| Version | Summary | Created by | Modification | Content Size | Created at | Operation |

|---|---|---|---|---|---|---|

| 1 | CHANDER PRAKASH | + 2927 word(s) | 2927 | 2021-07-06 05:23:50 | | | |

| 2 | Bruce Ren | -21 word(s) | 2906 | 2021-07-12 11:21:32 | | |

Video Upload Options

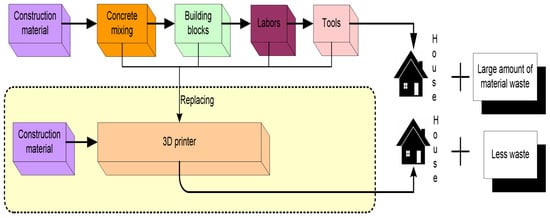

The United Nations (UN) 2030 agenda on sustainable development goals (SDGs) encourages us to implement sustainable infrastructure and services for confronting challenges such as large energy consumption, solid waste generation, depletion of water resources and emission of greenhouse gases in the construction industry. Therefore, to overcome challenges and establishing sustainable construction, there is a requirement to integrate information technology with innovative manufacturing processes and materials science. Moreover, the wide implementation of three-dimensional printing (3DP) technology in constructing monuments, artistic objects, and residential buildings has gained attention. The integration of the Internet of Things (IoT), cloud manufacturing (CM), and 3DP allows us to digitalize the construction for providing reliable and digitalized features to the users. In this review article, we discuss the opportunities and challenges of implementing the IoT, CM, and 3D printing (3DP) technologies in building constructions for achieving sustainability.

1. Introduction

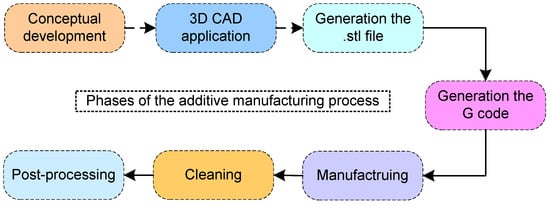

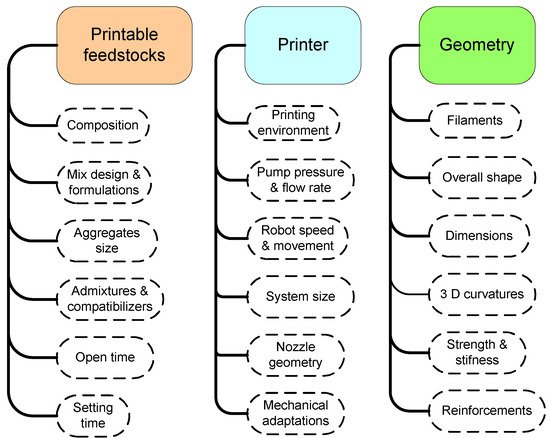

2. 3D Printing (3DP)

(a)

(b)

(c)

