The costs and environmental aspects of all cement and cementless-based compositions for construction depending on the sources and the transportation distance of raw materials. The CO2 footprint caused by aggregate transportation could reach 20% of total CO2 emissions, but this value is significantly governed by the amount of aggregate and distance to local sources [128]. Regarding the use of a high ratio of aggregates to other raw materials in concretes, the transportation of aggregates also has a major effect on the final cost of the compositions. Therefore, using recycled C&D waste as aggregates in cementitious concretes and alkali-activated concretes could have superior impacts in terms of financial and environmental aspects.

In terms of environmental analysis, Yang et al. [128] found that the contribution of the binder results in greater CO2 emissions with OPC concrete, while the contribution of aggregate transportation is more critical in alkali-activated binders [129]. In terms of cost analysis, the type of aggregate has the greatest impact on increasing the total cost of fly ash-based alkali-activated concretes [96], so that replacing RA with NA increased the material costs in the range of 30–35% [88].

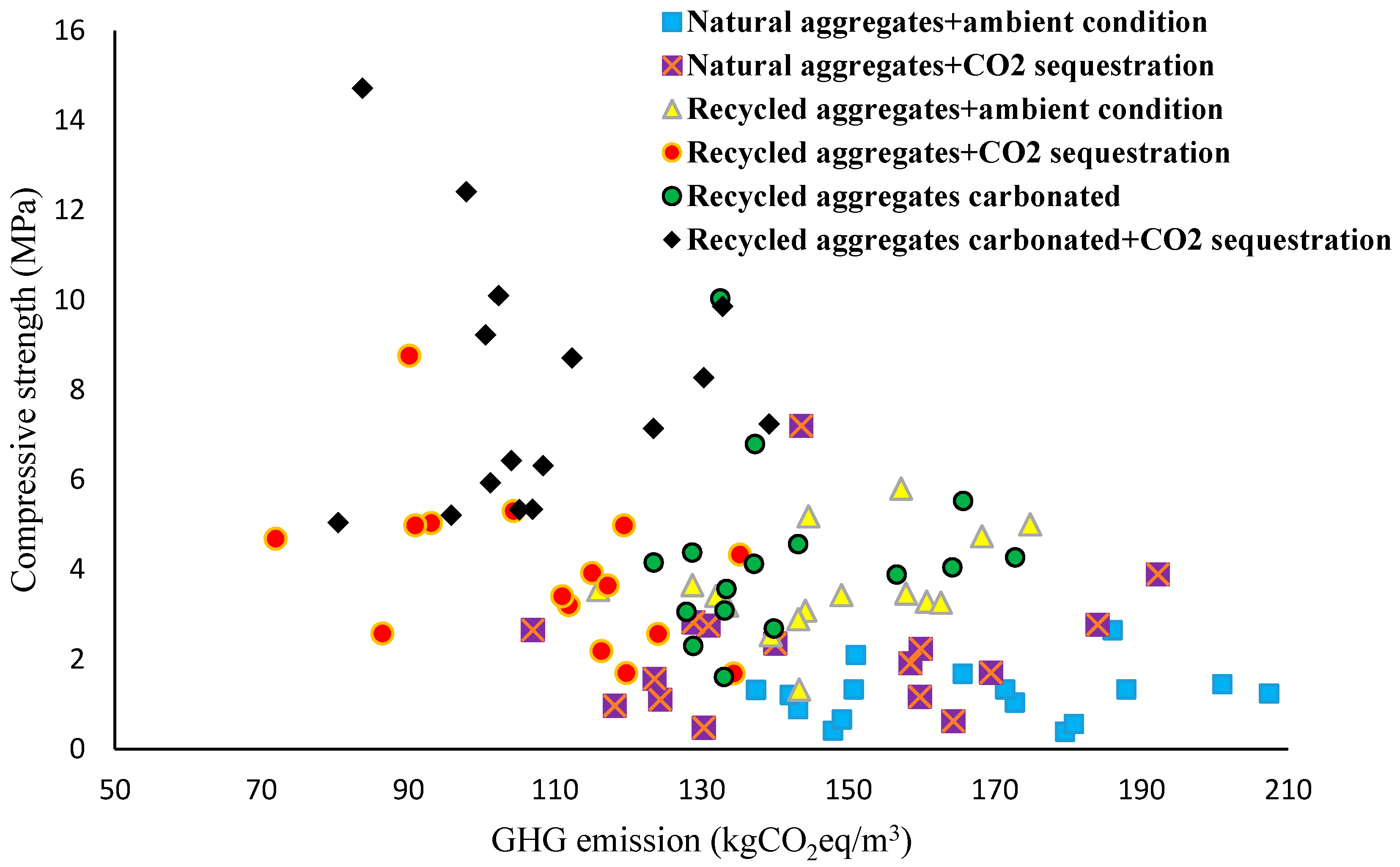

In 2012, van Deventer et al. [130] proposed that E-Crete (Zeobond’s proprietary geopolymer technology product, which consists of fly ash, slag, and NA) could release emissions equal to 100 to 300 CO2 per tonne, while this emission varied in the range of 300 to 900 CO2 per ton with OPC content. Yang et al. [128] confirmed that the emission of carbon dioxide into the atmosphere could vary from 100–200 CO2 per tonne in different alkali-activated binders (slag, fly ash, and metakaolin) with NA and medium compressive strength (up to 40 MPa). Mastali et al. [96] also reported that GHG emissions in different fly ash-based alkali-activated binders containing RA (as uncarbonated and carbonated) and cured in either a carbonation chamber (named as accelerated carbon dioxide sequestration) or ambient conditions varied in the range of 70 to 200 CO2 per ton. Mastali et al. [96] also investigated the influences of different types and contents (aggregate to binder ratios of 4 and 5) of RA under different curing regimes in different fly ash-based alkali-activated concretes. Their results with regard to the compressive strength of the different developed fly ash-based alkali-activated binders versus GHG emissions are shown in Figure 8.

According to the results, regardless of the curing conditions, using RA leads to reduced GHG emissions [96]. Curing specimens with accelerated carbon dioxide sequestration significantly reduced the carbon emissions as compared to cure in ambient conditions. This reduction in GHG emissions could be related to an increase in carbon dioxide uptake [96].

It could be generally concluded that the cure regime has a major impact on the reduction of GHG emissions, and RA treatment using carbonated aggregates could have the greatest impact on decreasing it. A comparison of the results indicates that simultaneous flow-through CO2 curing and RA carbonation could decrease GHG emissions by roughly 50% when compared to the use of NA and curing in ambient conditions.

The results, shown in Figure 1, clearly demonstrate that using carbonated RA and flow-through CO2 curing reduces GHG emissions and increases strength in alkali-activated concretes, so that GHG emissions of alkali activated concretes varied in the range of 80 to 150 CO2 per ton and the compressive strength range from 5 to 15 MPa. The aim of that investigation was the development of bricks with alkali-activated binders containing RA with very low GHG emissions. Because the required strength of a brick is in the range of 5 MPa [129], based on the measured strength, the developed construction materials could be used as footpaths, driveways, and bricks with low GHG emissions.

Figure 1. Impacts of different curing regimes (ambient conditions or CO2 sequestration) on the compressive strength versus GHG emissions of different fly ash-based alkali-activated concretes containing NA or RA [96].

This publication can be found here:https://www.mdpi.com/1996-1944/12/23/4016