Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Raad Z. Homod | -- | 4034 | 2022-11-21 12:33:07 | | | |

| 2 | Rita Xu | Meta information modification | 4034 | 2022-11-22 03:37:06 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Almssad, A.; Almusaed, A.; Homod, R.Z. Masonry in the Context of Sustainable Buildings. Encyclopedia. Available online: https://encyclopedia.pub/entry/35571 (accessed on 07 February 2026).

Almssad A, Almusaed A, Homod RZ. Masonry in the Context of Sustainable Buildings. Encyclopedia. Available at: https://encyclopedia.pub/entry/35571. Accessed February 07, 2026.

Almssad, Asaad, Amjad Almusaed, Raad Z. Homod. "Masonry in the Context of Sustainable Buildings" Encyclopedia, https://encyclopedia.pub/entry/35571 (accessed February 07, 2026).

Almssad, A., Almusaed, A., & Homod, R.Z. (2022, November 21). Masonry in the Context of Sustainable Buildings. In Encyclopedia. https://encyclopedia.pub/entry/35571

Almssad, Asaad, et al. "Masonry in the Context of Sustainable Buildings." Encyclopedia. Web. 21 November, 2022.

Copy Citation

The process of combining various parts to create a structure is called building. The most effective and significant component of any construction is masonry. The Colosseum, buildings from ancient Greece and Rome, Central American buildings, and Mycenaean structures all used this material as one of their primary building elements. The oldest form is dry masonry of irregularly shaped stones. The ecological qualities of masonry, as a restorative material with a low impact on the environment, as well as the environmental control capacity of the massive wall, bring masonry back to attention as a suitable material for sustainable building in the context of current concerns for sustainable architecture.

contemporary architecture

bricks

masonry

1. Introduction and Background

Adobe is the name given to the earliest-used bricks in the western hemisphere, initially by the Aztecs [1][2]. Durand and colleagues [3] affirm that the precipitation of calcium carbonate is common in soils (especially those in arid regions) and regolith’s. Calcareous porous clay is also found in arid regions of the world, and is commonly mined in Central America, Mexico, and the southwestern United States. Manzanilla and co-authors [4] have concluded that the Pyramid of the Sun, which has stood the test of time, was created from adobe in the fifteenth century. Unlike modern bricks, the ancient one—adobe in other words—was square and flat (sides 30–60 cm, thickness only 3–9 cm).

