| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Zhong qi Xie | -- | 3766 | 2022-11-24 02:59:56 | | | |

| 2 | Zhong qi Xie | + 76 word(s) | 3842 | 2022-11-24 03:29:21 | | | | |

| 3 | Rita Xu | -7 word(s) | 3835 | 2022-11-24 03:50:06 | | | | |

| 4 | Zhong qi Xie | -7 word(s) | 3835 | 2022-11-24 03:58:35 | | |

Video Upload Options

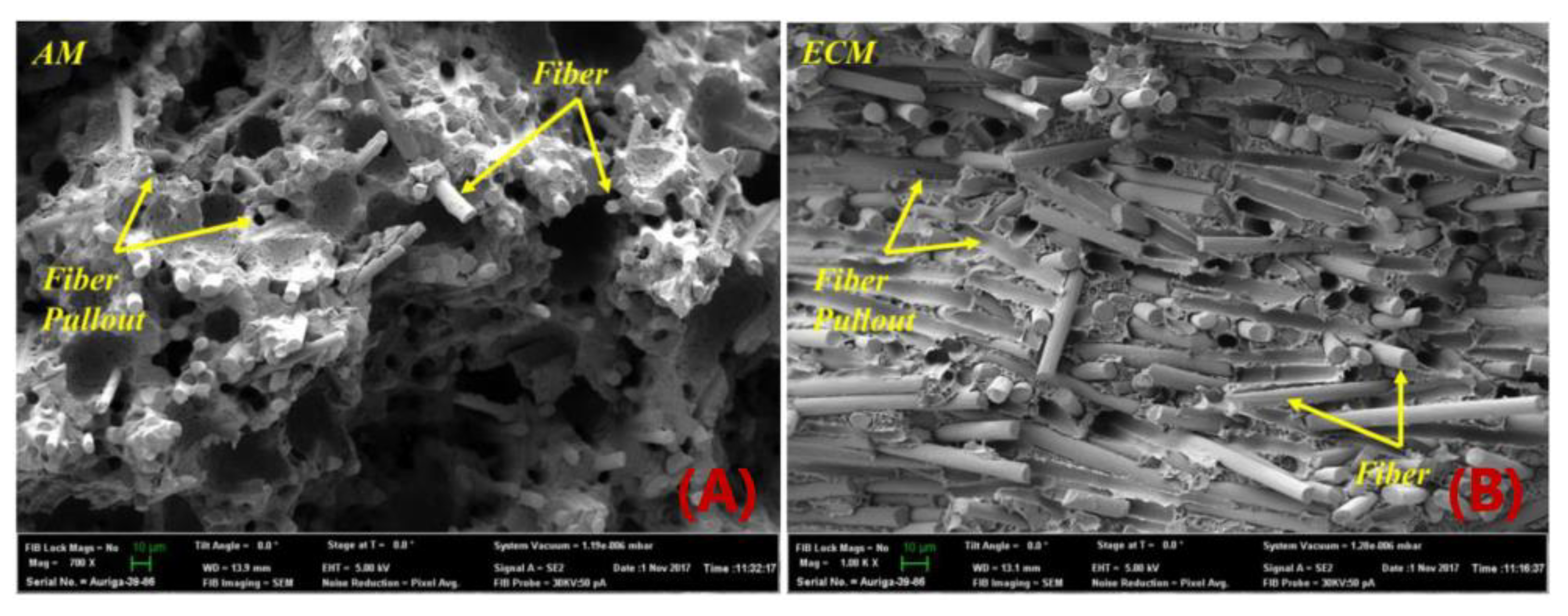

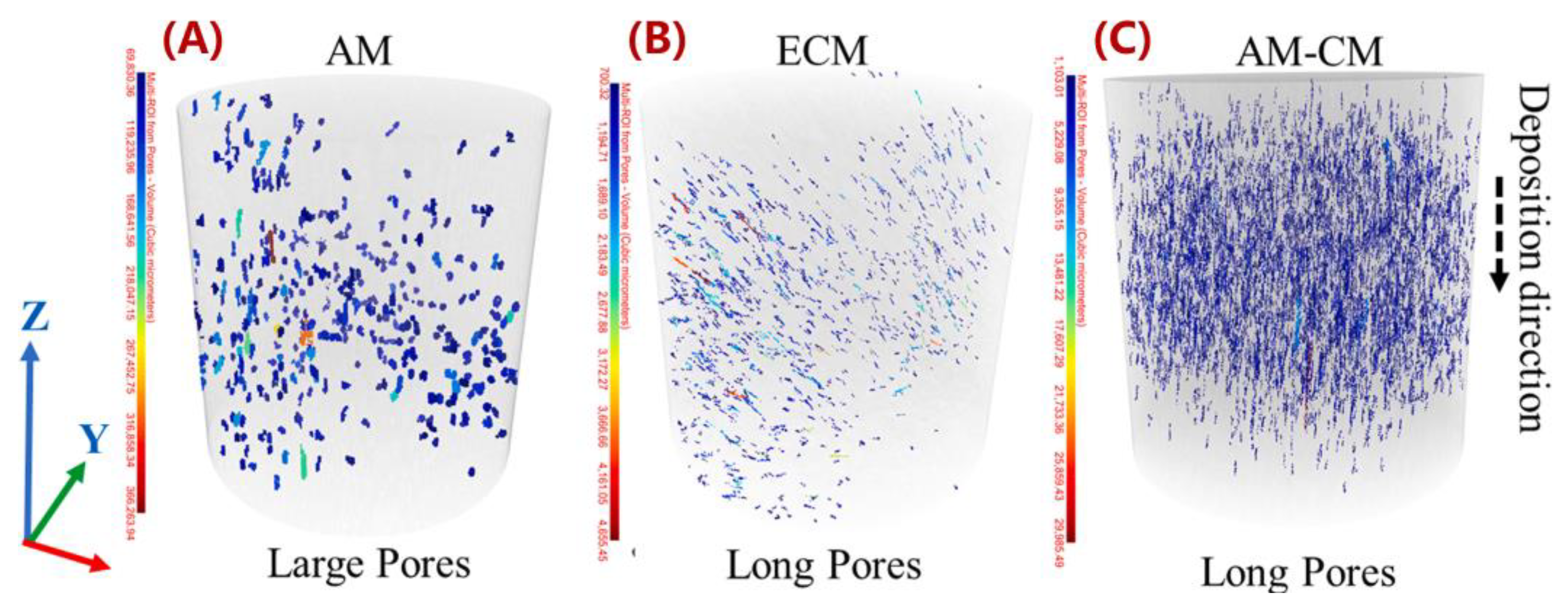

A discontinuous fiber-reinforced polymer composite (DFRPC) provides superior mechanical performances in material extrusion additive manufacturing (MEAM) parts, and thus promotes their implementations in engineering applications. The process-induced structural defects of DFRPCs increase the probability of pre-mature failures as the manufactured parts experience complicated external loads. The process-induced fiber length attrition and micro-voids formations in MEAM applications is provided. By gaining a clearer view of the correlations between the MEAM processing parameters, and tooling and the resulting microstructures of produced DFRPCs, it is expected to manufacture composites parts with more preferable mechanical properties via MEAM.

1. Introduction

2. Fiber Length Attrition

3. Micro-Voids

References

- FDM European Union Trademark Information. Available online: https://www.trademarkelite.com/europe/trademark/trademark-detail/011163524/FDM (accessed on 5 September 2022).

- Guo, N.; Leu, M.C. Additive manufacturing: Technology, applications and research needs. Front. Mech. Eng. 2013, 8, 215–243.

- Daminabo, S.C.; Goel, S.; Grammatikos, S.A.; Nezhad, H.Y.; Thakur, V.K. Fused deposition modeling-based additive manufacturing (3D printing): Techniques for polymer material systems. Mater. Today Chem. 2020, 16, 100248.

- Ismail, K.I.; Yap, T.C.; Ahmed, R. 3D-Printed Fiber-Reinforced Polymer Composites by Fused Deposition Modelling (FDM): Fiber Length and Fiber Implementation Techniques. Polymers 2022, 14, 4659.

