Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Valentina Roviello | + 2988 word(s) | 2988 | 2022-01-14 09:20:00 | | | |

| 2 | Dean Liu | Meta information modification | 2988 | 2022-01-19 01:32:44 | | | | |

| 3 | Dean Liu | Meta information modification | 2988 | 2022-01-19 01:33:11 | | | | |

| 4 | Dean Liu | Meta information modification | 2988 | 2022-01-21 09:46:44 | | | | |

| 5 | Dean Liu | Meta information modification | 2988 | 2022-01-21 09:48:50 | | | | |

| 6 | Dean Liu | + 1 word(s) | 2989 | 2022-01-21 09:52:31 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Roviello, V. Anti-Graffiti Treatments on Natural Stone Materials. Encyclopedia. Available online: https://encyclopedia.pub/entry/18420 (accessed on 07 February 2026).

Roviello V. Anti-Graffiti Treatments on Natural Stone Materials. Encyclopedia. Available at: https://encyclopedia.pub/entry/18420. Accessed February 07, 2026.

Roviello, Valentina. "Anti-Graffiti Treatments on Natural Stone Materials" Encyclopedia, https://encyclopedia.pub/entry/18420 (accessed February 07, 2026).

Roviello, V. (2022, January 18). Anti-Graffiti Treatments on Natural Stone Materials. In Encyclopedia. https://encyclopedia.pub/entry/18420

Roviello, Valentina. "Anti-Graffiti Treatments on Natural Stone Materials." Encyclopedia. Web. 18 January, 2022.

Copy Citation

Graffiti vandalism represents an aesthetic and structural phenomenon of degradation both for buildings and cultural heritage: the most used sprays and markers can permeate the stone materials exposing them to degradation. Hence, great attention is being currently devoted to new non-invasive chemical approaches to face this urgent problem. This work is aimed at deeply examining the effects of some of the most sustainable chemical protective methods on the physical properties of natural building materials (e.g., tuff and limestone) by testing two commercial antigraffiti products.

vandal graffiti

anti-graffiti products

sustainable chemical methods

alteration of stone materials

tuff

limestone

cleaning tests

spray

markers

1. Introduction

Graffiti vandalism or graffiti writing is a phenomenon of urban decay born as a subversive act towards the social, economic, and political system. Over time this phenomenon became an instrument enabling graffiti writers to obtain considerable visibility, having sometimes criminal connotations, punishable by the law [1]. The illegal nature of graffiti vandalism is associated with the serious risk of damaging not only the building walls. Lastly, and most importantly, it damages the historical-architectural heritage. Writers use different techniques to realize their signatures (or tags), that are an expression of their groups. Heavily graffitied urban areas assume increasingly negative reputations, since graffiti-rich areas are often labeled as socio-economically poor[2]. Many monuments, statues, artistic installations, facades of historical buildings are placed at risk by the application of tags with different kinds of commercial paints, including those modified by writers, that can penetrate inside materials with a highly receptive and absorbent surface. Since the 1990s, conservation scientists have been searching for solutions and methodologies to remove graffiti from buildings and monuments safely and selectively as well as effective anti-graffiti products to protect surfaces of artistic interest, that prevent the adhesion of paint layers. There are several removal methods currently in use that can be grouped for simplicity in three classes: physical-mechanical, biological, and chemical.Chemical methods are also used to protect surfaces by using commercial and synthetic anti-graffiti inorganic-organic based compounds, such as resins, waxes, and polymers [3][4]. According to the guidelines released by the Italian Ministry for Cultural Heritage and Activities and for Tourism, these products must be accompanied by a data sheet describing their chemical class and reversibility characteristics, the percentage of the active substance, as well as the compatibility of the product with other materials and the application and removal procedures[5].