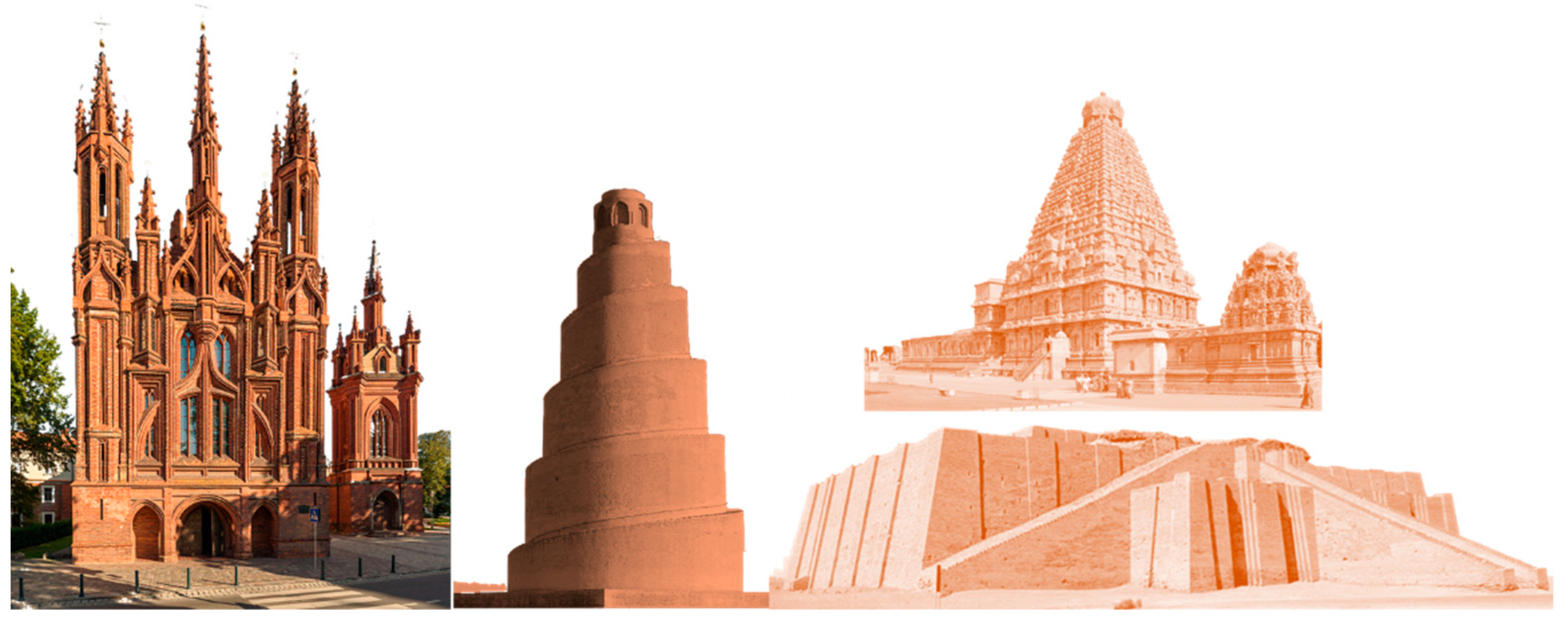

Brick walls are typically used to create the outside walls of structures, parapets, interior partitions, freestanding walls, retaining walls, and other vertical construction elements (see Figure 1). One may define masonry simply as the art of building with bricks. It implies that there are two types of masonry—one of which is brick. It can be further sub-categorized as clay-work and cement work, with clay and cement used to fill up the joints and build walls. The strength of masonry is simply its ability to support the load imposed by the structural elements above it.

Figure 1. Brick different forms and structures.

In contrast, its ability to maintain its position under horizontal loading is referred to as its stability. The application of loads to masonry creates internal stresses and deformations. The brand of mortar and brick, the shape and size of the masonry materials, and the thickness and density of the mortar layers together determine the strength of the masonry.

2. History—The Evolution from BC to AD

2.1. Ancient Civilizations—Rome, Mesopotamia, Greece, and China

Thirty centuries ago, humans were already familiar with processing (hewing, grinding) unfired bricks and building various structures using them. At the same time, there was a transition from laying “dry” to laying on clay and, subsequently, around 1000 BC, to laying on lime mortar. Hamburg and Lorenzon [5] propound the idea that, in the second and first millennia BC, using mudbricks (sun-dried clay bricks) and adobes (clay mixed with straw), civilizations commenced in the construction of fortresses and palaces, as well as mansions. The bricks were introduced in cases where a paucity of unfired bricks was experienced. Initially, as mentioned, raw bricks were usually superimposed, one on top of the other, without mortar. They cohered to each other lightly, creating a monolithic masonry.

Suzan and colleagues [6] opine that in the clayey river meadows of the Nile valley in Egypt, about 150 centuries ago, people fabricated artificial bricks from clay using molds solidified by an admixture of chopped straw and camel dung. A technological quantum jump occurred when ‘burnt brick’ was invented around 4000 BC. [7], and this made it possible to produce bricks in different colors. Binici and colleagues [8][9] have referred to excavations in burnt-brick buildings that have been utilized for a very long period, as evidenced by their employment in Mesopotamia, Egypt, and other early centers of civilization. Almusaed and co-authors [10] have explained that the brick-makers who made the unburnt fiber tiles (alternatives to burnt bricks) simply soaked and kneaded clay soil, mixed it with various additives (straw, manure, chips, etc.) and, having densified it, solar-dried the mass. Raad Z.H. et al. [11] assumed that bricks were strong, did not break when dropped from a height of about 2 m, and did not get wet for 1–2 days when exposed to rainfall. Moisture resistance was the main disadvantage of the unburnt fiber tiles, which were thus unsuitable for wetter climates.

Bricks have the reputation of being the earliest construction materials, and the first ones—mud bricks—were molded and naturally dried clay bars. Adding small pebbles and straws to the raw materials was expected to increase strength and reduce shrinkage [12]. However, the approaches were vastly different from the Egyptians sometimes laying dried bricks into the wall on a liquid clay mortar, and the Assyrians gluing freshly molded material into a monolith. Greater strength facilitated the construction of more massive structures—palaces, temples, etc.—in combination with burnt brick, which conferred durability to the structures. Han et al. have noted that burnt bricks are standard features between structural frames in the building and construction sectors owing to their simplicity of use [13].

In ancient Rome, a hydraulic binder—pozzolana (the origin of the name can be traced to Pozzuoli in Naples)—was used for masonry mortar. Excavations in Babylon show that the part of the city east of the Euphrates—4 million m2 in the area—was shielded by brick walls. When the Mesopotamian culture was at its peak, decorative brick walls were a common sight. Adamo and Almusaed refer to the processional route from the Ishtar Gate to the city of Babylon, built by King Nebuchadnezzar and rebuilt by the Persian king Darius I around 500 BC [14][15][16].

