| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | REHAB RAMADAN | -- | 1266 | 2022-08-05 20:00:00 | | | |

| 2 | Jason Zhu | Meta information modification | 1266 | 2022-08-08 04:19:45 | | |

Video Upload Options

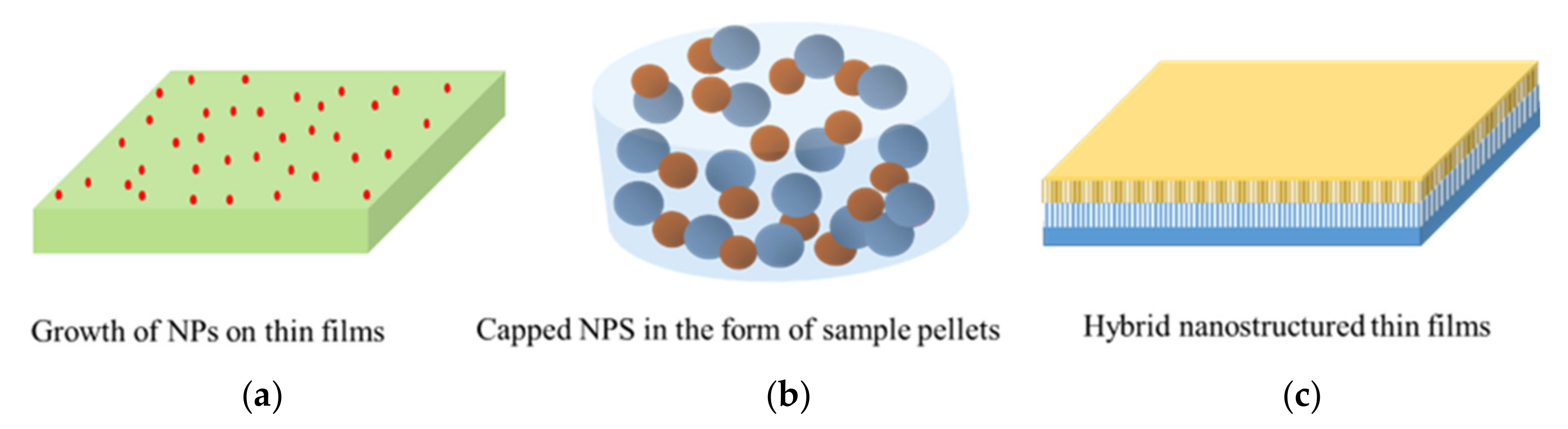

Nanostructured materials remarkably improve the overall properties of thermoelectric devices, mainly due to the increase in the surface-to-volume ratio. This behavior is attributed to an increased number of scattered phonons at the interfaces and boundaries of the nanostructures. Among many other materials, nanostructured Si was used to expand the power generation compared to bulk crystalline Si, which leads to a reduction in thermal conductivity. However, the use of nanostructured Si leads to a reduction in the electrical conductivity due to the formation of low dimensional features in the heavily doped Si regions. Accordingly, the fabrication of hybrid nanostructures based on nanostructured Si and other different nanostructured materials constitutes another strategy to combine a reduction in the thermal conductivity while keeping the good electrical conduction properties.

1. Introduction

2. Si-Based Thermoelectric Materials

3. Thermoelectric Devices Modified by Nanostructured Silicon

4. Thermoelectric Materials Modified by Hybrid Nanocomposites

References

- Price, S. The Peltier Effect and Thermoelectric Cooling, WWW-Dokumentti. Available online: http://ffden-2.phys.uaf.edu/212_spring2007.web.dir/sedona_price/phys_212_webproj_peltier.html (accessed on 20 May 2017).

- Goldsmid, H.J. Bismuth Telluride and Its Alloys as Materials for Thermoelectric Generation. Materials 2014, 7, 2577–2592.

- Wongprakarn, S.; Pinitsoontorn, S.; Tanusilp, S.-A.; Kurosaki, K. Enhancing thermoelectric properties of p-type SiGe alloy through optimization of carrier concentration and processing parameters. Mater. Sci. Semicond. Process. 2018, 88, 239–249.

- Zhu, G.H.; Lee, H.; Lan, Y.C.; Wang, X.W.; Joshi, G.; Wang, D.Z.; Yang, J.; Vashaee, D.; Guilbert, H.; Pillitteri, A.; et al. Increased Phonon Scattering by Nanograins and Point Defects in Nanostructured Silicon with a Low Concentration of Germanium. Phys. Rev. Lett. 2009, 102, 196803.

