Your browser does not fully support modern features. Please upgrade for a smoother experience.

Submitted Successfully!

Thank you for your contribution! You can also upload a video entry or images related to this topic.

For video creation, please contact our Academic Video Service.

| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | Melkie Getnet Tadesse | + 2661 word(s) | 2661 | 2021-11-02 11:04:18 | | | |

| 2 | Vicky Zhou | Meta information modification | 2661 | 2021-11-03 01:52:02 | | |

Video Upload Options

We provide professional Academic Video Service to translate complex research into visually appealing presentations. Would you like to try it?

Cite

If you have any further questions, please contact Encyclopedia Editorial Office.

Tadesse, M. Wearable Functional Textiles. Encyclopedia. Available online: https://encyclopedia.pub/entry/15630 (accessed on 13 January 2026).

Tadesse M. Wearable Functional Textiles. Encyclopedia. Available at: https://encyclopedia.pub/entry/15630. Accessed January 13, 2026.

Tadesse, Melkie. "Wearable Functional Textiles" Encyclopedia, https://encyclopedia.pub/entry/15630 (accessed January 13, 2026).

Tadesse, M. (2021, November 02). Wearable Functional Textiles. In Encyclopedia. https://encyclopedia.pub/entry/15630

Tadesse, Melkie. "Wearable Functional Textiles." Encyclopedia. Web. 02 November, 2021.

Copy Citation

Wearable E-textile systems should be comfortable so that highest efficiency of their functionality can be achieved. The development of electronic textiles (functional textiles) as a wearable technology for various applications has intensified the use of flexible wearable functional textiles instead of wearable electronics. However, the wearable functional textiles still bring comfort complications during wear. The purpose of this review paper is to sightsee and recap recent developments in the field of functional textile comfort evaluation systems. For textile-based materials which have close contact to the skin, clothing comfort is a fundamental necessity.

wearable technologies

functional textiles

comfort evaluation

intelligent systems

1. Introduction

Comfort is the most significant feature of materials that have close contact with human skin. Rossi [1] defined clothing comfort as a feeling or condition of pleasing ease, well-being, and contentment. He classified comfort dimensions as thermophysiological, psychological, and sensorial. Thermophysiological comfort is concerned with the heat balance of the body during various levels of activity, while psychological comfort is all about being at peace with oneself. Sensorial comfort is a fabric handle related to tactile, moisture, pressure, and thermal sensations [2]. Furthermore, some attempts have been made to give definitions in relation to clothing comfort. Here are some of them:

-

A term related to the roles, values, and societal standing is the so-called physiological comfort [3];

-

A state of harmony between the wearer and the surrounding environment [4]; and

-

Balanced thermal regulation of the body—thermal comfort or a combination of physiological, psychological, and mental wellbeing of the human being [5].

All the said definitions are equally important in the aspects of clothing comfort. Comfort is a very fundamental and decisive factor for when people buy clothes. Knowingly or unknowingly, people check for physiological or psychological clothing comfort. Therefore, a fundamental understanding of clothing comfort, more specifically wearable functional textiles, is very important for quality of life.

