| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Sachin Chavan | -- | 2801 | 2022-06-16 03:36:44 | | | |

| 2 | Beatrix Zheng | -19 word(s) | 2782 | 2022-06-16 04:33:47 | | |

Video Upload Options

Indoor farm facilities are broadly categorised into the following three levels of technological advancement: low-, medium- and high-tech with corresponding challenges that require innovative solutions. Furthermore, limitations on indoor plant growth and protected cropping systems (e.g., high energy costs) have restricted the use of indoor agriculture to relatively few, high value crops. Hence, there is a need to develop new crop cultivars suitable for indoor agriculture that may differ from those required for open field production. In addition, protected cropping requires high start-up costs, expensive skilled labour, high energy consumption, and significant pest and disease management and quality control. Overall, protected cropping offers promising solutions for food security, while reducing the carbon footprint of food production. However, for indoor cropping production to have a substantial positive impact on global food security and nutritional security, the economical production of diverse crops will be essential.

1. Current Techniques and Technologies in Protected Cropping

1.1. New Technologies for Low-Tech Poly-Tunnels

1.2. Upgrading Medium-Tech Greenhouses with Innovations and New Technologies

1.3. Innovations of Science and Technology for High-Tech Greenhouses

1.4. Developing Vertical Farms for Future Needs

2. Target Crops in Protected Cropping

-

Those that grow on vines or bushes (tomato, strawberry, raspberry, blueberry, cucumber, capsicum, grape, kiwifruit);

-

High-value specialist crops (hops, vanilla, saffron, coffee);

-

Medicinal and cosmetic crops (seaweed, Echinacea);

-

Small trees (cherries, chocolate, mango, almonds) are other viable options [31].