2. FT-IR Infrared Spectrometry

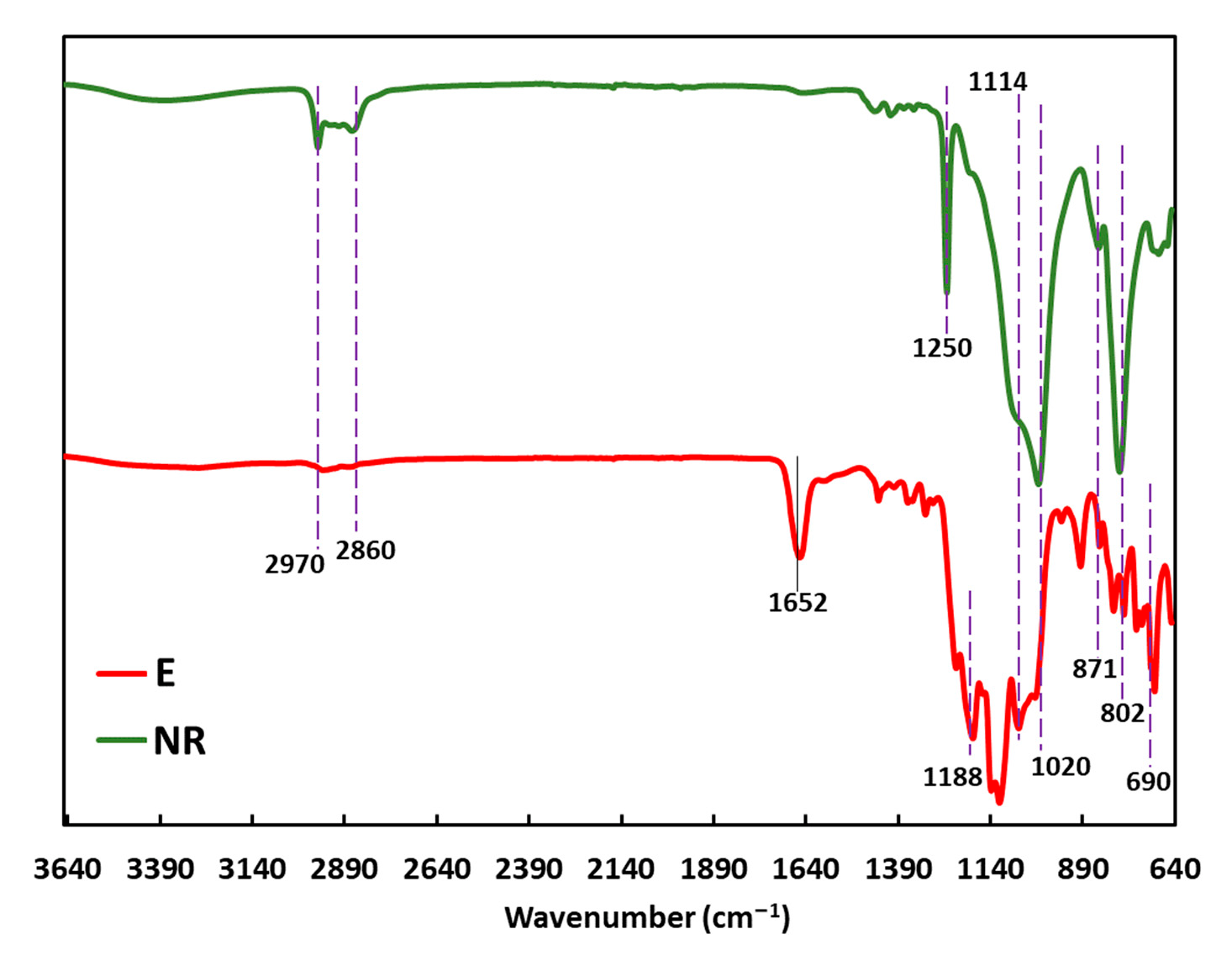

In order to determine the main classes of chemical constituents of the two anti-graffiti products, researchers first conducted a characterization using FT-IR infrared spectrometry. In Figure 1, the FT-IR spectra for the analyzed formulations (E and NR) are reported. Both spectra show infrared bands occurring at 2860 cm−1 and 2970 cm−1 (stretching vibration of the C–H in unsaturated moieties)[6], at 1020 cm−1 (mono-and para-substituted benzene derivatives)[7], at 802 cm−1 and 871 cm−1 (aromatic C–H stretching in para and ortho, respectively) [6][8]. Consequently, it may be possible to affirm that E and NR are mainly based on epoxy resins as polymer binder systems.