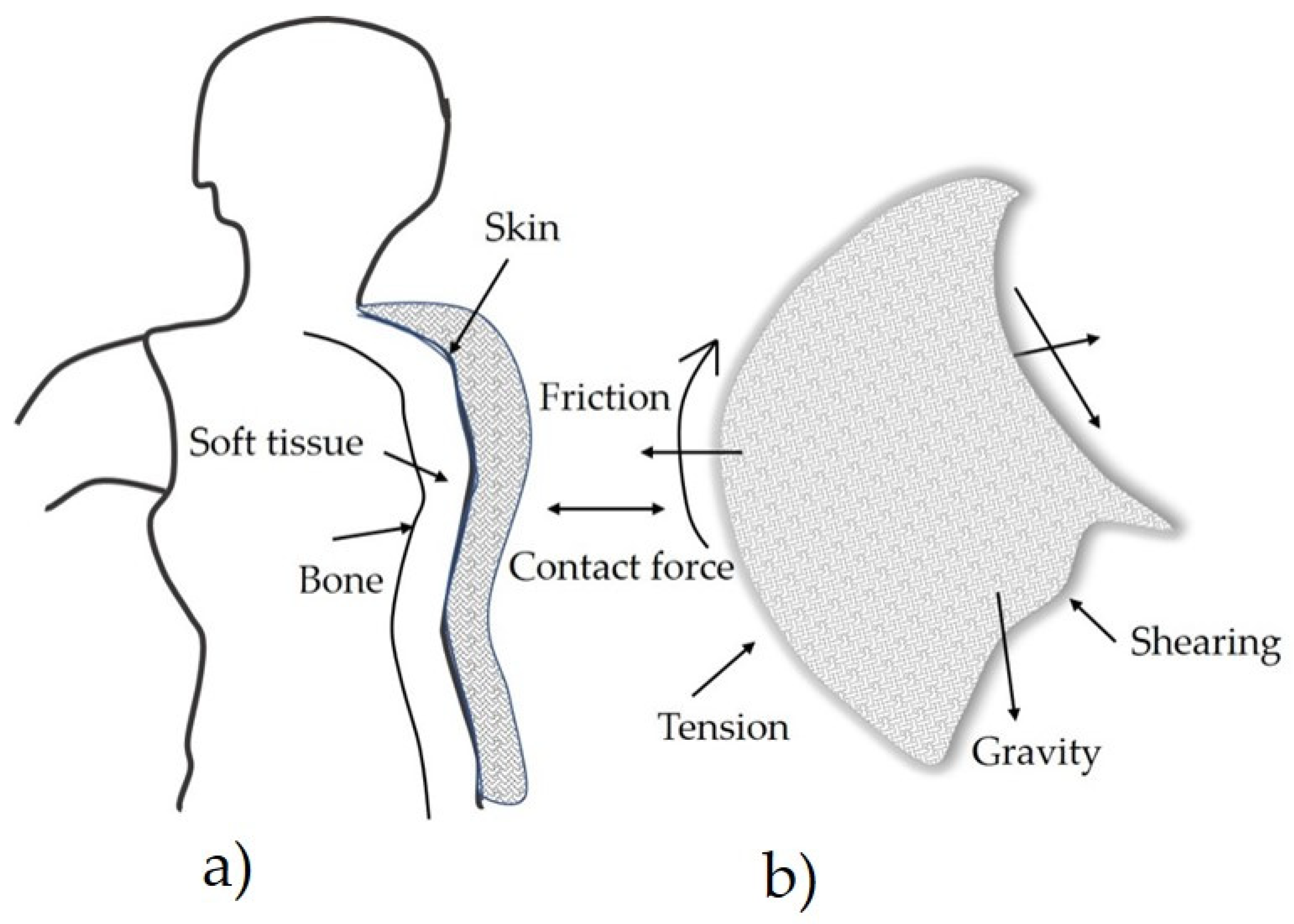

Assessing the clothing comfort of clothing material is critical as there are many dynamic contacts between the clothing and the human body, such as tension force and bending of clothing occurs as the garment is worn on the human body where there are body parts brought the fabric to be bent or tensioned, as well as friction, compression, and some gravitational force against the human body where it stands. Figure 1 details various factors that contribute to discomfort of clothing.

Figure 1. Illustrates where a rigid body (a) (assumed) is in continuous contact with a dynamically moving cloth (b). At first contact, the garment touches the skin; then, when the movement and friction tighten, it touches the soft tissues, and finally has the probability of disturbing the bone. The directions of the arrow on the cloth indicate the reaction of the cloth with the human skin. For example, the direction of gravity shows where the fabric has external forces beyond friction and contact with the skin.

Figure 1. Illustrates where a rigid body (a) (assumed) is in continuous contact with a dynamically moving cloth (b). At first contact, the garment touches the skin; then, when the movement and friction tighten, it touches the soft tissues, and finally has the probability of disturbing the bone. The directions of the arrow on the cloth indicate the reaction of the cloth with the human skin. For example, the direction of gravity shows where the fabric has external forces beyond friction and contact with the skin.In a neutral environment, there is always a set friction between the garment and skin [6], gravity is exerted [7], there is shearing force due to the irregular body shapes [8], there is tensile force due to tensions, and elasticity and pressure have been exercised on the garment [9]. Compressional force is also not neglected [10]. All these clothing comfort issues are always naturally present between the worn garment and the human skin. Therefore, assessing the comfort of clothing materials whether conventional or e-textile is a required practice.

Clothing is one of the very general basics which the wearer requires to cover the body and protect it from very extreme surrounding conditions such as weather conditions. However, due to the various demands of the human being, clothing nowadays serves as protection, gives extra application, and is used for health monitoring, support in sport activities, and as a means of communications channels. Simply speaking, today, their names are preceded by a prefix called “smart” and thus are so called “smart textiles” or wearable textiles or functional textiles. The term smart textiles make things easier and simpler.

