Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Guangjing Xu | -- | 1800 | 2022-05-12 11:54:14 | | | |

| 2 | Amina Yu | + 1 word(s) | 1801 | 2022-05-13 04:29:16 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Xu, G.; , . Pollution Control of Industrial Mariculture Wastewater. Encyclopedia. Available online: https://encyclopedia.pub/entry/22864 (accessed on 07 February 2026).

Xu G, . Pollution Control of Industrial Mariculture Wastewater. Encyclopedia. Available at: https://encyclopedia.pub/entry/22864. Accessed February 07, 2026.

Xu, Guangjing, . "Pollution Control of Industrial Mariculture Wastewater" Encyclopedia, https://encyclopedia.pub/entry/22864 (accessed February 07, 2026).

Xu, G., & , . (2022, May 12). Pollution Control of Industrial Mariculture Wastewater. In Encyclopedia. https://encyclopedia.pub/entry/22864

Xu, Guangjing and . "Pollution Control of Industrial Mariculture Wastewater." Encyclopedia. Web. 12 May, 2022.

Copy Citation

The main targets of mariculture wastewater treatment are organic carbon, nitrogen and phosphorus, while the other pollutants, such as chemicals, need to be controlled from the feed sources. That is to say, the main target of mariculture wastewater is to remove most of the organic solid wastes containing the above pollutants. The conventional physical, chemical, biological and ecological technologies are feasible for the treatment of all the biodegradable pollutants.

marine pollution

algae

denitrification filter

constructed wetlands

1. Current Situation of Mariculture Wastewater Pollution in China

As industrial mariculture has always been a high-density culture, the nutrients in the natural seawater are far from meeting the growth needs of aquatic animals. Therefore, it is necessary to add feed to ensure the nutritional requirements of farmed animals. However, some of the feed cannot be consumed and will be discharged into the sea after gravity settling [1][2]. In the process of manually changing water and cleaning fishponds, organic particles from the wall and bottom of fishponds are directly discharged into the sea. Residual feed, excrements and urea can be broken down by microorganisms, releasing soluble nitrogen and phosphorus, which led to eutrophication of the coastal water [3][4][5]. In addition, the use of drugs such as levofloxacin, sulfamethoxazole and azithromycin, as well as pesticides such as rotenone, diuron and vitamins, also raises environmental concerns, as serious diseases associated with industrial mariculture farming require regular disinfection and sterilization [3][6][7].

The eutrophication is still a current focus of concern, since it causes a serious degradation of the marine ecosystem. In 2020, a total of 31 red tides caused by the sudden proliferation of algae were found in China’s seas, covering a total area of 1748 km2, among which two toxic red tides were found in the coastal waters of Tianjin and Shenzhen Bay, with a total area of 81 km2 [8]. Compared with the past decade, the number of red tides in 2020 has decreased significantly. Besides, compared with the average of the past five years, the maximum coverage area of green tide decreased by 54.9%, and the maximum daily biomass decreased from 1.508 million tons to 0.68 million tons in 2020 [9]. Therefore, China has made remarkable achievements in the prevention and control of eutrophication, but the problem of coastal water pollution still remains serious in China.

Nitrogen and phosphorus are the main drivers of eutrophication in the marine. In recent years, with the improvement of China’s wastewater discharge standards, the input of exogenous nitrogen into coastal water has gradually decreased, while total phosphorus has become the main pollutant exceeding the standard. [9], something which creates long-term eutrophic conditions because phosphorus is trapped in the water for a long time [10]. Since 2010, the annual average area of red tide has reached 2200 km2 in China, and most estuaries and gulf ecosystems are in an unhealthy state, losing ecosystem functions [3]. By establishing the regression relationship between the total aquaculture output and the total pollution load, It can be showed that there is a significant positive correlation between the total pollutant discharge and the total output value of mariculture [11].

The total amount of pollutants produced by mariculture has been estimated based on the production–discharge coefficient manual of aquaculture pollution sources in the first national survey of pollution sources of China and the Chinese Fishery Statistical Yearbook in Liaoning province in 2021 [12].

