Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Wuyi Ming | -- | 2938 | 2022-05-19 12:39:02 | | | |

| 2 | Conner Chen | -18 word(s) | 2920 | 2022-05-20 08:04:34 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Ming, W.; Luo, �.; , .; Xie, Z.; Li, L. Transparent Nano-Ceramics for Solid-State LASERs. Encyclopedia. Available online: https://encyclopedia.pub/entry/23120 (accessed on 07 February 2026).

Ming W, Luo �, , Xie Z, Li L. Transparent Nano-Ceramics for Solid-State LASERs. Encyclopedia. Available at: https://encyclopedia.pub/entry/23120. Accessed February 07, 2026.

Ming, Wuyi, 国富 Luo, , Zhuobin Xie, Liwei Li. "Transparent Nano-Ceramics for Solid-State LASERs" Encyclopedia, https://encyclopedia.pub/entry/23120 (accessed February 07, 2026).

Ming, W., Luo, �., , ., Xie, Z., & Li, L. (2022, May 19). Transparent Nano-Ceramics for Solid-State LASERs. In Encyclopedia. https://encyclopedia.pub/entry/23120

Ming, Wuyi, et al. "Transparent Nano-Ceramics for Solid-State LASERs." Encyclopedia. Web. 19 May, 2022.

Copy Citation

Solid-state lasers play a leading role in the field of laser application because they have the advantages of high peak power, high efficiency, long service life, safety, and reliability.

transparent nano-ceramics

nano powder

microstructure

1. Brief Introduction

Solid-state lasers play a leading role in the field of laser application because they have the advantages of high peak power, high efficiency, long service life, safety, and reliability. In solid-state lasers, the gain medium has the most significant influence on the laser’s output performance. Doped yttrium aluminum garnet (YAG) has the advantages of high thermal conductivity, high melting point, stable chemical properties, high mechanical strength, and high creep resistance. Compared with a single crystal and glass, the main advantages of YAG transparent nano-ceramics are: (1) the process of high concentration doping is simple, which can easily improve its properties; (2) it is easy to prepare ceramics with a large size and complex shape; (3) the preparation cost is low and the cycle is short; (4) it is convenient to realize special structures and functions. Therefore, it is the focus of research in the academic community, and many countries have invested a lot of human and material resources. Nowadays, YAG transparent nano-ceramics are widely used in the gain medium of solid-state lasers. According to the literature, the performance of transparent nano-ceramics is related to the controllable doping of rare earth ions and the size of nano-powder.