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C.A. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898.

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Fused filament fabrication of fiber-reinforced polymers: A review. Addit. Manuf. 2018, 21, 1–16.

- $20 Million Additive Manufacturing Initiative Connects Local Economies with National Lab, UMaine Resources. Available online: https://composites.umaine.edu/2019/05/02/new-20-million-additive-manufacturing-initiative-connects-local-economies-with-national-lab-umaine-resources/ (accessed on 30 May 2021).

- The Strati: World’s First 3D Printed Car Built in 44 Hours. Available online: https://fossbytes.com/strati-worlds-first-3d-printed-car-built-44-hours/ (accessed on 5 September 2022).

- Talagani, M.R.; DorMohammadi, S.; Dutton, R.; Godines, C.; Baid, H.; Abdi, F.; Kunc, V.; Compton, B.; Simunovic, S.; Duty, C.; et al. Numerical simulation of big area additive manufacturing (3D printing) of a full size car. Sampe J. 2015, 51, 27–36.

- LSAM Large Scale Additive Manufacturing Systems. Available online: https://www.advanced-machine-systems.co.uk/product/lsam-systems/ (accessed on 5 September 2022).

- This 3D-Printed Sub Could Be the Future of Undersea Warfare. Available online: https://www.popularmechanics.com/technology/robots/a34826410/dive-technology-3d-printed-submarine/ (accessed on 5 September 2022).

- Nieto, D.M.; López, V.C.; Molina, S.I. Large-format polymeric pellet-based additive manufacturing for the naval industry. Addit. Manuf. 2018, 23, 79–85.

- Peterson, E. Technical Challenges to Adopting Large Scale Additive Manufacturing for the Production of Yacht Hulls. In International Conference on Human Systems Engineering and Design: Future Trends and Applications; Springer: Berlin/Heidelberg, Germany, 2020; pp. 15–20.

- Post, B.K.; Chesser, P.C.; Lind, R.F.; Roschli, A.; Love, L.J.; Gaul, K.T.; Sallas, M.; Blue, F.; Wu, S. Using Big Area Additive Manufacturing to directly manufacture a boat hull mould. Virtual Phys. Prototyp. 2019, 14, 123–129.

- AM Opportunities in the Wind Turbine Industry. Available online: https://www.engineerlive.com/content/am-opportunities-wind-turbine-industry (accessed on 5 September 2022).

- Bishop, E.G.; Leigh, S.J. Using large-scale additive manufacturing as a bridge manufacturing process in response to shortages in personal protective equipment during the COVID-19 outbreak. Int. J. Bioprinting 2020, 6, 281.

- Yan, Y.; Ngo, K.D.T.; Mei, Y.; Lu, G.-Q. Additive manufacturing of magnetic components for power electronics integration. In Proceedings of the 2016 International Conference on Electronics Packaging (ICEP), Hokkaido, Japan, 20–22 April 2016; IEEE: Piscataway, NJ, USA, 2016; pp. 368–371.

- Espalin, D.; Muse, D.W.; MacDonald, E.; Wicker, R.B. 3D Printing multifunctionality: Structures with electronics. Int. J. Adv. Manuf. Technol. 2014, 72, 963–978.

- Mackay, M.E. The importance of rheological behavior in the additive manufacturing technique material extrusion. J. Rheol. 2018, 62, 1549–1561.

- Xia, H.; Lu, J.; Tryggvason, G. A numerical study of the effect of viscoelastic stresses in fused filament fabrication. Comput. Methods Appl. Mech. Eng. 2019, 346, 242–259.

- Serdeczny, M.P.; Comminal, R.; Mollah, M.T.; Pedersen, D.B.; Spangenberg, J. Viscoelastic simulation and optimisation of the polymer flow through the hot-end during filament-based material extrusion additive manufacturing. Virtual Phys. Prototyp. 2022, 17, 205–219.

- Pollard, D.; Ward, C.; Herrmann, G.; Etches, J. The manufacture of honeycomb cores using Fused Deposition Modeling. Adv. Manuf. Polym. Compos. Sci. 2017, 3, 21–31.