A Greek house with walls lined with raw bricks, dating back to 800–600 BC, was unearthed in Kamesh-Burden. However, southern Europe’s large-scale use of ceramic bricks (59 cm long, and 4–7 cm thick) dates back to 200–100 BC. According to Giuseppe and co-authors, the raw materials for these bricks used in southern Europe comprised clay and resin. The practice began with unbaked bricks—the clay drying up in the sun’s heat and hardening [17]. Rossi & Almusaed believe that the ancient Egyptians, who pioneered and mastered the art of firing bricks in kilns, checked the correctness of the masonry of the walls with a triangle, and that the bricks were worn on the yokes, and assert that they adhered to this method of construction consistently [18][19].

The history of Chinese building construction has gone through three stages. One is the era of the most ancient caves and various nests, and then the era of the coexistence of wooden houses and thatched houses. In China, fired bricks have been employed in construction for at least 2000 years. Since the middle of the 19th century, a new system has replaced the previous one in the brick manufacturing process. European red brick and other contemporary goods have progressively supplanted the distinctive Chinese blue brick [20]. After modern times, adobe houses and red bricks appeared. Accordingly, a building made of red brick is not susceptible to damage from wind and rain and is durable, even for a hundred years. One can talk of sintered (clay) and non-sintered (lime–sand and fly ash) bricks in China. The former is made of clay, shale, and coal gangue material and is subjected to mud treatment, drying, and roasting processes, according to Amin Al-Fakih and co-authors. When the Qin and Han dynasties ruled China 221–207 BC, architecture flourished, and with it, the technology, scale of production, quality, and diversity of bricks [21]. Most old homes, including those in the ancient city of Pingyao in Shanxi, Huizhou homes, the old courtyard in Beijing, and other conserved historical buildings, such as the Big Wild Goose Pagoda and the old city wall, are constructed of blue bricks. Blue bricks made up most of the materials used to build load-bearing buildings in ancient China [22].

Focusing on ancient Rome, researchers define the concept—opus maximum-layered masonry—referring to walls being made of layers of different materials, usually bricks alternating with each other. The brick facade included strips of baked bricks running along the entire depth of the wall. With all these types of masonry, it must be emphasized that the bricks were usually cut, that is, they were treated like stones. The bricks delivered to the construction site from the kiln were considered simply as blocks that could be trimmed (cut to the required size, in other words) in situ, before being laid into the wall. The Romans embellished brickwork with images, thus beautifying it even further. Nadali considers that sometimes they, “like the Babylonians”, used bricks tapering towards one end, making the mortar layers’ visible side thinner [23]. They were also very meticulous about the final processing of the mortar layer. After the masonry was completed, another layer of mortar was applied—a technique which in architectural/construction parlance is called ‘additional grouting’. The mortar layers grid was to look as flat as possible, but sometimes beveled and concave mortar layers were made. As referred to earlier also, about three millennia ago, masonry started being fastened with mortar. Dabaieh and colleagues have pointed out that this ‘fastening’ was done with lime and was used not only for constructing fortresses/defensive structures but also for residential ones. Around this time, ancient Rome could also avail of sun-dried clay bricks [24].

The Romans disseminated the craft of brickmaking throughout the West. Baudin and colleagues have written about Roman bricks used in Norman and Anglo-Saxon buildings [25]. Wherever their campaigns took them, the Romans took the bricks with them. Their practical sense helped them immediately grasp the advantages of bricks for the construction of vaults, as several structures still testify. Brick, the material of choice for the Romans, automatically became one for the entire world, owing to their conquests and trading links. Stefani Dou and colleagues believe most Roman and Byzantine bricks were plates measuring 30 cm square, and between 2.5 and 6 cm thick. Various additions, such as fine and coarse aggregates or fibrous materials, were utilized to enhance their qualities. Due to their extensive porosity and matrix fissures, ancient bricks from those eras often had low apparent specific densities (1.5–1.8 kg/m3), high absorption rates (13–30%), and average compressive strengths (5–20 MPa) [26].

2.2. Medieval Times

Medieval architects advanced much further than their predecessors from ancient cultures, and cleverly manipulated brick’s structural and decorative possibilities in construction. Hvattum has written that along with patterned masonry, its combination with terracotta and majolica details was also popular and in vogue [27]. Europe assimilated all the experience of ancient humans and the millennia of the past into its societal structures, with brick entrenching itself firmly around the 4th century AD. At the end of the 10th century AD, with the revival of cities, 2–3-storied brick residential buildings were built with shops/workshops at the ground level. Patterned masonry bricks with embellishments on their surfaces and a strong shiny glaze became the trends of those times. However, these were affordable only to the affluent—kings, funded monasteries, and powerful feudal lords/landed gentry.