2. Doped YAG Transparent Nano-Ceramics

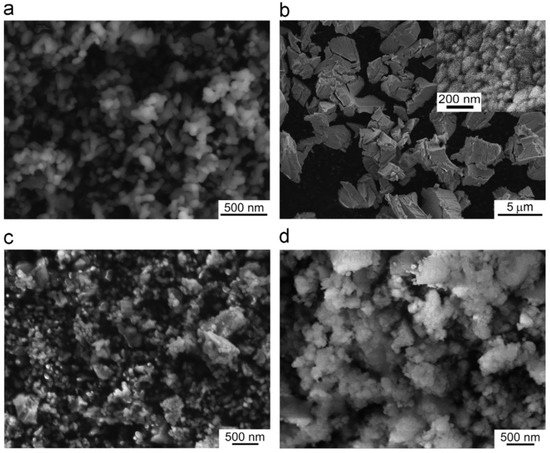

Nd3+-doped. In 1995, Nd:YAG transparent ceramics for solid-state lasers with continuous wave (CW) laser emissions were first reported by Ikesue and Kinoshita [1], and the nano powers of Y2O3, Al2O3, and Nd2O3 were used as starting materials with the average particle diameters of 60, 400, and 500 nm, respectively. The optical scattering loss of Nd:YAG was about 0.9%/cm. The experiment demonstrated that the performance of solid-state lasers could be obtained with an oscillation threshold of 309 mW and a slope efficiency of 28%, respectively. In 2002, Lu et al. [2] developed Y3Al5O12 optical ceramic materials based on highly transparent nanocrystalline YAG. The pore volume concentration of YAG transparent ceramics was 1 ppm, and the average diameter of particles was about 10 μm. The grain boundary width was only about 1 nm. The results showed that in the preliminary comparative laser experiment of Nd:YAG ceramic and single-crystal rods, the output power of 88 and 99 W were obtained, respectively. This means that it could be used in high-power, solid-state lasers. Compared with single-crystal Nd:YAG, the light-to-light efficiency of Nd:YAG transparent ceramics with nanocrystalline needs to be further improved. However, it will become a good substitute for the widely used Nd: YAG single crystal, due to its low manufacturing cost, for different types of solid-state lasers. In 2010, Suárez et al. [3] first obtained 1 at.% Nd:YAG nano powder with an average particle size of 100 nm by using a reverse-strike precipitation method. Then, the Nd:YAG transparent nano-ceramics were prepared by the hot isostatic pressing (HIP) method. They found that the optical properties were significantly different with different sintering and HIP parameters. The infrared transmittance of the fabricated sample was 80%, and its emission spectrum was the same as a 1 at.% Nd:YAG single crystal. In 2011, Stevenson et al. [4] sintered Nd:YAG transparent ceramics at 1600 °C with B2O3 and SiO2 double-sintering additives. They adopted the solid-state reaction method to prepare the Nd:YAG transparent ceramics and α-Al2O3 (>99.99%, 100–300 nm), Y2O3 (>99.999%, 50 nm), and used Nd2O3 (>99.99%, 200 nm) nano powders as the starting materials. Additionally, the B3+: Si4+ atomic ratio ranged from 0.5 to 2 while keeping the total doping level at 1.35 mol%. The results demonstrated that the relative density of the samples exceeded 99.9% and the transmittance in the visible band was as high as 84%. They also found that densification could be completed at about 100 °C lower than the normal sintering temperature since B3+ greatly improved the driving force of densification. In 2014, Yavetskiy et al. [5] also utilized the solid-state reaction method to fabricate a Nd:YAG transparent ceramic, and investigated its phase formation and densification mechanism in the sintering process. As depicted in Figure 3, the particle size of Al2O3, Y2O3 starting powders, as well as 2.88 Y2O3–0.12Nd2O3–5Al2O3 powder mixture and Y2O3 powders after planetary ball milling for 15 h, ranged from 80 to 800 nm. The results showed that using Y2O3 nano powder, under bimodal particle size distribution (D50 ≈ 160 nm and 400 nm), could make the shrinkage effect higher than the expansion effect in the formation of the YAG phase during sintering. Additionally, the transmittance of the prepared 4 at.% Nd:YAG sample (1 mm thick) at 650 nm was 80%, which was close to that of Nd:YAG single crystal. In addition, Zhang et al. [6] studied the effect of Nd dopant and LiF additive on the microwave dielectric and optical properties of transparent YAG ceramics in the spark plasma sintering (SPS) process in 2016. The SEM images demonstrated that the size of YAG nano powder was almost between 50 and 100 nm, and the infrared transmittance of the sample was 81.8% after sintering at 1360 °C. In 2021, Jia et al. [7] comparatively analyzed the influence of tetraethoxysilane (TEOS) additives on the sintering kinetics of Nd:YAG transparent ceramics. The vacuum sintering method was used to evaluate the densification process and sintering kinetics of Nd:YAG transparent ceramic samples. The densification rate of ceramic samples rose dramatically when the amount of TEOS was raised from 0 to 3.0 wt.%. The experiment showed that the transmittance of the 0.5 wt.% TEOS sample reached 75% in the near-infrared region.