With the rapid developments in wearable technology and ever-increasing demands for electronic textiles (functional textiles), wearable electronics are becoming inadequate for use due to their heavy weight and non-flexible nature. They do have ridges and can press against the human body, bringing discomfort. Commonly, conventional clothing is expected to have a good ergonomic fit, be comfortable to wear, and be lightweight and flexible. Nowadays, due to the heavy weight of wearable electronics, the non-functionality of conventional clothing, and societal demands, smart textiles are now being widely developed [11][12][13]. Smart textiles or functional textiles are demarcated as textile constituents that are capable of changing their characteristic behavior with response to the inspiration of peripheral features or technical stimuli from the surrounding environment, with mechanical, thermal, electrical, chemical, or other external sources impacting the change [14][15]. The consumer-wearable electronics of today are past their commencement but are still very much in their early stages. One of the reasons could be comfort issues in different aspects. However, research on the comfort evaluation of wearable electronics is not growing fast when compared to research on wearable technology development and marketing. Most of the research on wearable electronics focuses on specific areas such as sensors, actuators, and electronic health record sharing systems (eHealth). The user most focuses on the benefits that are obtained from the functional fabric without worrying about clothing comfort.

2. Intelligence Systems/Soft Computing Systems in Clothing Comfort Evaluation

Neuro computing, fuzzy logic, and other evolutionary algorithms such as artificial neural network (ANN) and adaptive neuro-fuzzy inference systems (ANFIS) which are used for the prediction, modeling, and optimization of textile properties are called soft computing systems or intelligent systems [16]. Human tactile sensations for the textile goods are very complex [17] and hence linear modelling cannot solve such relationships. The comfort of textile goods, which is closely related to the user’s perception and acceptance, has been currently studied and relationships between the physiological perception and the instrumental data have been estimated using various intelligence techniques. The most frequently used intelligence methods applied in the prediction of the tactile comfort of textile goods are fuzzy logic, artificial neural network (ANN), and adaptive neuro-fuzzy inference system (ANFIS). Settle et al. [16] discussed the importance of soft computing/intelligence techniques in the textile industry. The use of fuzzy logic has been used by many researchers recently after LA Zadeh’s pioneering work in 1965 [18]. Zadeh applied fuzzy logic for solving uncertainty or fuzziness or ambiguity of different parameters. The comfort of textile goods, particularly physiological perception, is full of uncertainty and fuzzy logic was the perfect fit for this concept. After Zadeh’s work, Zimmerman [19] and Mamdani [20] introduced the IF-THEN rules which support the ideas of Zadeh.

