Electrical Properties of Yttrium–Indium–Zinc-Oxide Thin Film Transistors Fabricated Using the Sol–Gel Process and Various Yttrium Compositions

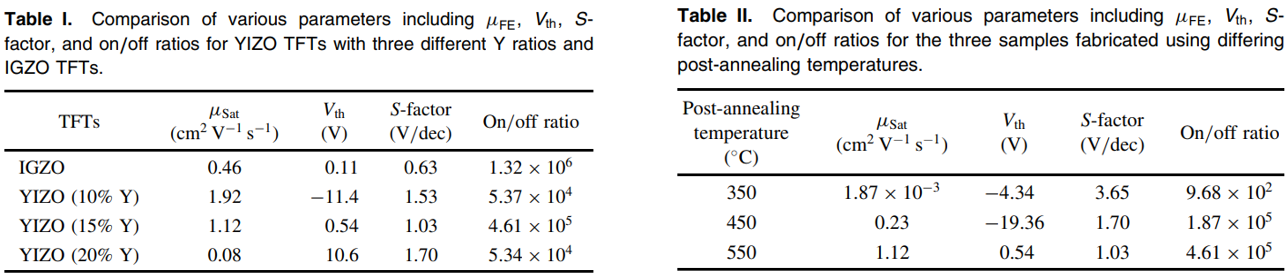

This study was the first to investigate the fabrication of yttrium–indium–zinc-oxide (YIZO) thin film transistors (TFTs) using the sol–gel process. YIZO thin films were made using various yttrium (Y) compositions from 10 to 20%. Thermogravimetry and differential scanning calorimetry (TG– DSC) data from the 15% Y sample revealed that the YIZO thin films crystallized above the temperature of 535°C, much hotter than that of indium– gallium–zinc-oxide (IGZO) thin films. The best performance of YIZO TFTs was observed with a 15% ratio of Y to Zn: this yielded a saturation mobility of 1.12 cm2 V-1 s-1, an on/off ratio of 4.61 x 105, a threshold voltage of 0.54 V, and a subthreshold swing of 1.03 V/decade. This study also assessed the post-annealing temperature dependence of YIZO TFTs. The findings demonstrated the possibility of using Y to replace gallium (Ga), which has been used in previously reported solution-processed IGZO TFTs.

DOI: https://doi.org/10.1143/JJAP.49.03CB01

- Yttrium-indium-zinc-oxide (YIZO)

- Thin film transistors

- Solution process

- Post-annealing temperature dependency

In table 1, of all the tested YIZO samples, the 15% Y sample exhibited the best transfer characteristics, which were competitive with IGZO TFT results previously reported by our group. For the 350 °C post-annealing sample, transfer characteristics resembled those of an insulator because chemical reactions were done imperfectly due to the low annealing temperature and, as a results, there seemed to exist organic remainders, which can affect TFT performance. The 450 °C post-annealing sample had just begun to crystallize, at which temperature the formation of dehydroxylation and alloy mechanism was unfinished. Thus, the sample exhibited reasonable on-off characteristics but the threshold voltage of TFT was negatively shifted compared to the 550 °C post-annealing sample.