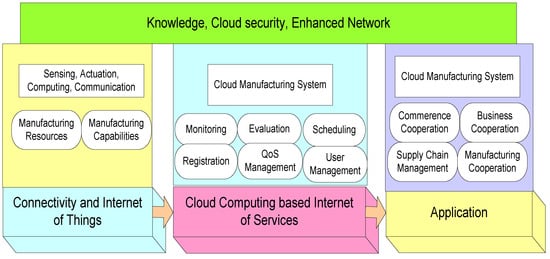

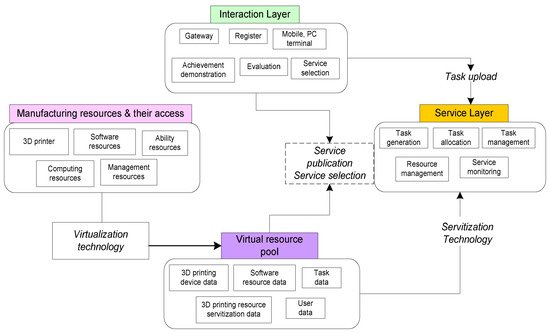

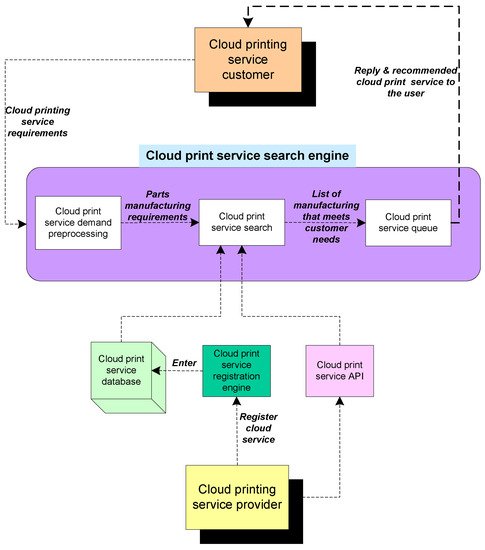

3. CM and 3DP Based Construction of Buildings

3.1. Cloud Manufacturing (CM)

3.2. CM Assisted 3DP

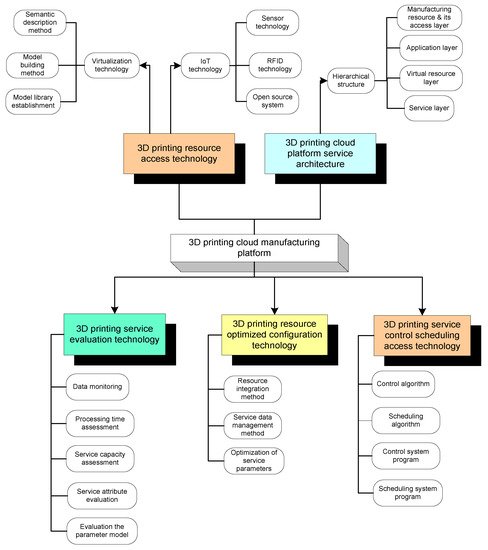

3.3. Architecture for 3D Printing Cloud Platform Service

References

- Social Development for Sustainable Development. DISD. Available online: (accessed on 15 March 2021).

- THE 17 GOALS. Sustainable Development. Available online: (accessed on 15 March 2021).

- Bamgbade, J.A.; Kamaruddeen, A.M.; Nawi, M.N.M. Malaysian construction firms’ social sustainability via organizational innovativeness and government support: The mediating role of market culture. J. Clean. Prod. 2017, 154, 114–124.

- Mavi, R.K.; Gengatharen, D.; Mavi, N.K.; Hughes, R.; Campbell, A.; Yates, R. Sustainability in Construction Projects: A Systematic Literature Review. Sustainability 2021, 13, 1932.

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791.

- 2019 Global Status Report for Buildings and Construction Sector. UNEP—UN Environment Programme. Available online: (accessed on 15 March 2021).

- Marzouk, M.; Azab, S. Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour. Conserv. Recycl. 2014, 82, 41–49.

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, K.L.O.; Qian, S. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 2020, 261, 121245.

- Hill, R.C.; Bowen, P.A. Sustainable construction: Principles and a framework for attainment. Constr. Manag. Econ. 1997, 15, 223–239.

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299.

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711.

- Cameli, S.A. 3D Printing of Cities: Is Urban Planning Ready? Plan. Theory Pract. 2019, 20, 776–784.

- Wang, Y.; Zheng, P.; Xu, X.; Yang, H.; Zou, J. Production planning for cloud-based additive manufacturing—A computer vision-based approach. Robot. Comput. Integr. Manuf. 2019, 58, 145–157.

- Wang, Y.; Lin, Y.; Zhong, R.Y.; Xu, X. IoT-enabled cloud-based additive manufacturing platform to support rapid product development. Int. J. Prod. Res. 2019, 57, 3975–3991.

- Rossi, E.; di Nicolantonio, M.; Barcarolo, P.; Lagatta, J. Sustainable 3D printing: Design opportunities and research perspectives. Adv. Intell. Syst. Comput. 2020, 975, 3–15.

- Mintsaev, M.S.; Bataev, D.S.; Mazhiev, K.K.; Mazhiev, A.K.; Mazhieva, A.K.; Mazhiev, A.K.; Mazhiev, M.K. Prospects for Using 3D-Printing Technologies in Construction of Buildings in Seismic Areas. ISEES 2019, 311–315.

- Rosenthal, A.; Mork, P.; Li, M.H.; Stanford, J.; Koester, D.; Reynolds, P. Cloud computing: A new business paradigm for biomedical information sharing. J. Biomed. Inform. 2010, 43, 342–353.

- Tao, F.; Li, C.; Liao, T.W.; Laili, Y. BGM-BLA: A new algorithm for dynamic migration of virtual machines in cloud computing. IEEE Trans. Serv. Comput. 2015, 9, 910–925.

- Manyika, J.; Chui, M.; Brown, B.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Byers, A.H. Big Data: The Next Frontier for Innovation, Competition, and Productivity; McKinsey Global Institute: Washington, DC, USA, 2011.