Yakovlev and co-authors have written that, in the 11–12th centuries, thin and heavy slabs of different sizes, called plinths, were used, before bar-shaped bricks became ubiquitous [28]. The plinth, however, is typically viewed as a symbol of the structure’s elevation towards the sacred and its isolation from profane daily life, whereas in modern usage, a plinth is a lower, square slab that sits at the base of a column and symbolizes the base course of a building or the outward-projecting base of a wall. In Germany, brick-Gothic architecture dominated all through the 12th–16th centuries. The European brick cathedrals, but from the 10th through the 15th century, are significant tourist attractions in the places where they were built. While the English were the first to introduce mechanical brick making, pioneering developments happened in Germany. The first usable extrusion press was made by the Berlin-based manufacturer Schlickeysen in 1854; the first ring kiln was set up by master builder Friedrich Hoffmann (it was registered as a Prussian and Austrian patent in 1858). At the same time, clay-working machines, runners, vyaltsy, and pug mills were set up in different parts of the continent.

The first brick-making machines were steam-powered, and wood or coal was used to fire bricks [29]. With rapid industrialization and the establishment of the belt press and ring kiln (referred to earlier), the brick dimensions were stabilized (suitable for mass production). At about this time, spurred by the Industrial Revolution, a new type of brick—refractory brick—came into vogue, being for use in furnaces to withstand very high temperatures. By the beginning of the 17th century, bricks had become the first choice for residential buildings. Their dimensions had come closer to modern standards, though there were some minor differences among manufacturers. Discussions regarding a single standard size were held among builders and manufacturers. Joseph and Tretsiakova-McNally have stated that it was in the second half of the 19th century that it was possible to standardize the size of raw bricks [30]. Fiala and colleagues state that the best way to dress the mortar layers in brickwork (considering the thickness of the mortar layers) is with the following dimensions: 250 × 120 × 65 mm [31].

In England, for example, researchers find the neo-Gothic style which dominates the cityscapes of the country even today [32]. In the neo-Gothic style of architecture, the practitioners often chose unflustered brick as a facing material. By this time, the industrial revolution had already sped up all the processes in the value chain of the bricks, including transport [33].

The prevalent perception of medieval architecture as distinct from Renaissance town buildings can be questioned [34]. Lombardy, France, and Germany were major hubs for brick construction in medieval times. Bricks were used increasingly often during the Romanesque, Gothic, and Renaissance periods. The northern European nations—particularly northern Germany, Belgium, Holland, Scandinavia, and England—are home to numerous magnificent brick structures constructed from hand-made bricks in different hues.

Although manufacturing roof tiles in Flanders may be traced back to the 10th century thanks to archaeological discoveries, how the process evolved to produce bricks is still unknown. More than just as a less expensive alternative to stone, the invention and spread of brick in medieval Flanders must be understood in the context of the vibrant, sustainable building industry in a heavily populated and urbanized region [35].

Just as the Romans took the brick to England (which they were ruling), the British, when it was their turn, took it to Canada, towards the end of the 18th century. In fact, Quebec, a French colony, had not been enamored of bricks at that time, as the French evidently had not taken a liking for it as much as the British did. Most of these bricks were first imported from the British Isles and were used as ballast to stabilize the tall ships that came to Quebec to stock up on wood. Bricks continue to occupy a place of pride in industrial architecture too. Manufactured inexpensively in different standardized shapes and dimensions, they are just perfect for the furnaces and chimneys. Industrial buildings compensate for their drabness by having decorative motifs and ornamental cornices made of an arrangement of bricks of various colors or sets of reliefs and projecting bands.

Modernists began using ordinary-shaped or modular bricks as a decorative element by abandoning traditional principles, forms, and materials in favor of more natural and dynamic ones. They conferred upon Art Nouveau buildings a calm naturalness and a strong sense of individuality. The division into structural and decorative elements of the building disappears; elements of load-bearing structures and material go to the facade, giving buildings a new dynamic. Expressionist architects developed their ornamental language with rough, sharp, and often pointed elements, as well as horizontal and vertical forms. Purposefully laying bricks achieved the liveliness of the facade’s characteristic of brick expressionism in patterns and ornaments on most buildings’ facades. Additionally, the masonry pattern could give the building a pronounced horizontal or vertical movement. The use of brick was dictated by the tension of the post-war period, climatic conditions, and the economic situation of the area where it was distributed—Northern Germany in the 1920s. Despite the decisive renewal of forms and designs, the rejection of older styles, and the use of new materials, modernism did not abandon the use of bricks.

3. The Contemporary Brick Masonry Techniques

3.1. Masonry in the Application and Conceptual Framework

The management of masonry building assets throughout their lifecycle has undergone a significant change recently because of technological advancements in brick manufacturing and application models, particularly in construction activities which aim to increase productivity during the building creation phases. However, the traditional manual labor method might have several drawbacks, such as a high rate of mistakes and its constituting a waste of time and money [36]. Today, many examples applied modern technology in building conception and construction. Many architects and designers took the initiative to re-evaluate embossed brickwork. Their projects include a database created using algorithms based on traditional national patterns. The relief of the facade is based on the rhythmic repetition of the most basic forms and is extremely simple to create, like conventional geometric patterns. They have embodied the notion that anybody may and should be able to utilize bricks for cosmetic reasons. Brick walls line the entry road of Sala, which was created by onion architects [37]. Their contours imaginatively framed the sky and were made “the old-fashioned way”, without the use of computer calculations. If researchers refer to “old brick construction,” they refer at once to red ceramic bricks, which for most of history was exclusively a building material. Architects valued its functionality—strength, and affordability—but did not pay much attention to the aesthetic aspects—appearance. Today, the situation is rather the opposite [38][39]. Brick remains a reliable material, but architects, builders, and sellers rely on the aesthetics of brickwork—smooth and corrugated surfaces, different colors, and decorative inclusions. Technology assists in adding aesthetic components while improving functionality. The task of building then at once becomes a science, a business, and an art.