- Mao, A.; Zhao, N.; Liang, Y.; Bai, H. Mechanically Efficient Cellular Materials Inspired by Cuttlebone. Adv. Mater. 2021, 33, 2007348.

- D’Amico, A.A.; Debaie, A.; Peterson, A.M. Effect of layer thickness on irreversible thermal expansion and interlayer strength in fused deposition modeling. Rapid Prototyp. J. 2017, 23, 943–953.

- Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A de-sign-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803.

- Shubham, P.; Sikidar, A.; Chand, T. The influence of layer thickness on mechanical properties of the 3D printed ABS polymer by fused deposition modeling. In Key Engineering Materials; Trans Tech Publications Ltd: Bäch, Switzerland, 2016; Volume 706, pp. 63–67.

- Vicente, C.M.; Martins, T.S.; Leite, M.; Ribeiro, A.; Reis, L. Influence of fused deposition modeling parameters on the mechanical properties of ABS parts. Polym. Adv. Technol. 2020, 31, 501–507.

- Buj-Corral, I.; Domínguez-Fernández, A.; Durán-Llucià, R. Influence of print orientation on surface roughness in fused deposition modeling (FDM) processes. Materials 2019, 12, 3834.

- Hernandez, R.; Slaughter, D.; Whaley, D.; Tate, J.; Asiabanpour, B. Analyzing the tensile, compressive, and flexural properties of 3D printed ABS P430 plastic based on printing orientation using fused deposition modeling. In Proceedings of the 2016 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 8–10 August 2016.

- Ravindrababu, S.; Govdeli, Y.; Wong, Z.W.; Kayacan, E. Evaluation of the influence of build and print orientations of unmanned aerial vehicle parts fabricated using fused deposition modeling process. J. Manuf. Process. 2018, 34, 659–666.

- Galicia JA, G.; Benes, B. Improving printing orientation for Fused Deposition Modeling printers by analyzing connected components. Addit. Manuf. 2018, 22, 720–728.

- Beattie, N.; Bock, N.; Anderson, T.; Edgeworth, T.; Kloss, T.; Swanson, J. Effects of Build Orientation on Mechanical Properties of Fused Deposition Modeling Parts. J. Mater. Eng. Perform. 2021, 30, 5059–5065.

- Kuipers, T.; Doubrovski, E.L.; Wu, J.; Wang, C.C. A Framework for Adaptive Width Control of Dense Contour-Parallel Toolpaths in Fused Deposition Modeling. Comput. Des. 2020, 128, 102907.

- Kumar, N.; Shaikh, S.; Jain, P.K.; Tandon, P. Effect of fractal curve based toolpath on part strength in fused deposition modelling. Int. J. Rapid Manuf. 2015, 5, 186–198.

- Shaikh, S.; Kumar, N.; Jain, P.K.; Tandon, P. Hilbert curve based toolpath for FDM process. In CAD/CAM, Robotics and Factories of the Future; Springer: New Delhi, India, 2016; pp. 751–759.

- Liu, W.; Li, Y.; Liu, B.; Wang, G. Development of a novel rectangular–circular grid filling pattern of fused deposition modeling in cellular lattice structures. Int. J. Adv. Manuf. Technol. 2020, 108, 3419–3436.

- Dev, S.; Srivastava, R. Effect of infill parameters on material sustainability and mechanical properties in fused deposition modelling process: A case study. Prog. Addit. Manuf. 2021, 6, 631–642.

- Dave, H.K.; Patadiya, N.H.; Prajapati, A.R.; Rajpurohit, S.R. Effect of infill pattern and infill density at varying part orientation on tensile properties of fused deposition modeling-printed poly-lactic acid part. J. Mech. Eng. Sci. 2021, 235, 1811–1827.

- Milde, J.; Morovič, L. The influence of internal structures in fused deposition modeling method on dimensional accuracy of components. Ved. Práce Mater. Fak. Slov. Tech. Univ. 2016, 24, 73.