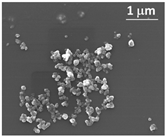

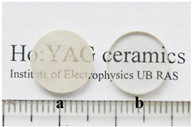

Ho-doped. Under direct pumping, the Ho3+ ion emits a quasi-three-level emission at 2.0 μm, exploited for efficient CW lasing [8][9]. Additionally, infrared lasers have also been made with Ho:YAG transparent ceramics. In 2015, Bagayev et al. [10] fabricated nano powders generated by laser ablation and then used two ways to make Ho:YAG transparent ceramics. The nano powders were made up of near-spherical particles with an average size of 8–14 nm and specific surface areas of 83.8 and 46.0 m2/g for the Al2O3 and Ho:Y2O3 particles, respectively. The results revealed that the transparent ceramics produced by their proposed method had better transmittance (82%) in the infrared band. Additionally, the slope efficiency of laser oscillations in the fabricated Ho:YAG transparent ceramic sample (1 mm thick) for pumping power was 40% (at 1.85 μm). In 2018, Zhao et al. [11] demonstrated a Ho:Y2O3 ceramic laser with high power, which fabricated Ho:Y2O3 ceramics by vacuum sintering and HIP methods. The in-band pumping method produced a 2117 nm laser with an output power of 24.6 W, nearly an order of magnitude higher than other ceramics. For high-power, solid-state lasers, therefore, Ho-doped sesquioxide ceramics are ideal materials.

Er-doped. Er-doped YAG transparent ceramics have very low levels of quantum defects, and their laser behavior is IR transitions at 1.5 and 3 μm. In 2011, Zhang et al. [12] demonstrated a 0.5 at.% Er:YAG ceramic laser, which exhibited CW emission at 1617 nm and had a slope efficiency of 51.7%. In 2015, Zhang et al. [13] reported a passively Q-switched ceramic Er:YAG laser using a saturable absorber, which emitted 1617 nm. The experimental result confirmed that the laser could reach a peak power of 11.3 kW. In 2018, a laser adopted by 0.5 at.% Er:YAG transparent ceramics, with a resonantly pumped eye-safe, was developed by Bigotta et al. The fabricated ceramics adopted a two-step approach, combining SPS+HIP methods [14]. In their study, high-purity 0.5 at.% Er3+:YAG powder with a specific surface area of 7 m2/g and an average size of 271 nm was used. The experimental results confirmed that the light-light efficiency of this laser was 20%, and the maximum slope efficiency was 31%.

Tm-doped. The Tm3+ concentration should be at least 6% to guarantee efficient down-conversion energy transfer [15]. Experiments showed that the transparent ceramics doped with Tm3+ have good light transmittance [16]. Zhang et al. [17] prepared highly transparent Tm:YAG ceramic by solid-phase reaction and vacuum sintering and studied its optical properties, microstructure and laser properties. Zou et al. [18] developed a high-efficiency, continuous-wave Tm:YAG transparent nano-ceramic laser pumped using a Ti:sapphire laser. Output power of up to 860 mW was produced with an absorbed pump power of 2.21 W at 785 nm, equating to a slope efficiency of 42.1% and a light-to-light efficiency of 22%. Zhan et al. presented a 2.7 mm long passively mode-locked laser based on 6 at.% Tm:YAG ceramics [19]. The pulse duration was 55 ps, and the highest output power was 116.5 mW at 2007 nm. Based on these findings, Tm:YAG transparent nano-ceramics looked to be promising candidates for ultrafast lasers with high power densities and high-efficiency output.

Yb-doped. The Yb3+-doped ceramics’ spectral properties ensure nearly pure four-level lasing, which can be easily controlled by adjusting the ambient temperature or the temperature inside the pumped lasing medium. In 2008, Nakamura et al. [20] developed a CW laser based on Yb:YAG transparent ceramics. With a slope efficiency of 72%, a 6.8 W CW output power was obtained, and the transverse intensity distribution of the Yb:YAG ceramic laser beam was a Gaussian beam. In 2012, Luo et al. [21] used Yb:YAG ceramics and a 940 nm fiber-coupled laser diode to accomplish CW lasing at 1030 nm. The basic materials were commercial Al2O3 powder (99.99 percent purity, 250 nm) and co-precipitated Y2O3 and Yb2O3 powders (60–80 nm, 9.5–10.0 m2/g). For a 3 mm-thick mirror-polished Yb:YAG ceramics sample, in-line transmittances at 1300 nm and 400 nm were measured to be 83.6 and 81.8%, respectively. The slope effectiveness of this laser was 62.7% according to the testing data.

Table 1 summarizes the doped YAG transparent nano-ceramics, which are described in the text grouped by doped type and publication year. It can be drawn that doped YAG laser transparent nano-ceramics have a short preparation period, low production cost, large-scale production, and high doping concentration.