Figure 1. FT-IR spectra of investigated products: E and NR.

Moreover, the band at 1114 cm−1 is due to Si-O stretching and discloses the use of silica nanoparticles as fillers in both formulations[9][10]. For the E system, the band at 1188 cm−1 (in-plane CH deformations) suggests the presence of a silane agent, which may contain halo-atoms (X), since the band stretching at 690 cm−1 is normally ascribed to C-X groups[11]. The band at 1652 cm−1 (C-H bending of aromatic moieties)[6], is probably due to the presence of a solvent in E formulation. On the contrary, the lack of this band in the NR system together with the band at 1250 cm−1 (C-N stretching)[8] suggests that there are not any halo-based silane agents but rather nitrogen containing ones, which may act as coupling agents for silica nanoparticles. The above FT-IR analysis is in good agreement with the reported chemical composition in the labels of both commercial formulations.

3. Chromatic Modifications

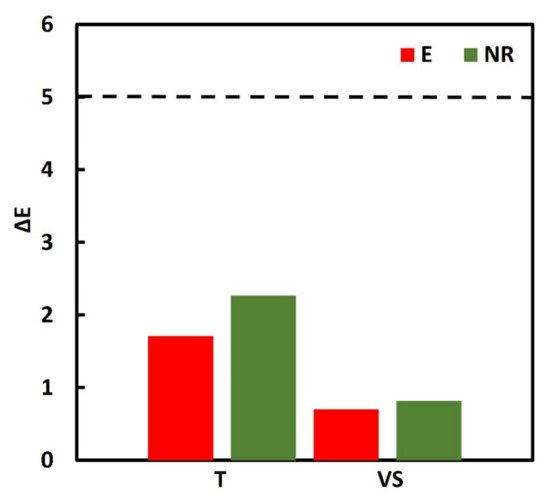

A colorimetric analysis was performed (Figure 2) to appreciate the possible chromatic variations of the stone surfaces after anti-graffiti coatings.

Figure 2. Colorimetric analysis: total color changes (ΔE) for the brushing treated samples of T and VS, with E and NR. Dotted line highlights the threshold value of ΔE = 5.

It was gratifying to observe that commercial products did not cause chromatic changes: ΔE values were found always less than 3 and, therefore, the color changes are not visible to the human eye. Moreover, ΔE < 5 ensures their compliance with the pertaining regulations. This is more evident with NR than E, that shows a slight increase of ΔE for red T when compared to VS.