2. Treatment Technologies of Industrial Mariculture Wastewater

2.1. Treatment of Raw Mariculture Wastewater

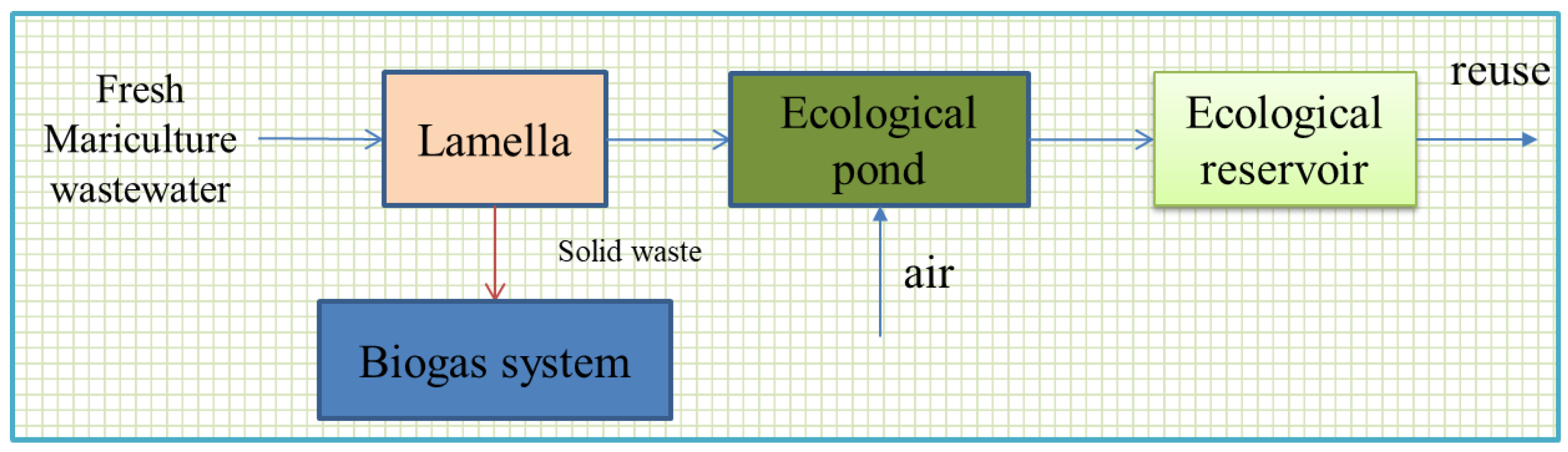

Traditional mariculture is culture fish in open ponds and raceways and needs frequent water exchange to maintain a good water environment. The schematic diagram of fresh mariculture wastewater is shown in Figure 1. The main pollutants of this method are fresh feed and excrements, which can be separated by physical filtration methods. Organic waste can be treated for methane production by co-digestion with waste plants or algae. The supernatant wastewater containing few pollutants can be treated in an ecological pond, and then stored in an ecological reservoir for recycling or discharged after in-depth removal of suspended sludge and phosphorus by an artificial wetland.

Figure 1. Biological nutrients removal of raw mariculture wastewater.

Inclined tube settling tank (Lamella) is suggested for the removal of the fresh organic solids at a long hydraulic retention time (HRT). After concentration, the waste sludge enters into a sludge pressure filter or centrifugal dehydrator, and the mud cake is transported for centralized disposal and treatment. Anaerobic co-digestion of organic residual feed, excrements, waste sludge and algae can be used to produce methane for energy recovery [13]. The anaerobic digestion liquid is rich in nitrogen and phosphorus, which can be used for the cultivation of algae or irrigation of coastal constructed wetlands.