- Hsueh, M.H.; Lai, C.J.; Liu, K.Y.; Chung, C.F.; Wang, S.H.; Pan, C.Y.; Huang, W.C.; Hsieh, C.H.; Zeng, Y.S. Effects of Printing Temperature and Filling Percentage on the Mechanical Behavior of Fused Deposition Molding Technology Components for 3D Printing. Polymers 2021, 13, 2910.

- Aloyaydi, B.A.; Sivasankaran, S.; Ammar, H.R. Influence of infill density on microstructure and flexural behavior of 3D printed PLA thermoplastic parts processed by fusion deposition modeling. AIMS Mater. Sci. 2019, 6, 1033–1048.

- Srinivasan, R.; Ruban, W.; Deepanraj, A.; Bhuvanesh, R.; Bhuvanesh, T. Effect on infill density on mechanical properties of PETG part fabricated by fused deposition modelling. Mater. Today Proc. 2020, 27, 1838–1842.

- Cuan-Urquizo, E.; Álvarez-Trejo, A.; Gil, A.R.; Tejada-Ortigoza, V.; Camposeco-Negrete, C.; Uribe-Lam, E.; Treviño-Quintanilla, C.D. Effective stiffness of fused deposition modeling infill lattice patterns made of PLA-wood material. Polymers 2022, 14, 337.

- Feng, Q.; Maier, W.; Möhring, H.C. Application of machine learning to optimize process parameters in fused deposition mod-eling of PEEK material. Procedia CIRP 2022, 107, 1–8.

- Bhatt, P.M.; Malhan, R.K.; Rajendran, P.; Gupta, S.K. Building free-form thin shell parts using supportless extrusion-based additive manufacturing. Addit. Manuf. 2020, 32, 101003.

- Barrrionuevo, G.O.; Ramos-Grez, J.A. Machine learning for optimizing technological properties of wood composite fi-la-ment-Timberfill fabricated by fused deposition modeling. In Proceedings of the International Conference on Applied Technologies, Quito, Ecuador, 3–5 December 2019; Springer: Berlin/Heidelberg, Germany, 2019; pp. 119–132.

- Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174.

- Abeykoon, C.; Sri-Amphorn, P.; Fernando, A. Optimization of fused deposition modeling parameters for improved PLA and ABS 3D printed structures. Int. J. Lightweight Mater. Manuf. 2020, 3, 284–297.

- Camposeco-Negrete, C. Optimization of printing parameters in fused deposition modeling for improving part quality and process sustainability. Int. J. Adv. Manuf. Technol. 2020, 108, 2131–2147.

- Dey, A.; Hoffman, D.; Yodo, N. Optimizing multiple process parameters in fused deposition modeling with particle swarm optimization. Int. J. Interact. Des. Manuf. 2020, 14, 393–405.

- Uddin, M.S.; Sidek, M.F.R.; Faizal, M.A.; Ghomashchi, R.; Pramanik, A. Evaluating mechanical properties and failure mechanisms of fused deposition modeling acrylonitrile butadiene styrene parts. J. Manuf. Sci. Eng. 2017, 139, 081018.

- Upadhyay, K.; Dwivedi, R.; Singh, A.K. Determination and comparison of the anisotropic strengths of fused deposition modeling P400 ABS. In Advances in 3D Printing & Additive Manufacturing Technologies; Springer: Singapore, 2017; pp. 9–28.

- Somireddy, M.; Czekanski, A. Anisotropic material behavior of 3D printed composite structures–Material extrusion additive manufacturing. Mater. Des. 2020, 195, 108953.

- Gao, X.; Qi, S.; Kuang, X.; Su, Y.; Li, J.; Wang, D. Fused filament fabrication of polymer materials: A review of interlayer bond. Addit. Manuf. 2021, 37, 101658.

- Tronvoll, S.A.; Welo, T.; Elverum, C.W. The effects of voids on structural properties of fused deposition modelled parts: A probabilistic approach. Int. J. Adv. Manuf. Technol. 2018, 97, 3607–3618.

- Tao, Y.; Kong, F.; Li, Z.; Zhang, J.; Zhao, X.; Yin, Q.; Xing, D.; Li, P. A review on voids of 3D printed parts by fused filament fabrication. J. Mater. Res. Technol. 2021, 15, 4860–4879.