- Yi, T.; Chen, S.; Li, S.; Yang, H.; Bux, S.; Bian, Z.; Katcho, N.A.; Shakouri, A.; Mingo, N.; Fleurial, J.-P. Synthesis and characterization of Mg 2 Si/Si nanocomposites prepared from MgH2 and silicon, and their thermoelectric properties. J. Mater. Chem. 2012, 22, 24805–24813.

- Cojocaru, A.; Carstensen, J.; De Boor, J.; Kim, D.S.; Schmidt, V.; Föll, H. Production and Investigation of Porous Si-Ge Structures for Thermoelectric Application. ECS Trans. 2011, 33, 193–202.

- de Boor, J.; Kim, D.S.; Ao, X.; Becker, M.; Hinsche, N.F.; Mertig, I.; Zahn, P.; Schmidt, V. Thermoelectric properties of porous silicon. Appl. Phys. A 2012, 107, 789–794.

- Domínguez-Adame, F.; Martín-González, M.; Sánchez, D.; Cantarero, A. Nanowires: A route to efficient thermoelectric devices. Phys. E Low Dimens. Syst. Nanostructures 2019, 113, 213–225.

- Bux, S.K.; Blair, R.G.; Gogna, P.K.; Lee, H.; Chen, G.; Dresselhaus, M.S.; Kaner, R.B.; Fleurial, J.-P. Nanostructured Bulk Silicon as an Effective Thermoelectric Material. Adv. Funct. Mater. 2009, 19, 2445–2452.

- Martín-Palma, R.; Cabrera, H.; Martín-Adrados, B.; Korte, D.; Pérez-Cappe, E.; Mosqueda, Y.; Frutis, M.; Danguillecourt, E. Thermoelectric properties of nanostructured porous silicon. Mater. Res. Express 2018, 5, 015004.

- Ramadan, R.; Martín-Palma, R.J. Electrical Characterization of MIS Schottky Barrier Diodes Based on Nanostructured Porous Silicon and Silver Nanoparticles with Applications in Solar Cells. Energies 2020, 13, 2165.

- Ramadan, R.; Martín-Palma, R.J. The Infiltration of Silver Nanoparticles into Porous Silicon for Improving the Performance of Photonic Devices. Nanomaterials 2022, 12, 271.

- Zhang, T.; Wu, S.; Xu, J.; Zheng, R.; Cheng, G. High thermoelectric figure-of-merits from large-area porous silicon nanowire arrays. Nano Energy 2015, 13, 433–441.

- Saxena, N.; Čorić, M.; Greppmair, A.; Wernecke, J.; Pflüger, M.; Krumrey, M.; Brandt, M.S.; Herzig, E.M.; Müller-Buschbaum, P. Morphology-Function Relationship of Thermoelectric Nanocomposite Films from PEDOT:PSS with Silicon Nanoparticles. Adv. Electron. Mater. 2017, 3, 1700181.

- Martín-Palma, R.J.; McAtee, P.D.; Ramadan, R.; Lakhtakia, A. Hybrid Nanostructured Porous Silicon-Silver Layers for Wideband Optical Absorption. Sci. Rep. 2019, 9, 7291.

- Kolhatkar, G.; Boucherif, A.; Boucherif, A.R.; Dupuy, A.; Fréchette, L.G.; Arès, R.; Ruediger, A. Extreme temperature stability of thermally insulating graphene-mesoporous-silicon nanocomposite. Nanotechnology 2018, 29, 145701.

- Chen, X.; Lin, P.; Zhang, K.; Baumgart, H.; Geist, B.; Kochergin, V. Seebeck Coefficient Enhancement of ALD PbTe/PbSe Nanolaminate Structures Deposited inside Porous Silicon Templates. ECS J. Solid State Sci. Technol. 2016, 5, P503–P508.

- Rowe, D. CRC Handbook of Thermoelectrics; CRC Press: Boca Raton, FL, USA, 1995.

- Joshi, G.; Lee, H.; Lan, Y.; Wang, X.; Zhu, G.; Wang, D.; Gould, R.W.; Cuff, D.C.; Tang, M.Y.; Dresselhaus, M.S.; et al. Enhanced Thermoelectric Figure-of-Merit in Nanostructured p-type Silicon Germanium Bulk Alloys. Nano Lett. 2008, 8, 4670–4674.

- Zamanipour, Z.; Shi, X.; Dehkordi, A.M.; Krasinski, J.S.; Vashaee, D. The effect of synthesis parameters on transport properties of nanostructured bulk thermoelectric p-type silicon germanium alloy. Phys. Status Solidi a 2012, 209, 2049–2058.