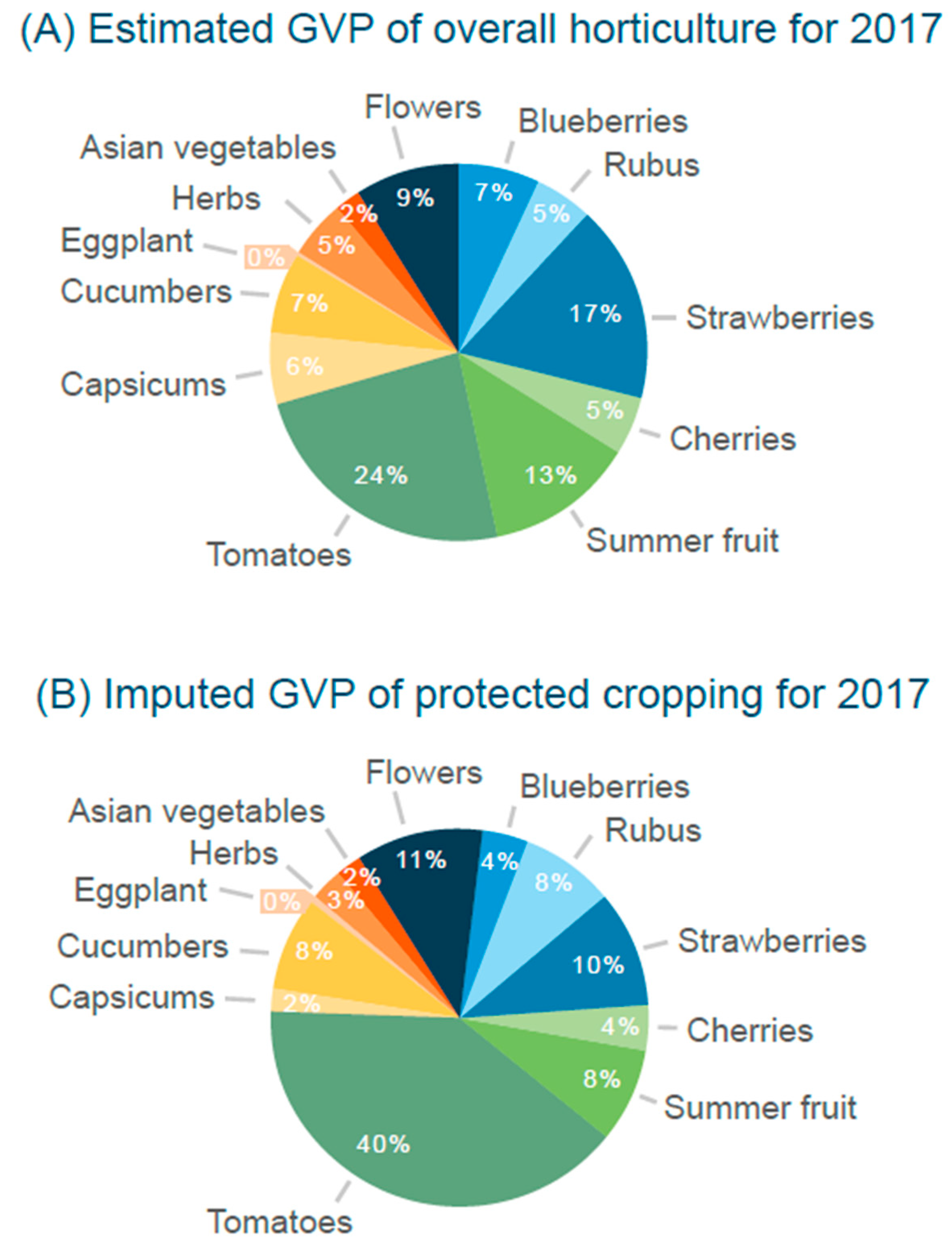

2.1. Existing Crops Grown in Low, Medium and High-Tech Facilities

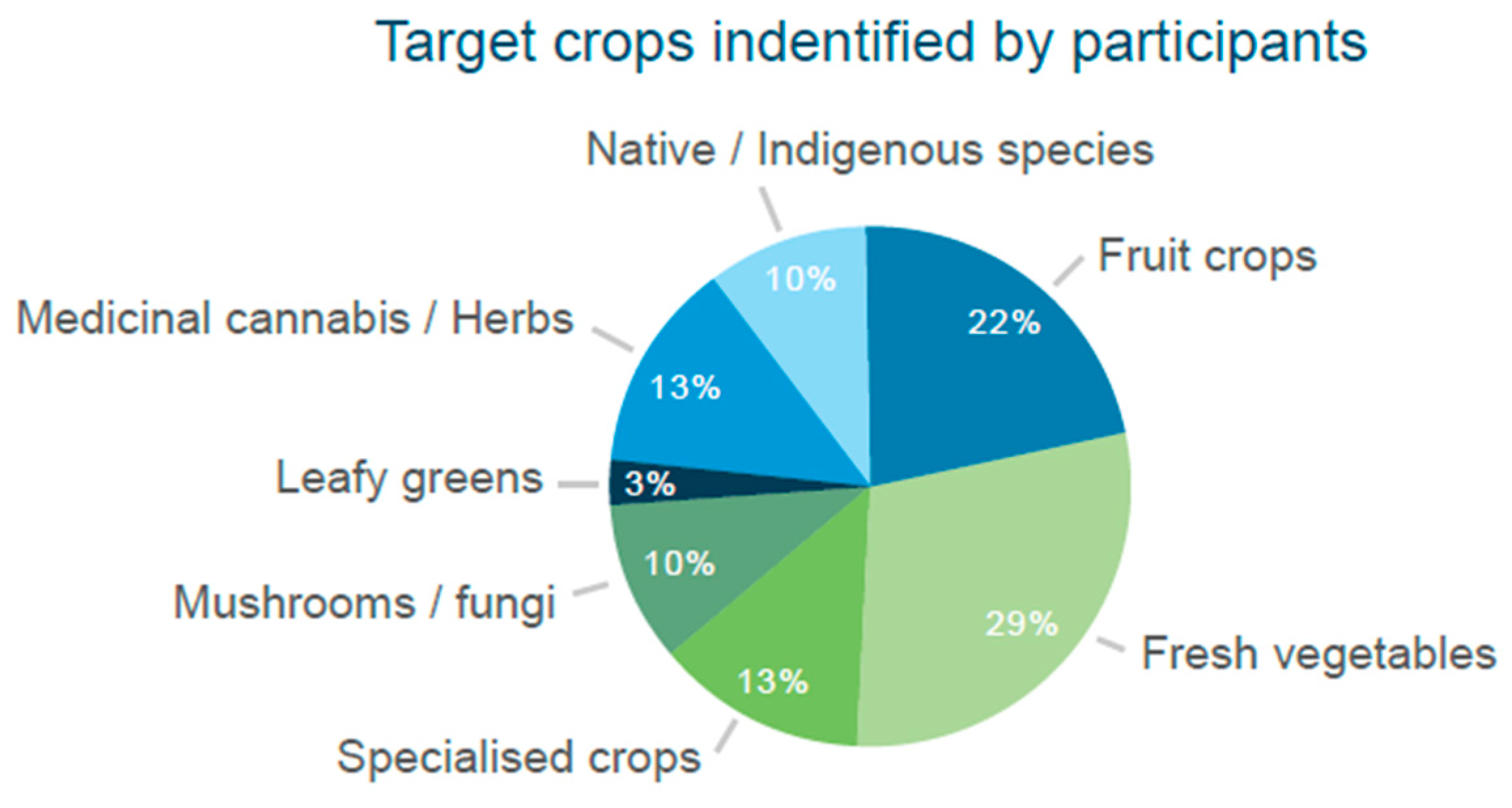

2.2. Industry Survey: Where Do Participants’ Interests Lie?

2.3. Breeding New Cultivars for Controlled-Environment Facilities

References

- Cuesta Roble releases 2019 global greenhouse statistics . Produce Grower. Retrieved 2022-6-16

- Hadley, D. (2017). Controlled Environment Horticulture Industry Potential in NSW (p. 25). https://www.une.edu.au/__data/assets/pdf_file/0010/174565/controlled-environment-horticulture-industry-potential-hadley.pdf

- World Vegetable Map 2018: More than Just a Local Affair . Rabobank. Retrieved 2022-6-16

- General Industry Information . Graeme Smith Consulting. Retrieved 2022-6-16

- Davis, J. Growing Protected Cropping in Australia to 2030; Protected Cropping Australia: Perth, Australia, 2020; p. 15.

- Indoor Soilless Farming: Phase I: Examining the industry and impacts of controlled environment agriculture . World Wildlife Fund. Retrieved 2022-6-16

- Christopher J. M. Emmott; Jason A. Röhr; Mariano Campoy-Quiles; Thomas Kirchartz; Antonio Urbina; Nicholas J. Ekins-Daukes; Jenny Nelson; Organic photovoltaic greenhouses: a unique application for semi-transparent PV?. Energy & Environmental Science 2015, 8, 1317-1328, 10.1039/c4ee03132f.

- Alvaro Marucci; Ilaria Zambon; Andrea Colantoni; Danilo Monarca; A combination of agricultural and energy purposes: Evaluation of a prototype of photovoltaic greenhouse tunnel. Renewable and Sustainable Energy Reviews 2018, 82, 1178-1186, 10.1016/j.rser.2017.09.029.