Table 1. Summary of doped YAG transparent nano-ceramics described in the text grouped by doped type and published year.

| Doping Type | Year, Powder, and Fabrication | Findings | Performance | Remarks |

|---|---|---|---|---|

| Nd3+-doped | 1995; the starting nano powders include Y2O3 (60 nm), Al2O3 (400 nm), and Nd2O3 (500 nm); solid-state reaction method (Czochralski method). |  The average grain size and relative density of the 1.1 at. % Nd:YAG ceramics were about 50 μm and 99.98%, respectively. |

The optical scattering loss of Nd:YAG was about 0.9%/cm. Oscillation threshold of 309 mW and a slope efficiency of 28% [1]. | For the first time, polycrystalline ceramics were successfully used for effective laser cutting. |

| 2002; raw nano powder of oxide of aluminum, yttrium, and neodymium; ball milling -> slip casting -> vacuum sintering -> YAG transparent nano-ceramics. |  The pore volume concentration was 1 ppm, and the average diameter of particles was about 10 μm. The grain boundary width was only about 1 nm [2]. |

In laser experiment of Nd:YAG ceramic and single-crystal rods, the output powers of 88 W and 99 W were obtained, respectively [2]. | Compared with single-crystal Nd:YAG, the light-to-light efficiency of Nd:YAG nanocrystalline ceramics needs to be further improved. | |

| 2010; an average particle size of 100 nm by reverse-strike precipitation method; HIP method. |  Freeze drying was proven to be an effective method to avoid caking and produced a material nano size distribution with uniform particles [3]. |

The infrared transmittance of the sample was 80%, and its emission spectrum was the same as 1 at.% Nd:YAG single crystal [3]. | Nd: YAG nano powder with an average size of about 100 nm was prepared for the first time. | |

| 2021; high-purity powder mixture; cold isostatic pressing. |  The addition of TEOS promoted the densification of transparent ceramics. |

The transmittance of the 0.5 wt.% TEOS sample reached 75% in the near-infrared region [7]. | The densification rate of Nd: YAG transparent ceramics could be adjusted by adding different wt.% TEOS so as to improve its transmittance. | |

| Ho-doped | 2015; the nano powders were made up of near-spherical particles; solid-state reaction involving a pre-calcining stage. |  The transmittance in the infrared region was 82% [10]. |

The slope efficiency of laser oscillations in the fabricated Ho:YAG transparent ceramic sample for pumping power was 40% (at 1.85 μm) [10]. | Based on the nano-powders prepared by laser ablation, Ho:YAG optical ceramics with finer particle size were prepared. |

| 2018; uniform ceramic grain; HIP method. |  The total absorption spectral width was about 16 nm and suitable for pumping of diode lasers or fiber lasers, and the light-to-light efficiency was 52%. |

The in-band pumping method produced a 2117 nm laser with an output power of 24.6 W [11]. | Further development of large-scale, YAG transparent ceramics with low Ho3+ doping concentration is required to alleviate the thermal effect during the lasing process. | |

| Er-doped | 2018; high-purity 0.5 at.% Er3+:YAG powder; SPS+HIP methods. |  At 400 and 1100 nm wavelengths, the on-line transmission values were 75.8% and 82.7%, respectively [14]. |

The light–light efficiency of laser was 20%, and the maximum slope efficiency was 31% [14]. | Transmission values of the Er3+: YAG transparent ceramics were lower than that of Er3+:YAG single crystals, which requires further improvement of the fabrication process. |

| Tm-doped | 2010. |  Light-to-light efficiency was 22%. |

Under an absorbed pump power of 2.21 W at 785 nm, an output power of up to 860 mW was produced [18]. | Tm:YAG ceramic is a promising laser working medium. Higher power and efficiency can be achieved by using an improved laser cavity and an optimized transmission optical path. |

| Yb-doped | 2008. |  The transverse intensity distribution of the Yb:YAG ceramic laser beam was a Gaussian beam [20]. |

The ceramic Yb:YAG laser exhibited a continuous tunability at a maximum output power of 1.6 W [20]. | Except for crystal Yb:YAG investigations, this was the first study of the tunability of ceramic Yb:YAG lasers. |