The ecological system is the key for diluted nutrients, especially phosphorus removal. According to the concentrations of pollutants, a small number of fixed-bed fiber carriers can be installed below the ecological floating bed, enhancing removal of organic carbon and nitrogen. Ammonia is oxidized to nitrite by ammonium-oxidizing bacteria (AOB), and then further to nitrate by nitrite-oxidizing bacteria (NOB), while the nitrate will be denitrified to N2 by denitrifying bacteria in the inner biofilm [14]. The plants or algae further assist in the removal of phosphorus and nitrogen. The biological fiber carriers are fixed in the water with the planted float system as the shelter, which not only achieves simultaneous carbon, nitrogen and phosphorus removal, but also increases the beauty of the water treatment system. Aeration device is also needed to increase dissolved oxygen for aerobic organisms, though the DO is high in the raw wastewater. Moreover, aquatic plants should be regularly harvested to transfer nutrients. What needs to be pointed out is that the ecosystem relies on the physical interception of residual feed and excrements. Only through a physical separation process to maximize the retention of organic solid waste, the treatment load of the ecological unit can be reduced to ensure a stable operation of the ecosystem.

Microalgae-attached biocarriers can be installed in the shallow water to enhance nutrients removal and algae collection, or some shellfish can also be raised underwater to assist in filtering particulate organic matters or algae [15]. Besides, the other ecological technologies, such as constructed wetland, ecological floating island and artificial submerged bed can also be used for advanced water purification. Finally, the treated wastewater can be stored for recycling in the landscape pond.