4. Morphological Observations and Static Contact Angle Characterization

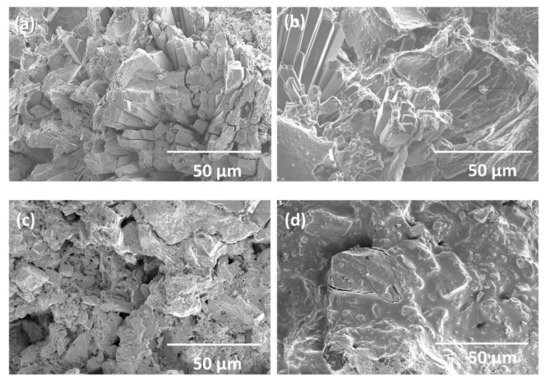

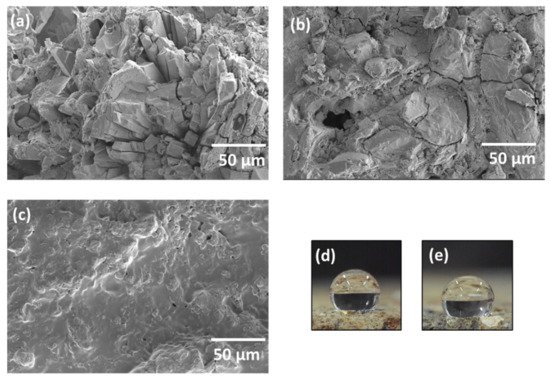

The T samples were covered on the surface with graffiti paints and subsequently examined by SEM (Figure 3) to verify the alteration of stone morphology. Researchers chose T as representative material as, being endowed with higher roughness and heterogeneity than VS, it showed better morphological evidence.

Figure 3. SEM micrographs of T before (a) and after coating with spray Colors Black (b), spray Montana Cans (c) and marker Molotow (d).

The morphology of the stone material was observed before (blank in a), with Spray paints coating (Motip Dupli black in b, Montana Cans Tar Black in c), and with the bitumen black marker (Molotow in d). The sprays seem to leave the morphology of the materials almost unchanged if compared with the untreated sample (a), and the texture and mineralogy of tuff is still recognizable. On the contrary, the marker (d) forms a film altering completely the morphology that appears rather uniform and with a low surface roughness. The bitumen marker is a very complex mixture consisting of molecules with various and high molecular weights (which add waterproof, sticky [2] and highly viscous properties) that fail to pass through the pores of the materials on which the marker is deposited. As observed in Figure 3d, this kind of marker forms a compact film, making even the roughest stone material, such as tuff, uniform and smooth. This suggests that the removal of markers should be more difficult compared to all sprays. However, one should not underestimate the removal difficulties related to the sprays that being conveyed by the connectivity of pores necessitate difficult cleaning processes. SEM observations after stone were treated with anti-graffiti products are shown in Figure 4 and Figure 5, where also the static contact angle analyses are reported.

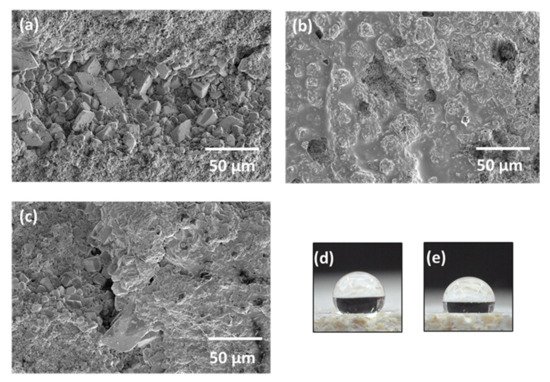

Figure 4. SEM Micrographs of untreated VS (a) compared with coatings with E (b) and NR (c) products. In addition, (d,e) report micro-photos captured for contact angle measurements for samples coated with E and NR, respectively.

Figure 5. SEM images for (a) pristine T, coated samples with E (b) and NR (c) products. In addition, (d,e) report micro-photos captured during contact angle measurements for samples coated with E and NR, respectively.

When this stone is treated with E (Figure 4b), the morphology shows only on a part of the surface the presence of a veil, uneven, with pores in evidence, created by the coating itself. Observing the treatment with NR (Figure 4c), the material seems to maintain almost unchanged morphology, as the calcite crystals are visible on the surface. The morphology of T (Figure 5) shows irregular crystals well evident (Figure 5a), with anti-graffiti E becoming completely submerged by a crust coating (Figure 5b) that forms pores, not deriving from the underlying substrate. Finally, with NR (Figure 5c) the surface appears quite smooth, even more modified.