3. Application

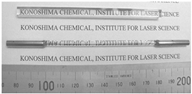

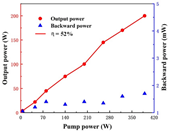

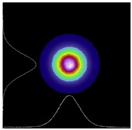

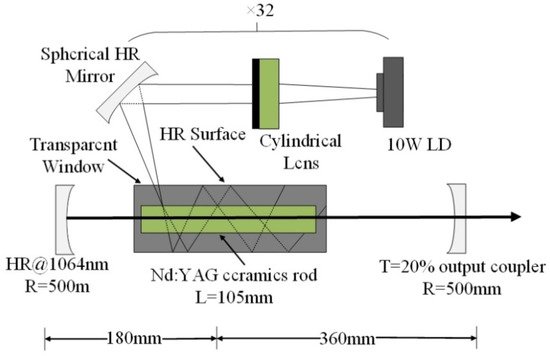

The schematic diagram of YAG transparent nano-ceramics’ application in a laser diode pumping system is shown in Figure 4. As depicted in Figure 4, a symmetrical ring pump source was created using 32 groups of laser diodes (the highest output of an LD at 807 nm was 10 W) and a ϕ4 mm × 105 mm 0.6% Nd:YAG transparent nano-ceramic rod. Then, a high-power Nd:YAG ceramic laser with CW 1.46 kW was developed [2], and this was the first time that the output power of a ceramic laser exceeded the kilowatt level. The experimental findings showed that increasing the pump power to 290 W resulted in an 88 W multimode CW laser output. This meant that the light-to-light efficiency of YAG transparent nano ceramics was about 30%. In 2010, Marsh Corporation in the United States used multiple Nd:YAG transparent ceramic slabs with composite structures to achieve a laser output of more than 100 kW using direct pumping technology, of which the output power of a single Nd:YAG slab could reach 17 kW [22][23]. Nakamura [20] developed a high-power efficient transparent ceramic Yb:YAG laser with a Yb concentration of 9.8%, a pumping power of 13.8 W, a T = 10% output coupler, and a cavity length of 20 mm at a room temperature of 20 °C. At a maximum output power of 1.6 W, the ceramic Yb:YAG laser showed continuous tunability in the spectral region of 63.5 nm from 1020.1 to 1083.6 nm. A high-power passive Q-switched Ho:YAG ceramic laser was created by Yuan et al. [24]. The maximum pulse energy of this laser was 0.94 mJ, the pulse width was 28 ns, and the peak power was 33.5 kW at a pulse-repetition frequency of 28.8 kHz.

Figure 4. Schematic diagram of YAG transparent nano-ceramics’ application in laser diode pumping system.

4. Summary

Since it took Ikesue and Kinoshita [1] 31 years to use lasers for Nd:YAG transparent nano-ceramics in 1995, this was not a rapid development. Over the next seven years, advances in powder synthesis and ceramic sintering allowed the 1 kW output power threshold to be broken in 2002 [2], followed by another seven years until the 100 kW mark was crossed in 2009 [22][23].

In terms of powder-preparation methods, the most mature technologies are the solid-state reaction method and liquid-phase coprecipitation process. The solid-state reaction method has a simple process, but the commercial raw material powder used has low sintering activity, which is not conducive to the densification of transparent ceramics. In terms of doped YAG transparent ceramics’ sintering, vacuum sintering is currently the most commonly used sintering technology for fabricating them. Although vacuum sintering helps to eliminate pores and improve the density, it is nevertheless unable to entirely eradicate residual pores inside the ceramics, resulting in most sintered samples having a transmittance of less than 80%. In addition, according to the needs of solid-state lasers, rare earth ion-doped YAG transparent ceramics can be used to make laser materials with excellent performance, which are widely used in the field of solid-state lasers.

It can be seen from the above experiments that after doping with Nd3+, the transmittance increases to 81.8%; the output power of Ho-doped sesquioxide ceramics is nearly an order of magnitude higher than that of other ceramics; Er-doped YAG transparent ceramics have very low levels of quantum defects, and their peak power can also reach 11.3 kW; Tm-doped ceramics can ensure an efficient step-down version of energy transfer; and Yb doping can adjust the environment and the temperature inside the pumping laser medium. In general, the transmittance and output power of ceramics doped with YAG were greatly improved, and the temperature could be controlled at the same time, which makes them a good candidate for ultrafast lasers with a high power density and high power output.