- Van de Werken, N.; Tekinalp, H.; Khanbolouki, P.; Ozcan, S.; Williams, A.; Tehrani, M. Additively manufactured carbon fiber-reinforced composites: State of the art and perspective. Addit. Manuf. 2020, 31, 100962.

- Hu, C.; Qin, Q.H. Advances in fused deposition modeling of discontinuous fiber/polymer composites. Curr. Opin. Solid State Mater. Sci. 2020, 24, 100867.

- Chen, F.; Ekinci, A.; Li, L.; Cheng, M.; Johnson, A.A.; Gleadall, A.; Han, X. How do the printing parameters of fused filament fabrication and structural voids influence the degradation of biodegradable devices? Acta Biomater. 2021, 136, 254–265.

- Allum, J.; Moetazedian, A.; Gleadall, A.; Silberschmidt, V.V. Interlayer bonding has bulk-material strength in extrusion additive manufacturing: New understanding of anisotropy. Addit. Manuf. 2020, 34, 101297.

- Verbeeten WM, H.; Lorenzo-Bañuelos, M.; Arribas-Subiñas, P.J. Anisotropic rate-dependent mechanical behavior of poly (lactic acid) processed by material extrusion additive manufacturing. Addit. Manuf. 2020, 31, 100968.

- Brenken, A.B.; Favaloro, E.; Barocio, R.B. Pipes, Simulation of semi-crystalline composite tooling made by extrusion deposition additive manufacturing. In Proceedings of the International SAMPE Technical Conference, Seattle, WA, USA, 22–25 May 2017; pp. 1758–1770.

- Heller, B.P.; Smith, D.E.; Jack, D.A. Effects of extrudate swell and nozzle geometry on fiber orientation in Fused Filament Fab-rication nozzle flow. Addit. Manuf. 2016, 12, 252–264.

- Turner, B.N.; Gold, S.A. A review of melt extrusion additive manufacturing processes: II. Materials, dimensional accuracy, and surface roughness. Rapid Prototyp. J. 2015, 21, 250–261.

- Ding, Q.; Li, X.; Zhang, D.; Zhao, G.; Sun, Z. Anisotropy of poly (lactic acid)/carbon fiber composites prepared by fused deposition modeling. J. Appl. Polym. Sci. 2020, 137, 48786.

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.A.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150.

- Duty, C.E.; Kunc, V.; Compton, B.; Post, B.; Erdman, D.; Smith, R.; Lind, R.; Lloyd, P.; Love, L. Structure and mechanical behavior of Big Area Additive Manufacturing (BAAM) materials. Rapid Prototyp. J. 2017, 23, 181–189.

- Mulholland, T.; Goris, S.; Boxleitner, J.; Osswald, T.A.; Rudolph, N. Fiber Orientation Effects in Fused Filament Fabrication of Air-Cooled Heat Exchangers. JOM 2018, 70, 298–302.

- Brenken, B.; Barocio, E.; Favaloro, A.; Kunc, V.; Pipes, R.B. Development and validation of extrusion deposition additive manufacturing process simulations. Addit. Manuf. 2019, 25, 218–226.

- Compton, B.G.; Post, B.K.; Duty, C.E.; Love, L.; Kunc, V. Thermal analysis of additive manufacturing of large-scale ther-mo-plastic polymer composites. Addit. Manuf. 2017, 17, 77–86.

- Hoskins, D.; Kim, S.; Hassen, A.; Lindahl, J.; Kunc, V.; Duty, C. Modeling thermal expansion of a large area extrusion depo-sition additively manufactured parts using a non-homogenized approach. In Proceedings of the Solid Freeform Fab-rication Symposium, Austin, TX, USA, 12–14 August 2019; pp. 1165–1174.

- Kim, P.; Baid, H.; Hassen, A.; Kumar, A.; Lindahl, J.; Hoskins, D.; Ajinjeru, C.; Duty, C.; Yeole, P.; Vaidya, U.; et al. Analysis on Part Distortion and Residual Stress in Big Area Additive Manufacturing with Carbon Fiber-Reinforced Thermoplastic Using Dehomogenization Technique; Oak Ridge National Lab (ORNL): Oak Ridge, TN, USA, 2019.

