1000/1000

Hot

Most Recent

The recent introduction of three-dimensional (3D) printing is revolutionizing dentistry and is even being applied to orthodontic treatment of malocclusion. Clear, personalized, removable aligners are a suitable alternative to conventional orthodontic appliances, offering a more comfortable and efficient solution for patients. Including improved oral hygiene and aesthetics during treatment. Contemporarily, clear aligners are produced by a thermoforming process using various types of thermoplastic materials. The thermoforming procedure alters the properties of the material, and the intraoral environment further modifies the properties of a clear aligner, affecting overall performance of the material. Direct 3D printing offers the creation of highly precise clear aligners with soft edges, digitally designed and identically reproduced for an entire set of treatment aligners; offering a better fit, higher efficacy, and reproducibility. Despite the known benefits of 3D printing and the popularity of its dental applications, very limited technical and clinical data are available in the literature about directly printed clear aligners.

As previously described—just as the move from orthodontic rings to brackets was made possible through advances in dental materials; the use of clear aligners will spur the research and development of new materials specifically for use in direct 3D printing. 3D printing, also known as additive manufacturing, dates back to the 1980s and is now reaching a level of maturity where it is increasingly being utilized in the fields of dental and medical modeling. There are multiple applications in oral surgery, prosthodontics, restorative dentistry, orthodontics, implantology and instrument manufacturing [1]. 3D printing enables the manufacturing of pieces layer-by-layer instead of common manufacturing methods that rely on machining, molding, and subtractive methods [2]. Current materials used for 3D printing in orthodontics include acrylonitrile-butadiene-styrene plastic, stereolithography materials (epoxy resins), polylactic acid, polyamide (nylon), glass-filled polyamide, silver, steel, titanium, photopolymers, wax, and polycarbonate [3].

An example of the application of 3D printing in the production of clear aligners is the above-mentioned 3D printing of dental models for the clear aligners molding. The use of 3D printed models was the first step towards minimization of errors and mistakes (e.g., geometric inaccuracies) occurring during impression collection [4]. Rather than using error-prone plaster models that are scanned and modeled to develop various alignment stages, it is superior to use digital impression taking and 3D printing for improvement. Use of a clear aligner that is 3D printed for direct usage can eliminate the cumulative errors introduced from analog impression taking and the subsequent thermoplastic workflow [4]. In addition to greater accuracy, direct printing produces other benefits such as shorter supply chains, significantly shorter lead times, and lower costs. It is also a more sustainable process that generates significantly less waste than subtractive and thermoforming processes [5].

3D printing could be also used for direct printing of clear aligners by a single processing step using one or a combination of 3D-printing processes [1]. Despite the current improvements and increased use of different 3D printing technologies, there is a limited number of publications can be found describing the direct 3D printing of orthodontic clear aligners, or research regarding suitable materials for such printing.

Theoretically, various 3D printing processes may be used for direct printed clear aligners, such as fused filament fabrication (FFF), selective laser sintering (SLS) or melting (SLM), stereolithography (SLA), multi-jet photocured polymer process, HP MultiJet Fusion technology or continuous liquid interface production technology [1]. However, due to specific characteristics of clear aligners and specific requirements on their material properties and performance, 3D printing by photo-polymerization from clear resin seems like the most appropriate option.

While there are a number of registered patents describing this possibility, there are only a few recently published articles [1][4][6] that have appeared with the first companies focusing on directly printed aligners and materials for 3D printing. A study conducted by Jindal et al. [4] reported a successfully 3D-printed 0.75-mm thick clear aligner using Dental LT® (Long Term) clear resin (Form Labs, Somerville, MA, USA) and compared its mechanical and geometrical properties to a conventionally manufactured thermoformed dental clear aligners made of Duran foils. The authors suggested that 3D printed resin-based clear dental aligners are more suitable for patient use as they are geometrically more accurate; besides, they could resist more maximum load with a low displacement and can deform elastically with reversibility for lower displacements. Jindal et al. also reported that LT clear resin has been found to be comparable with Duran and Durasoft (Scheu-Dental GmbH, Iserlohn, Germany) thermoplastic materials under the mechanical stress of non-linear compressive forces equivalent to human bite cycles [7]; this means that 3D direct printing has sufficient mechanical strength to resist external loading without a decrease in clinical performance.