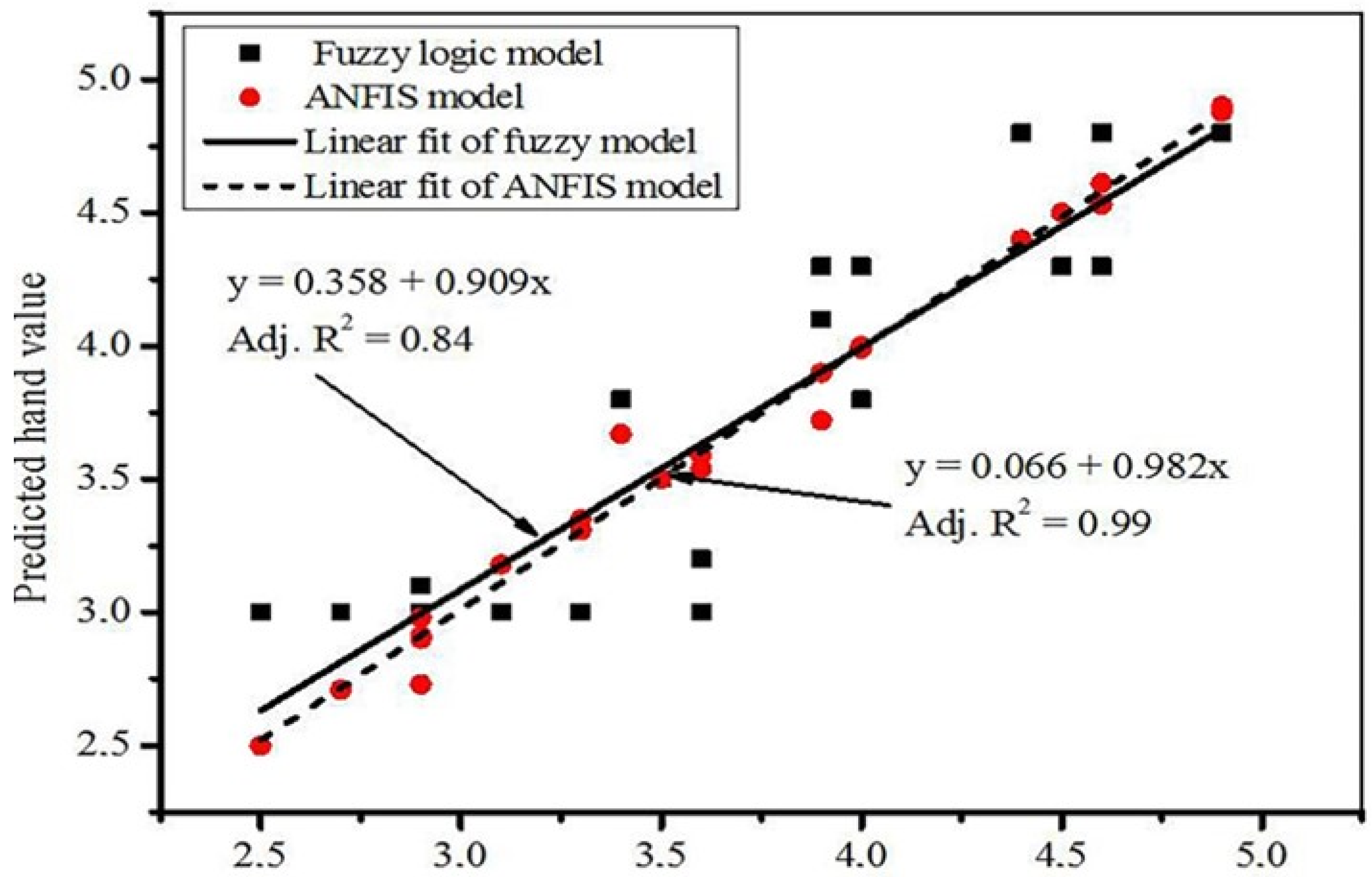

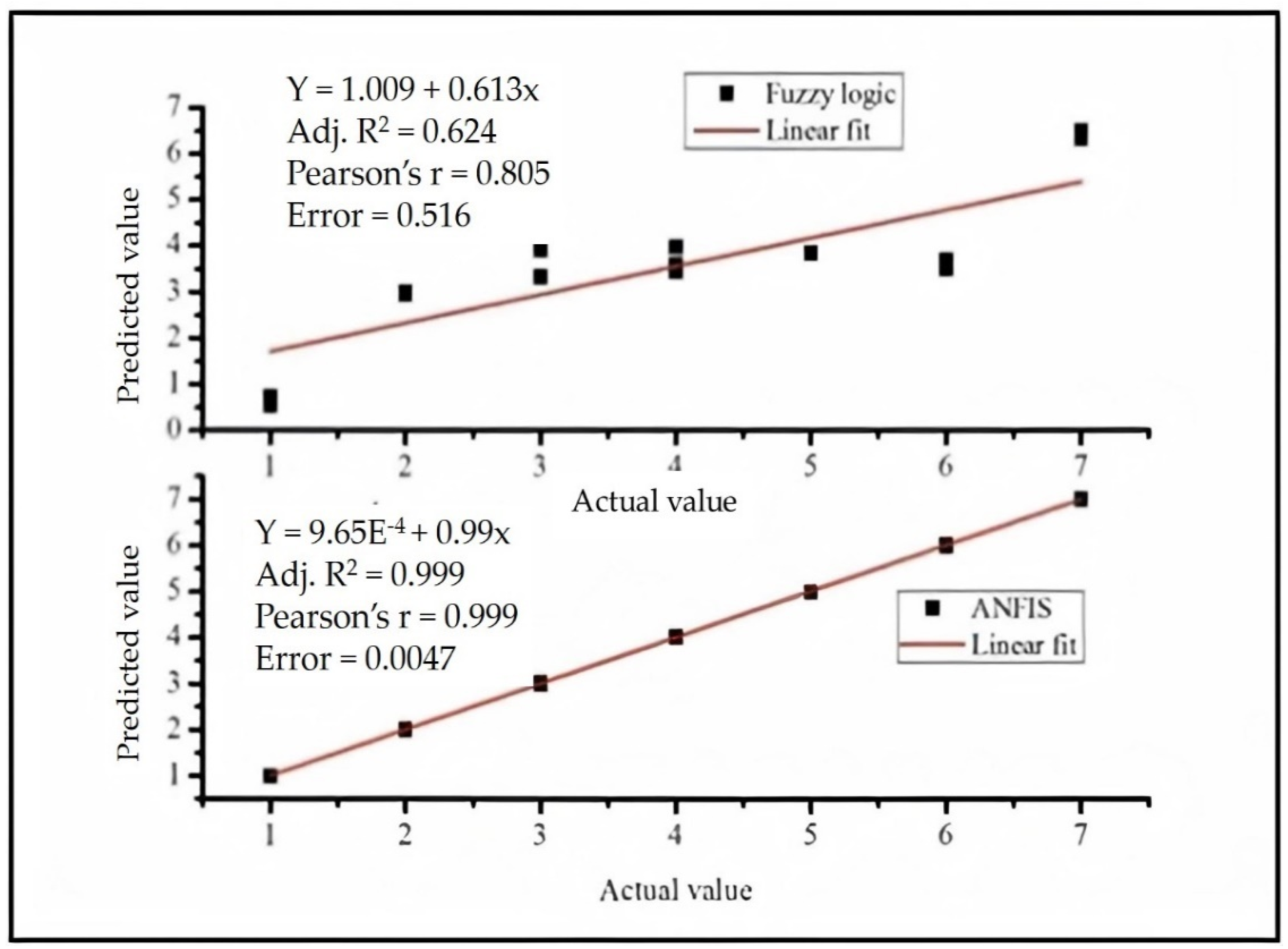

Thus, implementing fuzzy logic in the sensory evaluation of textile goods was started in 1991 by Raeel and co-workers [21]. The authors applied the fuzzy transformation matrix to predict the handle of lightweight dress fabrics and found good agreement between the subjective and the objective evaluation of the same fabric. The fuzzy transformation matrix enabled them to calculate the handle of the fabrics quantitatively, which further can be used as quality data which can be used for the communication between the user and the manufacturer. However, fuzzy logic has its own limitations as it does not have a specified technique that can be used as a mentor in the process of translating human perception into a rule-based fuzzy inference system (FIS) [22]. Other researchers [23][24][25][26][27] have applied fuzzy logic to predict and represent the comfort of textile goods. The conclusions from all authors confirmed that fuzzy logic is a better method for comfort prediction of textile goods when compared to linear statistical methods. However, the hybrid models, adaptive neuro-fuzzy inference system (ANFIS), can perform better than the fuzzy logic model. This is because ANFIS uses the FIS system to transform human knowledge into the rule-based fuzzy inference system [28]. To observe the difference between the efficiency of fuzzy logic and ANFIS, we used the work performed by Jeguirim et al. [29] on the use of the fuzzy logic model to predict the handle of knitted fabric from process parameters. We took the data from their work and we performed ANFIS using Matlab2017b® and found the following results (see Figure 2).

Figure 2. Comparison of fuzzy logic and ANFIS models on the prediction of the handle of knitted fabrics. The fuzzy logic model was taken without any modification from Jeguirim et al. [29] and the ANFIS model prediction result was performed using the same input parameters from Jeguirim and his co-worker’s work. The data were for the supple-rigid attribute only.