3.2. Masonry within the Architectural Model

Many brick buildings worldwide have a charm not easily found in wooden or reinforced concrete structures. Brick architecture not only overcomes the most apparent disadvantage of wooden architecture—vulnerability to fire—but also has the advantage of creating a stylish appearance by incorporating curved lines (arches). In terms of fire, reinforced concrete construction can also meet the requirements, but many other attractive features are unique to brick construction. It can create a building of any stylistic orientation and architectural complexity, and one which is composed of several stories. Furthermore, if the building’s façade has been precisely constructed with high-quality masonry, it does not require any additional finishing work.

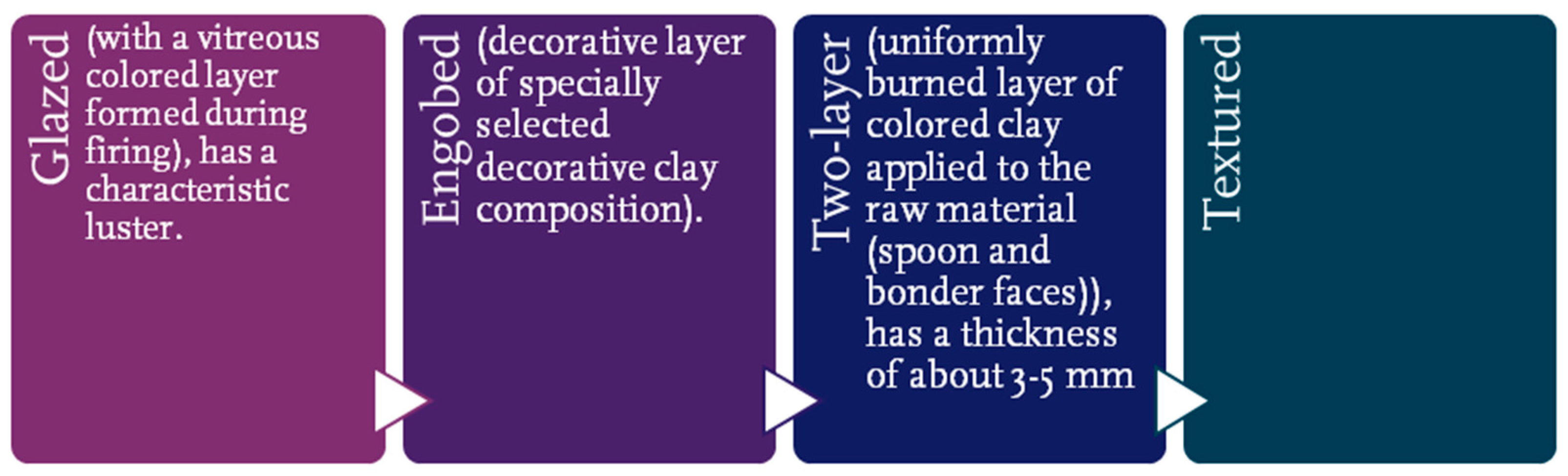

Bricks have excellent abrasion resistance, and their high strength is due to their opposition to the adverse impacts of temperature and humidity. Unlike wood, bricks do not rot, being resistant to deformation and fungal buildup. American architect Louis Kahn once said, “It is the architect’s responsibility to return each brick to its original position. The architect does not realize his dream but helps the brick realize his dream.” Facing (facing, facade, finishing) brick has a high surface quality and a precise, regular geometry. In addition, there are numerous options for brick processing surfaces (smooth, wavy, rough, “antique”, etc.). Mortar layers in such masonry are performed on ordinary and colored masonry mortars. Facade bricks allow you to create an original architectural appearance, harmoniously combined with the color of the roof, windows, landscape—the environment. Factories produce several types of facing bricks, as shown in Figure 2.

Figure 2. Facing brick types.

Most architects saw only a suitable constructive material in brick, mercilessly driving it into the thickness of walls or inside columns, hiding all its beauty under a thick layer of plaster. This was especially true of the facing of the monuments of the Renaissance, Baroque and Classical styles. In the middle of the 19th century, with a departure from the heritage of antiquity, turning to national traditions and searching for new ideas, architects turned their attention to this brick as a decorative element. Since the end of the 19th century, each new style has been given special meaning and function [40].