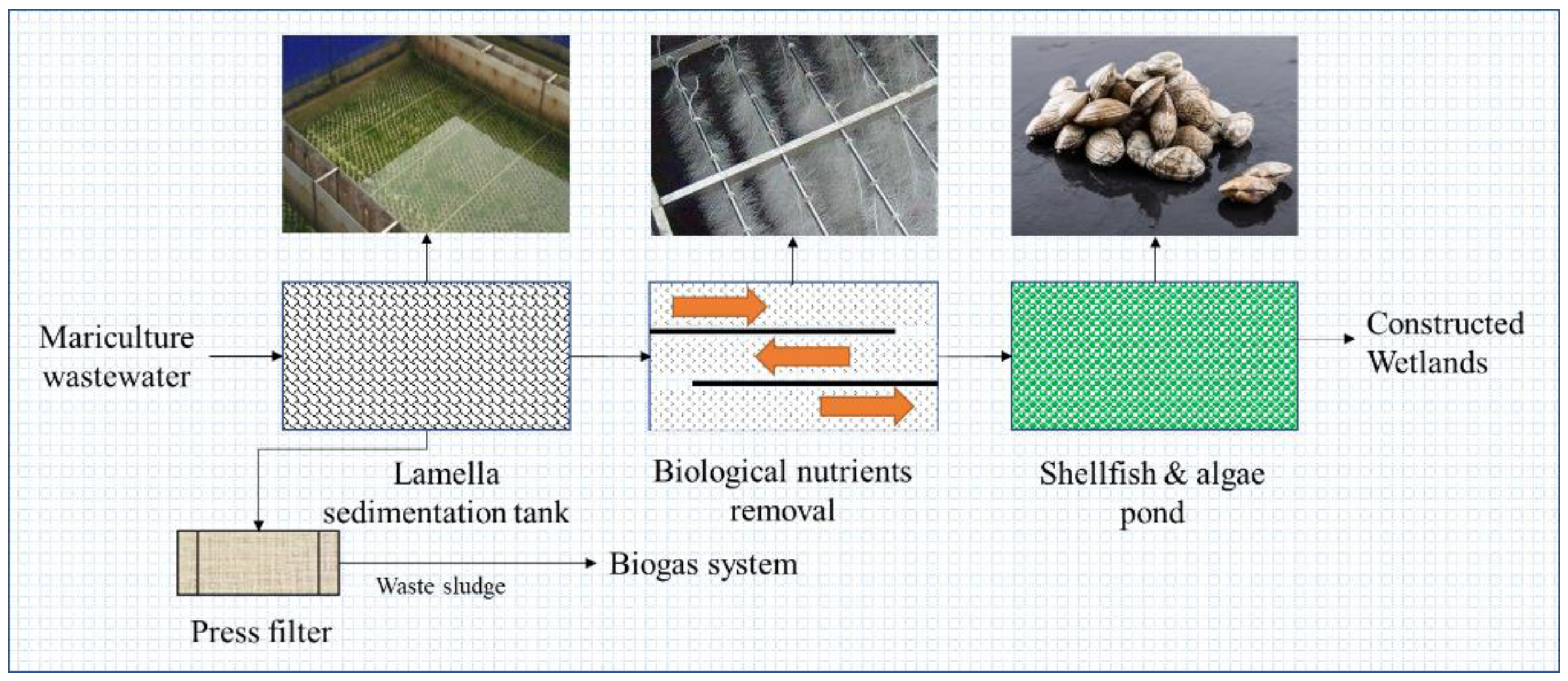

For large-scale farmers or industrial mariculture garden areas, the mariculture wastewater can be treated in a centralized way. Wastewater treatment stations are established with households as units, and the specific technological process is shown in Figure 2. After solid–liquid separation by a Lamella sedimentation tank, the concentrated feed and excrement are transferred to an anaerobic digestion system. Bacterial nitrification and denitrification process is used for the removal of nitrogen in the supernatant. The residual nitrate and phosphorus should be further removed in a shellfish and algae pond or ditches/river channels, while plant/algae floating beds are required for phosphorus removal. When the mariculture wastewater meets the discharge standard, it can be optionally discharged or reused.

Figure 2. Wastewater treatment technology of large-scale mariculture plants.