A linear fit was employed to observe the difference between the two models (Figure 10). As observed, the linear model has a better fit for the ANFIS model. The values obtained by the fuzzy logic model were highly scattered. Hence, the ANFIS model performed better in predicting the handle of the textile goods.

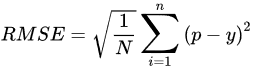

The root mean square error (RMSE) and mean relative percent error (MRPE) were calculated for ANFIS and compared with the fuzzy logic model from Jeguirim and his co-worker’s work. These two parameters were used to evaluate the prediction performance of the models.

where N; total number of observations, y; actual values, p; predicted values.

Based on this computation, the calculated RMSE, RMPE, and the standard deviation values for the ANFIS model were 0.083, 0.062, and 0.72, respectively, while the values according to the work of Jeguirim et al. were 0.29, 1.23, and 0.73, respectively. These results affirmed that the performance of the ANFIS model is higher than that of the fuzzy logic models. This is because fewer errors were observed in the case of the ANFIS model. Hence, this review paper recommends the ANFIS model over the fuzzy logic models. The adjusted R2 value is high. This confirms that the ANFIS model is the best model for predicting the handle of textile goods.

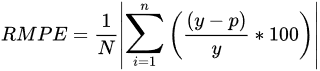

A similar review was made by Zeng et al. [30] (Figure 3). The researchers addressed the use of fuzzy logic to integrate human perception with the instrumental data on textile goods. They applied principal component analysis to support the extraction of fuzzy rules so that they could build the hand evaluation model. They found that fuzzy logic is an excellent model for such hand integration and estimation. We performed the ANFIS algorithm using the inputs from the paper and compared the results with fuzzy logic. We obtained the following result.

Figure 3. The performance difference between fuzzy and ANFIS models in the integration of human knowledge with the instrumental data. The input data from Zeng et al. [30] were taken as they are and we applied the ANFIS model to predict the handle of textile goods. The fuzzy logic model results are taken from Zeng et al. as they are for comparison purposes.