Finnish architect Alvar Aalto, for example, reimagined a brick building with the Muuratsalo Experimental House, which features over fifty types of bricks and masonry for the façade. This heterogeneous facade was also a testing ground for tracking the aesthetic possibilities of different bricks and their properties. Modernists also rejected the established association with brick as a material for heavy and monumental buildings. The façades of the famous Church of Christ in Uruguay and some other structures in the South American country were designed by Eladio Dieste, a modernist architect, in brick [41]. The main principles of organic architecture are freedom of spaces, deployed mainly in a horizontal plane, an endless combination of reinforced concrete and glass with more traditional and natural materials—wood, stone, and brick. In the postmodern era, brick is no longer used for decorative facades and is seldom used inside building structures. Instead, reinforced concrete, glass, and steel have supplanted its usage. Since the 1950s, masonry technology has remained virtually unchanged [42]. Some new solutions and additives improve the performance of a brick house—but the method of the masonry itself and the tools used are the same as more than half a century ago.

3.3. Brick Working Model

Firebricks are ideal if the masonry project aims to build a wall, framework, or building that is extremely heat- and fire-resistant. These bricks, also referred to as refractory bricks, are created from fireclay, a unique clay that mainly comprises silica and alumina. From the analysis of the bricks in action, bricks’ fundamental physical properties are high compressive strength and low tensile strength (about 10% of compressive strength). As a result, they are unsuitable for tensile and bending components, thus preventing their widespread use in various structural systems. Sand–lime brick, invented towards the end of the 19th century, is now the undisputed classic among masonry bricks.

In recent years, there has been an encouraging trend toward improving the external appearance of buildings. Therefore, face bricks with various sizes, forms, colors, and textures have arisen. Table 1 displays several brick forms and shapes used in traditional and contemporary architecture.

Table 1. Bricks formed into arches and domes.

| Form and Image | Description |

|---|---|

Folded arch |

Based on the folded fake coupons, the Romans invented the real vaulted coupons in the 2nd century BC [43]. The coupon can be understood as the basic element of the arch. Single-story arched structures, such as arched doors and windows in the walls, are coupons. |

Arch coupons |

The technique of arch coupons appeared in Mesopotamia as early as in the 4th millennium BC, and was later applied and developed in Babylon, Assyria, India, and Rome [44]. However, arch coupons appeared relatively late in China and went through several development steps of hollow brick beams and slabs, pointed arches, and folding arches, and formed in the early Western Han Dynasty. |

Barrel vault |

The barrel vault is an extension of the coupon. Before the invention of concrete, barrel vaults consisted of multiple test blocks side by side. The original barrel-shaped vault was composed of numerous coupons juxtaposed and later developed into interlaced masonry between the coupons and connected into a whole, called a longitudinal barrel vault. |

Dome |

The Romans created the dome arch from the tube arch structure, an alienated form of the barrel vault. The construction of domes is a millennias-old architectural tradition that persisted with several local variants worldwide [45]. |

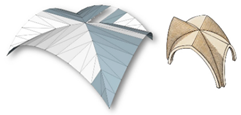

Four-petal arch |

Like the quadruple arch, it is also crosscut on the square tube arch, which consists of four identical parts; however, the top forms a more distinct cross shape than the quadruple arch, so the Romans call it a cross arch. |

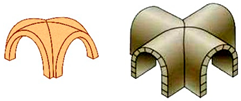

Cross vaults |

Although the cross arch got rid of the load-bearing wall, it could not rely on its own structure to balance the side thrust like the four-petal arch and the barrel vault, so the Romans arranged the cross arch in the longitudinal direction, and the adjacent parts balanced the longitudinal side thrust with each other. |

Rib vaults |

The ribbed arch appeared in the late Roman Empire. Compared with the cross arch, the ribbed arch is divided into load-bearing and enclosed parts. The main load is concentrated on the arch, and the rest is enclosed by light bricks slabs, saving materials and lightening the valuts top weight. |

References

- Tamás, H.; Nagy, D.U.; Pál, R.W. Adobe bricks can help identify historic weed flora—A case study from south-western Hungary. Plant Ecol. Divers. 2016, 9, 113–125.

- Dipasquale, L.; Rovero, L.; Fratini, F. Ancient stone masonry constructions. In Nonconventional and Vernacular Construction Materials; Woodhead Publishing: Sawston, UK, 2020; pp. 403–435.

- Nicolas Durand, H.; Monger, C.; Matthew, G.C. 9-Calcium Carbonate Features. In Interpretation of Micromorphological Features of Soils and Regoliths; Elsevier: Amsterdam, The Netherlands, 2010; pp. 149–194.

- Manzanilla, L.; López, C.; Freter, A. Dating Results from Excavations in Quarry Tunnels Behind the Pyramid of the Sun at Teotihuacan. Anc. Mesoam. 1996, 7, 245–266.