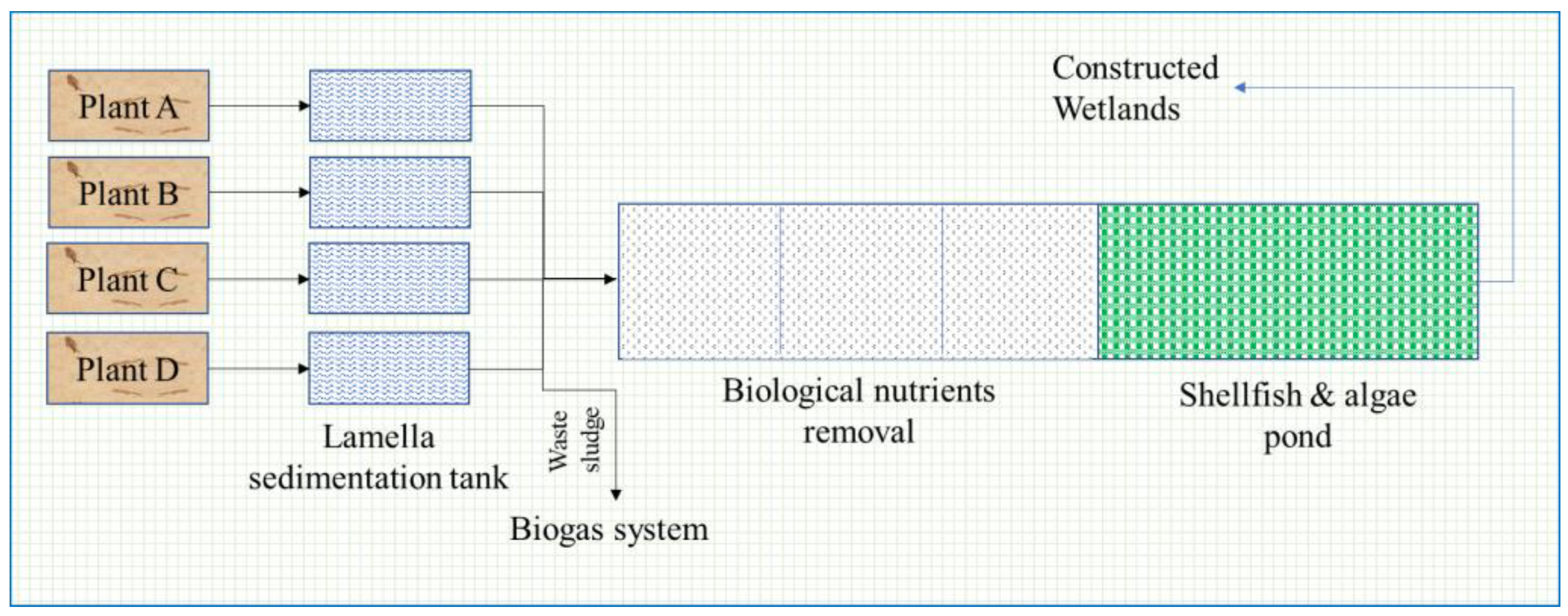

For small-scale farmers in mariculture zones, local governments can control the amount of water used by fisheries and centralize wastewater treatment (Figure 3). The mariculture wastewater of each farmer is first treated in its own Lamella sedimentation tank. The residual feed and excrement are transported for centralized disposal, and the supernatant is discharged into the public drainage ditch or pipe network. Only the concentrations of suspended sludge are needed to be controlled at each wastewater outlet. The ecological channel can be filled with biological fillers or large sand gravels, and the bottom is seeded with filter-feeding shellfish. Constructed wetland technology can be selectively used to remove nitrogen and phosphorus. What needs to be emphasized is that the public wastewater treatment facilities should be led by the local government, operated by professional companies, while farmers need to pay a small fee of wastewater treatment.

Figure 3. Wastewater treatment technology of small-scale mariculture plants.

2.2. Treatment of RAS Mariculture Wastewater

Compared with the traditional process, the daily exchanging water of RAS is only 5%–10%. RAS wastewater mainly contains high-level nitrate and active phosphorus. Nitrate can be removed using traditional denitrification process with addition of external organic carbon source, such as glucose, acetate or others [16][17]. However, phosphorus cannot be removed under the anoxic conditions, and needs to be further removed by chemically enhanced phosphorus removal or photosynthesis [18]. For the denitrification, it is necessary to overcome the high salt and high DO, which highly inhibit the anaerobic denitrifying bacteria [19][20]. In fact, a large amount of external carbons are oxidized to carbon dioxide using the DO, rather than nitrate as electron acceptor [21]. Besides, a further nitrogen and phosphorus removal is required using ecological methods.