The results (Figure 3) clearly indicate that the ANFIS model is the best method for predicting the handle of the textile goods from instrumental and human perception data when compared to the fuzzy logic model. The calculated error based on the linear fit is much higher in the fuzzy logic model than in the ANFIS model. The Pearson correlation coefficient values indicated that the ANFIS model results are highly correlated to the actual values of the handle property of the textile goods. Therefore, even though fuzzy logic can be used to predict the handle of the textile goods, the best modelling is the ANFIS model. For this, a work performed somewhere else [31] discussed the application of fuzzy logic, neural network, data aggregation, classification, and clustering in predicting the handle of textile goods so that it can be used as a data source for quality inspectors, evaluators, and consumers for the clothing comfort quality check of their products. However, most recently, Xue et al. [32] have discussed advanced fuzzy logic techniques such as fuzzy genetic and fuzzy inclusion algorithms to predict human perception of the tactile comfort of textile goods. They claimed that the method they employed provides a good opportunity to analyze and interpret the vague qualities perceived by human knowledge. The work was also dedicated to showing how to assess fabrics using visuo-tactile scenarios which are equivalent to our daily experience, which the users used to assess the quality of the garment during buying decisions. They claimed that these intelligent techniques can solve the problems that exist in the classical computing techniques. The possible reason for this issue is that the soft computing techniques are used to develop problem-oriented descriptions and they are more flexible in nature.

Artificial neural network (ANN) is another intelligence method to estimate the comfort of textile goods. ANN has been used to predict the handle of textile goods from production and mechanical parameters [29][33][34]. It was claimed that the ANN model was slightly better than fuzzy logic models for calculating the RMSE and RMPE values of the predicted results. To this end, the optimization performed using principal component analysis (PCA) may decrease the performance of fuzzy logic. PCA is a technique for reducing the dimensionality of such datasets, increasing interpretability but at the same time minimizing information loss. It does so by creating new uncorrelated variables that successively maximize variance. Otherwise, the fuzzy logic and ANN models have comparative advantages for the sensory evaluation of goods [35].

An interesting and efficient method for the integration of human perception and instrumental data for the hand evaluation of textile goods is known as adaptive neuro-fuzzy inference system (ANFIS). ANFIS combines the advantages of ANN and fuzzy logic to transform human perception into interpretable data [36]. The ANFIS method can be used to construct the input-output mapping of human-based knowledge using the IF-THEN rules and then stipulate the data pairs. It uses the 3D and two-dimensional (2D) surface modelling system to forecast the input based on human knowledge to obtain the quantitative output data pairs. ANFIS has been used to study the subjective evaluation of some knitted fabrics by correlating sensory attributes and instrumental measurements [37] and subjective assessment of knit fabrics [28]. The researchers applied ANFIS to evaluate the subjective preferences for some attributes such as roughness and smoothness and they were able to relate the non-linear relationships between subjective preferences. They showed that ANFIS performs better than linear regression analysis methods. The merits of using ANFIS are its capability for predicting and integrating the non-linear relationships between physiological factors.

The objective data of functional fabrics from instrumental value [38] and the subjective assessment values from human experts [39] have been predicted using intelligent systems. Artificial neural network, fuzzy logic, and adaptive neuro-fuzzy inference system were implemented for clothing comfort prediction while the data were obtained both subjectively and objectively. The analysis indicated that the comfort of functional fabrics can be predicted using intelligence systems which make it easy to assess biased tasks. The actual predicted values show proximate reasoning.

3. Future Perspectives

Clothing comfort, more precisely, wearable textile comfort markedly influences not only our health, well-being, and work productivity, but also, we may lose the functional aspects. It indicates that there is a noteworthy discrepancy in clothing comfort requirements due to diversified needs and various functional finishing aspects. Thus, studying the comfort of functional clothing needs to be profoundly investigated in advance. Smart/functional textile research has grown for the last two decades. However, the world market share is still at an infant stage. The possible reasons could be:

-

There are few smart/functional fabrics on the market [40];

-

There are no specific protocols or standards for the development and manufacturing of smart/functional clothing [41];

-

The key factor for the quality of the product in terms of comfort is missing;

-

The sensory evaluation of smart/functional clothing is currently investigated using methods developed for conventional fabric; and

-

There are no standards for the comfort evaluation of smart/functional clothing.

On the other hand, there are a lot of research works being conducted on smart/functional fabrics such as WEALTHY, WearIT@work, MyHeart, MERMOTH, Avalon, Biotex, ProeTEX, Stella, OFSETH, Lidwine, and INTELTEX [42]. None of these projects deal with comfort issues but instead deal with the development and manufacturing aspect. Therefore, side by side, assessing the comfort of smart/functional fabrics should be given attention.

References

- Rossi, R. Interactions between protection and thermal comfort. In Textiles for Protection; Sr, A., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2005; pp. 233–253.

- Gonca, Ö.; Kayseri, N.; Nilgün, Ö.; Gamze, S. Sensorial Comfort of Textile Materials. In Woven Fabrics; Jeon, H.-Y., Ed.; IntechOpen: Shanghai, China, 2012; pp. 235–267.

- Kamalha, E.; Zeng, Y.; Mwasiagi, J.I.; Kyatuheire, S. The comfort dimension; a review of perception in clothing. Sens. Stud. 2013, 28, 423–444.