However, Dental LT resin is an approved Class IIa biocompatible material with high resistance to breaking and it is ideal for gnathological splints, dental retainers, and other rigid direct-printed orthodontic appliances as functional ones. Its usage for direct 3D printing of clear aligners has not reported before, and all authors are omitting the main limitation of their studies, or rather the lack of clinical data to evaluate the performance of Dental LT resin and its resistance during its use in the oral cavity of patients [8].

Increasingly, a number of preliminary studies regarding 3D printed clear aligners have been carried out in the later stages. As previously mentioned in regards to thermoformed aligners, the thickness of the aligner influences the magnitude of force it delivers to generate optimal tooth movement and performance. 3D printing represents a complex method in controlling the thickness of dental aligners and subsequently the exerted force. Edelmann et al. reported an increase of overall thickness than the corresponding design file, especially with LT clear resins [9]. The results obtained in the study showed that the 3D printing workflow did not precisely realize the designed thickness with clear material and it may produce deleterious effects of clinical utility of aligners.

Deviation in the dimensional accuracy of the printed aligners can result in undesired tooth movement. One of the factors responsible for the adaptation between the aligner and the teeth is the print orientation and the post-print curing duration. McCarty et al. showed little effect on the overall dimensional accuracy of 3D printed aligner design could be also modified in the first stages of printing such as in post-curing of biocompatible resins [10]. Also, Jindal et al. reported that the effects of post-curing conditions on the mechanical characteristics of printed aligners demonstrated that time and temperature are extremely important in the compression load resistance of the printed resin [11]. The correct post-curing process is essential to provide sufficient strength and biocompatibility for the final 3D printed product. Allowing for extra cross linking of the polymer, ultimately enhances mechanical properties of the printed material and reduces any residual stress.

Additive processes, as opposed to subtractive ones, involve the building of parts layer by layer of a liquid photopolymer resin to create a solid polymer. An intrinsic property of 3D layering is mechanical anisotropy; the environmental variations, post-cure time, and bath variations influence the mechanical properties of printed parts. Shanmugasundaram et al. analyzed the mechanical anisotropy in additively manufacturing by stereolithography [12]. It has been shown that printed parts that can be classified as isotropic have a great advantage over other techniques providing for greater accuracy and clinical performances. It was also confirmed that aging and post-cure time had a direct relationship with superior mechanical properties compared to uncured resins and thermoformed clear aligners [4].

3D printed materials are highly toxic before 3D printing, and the toxicity gradually decreases post-polymerization. Post curing and processing are vital for eliminating the toxicity levels as recommended by the manufacture of 3D printing material [13]. The cytotoxicity of directly 3D printed clear aligners from three different resins has been investigated [6]. Three different materials were compared: Accura 60® SLA (3D Systems, Rockhill, SC, USA), Dental LT® clear resin (Form Labs, Somerville, MA, USA), and Invisalign® (Align Technology, San Jose, CA, USA). Similarly, Dental LT resin and Accura 60® SLA are not approved for direct printed clear aligners and were not previously tested nor described for this intention. The study verified that Invisalign® material was the least cytotoxic, followed by Dental LT® and Accura 60®. However, Invisalign® aligners are not directly 3D printed. Unfortunately, the absence of clinical data is similarly the main limitation of the study. Recently, an in-vitro study of cell viability by Ahamed et al. showed that Invisalign® material was found to be more biocompatible compared to directly printed aligner materials [13]. Cytotoxicity was found to be more on the first day and then gradually decreases; these results suggest new future studies to evaluate the 3D printed aligners clinically, determining their properties on patients.

Technical properties and cytotoxicity parameters of the most used thermoplastic materials and printing resins are summarized in Table 1 [14][15][6][13].

Table 1. Technical data (supplier specifications) and cytotoxicity (experimental outcomes) of the most common materials used for thermoformed (T) and directly printed (P) clear aligners.

| Brand | Material Composition | Density (g/cm3) | Elastic Modulus (MPa) | Tensile Stress (MPa) | Elongation at Break (%) |

Cell Viability (%) |

Cytotoxicity |

|---|---|---|---|---|---|---|---|

| Duran (Scheu-Dental GmbH) (T) |

Polyethylene terephthalate glycol (PET-G) | 1.27 | 2200 | 53 | >40 | 84.6 (Day 14) | Slight |

| Biolon (Dreve Dentamid GmbH) (T) |

Polyethylene terephthalate glycol (PET-G) | 1.27 | 2020 | 45 | >35 | 64.6 (Day 14) | Slight |

| Zendura (Bay Material LLC) (T) |

Polyurethane resin (PU) | 1.203 | - | - | - | 74.4 (Day 14) | Slight |

| SmartTrack (Align Technology) (T) |

Multilayer aromatic thermoplastic polyurethane/copolyester | - | - | - | - | 94.1 (Day 7) 78.8 (Day 14) |