- Marta Torrellas; Assumpció Antón; Juan Carlos López; Esteban José Baeza; Jerónimo Pérez Parra; Pere Muñoz; Juan Ignacio Montero; LCA of a tomato crop in a multi-tunnel greenhouse in Almeria. The International Journal of Life Cycle Assessment 2012, 17, 863-875, 10.1007/s11367-012-0409-8.

- M.G. Xibilia; L. Occhipinti; G. Nunnari; L. Fortuna; R. Caponetto; Soft computing for greenhouse climate control. IEEE Transactions on Fuzzy Systems 2000, 8, 753-760, 10.1109/91.890333.

- Doudou Guo; JiaXiang Juan; Liying Chang; JingJin Zhang; Danfeng Huang; Discrimination of plant root zone water status in greenhouse production based on phenotyping and machine learning techniques. Scientific Reports 2017, 7, 1-12, 10.1038/s41598-017-08235-z.

- Demis Hassabis; Artificial Intelligence: Chess match of the century. Nature 2017, 544, 413-414, 10.1038/544413a.

- Silke Hemming; Feije de Zwart; Anne Elings; Isabella Righini; Anna Petropoulou; Remote Control of Greenhouse Vegetable Production with Artificial Intelligence—Greenhouse Climate, Irrigation, and Crop Production. Sensors 2019, 19, 1807, 10.3390/s19081807.

- Morteza Taki; Saman Abdanan Mehdizadeh; Abbas Rohani; Majid Rahnama; Mostafa Rahmati-Joneidabad; Applied machine learning in greenhouse simulation; new application and analysis. Information Processing in Agriculture 2018, 5, 253-268, 10.1016/j.inpa.2018.01.003.

- Redmond R. Shamshiri, Ibrahim A. Hameed, Kelly R. Thorp, Siva K. Balasundram, Sanaz Shafian, Mohammad Fatemieh, Muhammad Sultan, Benjamin Mahns and Saba Samiei. Greenhouse Automation Using Wireless Sensors and IoT Instruments Integrated with Artificial Intelligence; IntechOpen: London UK, 2021; pp. 1-23.