The results obtained from microscopic observation are in line with the measurement of the contact angle (θ), i.e., the angle between the surface of the liquid and the outline of the contact surface [3], useful to measure the wettability of T and VS samples coated with E and NR. In the case of water, a surface can be classified as super hydrophilic (θ ≈ 0°), hydrophilic (θ < 90°) and hydrophobic (θ > 90°) [4]. Using distilled water, a contact angle of 140.8° ± 0.5° was evaluated for the VS support coated with E product (Figure 4), indicating the super-hydrophobic nature of this surface, since the contact angle is very close to 150°. This result is due to the hierarchical surface texture and roughness of VS surface, which is still preserved after the treatment with E (see Figure 4c,e). In agreement with the Cassie–Baxter model, the maximum contact angle of a water droplet on a non-textured surface is about 130°, while higher contact angles can be achieved only if the surface is rough [4][5][12][13]. A contact angle of 121.3° ± 0.7° was evaluated for the deposition of NR on VS, indicating a highly hydrophobic surface. In fact, this surface cannot be classified as super-hydrophobic because of the formation of a non-textured surface, showing a low degree of roughness (Figure 4). In contrast with E, the epoxy resin present in NR seems to modify the morphology of the VS surface, and it caused it to lose its hierarchical structure. The good performances of E may be also due to the contribution of halogen-containing silane agents, which strongly promote the increase of contact angle, especially in the presence of a rough surface. Silane agents are in both anti-graffiti products, though a proper surface morphology is essential to obtain high θ values. The surface of the T sample shows smooth pillars responsible for a hierarchical texture and high roughness (Figure 5) [14][15][16]. The high pillar density of this surface allows it to achieve contact angles near the super-hydrophobic threshold value for samples coated with E and NR, i.e., 140.7° ± 0.4° and 137.9° ± 0.8° respectively (Figure 5b,d). Researchers hypothesize that in the case of the VS the lower contact angle observed for NR indicates that the resin fills the pores of the surface more efficiently, making it smoother compared to the E product (Figure 4b,d). The pillar morphology of T allows it to trap air in the microgrooves of the rough surface so that water droplets lay on a composite surface formed by air and the tops of micro-protrusions, leading to a morphology more suitable to ensure very low area fractions of the solid-liquid interface than that observed for VS [4][5][12]. In summary, both NR and E formulations, containing silica nanoparticles bounded to the epoxy matrices, allow the suitable nanometric roughness that combined with the VS and T morphologies lead to hierarchical surface textures [17]. In our study, E shows better performance than NR product for both investigated stone materials, conferring higher surface hydrophobicity.

5. Water Absorption by Pipe Method

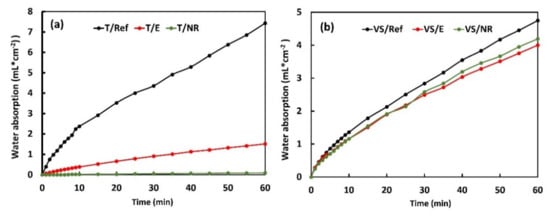

Low-pressure water absorption tests on T and VS materials before and after the treatment with the anti-graffiti were performed (Figure 6).

Figure 6. Water absorption by pipe method of T (a) and VS (b): reference sample (black line), after coating with E (red line) and NR (dark green line).

As shown in Figure 6, the T without treatments have an increasing trend of water absorption with a value of 7.4 mL/cm2 after 60 min. When it is coated with E anti-graffiti, the surface becomes quite waterproof, as the absorption value decreases to 1.5 mL/cm2 and even more after NR treatment (0.09 mL/cm2). VS has a porosity less than T and absorbs even less water. In this case, the water absorption value is 4.7 mL/cm2 after 60 min. Here the anti-graffiti product seems less efficient: in fact, with E and NR the water absorption values are respectively 4.0 and 4.2 mL/cm2 (NR is slightly higher than E). These results are fully in line with the SEM results and the measured static contact angles: the T treated with the same anti-graffiti of VS becomes more waterproof to water and perhaps even more oleophobic, because its irregular and wrinkly morphology becomes more uniform with the anti-scratch E and even smoother with NR, allowing it to obtain contact angles close to the threshold of super-hydrophobicity higher than VS. As emerged by SEM analysis of VS, E forms a film (Figure 4b) that appears not uniform but porous, allowing penetration of water (but also sprays and markers) into the accessible pores. NR when applied onto VS (Figure 4c) leaves the material morphology almost unaltered. This explains the similar trends observed in the water absorption graphs for E and NR. From the above findings, it is reasonable to expect a higher cleaning efficacy for the T surface when compared to VS. In addition, the treatment with E seems to operate more effectively than NR. All the above hypotheses were confirmed in the cleaning tests as explained below.

