| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Xenia Pascari | + 1505 word(s) | 1505 | 2022-01-26 06:50:09 | | | |

| 2 | Yvaine Wei | Meta information modification | 1505 | 2022-01-27 06:39:11 | | |

Video Upload Options

Mycotoxins are secondary fungal metabolites of high concern in the food and feed industry. Their presence in many cereal-based products has been numerously reported. Beer is the most consumed alcoholic beverage worldwide, and Fusarium mycotoxins originating from the malted and unmalted cereals might reach the final product. This entry aims to describe the possible Fusarium fungi that could infect the cereals used in beer production, the transfer of mycotoxins throughout malting and brewing as well as an insight into the incidence of mycotoxins in the craft beer segment of the industry. Studies show that germination is the malting step that can lead to a significant increase in the level of all Fusarium mycotoxins.

1. Introduction

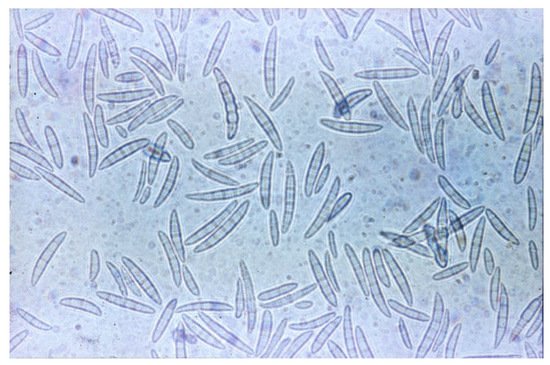

2. Fusarium Fungi in Brewing Cereals

2.1. Barley

2.2. Wheat

Wheat beer is a special type of beer that is fermented from a mix of malted wheat and barley, where wheat represents at least 50% of the malted cereal, according to the present Provisional Act on Purity of Beer (Vorläufiges Biergesetz). The malting procedure of wheat is similar to the one employed for barley; nonetheless, their differences in composition imply significantly different values required for the important malting and brewing parameters (e.g., shorter immersion time during steeping).

As it is in the case of barley, FHB is the main disease affecting wheat fields and has a negative effect on the malting parameters. The coexistence of up to 20 Fusarium species might be causing it, each of them having a different mycotoxin production profile: F. graminearum and F. culmorum produce DON, NIV and ZEN, F. avenaceum produces moniliformin (MON) and beauvericin (BEA), F. poae mainly produces NIV, T-2 and HT-2 toxins [15].

2.3. Sorghum

3. Fusarium Mycotoxins Transfer from the Cereals to Industrial-Like Beer

3.1. Malting

3.2. Mashing and Boiling

3.3. Fermentation

4. Fusarium Mycotoxins and Craft Beer

From the perspective of the possible presence of Fusarium mycotoxins, the few surveys analysing the presence of different mycotoxins in craft beers suggest that the main contribution to the final level in the product would be made by the malted and unmalted cereals employed in their production. Peters et al. (2017) [18] performed the most extensive survey up to date on the occurrence of different mycotoxins in 1000 beer samples from 47 countries, 60% of which were craft beers. They identified the sum of DON and DON-3-Glc to be above 10 µg/L in 406 samples (40%), 73% of which were craft beers, finding a statistically significant correlation between the %ABV (alcohol by volume) and the toxin concentration. FBs were present in concentrations up to 36 µg/L in the craft beer category of the studied samples, which is still considerably lower compared to the levels reported in traditional African beers, which reached above 1000 µg/L in different areas of the continent [19]. The Imperial Stout beers showed the highest contamination levels in all the analysed mycotoxins with 83% positive samples. Nonetheless, it is a beer style that is hardly consumed, even by craft beer enthusiasts, mostly due to its higher alcohol content, price and lower accessibility (complex technological steps require a more unique state of the art and knowledge). The hop-forward beer styles are the most popular among the consumers, representing above 20% of the world craft beer production, among them Indian Pale Ale (IPA), Imperial IPA and New England IPA (NEIPA) with bitterness ranging from 30 to 100 IBU (international bitterness units) [20].

References

- Arie, T. Fusarium Diseases of Cultivated Plants, Control, Diagnosis, and Molecular and Genetic Studies. J. Pestic. Sci. 2019, 44, 275–281.

- Meussdoerffer, F.G. A Comprehensive History of Beer Brewing. In Handbook of Brewing: Processes, Technology, Markets; Eßlinger, H.M., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2009; pp. 1–42. ISBN 9783527316748.