- Wang, L.T. Bending behavior of sandwich composite structures with tunable 3D-printed core materials. Compos. Struct. 2017, 175, 46–57.

- Hou, S.; Li, T.; Jia, Z.; Wang, L. Mechanical properties of sandwich composites with 3d-printed auxetic and non-auxetic lattice cores under low velocity impact. Mater. Des. 2018, 160, 1305–1321.

- Hassan, A.; Ahmed, W.; Zaneldin, E. Investigating the Impact of Inclusions on the Behavior of 3D-Printed Composite Sandwich Beams. Buildings 2022, 12, 1448.

- Essassi, K.; Rebiere, J.L.; El Mahi, A.; Souf, M.A.B.; Bouguecha, A.; Haddar, M. Experimental and analytical investigation of the bending behaviour of 3D-printed bio-based sandwich structures composites with auxetic core under cyclic fatigue tests. Compos. Part A Appl. Sci. Manuf. 2020, 131, 105775.

- Jiang, D.; Smith, D.E. Anisotropic mechanical properties of oriented carbon fiber filled polymer composites produced with fused filament fabrication. Addit. Manuf. 2017, 18, 84–94.

- Ning, F.; Cong, W.; Qiu, J.; Wei, J.; Wang, S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused dep-osition modeling. Compos. Part B Eng. 2015, 80, 369–378.

- Berzin, F.; Beaugrand, J.; Dobosz, S.; Budtova, T.; Vergnes, B. Lignocellulosic fiber breakage in a molten polymer. Part 3. Modeling of the dimensional change of the fibers during compounding by twin screw extrusion. Compos. Part A Appl. Sci. Manuf. 2017, 101, 422–431.

- Hausnerová, B.; Honkova, N.; Lengálová, A.; Kitano, T.; Saha, P. Rheology and fiber degradation during shear flow of car-bon-fiber-reinforced polypropylenes. Polym. Sci. Ser. A 2006, 48, 951–960.

- Aigner, M.; Salaberger, D.; Köpplmayr, T.; Heise, B.; Schausberger, S.; Buchsbaum, A.; Stifter, D.; Miethlinger, J. Determining the orientation, distributions, and concentration of glass fibers in polymer matrix using X-ray computed tomography and optical coherence tomography images. In Proceedings of the Conference on Industrial Computed Tomography-Non destructive Testing, 3D Materials Characterisation und Dimensional Measurement, Wels, Austria, 25–28 February 2014; pp. 395–402.

- Goris, S. Experimental Study on Fiber Attrition of Long Glass Fiber-Reinforced Thermoplastics under Controlled Conditions in a Couette Flow. In Proceedings of the Annual technical conference and exhibition-Society of Plastics Engineers, California, CA, USA, 8–10 May 2017.

- Zhuang, H.; Ren, P.; Zong, Y.; Dai, G. Relationship between fiber degradation and residence time distribution in the processing of long fiber reinforced thermoplastics. Express Polym. Lett. 2008, 2, 560–568.

- Bailey, R.; Kraft, H. A study of fibre attrition in the processing of long fibre reinforced thermoplastics. Int. Polym. Process. 1987, 2, 94–101.

- Bayush, T.L.; Thattai, B.; Pillay, S.; Vaidya, U. Processing and Characterization of Hemp Fiber Reinforced Polypropylene Composites. In Proceedings of the Eccm15—15th European Conference on Composite Materials, Venice, Italy, 24–28 June 2012.

- Gamon, G.; Evon, P.; Rigal, L. Twin-screw extrusion impact on natural fibre morphology and material properties in poly (lactic acid) based biocomposites. Ind. Crops Prod. 2013, 46, 173–185.

- Inoue, A.; Morita, K.; Tanaka, T.; Arao, Y.; Sawada, Y. Effect of screw design on fiber breakage and dispersion in injection-molded long glass-fiber-reinforced polypropylene. J. Compos. Mater. 2015, 49, 75–84.