- A. Subeesh; C.R. Mehta; Automation and digitization of agriculture using artificial intelligence and internet of things. Artificial Intelligence in Agriculture 2021, 5, 278-291, 10.1016/j.aiia.2021.11.004.

- Chris Lehnert; Chris McCool; Inkyu Sa; Tristan Perez; Performance improvements of a sweet pepper harvesting robot in protected cropping environments. Journal of Field Robotics 2020, 37, 1197-1223, 10.1002/rob.21973.

- Chris Lehnert; Chris McCool; Peter Corke; Inkyu Sa; Cyrill Stachniss; Eldert J. Van Henten; Juan Nieto; Special issue on agricultural robotics. Journal of Field Robotics 2019, 37, 5-6, 10.1002/rob.21926.

- Redmond Ramin Shamshiri; Cornelia Weltzien; Ibrahim A. Hameed; Ian J. Yule; Tony E. Grift; Siva K. Balasundram; Lenka Pitonakova; Desa Ahmad; Girish Chowdhary; Research and development in agricultural robotics: A perspective of digital farming. International Journal of Agricultural and Biological Engineering 2018, 11, 1-11, 10.25165/j.ijabe.20181103.4278.

- Balendonck, J. (2017). Sweeper robot picks first peppers. In Greenhouses : the international magazine for greenhouse growers, 6(2), 37-37.

- Yuan, T.; Zhang, S.; Sheng, X.; Wang, D.; Gong, Y.; Li, W. An autonomous pollination robot for hormone treatment of tomato flower in greenhouse. In Proceedings of the 2016 3rd International Conference on Systems and Informatics (ICSAI), Shanghai, China, 19–21 November 2016; pp. 108–113.

- Andy Meharg; Perspective: City farming needs monitoring. Nature 2016, 531, S60-S60, 10.1038/531s60a.

- Susanne Thomaier; Kathrin Specht; Dietrich Henckel; Axel Dierich; Rosemarie Siebert; Ulf B. Freisinger; Magdalena Sawicka; Farming in and on urban buildings: Present practice and specific novelties of Zero-Acreage Farming (ZFarming). Renewable Agriculture and Food Systems 2014, 30, 43-54, 10.1017/s1742170514000143.

- The green shoots of recovery . Open Forum. Retrieved 2022-6-16

- Dickson Despommier; Farming up the city: the rise of urban vertical farms. Trends in Biotechnology 2013, 31, 388-389, 10.1016/j.tibtech.2013.03.008.

- Jun Yang; Mengchen Liu; Jiayi Lu; Yiming Miao; M. Anwar Hossain; Mohammed F. Alhamid; Botanical Internet of Things: Toward Smart Indoor Farming by Connecting People, Plant, Data and Clouds. Mobile Networks and Applications 2017, 23, 188-202, 10.1007/s11036-017-0930-x.

- Premaratne Samaranayake; Weiguang Liang; Zhong-Hua Chen; David Tissue; Yi-Chen Lan; Sustainable Protected Cropping: A Case Study of Seasonal Impacts on Greenhouse Energy Consumption during Capsicum Production. Energies 2020, 13, 4468, 10.3390/en13174468.

- Terry Lin; Mark Goldsworthy; Sachin Chavan; Weiguang Liang; Chelsea Maier; Oula Ghannoum; Christopher I. Cazzonelli; David T. Tissue; Yi-Chen Lan; Subbu Sethuvenkatraman; et al.Han LinBaohua JiaZhong-Hua Chen A novel cover material improves cooling energy and fertigation efficiency for glasshouse eggplant production. Energy 2022, 251, 123871, 10.1016/j.energy.2022.123871.

- Premaratne Samaranayake; Chelsea Maier; Sachin Chavan; Weiguang Liang; Zhong-Hua Chen; David T. Tissue; Yi-Chen Lan; Energy Minimisation in a Protected Cropping Facility Using Multi-Temperature Acquisition Points and Control of Ventilation Settings. Energies 2021, 14, 6014, 10.3390/en14196014.

- C.A. O'Sullivan; G.D. Bonnett; C.L. McIntyre; Z. Hochman; A.P. Wasson; Strategies to improve the productivity, product diversity and profitability of urban agriculture. Agricultural Systems 2019, 174, 133-144, 10.1016/j.agsy.2019.05.007.

- Cathryn A. O’Sullivan; C. Lynne McIntyre; Ian B. Dry; Susan M. Hani; Zvi Hochman; Graham D. Bonnett; Vertical farms bear fruit. Nature Biotechnology 2020, 38, 160-162, 10.1038/s41587-019-0400-z.