- Hamburg, J.; Lorenzon, M. Before Meeting the Greeks: Kutaisi Influence in Late Bronze and Early Iron Age Colchian Settlements. J. Field Archaeol. 2022, 47, 13–31.

- Suzan, E.A.K.; Peta, J.M. Palynological records of climate and oceanic conditions in the late Pleistocene and Holocene of the nile cone, southeastern Mediterranean. Egypt Palynol. 2009, 33, 1–24.

- Chen, M. Harappa Civilization. In China and the World in the Liangzhu Era. Liangzhu Civilization; Springer: Singapore, 2022.

- Binici, H.; Binici, F.; Akcan, M.; Yardim, Y.; Mustafaraj, E.; Corradi, M. Physical–Mechanical and Mineralogical Properties of Fired Bricks of the Archaeological Site of Harran, Turkey. Heritage 2020, 3, 1018–1034.

- Almusaed, A.; Almssad, A. Introductory Chapter: Overview of a Competent Sustainable Building. In Sustainable Buildings—Interaction Between a Holistic Conceptual Act and Materials Properties; IntechOpen: London, UK, 2018; Available online: https://www.intechopen.com/chapters/61634 (accessed on 17 September 2022).

- Almusaed, A.; Almssad, A.; Najar, K. An Innovative School Design Based on a Biophilic Approach Using the Appreciative Inquiry Model: Case Study Scandinavia. Adv. Civ. Eng. 2022, 2022, 8545787.

- Homod, R.Z.; Almusaed, A.; Almssad, A.; Jaafar, M.K.; Goodarzi, M.; Sahari, K.S.M. Effect of different building envelope materials on thermal comfort and air-conditioning energy savings: A case study in Basra city, Iraq. J. Energy Storage 2021, 34, 101975.

- Dhandhukia, P.; Goswami, D.; Thakorb, P.; Thakker, J.N. Soil property apotheosis to corral the finest compressive strength of unbaked adobe bricks. Constr. Build. Mater. 2013, 48, 948–953.

- Han, L.C.; Mirasa, A.K.B.; Saad, I.; Bolong, N.B.; Asman, N.S.A.B.; Asrah, H.B.; Abdullah, E.S.R.B. Use of Compressed Earth Bricks/Blocks in Load-Bearing Masonry Structural Systems: A Review. Mater. Sci. Forum 2020, 997, 9–19.

- Adamo, N.; Al-Ansari, N. Babylon in a New Era: The Chaldean and Achaemenid Empires (330–612 BC). J. Earth Sci. Geotech. Eng. 2020, 10, 87–111.

- Almusaed, A.; Asaad Alasadi Almssad, A. A Research on the Biophilic Concept upon School’s Design from Hot Climate: A Case Study from Iraq. Publ. Adv. Mater. Sci. Eng. 2022, 2022, 7994999.

- Almusaed, A.; Yitmen, I.; Almssad, A.; Homod, R.Z. Environmental profile on building material passports for hot climates. Sustainability 2020, 12, 3720.

- CultroneItziar, G.; Carmen, A.; Casado, C.; Arizzi, A. Sawdust recycling in the production of lightweight bricks: How the amount of additive and the firing temperature influence the physical properties of the bricks. Constr. Build. Mater. 2020, 235, 117436.

- Rossi, C. On Measuring Ancient Egyptian Architecture. J. Egypt. Archaeol. 2020, 106, 229–238.

- Almusaed, A.; Almssad, A. Building materials in eco-energy houses from Iraq and Iran. In Case Studies in Construction Materials Journal; Elsevier: Amsterdam, The Netherlands, 2015; Volume 1, pp. 452–454.

- Shu, C.X.; Cantisani, E.; Fratini, F.; Rasmussen, K.L.; Rovero, L.; Stipo, G.; Vettori, S. China’s brick history and conservation: Laboratory results of Shanghai samples from 19th to 20th century. Constr. Build. Mater. 2017, 151, 789–800.

- Al-Fakih, A.; Mohammed, B.S.; Liew, M.S.; Nikbakht, E. Incorporation of waste materials in the manufacture of masonry bricks: An update review. J. Build. Eng. 2019, 21, 37–54.

- Wu, Y.; Bao, P. Experimental study on the properties of modern blue clay brick for Kaifeng People’s Conference Hall. Sci. Rep. 2021, 11, 20631.

- Nadali, D. Esarhaddon’s glazed bricks from Nimrud: The Egyptian campaign depicted. Iraq 2006, 68, 109–119.

- Dabaieh, M.; Heinonen, J.; El-Mahdy, D.; Hassan, D.M. A comparative study of life cycle carbon emissions and embodied energy between sun-dried bricks and fired clay bricks. J. Clean. Prod. 2020, 275, 122998.