- Slater, K. The Assessment of Comfort. J. Text. Inst. 1986, 77, 157–171.

- Guowen, S. Improving Comfort in Clothing; Woodhead Publishing Ltd.: Oxford, UK, 2011; pp. 3–57.

- Gwosdow, A.R.; Stevens, J.C.; Berglund, L.G.; Foundation, J.B.P.; Stolwijk, J.A.J. Skin Friction and Fabric Sensations in Neutral and Warm Environments. Text. Res. J. 1986, 56, 574–580.

- Lee, J.; Nam, Y.; Cui, M.H.; Choi, K.M.; Choi, Y.L. Fit Evaluation of 3D Virtual Garment. In Usability and Internationalization HCI and Culture UI-HCII 2007 Lecture Notes in Computer Science, 4559th ed.; Aykin, N., Ed.; Springer: Berlin/Heidelberg, Germany, 2007; pp. 550–558.

- Lindqvist, R. On the relationship between the shear forces in human skin and the grain direction of woven fabric direction of woven fabric. Int. J. Fash. Des. Technol. Educ. 2016, 9, 1–9.

- Gong, Y.; Mei, S. Stretch elasticity and garment pressure of shaping-underwear fabric Stretch elasticity and garment pressure of shaping-underwear fabric. Mater. Sci. Eng. 2019, 684, 012010.

- Taylor, P.; Mak, C.M.; Yuen, C.W.M.; Ku, S.K.; Kan, C.W. Objective evaluation of the Tencel fabric after fibrillation Objective evaluation of the Tencel fabric after fibrillation. J. Text. Inst. 2006, 97, 223–230.

- Shi, Q.; Sun, J.; Hou, C.; Li, Y.; Zhang, Q.; Wang, H. Advanced Functional Fiber and Smart Textile. Adv. Fiber Mater. 2019, 1, 3–31.

- Koncar, V.; Cochrane, C.; Kelly, F.M.; Soulat, D.; Legrand, X. Conductive polymers for smart textile applications. J. Ind. Text. 2018, 48, 612–642.

- Tao, X. Smart technology for textiles and clothing: Introduction and overview. In Smart Fibres, Fabrics and Clothing; Tao, X., Ed.; Woodhead Publishing Ltd.: Cambridge, UK, 2001; pp. 1–6.

- Koncar, V. Introduction to smart textiles and their applications. In Smart Textiles and Their Applications; Koncar, V., Ed.; Woodhead Publishing Ltd.: Amsterdam, The Netherlands, 2016; pp. 1–8.

- Kirstein, T. The future of smart-textiles development: New enabling technologies, commercialization and market trends. In Multidisciplinary Know-How for Smart-Textiles Developers; Woodhead Publishing Limited: Oxford, UK, 2013; pp. 1–25.

- Sette, S.; Van Langenhove, L. An Overview of Soft Computing in Textiles an Overview of Soft Computing in Textiles. J. Text. Inst. 2009, 94, 103–109.

- Sztandera, L.M.; Cardello, A.V.; Winterhalter, C.; Schutz, H. Identification of the most significant comfort factors for textiles from processing mechanical, handfeel, fabric construction, and perceived tactile comfort data. Text. Res. J. 2013, 83, 34–43.

- Zadeh, L.A. Information and control. Fuzzy Sets. 1965, 8, 338–353.

- Zimmerman, H.-J. Using fuzzy sets in operational research. Eur. J. Oper. Res. 1983, 13, 201–216.

- Mamdani, E. Application of fuzzy logic to approximate reasoning using linguistic synthesis. IEEE Trans. Comput. 1977, 26, 1182–1191.

- Raheel, M.; Liu, J. Empirical Model for Fabric Hand. Text. Res. J. 2015, 61, 79–82.

- Suparta, W.; Alhasa, K.M. Modeling of Tropospheric Delays Using ANFIS. In SpringerBriefs in Meteorology; Springer Nature: Basingstoke, UK, 2016; pp. 1–18.

- Wong, A.S.W.; Li, Y.; Yeung, P.K.W. Predicting Clothing Sensory Comfort with Artificial Intelligence Hybrid Models. Text. Res. J. 2004, 74, 13–19.

- Luo, X.; Hou, W.; Li, Y.; Wang, Z. A fuzzy neural network model for predicting clothing thermal comfort. Comput. Math. Appl. 2007, 53, 1840–1846.

- Zeng, X.; Koehl, L. Representation of the Subjective Evaluation of the Fabric Hand Using Fuzzy Techniques. Int. J. Intell. Syst. 2003, 18, 355–366.

- Chen, Y.; Zeng, X.; Happiette, M.; Bruniaux, P.; Ng, R.; Yu, W. Optimisation of garment design using fuzzy logic and sensory evaluation techniques. Eng. Appl. Artif. Intell. 2009, 22, 272–282.