6. Cleaning Test

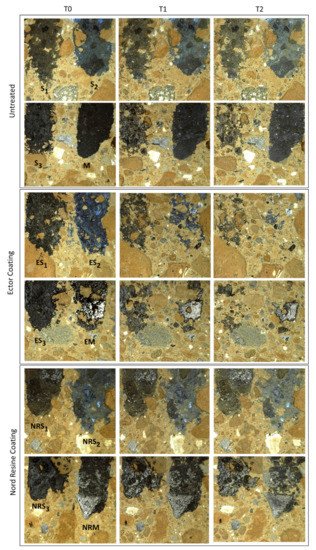

An accurate microphotographic report has been performed that showed the effectiveness of protection of E and NR and the removal efficiency of graffiti paints on T (Figure 7) and VS (Figure 8). In summary, the sprays Motip Dupli black and blue are indicated with the initials S1 and S2, the bitumen spray Montana Cans with S3 and the bitumen marker Molotow with M. Researchers observed, in order, a first group of pictures representing the untreated T, followed by a second group with this material treated with E (indicated with ES1, ES2, ES3 and EM) and finally a third group corresponding to the coating with NR (NRS1, NRS2, NRS3 and NRM). The initials T0, T1 and T2 indicate the number of cleaning cycles. These acronyms have been adopted both for T and for VS. In the case of T, as shown in Figure 7, researchers observed a gradual spray fading on the untreated T, passing from T0 to T2, with this effect being more evident in the case of anti-graffiti coating. As it can be observed in the same figure, E coating furnishes the best results. In fact, in this case the sprays were almost fully removed, even if the marker cleaning was only partially wiped. On the other hand, with NR coating we observed only a discoloration of both sprays and markers, but no complete or partial removal was achieved.

Figure 7. Digital pictures of the cleaning tests performed on T according to the technical sheets: samples not cleaned (T0), and after one (T1) and two (T2) cleaning treatments. Graffiti paints are indicated with the initials S1, S2, S3 and M; ES1, ES2, ES3, and EM indicate the material treated with E. NRS1, NRS2, NRS3 and NRM are the NR treatments.

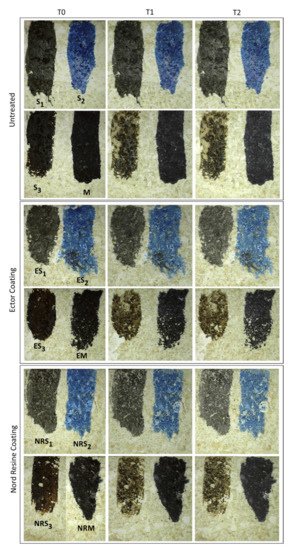

Figure 8. Digital pictures of the cleaning tests performed on VS according to the technical sheets: samples not cleaned (T0), and after one (T1) and two (T2) cleaning treatments. Graffiti paints indicated with the initials S1, S2, S3 and M; ES1, ES2, ES3, and EM indicate the material treated with E. NRS1, NRS2, NRS3, and NRM are the NR treatments.