- FAO. Good Agricultural Pratices for Greenhouse Vegetable Crops: Principles for Mediterranean Climate Areas; FAO Plant Production and Protection Paper; FAO: Rome, Italy, 2013; ISBN 978-92-5-107649-1.

- Hort Innovation Protected Cropping—Review of Research and Identification of R&D Gaps for Levied Vegetables (VG16083). Available online: https://www.horticulture.com.au/growers/help-your-business-grow/research-reports-publications-factsheets-and-more/project-reports/vg16083-1/vg16083/ (accessed on 13 April 2022).

- Kyoko Hiwasa-Tanase; Hiroshi Ezura; Molecular Breeding to Create Optimized Crops: From Genetic Manipulation to Potential Applications in Plant Factories. Frontiers in Plant Science 2016, 7, 539-539, 10.3389/fpls.2016.00539.

- Kozai, T. Why LED lighting for urban agriculture? In LED Lighting for Urban Agriculture; Kozai, T., Fujiwara, K., Runkle, E.S., Eds.; Springer: Singapore, 2016; pp. 3–18. ISBN 978-981-10-1848-0.

- Kurt Benke; Bruce Tomkins; Future food-production systems: vertical farming and controlled-environment agriculture. Sustainability: Science, Practice and Policy 2017, 13, 13-26, 10.1080/15487733.2017.1394054.

- Kwon, S., Lim, J. (2011). Improvement of Energy Efficiency in Plant Factories through the Measurement of Plant Bioelectrical Potential. In: Tan, H. (eds) Informatics in Control, Automation and Robotics. Lecture Notes in Electrical Engineering, vol 132. Springer, Berlin, Heidelberg. https://doi.org/10.1007/978-3-642-25899-2_86

- Giacomo Cocetta; Daria Casciani; Roberta Bulgari; Fulvio Musante; Anna Kołton; Maurizio Rossi; Antonio Ferrante; Light use efficiency for vegetables production in protected and indoor environments. The European Physical Journal Plus 2017, 132, 43, 10.1140/epjp/i2017-11298-x.

- Jones, M. New Breeding Technologies and Opportunities for the Australian Vegetable Industry; Horticulture Innovation Australia Limited: Sydney, Australia, 2016.

- Tüzel, Y.; Leonardi, C. Protected cultivation in mediterranean region: Trends and needs. Ege Üniversitesi Ziraat Fakültesi Derg. 2009, 46, 215–223.

- Véronique Bergougnoux; The history of tomato: From domestication to biopharming. Biotechnology Advances 2014, 32, 170-189, 10.1016/j.biotechadv.2013.11.003.

- Dalia Taher; Svein Ø. Solberg; Jaime Prohens; Yu-Yu Chou; Mohamed Rakha; Tien-Hor Wu; World Vegetable Center Eggplant Collection: Origin, Composition, Seed Dissemination and Utilization in Breeding. Frontiers in Plant Science 2017, 8, 1484-1484, 10.3389/fpls.2017.01484.

- Mohidul Hasan; Tufail Bashir; Ritesh Ghosh; Sun Keun Lee; Hanhong Bae; An Overview of LEDs’ Effects on the Production of Bioactive Compounds and Crop Quality. Molecules 2017, 22, 1420, 10.3390/molecules22091420.

- Chiara Piovene; Francesco Orsini; Sara Bosi; Rabab Sanoubar; Valeria Bregola; Giovanni Dinelli; Giorgio Prosdocimi Gianquinto; Optimal red:blue ratio in led lighting for nutraceutical indoor horticulture. Scientia Horticulturae 2015, 193, 202-208, 10.1016/j.scienta.2015.07.015.

- Choon-Tak Kwon; Jung Heo; Zachary H. Lemmon; Yossi Capua; Samuel F. Hutton; Joyce Van Eck; Soon Ju Park; Zachary B. Lippman; Rapid customization of Solanaceae fruit crops for urban agriculture. Nature Biotechnology 2019, 38, 182-188, 10.1038/s41587-019-0361-2.

- Choon-Tak Kwon; Jung Heo; Zachary H. Lemmon; Yossi Capua; Samuel F. Hutton; Joyce Van Eck; Soon Ju Park; Zachary B. Lippman; Rapid customization of Solanaceae fruit crops for urban agriculture. Nature Biotechnology 2019, 38, 182-188, 10.1038/s41587-019-0361-2.