In Proceedings of the Canadian International Petroleum Conference, Calgary, AB, Canada, 17–19 June 2008.

- Tang, M.; Zhang, G.; Ge, J.; Jiang, P.; Liu, Q.; Pei, H.; Chen, L. Investigation into the mechanisms of heavy oil recovery by novel alkaline flooding. Colloids Surf. A Physicochem. Eng. Asp. 2013, 421, 91–100.

- Sheng, J.; Leonhardt, B.; Al Azri, N.S. Status of Polymer-Flooding Technology. J. Can. Pet. Technol. 2015, 54, 116–126.

- Kume, G.; Gallotti, M.; Nunes, G. Review on Anionic/Cationic Surfactant Mixtures. J. Surfactants Deterg. 2007, 11, 1–11.

- Borchardt, J.; Bright, D.; Dickson, M.; Wellington, S. Surfactants for CO2 foam flooding. In Proceedings of the SPE Annual Technical Conference and Exhibition, Las Vegas, NV, USA, 22–26 September 1985.

- Khlaifat, A.L.; Dakhlallah, D.; Sufyan, F. A Critical Review of Alkaline Flooding: Mechanism, Hybrid Flooding Methods, Laboratory Work, Pilot Projects, and Field Applications. Energies 2022, 15, 3820.

- Guo, H.; Li, Y.; Wang, F.; Gu, Y. Comparison of Strong-Alkali and Weak-Alkali ASP-Flooding Field Tests in Daqing Oil Field. SPE Prod. Oper. 2017, 33, 353–362.

- Chen, F.; Gu, J.; Jiang, H.; Yao, X.; Li, Y. Laboratory evaluation and numerical simulation of the alkali–surfactant–polymer synergistic mechanism in chemical flooding. RSC Adv. 2018, 8, 26476–26487.

- Li, J.; Niu, L.; Lu, X. Performance of ASP compound systems and effects on flooding efficiency. J. Pet. Sci. Eng. 2019, 178, 1178–1193.

- Pratap, M.; Gauma, M.S. Field implementation of Alkaline-Surfactant-Polymer (ASP) flooding: A maiden effort in India. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 18–20 October 2004.

- Vargo, J.; Turner, J.; Vergnani, B.; Pitts, M.J.; Wyatt, K.; Surkalo, H.; Patterson, D. Alkaline-Surfactant-Polymer Flooding of the Cambridge Minnelusa Field. SPE Reserv. Eval. Eng. 2000, 3, 552–558.

- Pitts, M.J.; Dowling, P.; Wyatt, K.; Surkalo, H.; Adams, K.C. Alkaline-surfactant-polymer flood of the tanner field. In Proceedings of the SPE/DOE Symposium on Improved Oil Recovery, Tulsa, OK, USA, 20 April 2006.

- Seyler, B.; Grube, J.; Huff, B.; Webb, N.; Damico, J.; Blakley, C.; Madhavan, V.; Johanek, P.; Frailey, S. Reservoir Characterization of Bridgeport and Cypress Sandstones in Lawrence Field Illinois to Improve Petroleum Recovery by Alkaline-Surfactant-Polymer Flood; DOE Project DE-NT0005664; University of Illinois: Champaign, IL, USA, 2012.

- Meyers, J.; Pitts, M.; Wyatt, K. Alkaline-Surfactant-Polymer flood of the West Kiehl, Minnelusa Unit. In Proceedings of the SPE/DOE Enhanced Oil Recovery Symposium, Tulsa, OK, USA, 22–24 April 1992.

- French, T. Evaluation of the Sho-Vel-Tum Alkali-Surfactant-Polymer (ASP) Oil Recovery Project; DOE/SW/45030-1; National Petroleum Technology Office (NPTO): Tulsa, OK, USA, 1999.

- Charest, M. Alkaline-Surfactant-Polymer (ASP) Flooding in Alberta: Small Amounts of the Right Chemicals Can Make a Big Difference. Can. Discov. Dig. 2013, 1, 20–52.

- Pratap, M.; Gauma, M.S. Field implementation of Alkaline-Surfactant-Polymer (ASP) flooding: A maiden effort in India. In Proceedings of the SPE Asia Pacific Oil and Gas Conference and Exhibition, Perth, Australia, 18–20 October 2004.

- Chang, H.; Zhang, Z.; Wang, Q.; Xu, Z.; Guo, Z.; Sun, H.; Cao, X.; Qiao, Q. Advances in Polymer Flooding and Alkaline/Surfactant/Polymer Processes as Developed and Applied in the People’s Republic of China. J. Pet. Technol. 2006, 58, 84–89.

- Qi, Q.; Gu, H.; Li, D.; Dong, L. The pilot test of ASP combination flooding in Karamay oil field. In Proceedings of the International Oil and Gas Conference and Exhibition in China, Beijing, China, 7–10 November 2000.

- Wang, C.; Wang, B.; Cao, X.; Li, H. Application and design of Alkaline-Surfactant-Polymer system to close well spacing pilot Gudong oilfield. In Proceedings of the SPE Western Regional Meeting, Long Beach, CA, USA, 25–27 June 1997.

- Sheng, J.J. A comprehensive review of alkaline-surfactant-polymer (ASP) flooding. Asia-Pac. J. Chem. Eng. 2014, 9, 471–489.

- Clara, H.; Larry, C.; Lorenzo, A.; Reinaldo, A.; Eduardo, M.; Eucario, R.; De Audemard, N.; Charles, C.; Hernández, C.; Chacon, L.; et al. Single well chemical tracer test to determine ASP injection efficiency at Lagomar VLA-6/9/21 Area, C4 Member, Lake Maracaibo, Venezuela. In Proceedings of the SPE/DOE Improved Oil Recovery Symposium, Tulsa, OK, USA, 14–18 April 2002.

- Jiang, J.; Guo, D.; Li, X.; Zhao, P.; Wang, X.; Wu, X.; Li, G. Pilot Field Trial of Natural Mixed Carbox-ylates/Xanthan Flood at Well H5-15 Block in Huzhuangli Oil Field. Oilfield Chem. 2003, 1, 58–60.

More

Information

Subjects:

Engineering, Petroleum

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

2.7K

Revisions:

4 times

(View History)

Update Date:

28 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No