Slight |

| Dental LT (Formlabs Inc.) (P) |

Photo polymeric clear methacrylate oligomer and glycol methacrylate | 1.1 1.3 |

2300 | 84 | 12 | 60.3 (Day 1) 62.5 (Day 14) |

Slight |

| Accura 60 SLA (3D System) (P) | Polycarbonate-based photo-polymeric resin | 1.13 1.21 |

2690–3100 | 58–68 | 5–13 | 13.9 (Day 1) 24.5 (Day 7) |

Severe |

| E-Guard (EnvisionTEC) (P) |

Photo-polymeric clear resin | 1.06 1.12 |

2050–2130 | 79–85 | 3.81 | 64.1 (Day 1) 75.1 (Day 7) |

Slight |

There are multiple clear resins used for 3D printing of appliances in dentistry, but no clear resin is aimed for 3D printed clear aligners. In early 2018 EnvisionTEC (EnvisionTEC Inc., Dearborn, MI, USA) announced the commercial release of E-Ortholign, an innovative material for the direct 3D printing of clear aligners [16]. However, this clear resin is stated as a biocompatible, dimensionally stable, flexible, and strong material for the direct 3D printing of what is known in orthodontics as a “first aligner”—a retainer that is used after an orthodontist removes a patient’s brackets to hold teeth in place before the treatment is completed with a series of conventionally made thermoformed aligners [16]. Nowadays, there is no marketed and approved photopolymerizable resin suited for the direct printing of dental clear aligners but an increasing interest in the field of orthodontics is taking place, especially for the development of certified biocompatible resins [17]. Despite the lack of existing biocompatible resins for 3D direct clear aligners, some experimental trials have been carried out on voluntary patients with modified resins and post-printing protocols, but clinical outcomes need to be confirmed prior to scientific publishing (Figure 1).

Figure 1. Final step of an orthodontic treatment with 3D direct printed clear aligners (experimental trial on a voluntary patient).

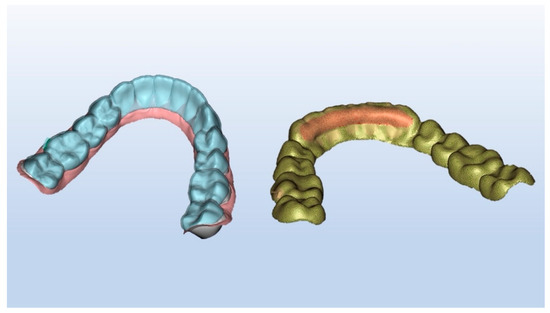

Likewise, to our knowledge, while there are several CAD software packages for treatment planning and preparation of 3D models for aligner molding, only Maestro 3D (Ortho Studio v.5.2, AGE Solutions S.r.l., Pontedera, Italy) has an add-on module that can also design aligners and export them in a format convenient for direct 3D printing. Thanks to post-export CAD software, it is also possible to fully customize the thickness of direct printed clear aligners in order to exert selective and directional forces (Figure 2).

Figure 2. Customization of design and thickness of directly printed aligners.

Objectively, the direct 3D printing of aligners offers several advantages over conventional fabrication, just utilizing the same digital features currently available for construction of bite splints:

borders are digitally designed and identically reproduced for all sets of aligners;

edges are smooth and do not need trimming or polishing;

undercuts do not exist because they are digitally defined;

aligners are fabricated with higher precision as there are no errors introduced during printing of a 3D molding model and thermoforming stage of fabrication;

higher precision leads to better fitting and higher effectiveness;

intra-aligner thickness is customizable, and this may reduce the need for attachments, which generally lower the transparency of clear aligners.

Given these strengths, once an ad-hoc resin is available in the market, directly 3D-printed aligners must be tested clinically to demonstrate their biomechanical effectiveness. Different designs should be probably used for the manufacturing of direct printed clear aligners compared to thermoformed ones due to the possibility of creating customizable thickness and attachments; mechanical properties of customizable aligners regarding the materials, thickness, and auxiliary elements can also be investigated by parametric modeling and finite element analysis [18].