However, most of the current research on Nd:YAG transparent ceramics is based on experimental results [25][26], and there is a lack of relevant theoretical simulation data. For example, there is still a lack of research on the relationship between structural defects (such as grain boundaries) and the photothermal damage of ceramics, as well as on the types and concentration distributions of doped rare earth ions. In addition, it is also necessary to study the occupancy mechanism and distribution of dopant ions of different types and concentrations inside the ceramic, as well as the influence of the surrounding crystal field. These breakthroughs in the mechanism of action need to be solved through effective theoretical models.

References

- Ikesue, A.; Kinoshita, T.; Kamata, K.; Yoshida, K. Fabrication and Optical Properties of High-Performance Polycrystalline Nd:YAG Ceramics for Solid-State Lasers. J. Am. Ceram. Soc. 1995, 78, 1033–1040.

- Lu, J.; Ueda, K.; Yagi, H.; Yanagitani, T.; Akiyama, Y.; Kaminskii, A.A.; Alloys, J. Neodymium doped yttrium aluminum garnet (Y3Al5O12) nanocrystalline ceramics-a new generation of solid state laser and optical materials. J. Alloy. Compd. 2002, 341, 220–225.

- Suárez, M.; Fernández, A.; Menéndez, J.; Nygren, M.; Torrecillas, R.; Zhao, Z. Hot isostatic pressing of optically active Nd:YAG powders doped by a colloidal processing route. J. Eur. Ceram. Soc. 2010, 30, 1489–1494.

- Stevenson, A.; Kupp, E.; Messing, G. Low temperature, transient liquid phase sintering of B2O3-SiO2-doped Nd:YAG transparent ceramics. J. Mater. Res. 2011, 26, 1151–1158.

- Yavetskiy, R.; Baumer, V.; Doroshenko, A.; Kopylov, Y.; Kosyanova, D.; Kravchenkoc, V.; Parkhomenkoa, S.; Tolmacheva, A. Phase formation and densification peculiarities of Y3Al5O12:Nd3+ during reactive sintering. J. Cryst. Growth 2014, 401, 839–843.

- Zhang, X.; Fan, G.; Lu, W.; Chen, Y.; Ruan, X. Effect of the spark plasma sintering parameters, LiF additive, and Nd dopant on the microwave dielectric and optical properties of transparent YAG ceramics. J. Eur. Ceram. Soc. 2016, 36, 2767–2772.

- Jia, W.; Wei, Q.; Zhang, H.; Su, C.; Ren, G.; Zhao, M.; Ma, C. Comparative analyses of the influence of TEOS additives on the sintering kinetics of Nd: YAG transparent ceramics. J. Mater. Sci. Mater. Electron. 2021, 32, 19218–19229.

- Zhang, W.; Zhou, J.; Liu, W.; Li, J.; Wang, L.; Jiang, B.; Pan, Y.; Cheng, X.; Xu, J. Fabrication, properties and laser performance of Ho:YAG transparent ceramic. J. Alloy. Compd. 2010, 506, 745–748.

- Yang, H.; Zhang, J.; Qin, X.; Luo, D.; Ma, J.; Tang, D.; Chen, H.; Shen, D.; Zhang, Q. Polycrystalline Ho:YAG transparent ceramics for eye-safe solid state laser applications. J. Am. Ceram. Soc. 2012, 95, 52–55.

- Bagayev, S.; Osipov, V.; Vatnik, S.; Shitov, V.; Vedin, I.; Platonov, V.; Steinberg, I.; Maksimov, R. Ho:YAG transparent ceramics based on nanopowders produced by laser ablation method: Fabrication, optical properties, and laser performance. Opt. Mater. 2015, 50, 47–51.

- Zhao, Y.; Wang, J.; Yao, W.; Shao, Z.; Shen, C.; Yin, D.; Wang, Y.; Liu, P.; Zhou, W.; Tang, D.; et al. High power Ho-doped sesquioxide ceramic laser in-band pumped by a Tm-doped all-fiber MOPA. IEEE Photon. J. 2018, 10, 1502107.