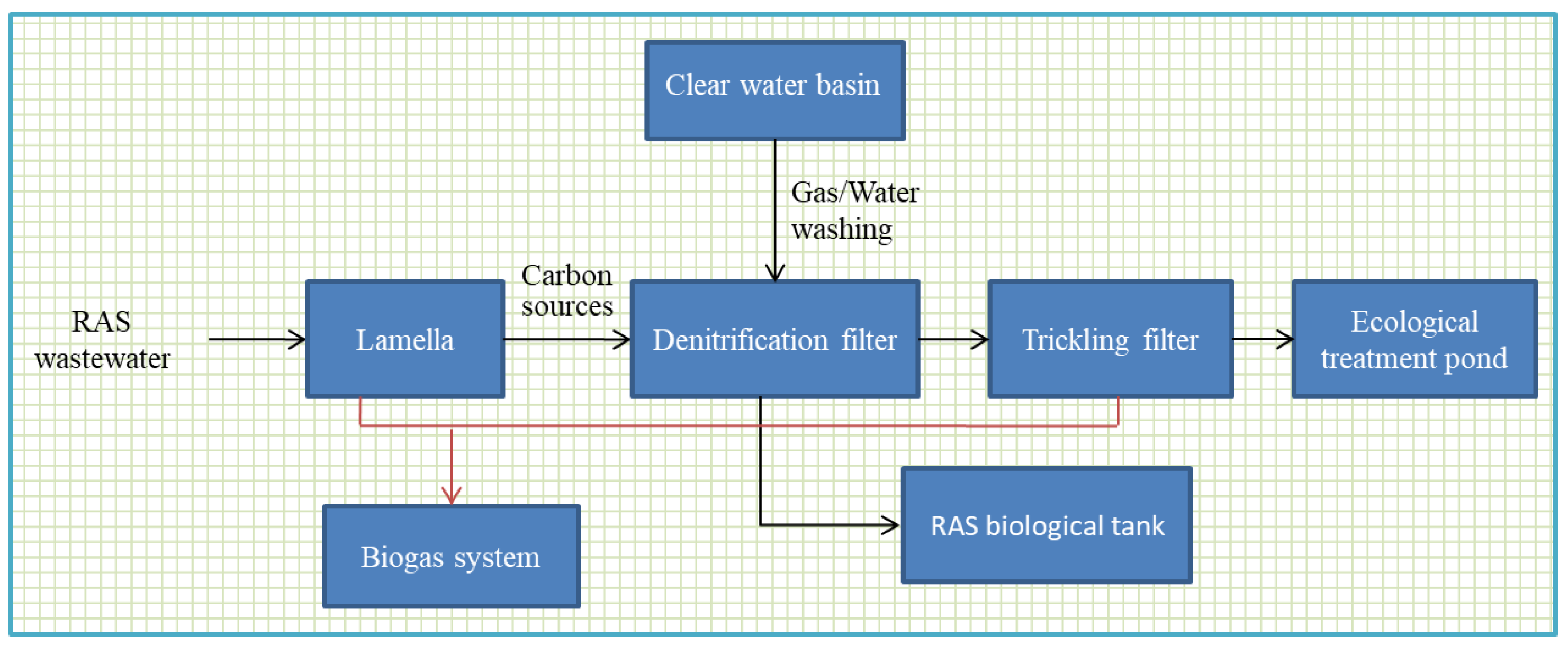

2.2.1. Combined Denitrification Filter and Ecological Method

This specific treatment process is shown in Figure 4. Denitrification filter is usually used to treat the effluent from a secondary sedimentation tank of municipal wastewater treatment plants [22]. External carbon addition should meet the requirement of COD/N above 3.5 due to aerobic oxidation of organic carbon at high DO. Denitrification filter is divided into upflow filter and downflow filter according to hydraulic flow pattern. The upflow filter is divided into a water distribution area, supporting layer, packing layer and clean water area from bottom to top, respectively, while the downflow filter is divided into water distribution area, packing layer, supporting layer and water outlet collection area from top to bottom, respectively. Denitrification filters have good filtration function, and the effluent suspended solids can meet the discharge standard. Normally, traditional denitrification filters need no aeration equipment in the filter, but there is a high concentration of sulfate in seawater. In the presence of organic carbons, sulfate can be reduced to an H2S gas that has strong toxicity to marine organisms [23]. Denitrification can inhibit the sulfate reduction process, but it is greatly affected by C/N/S ratio [24]. As such, intermittent aeration should be applied to inhibit oxygen sensitive sulfate reducing bacteria in the denitrification filters treating RAS mariculture wastewater, and otherwise the treated wastewater should be treated for the sulfide oxidation to sulfate in a large-volume trickling filter. Finally, the treated wastewater can be stored in an eco-purification pond. Another problem is that phosphorus will accumulate in ecological ponds as the N/P ratio is not suitable for photosynthesis and microalgae are difficult to be separated from the water. In fact, microalgae and the organic solids from Lamella and trickling filter are good biogas production sources.

Figure 4. Schematic diagram of a combined denitrification filter and ecological pond.