- Russell, T.; Jack, D.A. Fiber Aspect Ratio Characterization and Stiffness Prediction in Large-Area, Additive Manufactured, Short-Fiber Composites. In Proceedings of the SPE ACCE 2019, Novi, MI, USA, 4–6 September 2019.

- Wang, Z.; Smith, D.E.; Jack, D.A. A Statistical Homogenization Approach for Incorporating Fiber Aspect Ratio Distribution in Large Area Polymer Composite Deposition Additive Manufacturing Property Predictions. Addit. Manuf. 2021, 43, 102006.

- Yeole, P.; Hassen, A.A.; Kim, S.; Lindahl, J.; Kunc, V.; Franc, A.; Vaidya, U. Mechanical characterization of high-temperature carbon fiber-polyphenylene sulfide composites for large area extrusion deposition additive manufacturing. Addit. Manuf. 2020, 34, 101255.

- Béreaux, Y.; Charmeau, J.-Y.; Moguedet, M. Modelling of fibre damage in single screw processing. Int. J. Mater. Form. 2008, 1, 827–830.

- Phelps, J.H.; Abd El-Rahman, A.I.; Kunc, V.; Tucker, C.L., III. A model for fiber length attrition in injection-molded long-fiber composites. Compos. Part A Appl. Sci. Manuf. 2013, 51, 11–21.

- Bechara, A.; Goris, S.; Yanev, A.; Brands, D.; Osswald, T. Novel modeling approach for fiber breakage during molding of long fiber-reinforced thermoplastics. Phys. Fluids 2021, 33, 073318.

- Al-Maharma, A.Y.; Patil, S.P.; Markert, B. Effects of porosity on the mechanical properties of additively manufactured components: A critical review. Mater. Res. Express 2020, 7, 122001.

- Yu, S.; Bale, H.; Park, S.; Hwang, J.Y.; Hong, S.H. Anisotropic microstructure dependent mechanical behavior of 3D-printed basalt fiber-reinforced thermoplastic composites. Compos. Part B Eng. 2021, 224, 109184.

- Kong, X.; Luo, J.; Luo, Q.; Li, Q.; Sun, G. Experimental study on interface failure behavior of 3D printed continuous fiber reinforced composites. Addit. Manuf. 2022, 59, 103077.

- Papon, E.A.; Haque, A.; Spear, S.K. Effects of functionalization and annealing in enhancing the interfacial bonding and mechanical properties of 3D printed fiber-reinforced composites. Mater. Today Commun. 2020, 25, 101365.

- Chisena, R.S.; Engstrom, S.M.; Shih, A.J. Computed tomography evaluation of the porosity and fiber orientation in a short carbon fiber material extrusion filament and part. Addit. Manuf. 2020, 34, 101189.

- Somireddy, M.; Singh, C.V.; Czekanski, A. Mechanical behaviour of 3D printed composite parts with short carbon fiber rein-forcements. Eng. Fail. Anal. 2020, 107, 104232.

- Sommacal, S.; Matschinski, A.; Drechsler, K.; Compston, P. Characterisation of void and fiber distribution in 3D printed carbon-fiber/PEEK using X-ray computed tomography. Compos. Part A Appl. Sci. Manuf. 2021, 149, 106487.

- Kumar, V.; Alwekar, S.P.; Kunc, V.; Cakmak, E.; Kishore, V.; Smith, T.; Lindahl, J.; Vaidya, U.; Blue, C.; Theodore, M.; et al. High-performance molded composites using additively manufactured preforms with controlled fiber and pore morphology. Addit. Manuf. 2021, 37, 101733.

- Tagscherer, N.; Schromm, T.; Drechsler, K. Foundational Investigation on the Characterization of Porosity and Fiber Orientation Using XCT in Large-Scale Extrusion Additive Manufacturing. Materials 2022, 15, 2290.

- Awenlimobor, A.; Wang, Z.; Smith, D.E. Physical Modeling: Simulation of Micro-Void Development within Large Scale Polymer Composite Deposition Beads. In Proceedings of the 2021 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 2–4 August 2021; pp. 1402–1416.