- Ksieniewicz-Woźniak, E.; Bryła, M.; Waśkiewicz, A.; Yoshinari, T.; Szymczyk, K. Selected Trichothecenes in Barley Malt and Beer from Poland and an Assessment of Dietary Risks Associated with Their Consumption. Toxins 2019, 11, 715.

- Bianco, A.; Fancello, F.; Balmas, V.; Zara, G.; Dettori, M.; Budroni, M. The Microbiome of Sardinian Barley and Malt. J. Inst. Brew. 2018, 124, 344–351.

- Bertuzzi, T.; Rastelli, S.; Mulazzi, A.; Donadini, G.; Pietri, A. Known and Emerging Mycotoxins in Small- and Large-Scale Brewed Beer. Beverages 2018, 4, 46.

- Leslie, J.F.; Summerell, B.A. The Fusarium Laboratory Manual; Blackwell: Oxford, UK, 2007; ISBN 0813819199.

- Brown, D.W.; Proctor, R.H. Fusarium: Genomics, Molecular and Cellular Biology; Brown, D.W., Proctor, R.H., Eds.; Caiser Academic Press: Norfolk, UK, 2013; ISBN 9781908230256.

- Drakopoulos, D.; Sulyok, M.; Jenny, E.; Kägi, A.; Bänziger, I.; Logrieco, A.F.; Krska, R.; Vogelgsang, S. Fusarium Head Blight and Associated Mycotoxins in Grains and Straw of Barley: Influence of Agricultural Practices. Agronomy 2021, 11, 801.

- Perrone, G.; Ferrara, M.; Medina, A.; Pascale, M.; Magan, N. Toxigenic Fungi and Mycotoxins in a Climate Change Scenario: Ecology, Genomics, Distribution, Prediction and Prevention of the Risk. Microorganisms 2020, 8, 1496.

- Kaur, M.; Bowman, J.P.; Stewart, D.C.; Evans, D.E. The Fungal Community Structure of Barley Malts from Diverse Geographical Regions Correlates with Malt Quality Parameters. Int. J. Food Microbiol. 2015, 215, 71–78.

- Martínez, M.; Albuquerque, L.R.; Arata, A.F.; Biganzoli, F.; Pinto, V.F.; Stenglein, S.A. Effects of Fusarium Graminearum and Fusarium Poae on Disease Parameters, Grain Quality and Mycotoxins Contamination in Bread Wheat (Part I). J. Sci. Food Agric. 2020, 100, 863–873.

- Wegulo, S.N.; Baenziger, P.S.; Nopsa, J.H.; Bockus, W.W.; Hallen-Adams, H. Management of Fusarium Head Blight of Wheat and Barley. Crop Prot. 2015, 73, 100–107.

- Běláková, S.; Benešová, K.; Čáslavský, J.; Svoboda, Z.; Mikulíková, R. The Occurrence of the Selected Fusarium Mycotoxins in Czech Malting Barley. Food Control 2014, 37, 93–98.

- Khodaei, D.; Javanmardi, F.; Khaneghah, A.M. The Global Overview of the Occurrence of Mycotoxins in Cereals: A Three-Year Survey. Curr. Opin. Food Sci. 2021, 39, 36–42.

- Miedaner, T.; Juroszek, P. Climate Change Will Influence Disease Resistance Breeding in Wheat in Northwestern Europe. Theor. Appl. Genet. 2021, 134, 1771–1785.

- Ackerman, A.; Wenndt, A.; Boyles, R. The Sorghum Grain Mold Disease Complex: Pathogens, Host Responses, and the Bioactive Metabolites at Play. Front. Plant Sci. 2021, 12, 660171.

- Lahouar, A.; Crespo-Sempere, A.; Marín, S.; Saïd, S.; Sanchis, V. Toxigenic Molds in Tunisian and Egyptian Sorghum for Human Consumption. J. Stored Prod. Res. 2015, 63, 57–62.

- Peters, J.; van Dam, R.; van Doorn, R.; Katerere, D.; Berthiller, F.; Haasnoot, W.; Nielen, M.W.F. Mycotoxin Profiling of 1000 Beer Samples with a Special Focus on Craft Beer. PLoS ONE 2017, 12, e0185887.

- Lulamba, T.E.; Stafford, R.A.; Njobeh, P.B. A Sub-Saharan African Perspective on Mycotoxins in Beer—A Review. J. Inst. Brew. 2019, 125, 184–199.

- Donadini, G.; Porretta, S. Uncovering Patterns of Consumers’ Interest for Beer: A Case Study with Craft Beers. Food Res. Int. 2017, 91, 183–198.