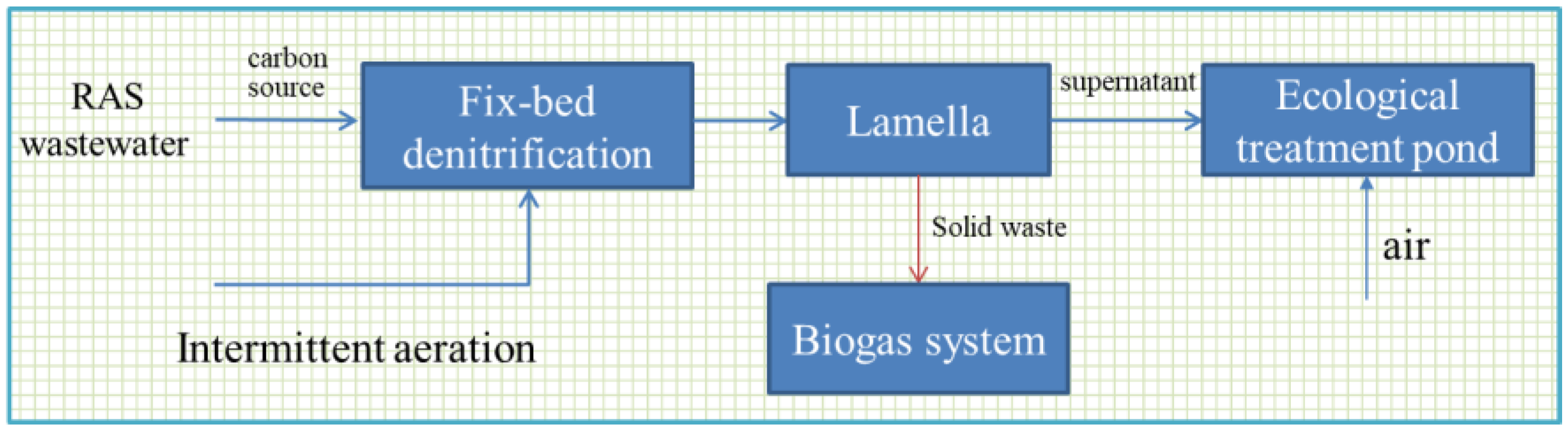

2.2.2. Combined Fixed-Bed Denitrification and Ecological Method

This is also a nitrogen denitrified process with external carbon source (Figure 5). Suspended solids need to be removed in a Lamella sedimentation tank. The plug-flow fixed-bed denitrification process is simple to operate compared with a denitrification filter. However, the DO concentrations in the effluent of denitrification tank are very low, so air should be supplied into the ecological pond.

Figure 5. Combined fixed-bed denitrification and ecological treatment system.

References

- Opstvedt, J.; Aksnes, A.; Hope, B.; Pike, I.H. Efficiency of feed utilization in Atlantic salmon (Salmo salar L.) fed diets with increasing substitution of fish meal with vegetable proteins. Aquaculture 2003, 221, 365–379.

- Grossowicz, M.; Tchernov, D.; Gildor, H. A Quantitative Management Tool Reflecting Impact of Nutrient Enrichment from Mariculture in the Levantine Basin. Front. Mar. Sci. 2017, 4, 134.

- Meng, W.; Feagin, R.A. Mariculture is a double-edged sword in China. Estuar. Coast. Shelf Sci. 2019, 222, 147–150.

- Li, H.; Li, X.; Li, Q.; Liu, Y.; Song, J.; Zhang, Y. Environmental response to long-term mariculture activities in the Weihai coastal area, China. Sci. Total Environ. 2017, 601–602, 22–31.

- Yang, P.; Lai, D.Y.; Jin, B.; Bastviken, D.; Tan, L.; Tong, C. Dynamics of dissolved nutrients in the aquaculture shrimp ponds of the Min River estuary, China: Concentrations, fluxes and environmental loads. Sci. Total Environ. 2017, 603–604, 256–267.

- Zhang, R.; Du, J.; Dong, X.; Huang, Y.; Xie, H.; Chen, J.; Li, X.; Kadokami, K. Occurrence and ecological risks of 156 pharmaceuticals and 296 pesticides in seawater from mariculture areas of Northeast China. Sci. Total Environ. 2021, 792, 148375.

- Lulijwa, R.; Rupia, E.J.; Alfaro, A.C. Antibiotic use in aquaculture, policies and regulation, health and environmental risks: A review of the top 15 major producers. Rev. Aquac. 2019, 12, 640–663.

- MNR. Bulletin of China Marine Disaster in 2020; Ministry of Natural Resources: Beijing, China, 2021.

- MEE. Bulletin of Marine Ecology and Environment Status of China in 2020, 2021 ed.; National Marine Environment Monitoring Center: Dalian, China, 2021.

- Bol, R.; Gruau, G.; Mellander, P.-E.; Dupas, R.; Bechmann, M.; Skarbøvik, E.; Bieroza, M.; Djodjic, F.; Glendell, M.; Jordan, P.; et al. Challenges of Reducing Phosphorus Based Water Eutrophication in the Agricultural Landscapes of Northwest Europe. Front. Mar. Sci. 2018, 5, 1–16.

- Han, Q.F.; Zhao, S.; Zhang, X.R.; Wang, X.L.; Song, C.; Wang, S.G. Distribution, combined pollution and risk assessment of antibiotics in typical marine aquaculture farms surrounding the Yellow Sea, North China. Environ. Int. 2020, 138, 105551.