- Bughin, J.; Chui, M.; Manyika, J. Clouds, big data, and smart assets: Ten tech-enabled business trends to watch. McKinsey Q. 2010, 56, 75–86.

- Li, B.H.; Zhang, L.; Wang, S.L.; Tao, F.; Cao, J.W.; Jiang, X.D.; Song, X.; Chai, X.D. Cloud manufacturing: A new service-oriented networked manufacturing model. Comput. Integr. Manuf. Syst. 2010, 16, 1–7.

- Tao, F.; Zhang, L.; Guo, H.; Luo, Y.-L.; Ren, L. Typical characteristics of cloud manufacturing and several key issues of cloud service composition. Comput. Integr. Manuf. Syst. 2011, 17, 477–486.

- Guo, L.; Qiu, J. Combination of cloud manufacturing and 3D printing: Research progress and prospect. Int. J. Adv. Manuf. Technol. 2018, 96, 1929–1942.

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933.

- Jang, H.; Kim, K.; Kim, J.H.; Kim, J. Labour productivity model for reinforced concrete construction projects. Constr. Innov. Inf. Process. Manag. 2011, 11, 92–113.

- Allouzi, R.; Al-Azhari, W.; Allouzi, R. Conventional Construction and 3D Printing: A Comparison Study on Material Cost in Jordan. J. Eng. 2020, 2020, 1424682.

- Hossain, M.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and its Impact on the Labor Market. Sustainability 2020, 12, 8492.

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64.

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110.

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11.

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196.

- Zuo, Z.; Gong, J.; Huang, Y.; Zhan, Y.; Gong, M.; Zhang, L. Experimental research on transition from scale 3D printing to full-size printing in construction. Constr. Build. Mater. 2019, 208, 350–360.

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348.

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231.

- Jia, M.; Komeily, A.; Wang, Y.; Srinivasan, R.S. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Autom. Constr. 2019, 101, 111–126.

- Deloitte. Plano Estratégico de Inovação e Competitividade 2030 Para o Setor AEC; Plataforma Tecnológica Port. da Construção: Lisboa, Portugal, 2018; p. 93.

- Tao, F.; Cheng, Y.; da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud computing and internet of things-based cloud manufacturing service system. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442.

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68.

- Siderska, J.; Jadaan, K.S. Cloud manufacturing: A service-oriented manufacturing paradigm. A review paper. Eng. Manag. Prod. Serv. 2018, 10, 22–31.

- Ren, L.; Zhang, L.; Wang, L.; Tao, F.; Chai, X. Cloud manufacturing: Key characteristics and applications. Int. J. Comput. Integr. Manuf. 2017, 30, 501–515.

- Cloud Manufacturing: A New Service-Oriented Networked Manufacturing Model–Computer Integrated Manufacturing Systems. Available online: (accessed on 17 March 2021).

- Ren, L.; Zhang, L.; Tao, F.; Zhao, C.; Chai, X.; Zhao, X. Cloud manufacturing: From concept to practice. Enterp. Inf. Syst. 2015, 9, 186–209.

- Zhang, L.; Luo, Y.; Tao, F.; Li, B.H.; Ren, L.; Zhang, X.; Guo, H.; Cheng, Y.; Hu, A.; Liu, Y. Cloud manufacturing: A new manufacturing paradigm. Enterp. Inf. Syst. 2014, 8, 167–187.

- Simeone, A.; Caggiano, A.; Boun, L.; Deng, B. Intelligent cloud manufacturing platform for efficient resource sharing in smart manufacturing networks. Procedia CIRP 2019, 79, 233–238.

- Liu, Y.; Xu, X. Industry 4.0 and cloud manufacturing: A comparative analysis. J. Manuf. Sci. Eng. Trans. ASME 2017, 139.

- Zhou, L.; Zhang, L.; Laili, Y.; Zhao, C.; Xiao, Y. Multi-task scheduling of distributed 3D printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 3003–3017.

- Wang, X.V.; Xu, X.W. ICMS: A Cloud-Based Manufacturing System; Springer: London, UK, 2013; pp. 1–22.

- Chen, J.; Huang, G.Q.; Wang, J.Q.; Yang, C. A cooperative approach to service booking and scheduling in cloud manufacturing. Eur. J. Oper. Res. 2019, 273, 861–873.

- Kaszyńska, M.; Skibicki, S.; Hoffmann, M. 3D Concrete Printing for Sustainable Construction. Energies 2020, 13, 6351.