- Arnaud, B.; Benoit, R. L’industrie Cistercienne (XIIe-XXIe siècle). Actes du Colloque International, Troyes, Abbaye de Clairvaux, Abbaye de Fontenay, Somogy, éditions d’art, 1er-5 Septembre 2015, pp. 14–15, Paris. Available online: https://www.academia.edu/38986164/Lindustrie_cistercienne_XIIe_XXIe_si%C3%A8cle_Actes_du_colloque_international_Troyes_Abbaye_de_Clairvaux_Abbaye_de_Fontenay_1er_5_septembre_2015_ (accessed on 17 September 2022).

- Stefanidou, M.; Papayianni, I.; Pachta, V. Analysis and characterization of Roman and Byzantine fired bricks from Greece. Mater. Struct. 2015, 48, 2251–2260.

- Hvattum, M. Panoramas of Style. J. Soc. Archit. Hist. 2011, 70, 190–209.

- Yakovlev, D.; Trushnikova, A.; Antipov, I. The cross-cultural interaction in the Baltic region in the fifteenth century: The vaults of the Faceted Palace in Novgorod the Great and Brick Gothic architecture. J. Balt. Stud. 2020, 51, 553–568.

- Brotherson, D. The fortification of Angkor Wat. Antiquity 2015, 89, 1456–1472.

- Joseph, P.; Tretsiakova-McNally, S. Sustainable Non-Metallic Building Materials. Sustainability 2010, 2, 400–427.

- Fiala, J.; Junior, J.; Mikolas, M. Special brick products and their application. In World Multidisciplinary Earth Sciences Symposium (WMESS 2019), Proceedings of the Earth and Environmental Science, Prague, Czech Republic, 9–13 September 2019; IOP Publishing Ltd.: Prague, Czech Republic, 2019; Volume 362, p. 362.

- Cases, I. Appartenir aux classes populaires: L’exemple du pub dans l’Angleterre victorienne. Cah. Victoriens Et Edouardiens 2008, 67, 103–114.

- Clark, K. The Landscape of Industry: Patterns of Change in the Ironbridge Gorge. In The Landscape of Industry: Patterns of Change in the Ironbridge Gorge; Routledge: London, UK, 1993; p. 192.

- Boerefijn, W. About the Ideal Layout of the City Street in the Twelfth to Sixteenth Centuries: The Myth of the Renaissance in Town Building. J. Urban Hist. 2016, 42, 938–952.

- Debonne, V. Brick Production and Brick Building in Medieval Flanders January 2014. In Proceedings of the European Association of Archaeologists (EAA) Meeting, Helsinki, Finland, 29 August–1 September 2012.

- Bahobail, M.A. The mud additives and their effect on thermal conductivity of adobe bricks. J. Eng. Sci. 2012, 40, 21–34.

- Kulakov, A.I.; Ri, A.U. Ceramics in architecture. IOP Conf. Ser. Earth Environ. Sci. 2021, 751, 012052.

- Ali, M.M.; Al-Kodmany, K. Tall Buildings and Urban Habitat of the 21st Century: A Global Perspective. Buildings 2012, 2, 384–423.

- Almusaed, A. Biophilic and Bioclimatic architecture. In Analytical Therapy for the Next Generation of Passive Sustainable Architecture; Springer-Verlag London Limited: London, UK, 2011; pp. 123–130. Available online: https://www.springer.com/gp/book/9781849965330 (accessed on 17 September 2022).

- Purici, Ş.; Mareci Sabol, H. From Beautification to Ennobling: The Exterior Mural Mosaics from Suceava of the Socialist Era. Societies 2022, 12, 107.

- Lainez JM, C.; Verdejo JR, J.; Macias, B.S.-M.; Calero, J.I.P. The Key-role of Eladio Dieste, Spain and the Americas in the Evolution from Brickwork to Architectural Form. J. Asian Archit. Build. Eng. 2009, 8, 355–362.

- De Lorenzis, L.; Teng, J.G. Near-surface mounted FRP reinforcement: An emerging technique for strengthening structures. Compos. Part B Eng. 2007, 38, 119–143.

- Artioli, G. 3 Materials and case studies: How to meet the needs. In Scientific Methods and Cultural Heritage: An Introduction to the Application of Materials Science to Archaeometry and Conservation Science; Oxford Academic: Oxford, UK, 2010.

- Reade, J. Alexander the Great and the Hanging Gardens of Babylon; British Institute for the Study of Iraq: London, UK, 2000; Volume 62, pp. 195–217.

- Ferrari, E.P. From Soil to Domes: Vernacular Architecture and Construction Techniques in Esfahak, South Khurasan. J. Br. Inst. Persian Stud. 2022, 60.

More

Information

Subjects:

Green & Sustainable Science & Technology

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.3K

Revisions:

2 times

(View History)

Update Date:

22 Nov 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No