- Zhang, C.; Shen, D.; Wang, Y.; Qian, L.; Zhang, J.; Qin, X.; Tang, D.; Yang, X.; Zhao, T. High-power polycrystalline Er:YAG ceramic laser at 1617 nm. Opt. Lett. 2011, 36, 4767–4769.

- Zhang, X.; Shen, D.; Huang, H.; Liu, J.; Zhang, J.; Tang, D.; Fan, D. Passively Q-switched 1617-nm polycrystalline ceramic Er:YAG laser using a Cr:ZnSe saturable absorber. Appl. Phys. B 2015, 120, 305–309.

- Bigotta, S.; Galecki, L.; Katz, A.; Bohmler, J.; Lemonnier, S.; Barraud, E.; Leriche, A.; Eichhorn, M. Resonantly pumped eye-safe Er3+:YAG SPS-HIP ceramic laser. Opt. Express 2018, 26, 3435–3442.

- Zou, Y.; Wei, Z.; Wang, Q.; Zhan, M.; Li, D.; Zhang, Z.; Zhang, J.; Tang, D. High-efficiency diode-pumped Tm:YAG ceramic laser. Opt. Mater. 2013, 35, 804–806.

- Liu, P.; Jin, L.; Liu, X.; Huang, H.; Zhang, J.; Tang, D.; Shen, D. A diode-pumped dual-wavelength Tm, Ho: YAG ceramic laser. IEEE Photon. J. 2016, 8, 1504007.

- Zhang, W.; Pan, Y.; Zhou, J.; Liu, W.; Li, J.; Jiang, B.; Cheng, X.; Xu, J. Diode-pumped Tm:YAG ceramic laser. J. Am. Ceram. Soc. 2009, 92, 2434–2437.

- Zou, Y.; Zhang, Y.; Zhong, X.; Wei, Z.; Zhang, W.; Jiang, B.; Pan, Y. Efficient Tm:YAG ceramic laser at 2 μm. Chin. Phys. Lett. 2010, 27, 074213.

- Zhan, M.; Zou, Y.; Lin, Q.; Wang, Z.; Han, H.; Lu, L.; Wei, Z.; Zhang, J.; Tang, D. Ti:saphire pumped passively mode-locked Tm:YAG ceramic laser. Acta Phys. Sin. 2014, 63, 014205.

- Nakamura, S.; Yoshioka, H.; Matsubara, Y.; Ogawa, T.; Wada, S. Efficient tunable Yb:YAG ceramic laser. Opt. Commun. 2008, 281, 4411–4414.

- Luo, D.; Jian, Z.; Xu, C.; Qin, X.; Tang, D.; Ma, J. Fabrication and laser properties of transparent Yb:YAG ceramics. Opt. Mater. 2012, 34, 936–939.

- Sanghera, J.; Kim, W.; Guillermo, V.; Brandon, S.; Colin, B. Ceramic laser materials. Opt. Mater. 2012, 5, 258–277.

- Mandl, A.; Klimek, D. Textron’s J-HPSSL 100 kW ThinZag laser program. In Conference on Lasers and Electro-Optics; Optical Society of America: San Jose, CA, USA, 2010.

- Yuan, J.; Duan, X.; Yao, B.; Li, J.; Cui, Z.; Shen, Y.; Dai, T.; Ju, Y.; Li, C.; Kou, H.; et al. Dual-end-pumped high-power Cr2+:ZnS passively Q-switched Ho:YAG ceramic laser. Appl. Phys. 2015, 119, 381–385.

- Feizbakhsh, M.; Yazd, N.S.; Keshavarzi, A.; Doosti, A. Anisotropic crystallization of YAG on the surface of glass by CO2 laser irradiation. Crystengcomm 2022, 24, 2753–2758.

- Li, T.; Zhou, T.; Cao, Y.; Cai, Z.; Zhao, C.; Yuan, M.; Zheng, X.; Huang, G.; Wang, Z.; Zhang, L.; et al. Optical properties and energy transfer performances in high quality Cr,Nd:YAG transparent laser ceramics for solar pumped lasers. Opt. Express 2022, 30, 8762–8776.

More

Information

Subjects:

Engineering, Manufacturing

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

928

Revisions:

2 times

(View History)

Update Date:

20 May 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No