This behavior is consistent with previous results and suggests a likely more noticeable oleophobicity in E coating than NR. In addition, the test carried out with E treatment demonstrates that even the use of only hot water can be an effective and sustainable method of removal of spray paints and bituminous markers, already at the second cycle of cleaning. Moreover, the use of an ecological product such as E, shows the feasibility of tackling the problem of vandalic graffiti with an environmentally friendly product, not harmful to human health. Only a gradual and slight fading, no removal, occurs in the case of VS (Figure 8) and it is more evident only for the S3 bituminous spray that begins to be removed already on the untreated material and gradually fades on the stone with E and NR treatment. All sprays and markers were found to be more dispersed and displayed irregular borders on treated VS when compared to the untreated material, suggesting that the coating was present, but its applied quantity was not enough to ensure the desired results. The scarce efficacy of these commercial products on VS emerged also from the water absorption tests conducted at low pressure (Figure 6) as well from SEM analysis (Figure 4), as discussed previously. This could depend on the scarce absorption of E and NR by VS or on the inadequacy of the cleaning methods. To better understand this phenomenon the materials were weighed before and after treatment with anti-graffiti products, and the percentage of product absorbed was determined. The T treated with E absorbed 0.13%, while with NR it absorbed almost the double, 0.24%. The VS, even less porous, absorbed only 0.05% when treated with E, while still the double quantity with NR (0.10%). Although the stone materials have different characteristics, the quantity of product NR absorbed was always double compared to E, because it has been applied first diluted 1:1 and then concentrated. However, in both cases the coatings were very thin, but in the case of T, they guaranteed an effective cleaning (with E) compared to the VS, on which probably a treatment either with several brush hands or with roller or spray could have had a different effect. There are, however, doubts about the effectiveness of the cleaning method on VS: given the delicacy of the stone it was not possible to the use harder bristle brushes or more aggressive methods that could damage it.

7. Conclusions

In this entry researchers analyzed the protective effects of two commercial anti-graffiti products, E and NR, on the surface of porous natural stone materials and their morphological characteristics. The anti-graffiti product E, a nanotechnological and environmentally sustainable product, has remarkable effects on the morphology of the treated stone materials, making them repellent to graffiti paints due to its high hydrophobicity. The beneficial action of E allows the easy cleaning of very porous building materials, such as tuff, damaged by vandal graffiti by the warm water method. However, the permanent character of this product hinders its application to the cultural heritage protection. The anti-graffiti NR provides a lower protection than E on both natural porous materials investigated (tuff and Vicenza Stone), even though its semi-sacrificial character makes it suitable for cultural heritage applications, according to the requirements of Italian Ministry for Cultural Heritage and Activities and for Tourism. Overall, the results of this entry highlight the importance of developing new anti-graffiti formulations endowed with both the hydrophobicity and the environmental sustainability of E and the sacrificial properties of NR, always keeping great attention on ecologic aspects of the products and their safety toward human health. Finally, new experiments as well the design of innovative and safe cleaning methodologies are planned by us on other porous materials of interest for cultural heritage.

References

- Minoletti, F. Profiling, I Profili Dell’Abuso, Il Graffitismo Vandalico. In Crimine & Società, 3rd ed.; Giornale Scientifico a Cura dell’Osservatorio Nazionale Abusi Psicologici: Florence, Italy, 2017.

- Sainan, X.; Junyan, Y.; Han, Z.; Decheng, F.; Zhaoyuan, S. Micromorphology and Micromechanical Properties Evolution of Bitumen and Bitumen Fractions Using Atomic Force Microscopy Considering Temperature Effect. Energy Fuels 2021, 35, 17434–17445.

- UNI EN 15802, Conservation of Cultural Property—Test Methods—Static Contact Angle Determinations. 2010. Available online: https://standards.iteh.ai/catalog/standards/cen/a93aafde-6380-4bc5-9d9b-d3b535dee619/en-15802-2009 (accessed on 29 November 2021).

- Kota, A.; Kwon, G.; Tuteja, A. The design and applications of superomniphobic surfaces. NPG Asia Mater. 2014, 6, e109.