- Liu, Y.; Wang, L.; Wang, X.V.; Xu, X.; Jiang, P. Cloud manufacturing: Key issues and future perspectives. Int. J. Comput. Integr. Manuf. 2019, 32, 858–874.

- Sustainable Buildings|UNEP—UN Environment Programme. Available online: (accessed on 25 February 2021).

- Lao, W.; Li, M.; Wong, T.N.; Tan, M.J.; Tjahjowidodo, T. Improving surface finish quality in extrusion-based 3D concrete printing using machine learning-based extrudate geometry control. Virtual Phys. Prototyp. 2020, 15, 178–193.

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366.

- Al Jassmi, H.; Al Najjar, F.; Mourad, A.-H.I. Large-Scale 3D printing: The way forward. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 12088.

- Lloret, E.; Shahab, A.R.; Linus, M.; Flatt, R.J.; Gramazio, F.; Kohler, M.; Langenberg, S. Complex concrete structures: Merging existing casting techniques with digital fabrication. Comput. Des. 2015, 60, 40–49.

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49.

- Jiang, Y.; Lu, B.; Fang, X.; Long, H. 3D printing-based Internet collect-manufacturing mode. Comput. Integr. Manuf. Syst. 2016, 22, 1424–1433.

- Ren, L.; Wang, S.; Shen, Y.; Hong, S.; Chen, Y.; Zhang, L. 3D printing in cloud manufacturing: Model and platform design. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, MSEC, Blacksburg, VA, USA, 27 June–1 July 2016; Volume 2.

- Modekurthy, V.P.; Liu, X.F.; Fletcher, K.K.; Leu, M.C. Design and implementation of a broker for cloud additive manufacturing services. J. Manuf. Sci. Eng. 2015, 137, 040904.

- Mai, J.; Zhang, L.; Tao, F.; Ren, L. Customized production based on distributed 3D printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 71–83.

- Wu, J.J.; Tan, Y.G.; Ma, G.F. 3D printing monitoring platform based on the Internet of Things. IET 2015.

- Tao, F.; Zuo, Y.; da Xu, L.; Zhang, L. IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans. Ind. Inf. 2014, 10, 1547–1557.

- Liu, X.M.; Huang, J.F. Education-oriented 3Dprinting and networked communication platform. Chin. J. Eng. Mach. 2015, 13, 82–87.

- Jun, Z.; Wen-jie, D. The research on service of valve with cloud manufacturing and 3D printing. Manuf. Autom. 2015, 37, 108–111.

- Brant, A.; Sundaram, M.M. A novel system for cloud-based micro additive manufacturing of metal structures. J. Manuf. Process. 2015, 20, 478–484.

- Li, F.; Liao, T.W.; Zhang, L. Two-level multi-task scheduling in a cloud manufacturing environment. Robot. Comput. Integr. Manuf. 2019, 56, 127–139.

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020.

- De Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311.

- Shaping the Future of Construction: A Breakthrough in Mindset and Technology. World Economic Forum. Available online: (accessed on 25 February 2021).

- Pacewicz, K.; Sobotka, A.; Gołek, Ł. Characteristic of materials for the 3D printed building constructions by additive printing. MATEC Web Conf. 2018, 222, 1013.

- Labonnote, N.; Rüther, P. Additive manufacturing: An opportunity for functional and sustainable constructions. In Challenges for Technology Innovation: An Agenda for the Future, Proceedings of the International Conference on Sustainable Smart Manufacturing, S2M 2016; CRC Press: Boca Raton, FL, USA, 2017; pp. 201–206.

- Zhong, D.; Lv, H.; Han, J.; Wei, Q. A practical application combining wireless sensor networks and internet of things: Safety management system for tower crane groups. Sensors 2014, 14, 13794–13814.

- Hansen, E.B.; Bøgh, S. Artificial intelligence and internet of things in small and medium-sized enterprises: A survey. J. Manuf. Syst. 2020, 58, 362–372.

- Ajayi, S.; Akinade, O.; Al-Hasan, A.; Alaka, H.; Ambituuni, A.; Amezaga, J.M.; Ball, P.; Bandera, C.; Bao, L.; Basole, R.C. Index Transactions on Engineering Management. IEEE Trans. Eng. Manag. 2019, 66. Available online: (accessed on 20 June 2021).

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521.

- Ram, J.; Afridi, N.K.; Khan, K.A. Adoption of Big Data analytics in construction: Development of a conceptual model. Built Environ. Proj. Asset Manag. 2019, 9, 564–579.