- Fisheries Administration Bureau of MARA, N. CSF. China Fishery Statistics Yearbooks; China Agriculture Press: Beijing, China, 2021.

- Karki, R.; Chuenchart, W.; Surendra, K.; Shrestha, S.; Raskin, L.; Sung, S.; Hashimoto, A.; Khanal, S.K. Anaerobic co-digestion: Current status and perspectives. Bioresour. Technol. 2021, 330, 125001.

- Li, C.; Liang, J.; Lin, X.; Xu, H.; Tadda, M.A.; Lan, L.; Liu, D. Fast start-up strategies of MBBR for mariculture wastewater treatment. J. Environ. Manag. 2019, 248, 109267.

- Rose, J.M.; Bricker, S.B.; Ferreira, J.G. Comparative analysis of modeled nitrogen removal by shellfish farms. Mar. Pollut. Bull. 2015, 91, 185–190.

- Liu, Y.; Guo, L.; Gao, P.; Yu, D.; Yao, Z.; Gao, M.; Zhao, Y.; Jin, C.; She, Z. Thermophilic bacteria combined with alkyl polyglucose pretreated mariculture solid wastes using as denitrification carbon source for marine recirculating aquaculture wastewater treatment. Sci. Total Environ. 2021, 792, 148447.

- Gao, Y.; Guo, L.; Shao, M.; Hu, F.; Wang, G.; Zhao, Y.; Gao, M.; Jin, C.; She, Z. Heterotrophic denitrification strategy for marine recirculating aquaculture wastewater treatment using mariculture solid wastes fermentation liquid as carbon source: Optimization of COD/NO3−-N ratio and hydraulic retention time. Bioresour. Technol. 2020, 304, 122982.

- Gao, Y.; Guo, L.; Jin, C.; Zhao, Y.; Gao, M.; She, Z.; Wang, G. Metagenomics and network analysis elucidating the coordination between fermentative bacteria and microalgae in a novel bacterial-algal coupling reactor (BACR) for mariculture wastewater treatment. Water Res. 2022, 215, 118256.

- Kampman, C.; Piai, L.; Temmink, H.; Hendrickx, T.L.G.; Zeeman, G.; Buisman, C.J.N. Effect of low concentrations of dissolved oxygen on the activity of denitrifying methanotrophic bacteria. Water Sci. Technol. 2018, 77, 2589–2597.

- Park, E.-J.; Seo, J.-K.; Kim, M.-R.; Jung, I.-H.; Kim, J.Y.; Kim, S.-K. Salinity acclimation of immobilized freshwater denitrifier. Aquac. Eng. 2001, 24, 169–180.

- Guo, Q.; Yang, Z.; Zhao, Q.; Chen, J.; Li, J.; Chen, L.; Shi, W.; An, P.; Wang, G.; Xu, G. A pilot-scale study of a novel two-stage denitrification filter. J. Water Process Eng. 2020, 39, 101873.

- Zheng, X.; Zhang, S.; Zhang, J.; Huang, D.; Zheng, Z. Advanced nitrogen removal from municipal wastewater treatment plant secondary effluent using a deep bed denitrification filter. Water Sci. Technol. 2018, 77, 2723–2732.

- Wang, X.; Wang, J.; Zhao, Y.-G.; Maqbool, F.; Guo, L.; Gao, M.; Jin, C.; Ji, J. Control of toxic sulfide in mariculture environment by iron-coated ceramsite and immobilized sulfur oxidizing bacteria. Sci. Total Environ. 2021, 793, 148658.

- Zhou, J.-M.; Song, Z.-Y.; Yan, D.-J.; Liu, Y.-L.; Yang, M.-H.; Cao, H.-B.; Xing, J.-M. Performance of a haloalkaliphilic bioreactor under different NO3-/SO42- ratios. Bioresour. Technol. 2014, 153, 216–222.

More

Information

Subjects:

Environmental Sciences

Contributors

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

689

Revisions:

2 times

(View History)

Update Date:

13 May 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No