- Lu, J.; Zhu, Y.; Zeng, X.; Koehl, L.; Ma, J.; Zhang, G. A linguistic multi-criteria group decision support system for fabric hand evaluation. Fuzzy Optim. Decis. Mak. 2009, 8, 395–413.

- Ju, J.; Ryu, H. A Study on Subjective Assessment of Knit Fabric by ANFIS. Fibers Polym. 2006, 7, 203–212.

- Jeguirim, S.E.; Babay, A.; Sahnoun, M.; Cheikhrouhou, M.; Schacher, L.; Adolphe, D. The use of fuzzy logic and neural networks models for sensory properties prediction from process and structure parameters of knitted fabrics. J. Intell. Manuf. 2011, 22, 873–884.

- Zeng, X.; Koehl, L.; Sanoun, M.; Bueno, M.A.; Renner, M. Integration of Human Knowledge and Measured Data for Optimization of Fabric. Int. J. Gen. Syst. 2004, 33, 243–258.

- Zeng, X.; Ruan, D.; Koehl, L. Intelligent sensory evaluation: Concepts, implementations, and applications. Math Comput Simul. 2008, 77, 443–452.

- Xue, Z.; Zeng, X.; Koehl, L. To Multisensory Studies of Textile Products. In Artificial Intelligence for Fashion Industry in the Big Data Era; Zeng, S.T., Ed.; Springer: Singapore, 2018; pp. 1–4.

- Yu, Y.; Hui, C.; Choi, T.; Au, R. Intelligent Fabric Hand Prediction System with Fuzzy Neural Network. IEEE Trans. Syst. Man Cybern. Part C Appl. Rev. 2010, 40, 619–629.

- Park, S.; Hwang, Y.; Kang, B. Applying Fuzzy Logic and Neural Networks to Total Hand Evaluation of Knitted Fabrics. Text. Res. J. 2000, 70, 675–681.

- Ruan, D.; Zeng, X. Intelligent Sensory Evaluation: Methodologies and Applications; Springer: Berlin, Germany, 2004; pp. 1–10.

- Jang, J.R. ANFIS: Adaptive-Network-Based Fuzzy Inference System. IEEE Trans. Syst. Man Cybern. 1993, 23, 665–685.

- Jeguirim, S.E.G.; Adolphe, D.C.; Sahnoun, M.; Douib, A.B.; Schacher, L.M.; Cheikhrouhou, M. Intelligent Techniques for Modeling the Relationships between Sensory Attributes and Instrumental Measurements of Knitted Fabrics. J. Eng. Fiber Fabr. 2012, 7.

- Tadesse, M.G.; Chen, Y.; Wang, L.; Nierstrasz, V.; Loghin, C. Tactile Comfort Prediction of Functional Fabrics from Instrumental Data Using Intelligence Systems. Fibers Polym. 2019, 20, 199–209.

- Tadesse, M.G.; Loghin, E.; Pislaru, M.; Wang, L.; Chen, Y.; Nierstrasz, V.; Loghin, C. Prediction of the tactile comfort of fabrics from functional finishing parameters using fuzzy logic and artificial neural network models. Text. Res. J. 2019, 89, 4083–4094.

- Cherenack, K.; Van Pieterson, L. Smart textiles: Challenges and opportunities Smart textiles: Challenges and opportunities. J. Appl. Phys. 2012, 112, 091301.

- Decaens, J.; Vermeersch, O. Specific testing for smart textiles. In Advanced Characterization and Testing of Textiles; Paricia Dolez, V.I., Ed.; Woodhead Publishing Ltd.: Boulevard, UK, 2018; pp. 351–374.

- Anne, S.; Lieva, V.L.; Philippe, G.; Denis, D. A roadmap on smart textiles. Text. Prog. 2010, 42, 99–180.

More

Information

Contributor

MDPI registered users' name will be linked to their SciProfiles pages. To register with us, please refer to https://encyclopedia.pub/register

:

View Times:

1.1K

Revisions:

2 times

(View History)

Update Date:

03 Nov 2021

Notice

You are not a member of the advisory board for this topic. If you want to update advisory board member profile, please contact office@encyclopedia.pub.

OK

Confirm

Only members of the Encyclopedia advisory board for this topic are allowed to note entries. Would you like to become an advisory board member of the Encyclopedia?

Yes

No

${ textCharacter }/${ maxCharacter }

Submit

Cancel

Back

Comments

${ item }

|

More

No more~

There is no comment~

${ textCharacter }/${ maxCharacter }

Submit

Cancel

${ selectedItem.replyTextCharacter }/${ selectedItem.replyMaxCharacter }

Submit

Cancel

Confirm

Are you sure to Delete?

Yes

No