- Koch, K.; Bhushan, B.; Jung, Y.C.; Barthlot, W. Fabrication of artificial Lotus leaves and significance of hierarchical structure for superhydrophobicity and low adhesion. Soft Matter 2009, 5, 1386–1393.

- Randle, R.R.; Whiffen, D.H. The infra-red intensities of a band near 1020 cm−1 in mono- and para-substituted benzene derivatives. Trans. Faraday Soc. 1956, 52, 9–13.

- Braatz, D.A.; Antonio, M.R.; Nilsson, M. Structural study of complexes formed by acidic and neutral organophosphorus reagents. Dalton. Trans. 2017, 46, 1194–1206.

- Bifulco, A.; Parida, D.; Khalifah, A.S.; Nazir, R.; Lehner, S.; Stämpfli, R.; Markus, H.; Malucelli, G.; Branda, F.; Gaan, S. Fire and mechanical properties of DGEBA-based epoxy resin cured with a cycloaliphatic hardener: Combined action of silica, melamine and DOPO-derivative. Mater. Des. 2020, 193, 108862.

- Bukalo, N.N.; Ekosse, G.E.; Odiyo, J.O.; Ogola, J.S. Fourier Transform Infrared Spectroscopy of Clay Size Fraction of Cretaceous-Tertiary Kaolins in the Douala Sub-Basin, Cameroon. Open Geosci. 2017, 9, 407–418.

- Bifulco, A.; Marotta, A.; Passaro, J.; Costantini, A.; Cerruti, P.; Gentile, G.; Ambrogi, V.; Malucelli, G.; Branda, F. Thermal and Fire Behavior of a Bio-Based Epoxy/Silica Hybrid Cured with Methyl Nadic Anhydride. Polymers 2020, 12, 1661.

- Joseph, T.; Varghese, H.T.; Panicker, C.Y.; Viswanathan, K.; Dolezal, M.; Van Alsenoy, C. Spectroscopic (FT-IR, FT-Raman), first order hyperpolarizability, NBO analysis, HOMO and LUMO analysis of N-[(4-(trifluoromethyl) phenyl] pyrazine-2-carboxamide by density functional methods. Arab. J. Chem. 2017, 10, S2281–S2294.

- Xue, C.H.; Jia, S.T.; Zhang, J.; Ma, J.Z. Large-area fabrication of superhydrophobic surfaces for practical applications: An overview. Sci. Technol. Adv. Mater. 2010, 11, 3.

- Pota, G.; Bifulco, G.; Parida, D.; Zhao, S.; Rentsch, D.; Amendola, E.; Califano, V.; Costantini, A. Tailoring the hydrophobicity of wrinkled silica nanoparticles and of the adsorption medium as a strategy for immobilizing lipase: An efficient catalyst for biofuel production. Microporous Mesoporous Mater. 2021, 328, 111504.

- D’Arienzo, L.; Scarfato, P.; Incarnato, L. New polymeric nanocomposites for improving the protective and consolidating efficiency of tuff stone. J. Cult. Herit. 2008, 9, 253–260.

- Vacchiano, C.; Incarnato, L.; Scarfato, P.; Acierno, D. Conservation of tuff-stone with polymeric resins. Constr. Build. Mater. 2008, 22, 855–865.

- Tesser, E.; Lazzarini, L.; Bracci, S. Investigation on the chemical structure and ageing transformations of the cycloaliphatic epoxy resin EP2101 used as stone consolidant. J. Cult. Herit. 2017, 31, 72–82.

- Avossa, J.; Bifulco, A.; Amendola, E.; Gesuele, F.; Oscurato, S.L.; Gizaw, Y.; Mensitieri, G.; Branda, F. Forming nanostructured surfaces through Janus colloidal silica particles with nanowrinkles: A new strategy to superhydrophobicity. Appl. Surf. Sci. 2019, 465, 73–81.

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.0K

Revisions:

6 times

(View History)

Update Date:

21 Jan 2022

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No